The Ultimate Guide to Setting Up a Portable Milking Parlor

Efficient Strategies for Dairy Farms

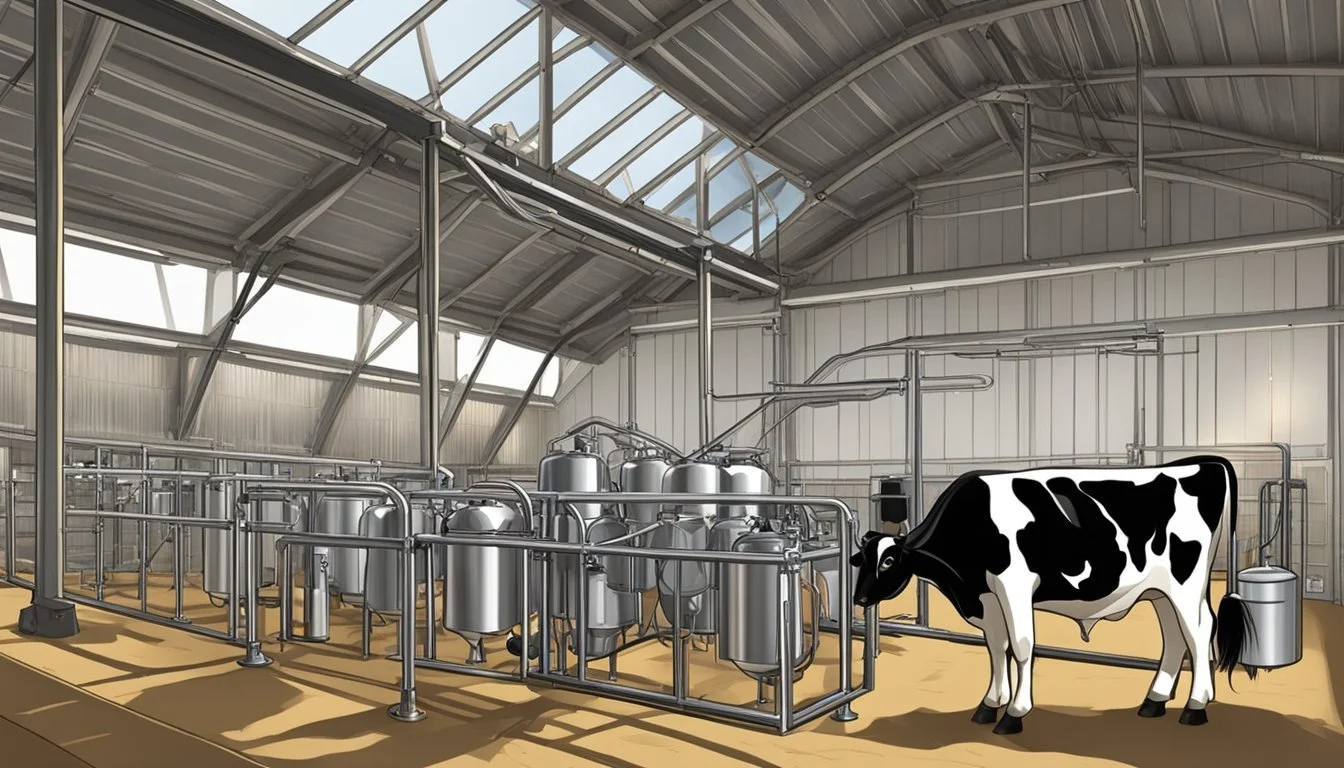

The modern dairy industry is ever-evolving, and efficiency is at the heart of profitable operations. This is where portable milking parlors come into play, offering dairy farmers the flexibility to manage their milking processes more effectively. A portable milking parlor, as the name suggests, is not anchored to a single location and can be moved as needed, which makes it an excellent solution for dairies that require versatility, whether due to changing pasture patterns, farm layout, or herd size.

When setting up a portable milking parlor, a farmer must consider several critical factors to ensure a smooth and efficient operation. These considerations include the design of the system, the number of cows that can be milked at a time, and how the equipment adapts to different environments. The mobility of a parlor is its greatest asset, as it allows for the operation to relocate without the commitment associated with a fixed system. This is particularly advantageous for smaller dairies or those looking to expand without constructing additional permanent facilities.

Moreover, the functionality of a portable milking parlor is paralleled by the meticulous attention to the health and comfort of the animals being milked. Ergonomics play a pivotal role in portable parlor design; accommodating the cows' natural behavior is crucial for maximum milk yield and quality. From ensuring gentle handling to optimizing the milking routine, every element is as systematic as it is humane, reflecting the balance between animal welfare and operational productivity essential to sustainable dairy farming.

Understanding the Basics of Dairy Operations

Dairy farming is a sophisticated agricultural practice that centers on milk production through careful herd management and efficient milking systems. The key to successful dairy operations lies in understanding milking procedures, selecting the right type of milking parlor, and recognizing the advantages a portable milking parlor can bring to the farm.

Essential Concepts of Milking

The cornerstone of dairy production is the milking process, which involves extracting milk from dairy animals in a manner that's safe for the animal and efficient for the operation. Key aspects include proper sanitation, animal health monitoring, and the maintenance of milking equipment. A primary concern is the prevention of contamination, which can compromise milk quality. Efficient milking also demands consistency in routine, as regular milking schedules are essential for optimal milk yield.

Different Types of Milking Parlors

There are various types of milking parlors that cater to different operational scales and farmer preferences:

Herringbone: The cows stand in a "V" formation. This setup allows farmers to milk more cows simultaneously, offering good visibility and accessibility to the udders.

Tandem: Cows stand parallel, separately in stalls, which can be better for individual animal attention but may require more space and time.

Parallel: Cows are positioned side by side, allowing for higher throughput, yet it may necessitate more movement for the milker.

Rotary: A rotary or carousel parlor moves cows on a rotating platform, enabling continuous milking and is highly efficient for large herds.

Choosing the right parlor depends on the farm's size, the number of animals, and the resources available for investment in infrastructure.

Benefits of a Portable Milking Parlor

A portable milking parlor presents various advantages for dairy operations:

Flexibility: It can be moved and adjusted according to the farm's changing needs.

Cost-effectiveness: Portable parlors often require a lower initial investment than permanent structures.

Convenience: Ideal for farms with leased land or those looking to expand without heavy construction.

Accessibility: They make it feasible for farmers to bring the milking facility closer to the herd, which can minimize animal stress.

In conclusion, understanding these basics paves the way for establishing an efficient and productive dairy operation that can adapt to various business goals and animal welfare standards.

Planning Your Portable Milking Parlor

A well-thought-out plan is essential for the successful implementation of a portable milking parlor. This section delves into the specifics of evaluating farm needs, analyzing herd size and milk production, and choosing the best location for setup.

Assessing Dairy Farm Needs

A dairy farm must consider both current demands and future growth. The portable milking parlor should align with the operational objectives, whether that involves streamlining the milking process or enhancing flexibility. Factors such as milking frequency and the number of operators are critical in this assessment.

Analyzing Herd Size and Milk Production

The size of the portable milking parlor fundamentally depends on herd size and the anticipated volume of milk production. It is important to calculate the number of cows milked at any given time and ensure the design facilitates efficient workflow. For instance, a herd that milks 25 cows will require a different parlor size compared to one that handles 60 cows.

Selecting the Ideal Location

The location for a portable milking parlor must provide easy access for both cattle and farm operators, taking into consideration factors like terrain and proximity to utilities. The chosen site should allow for sufficient space to operate effectively within the time constraints of milking sessions, while also offering flexibility to relocate as needed.

Design and Layout of Portable Milking Parlors

In the design and layout of portable milking parlors, functionality merges with flexibility. Farmers must consider cow flow, ease of cleaning, and the configuration of milking equipment to ensure operational efficiency.

Overview of Parlor Designs

Portable milking parlors are diverse in design to cater to different dairy operation sizes and needs. Typically, they incorporate features that allow for rapid deployment and reconfiguration. Common designs include:

Parallel Stalls: Cows are positioned side by side with rear udder access.

Herringbone Stalls: Cows are angled, allowing side access to udders.

Tandem Stalls: Cows are in individual stalls, aligned in a single row.

Rotary Platforms: A rotating platform that moves cows through the milking stations.

Each configuration is designed to optimize the use of space, ensure smooth cow movement, and provide easy access to the teats for milking.

Customization Options for Optimal Cow Flow

Cow flow is critical in a portable milking parlor design. It refers to the ease with which cows can enter and exit the milking area with minimal stress and delay. Optimal cow flow is achieved through:

Entrance and Exit Lane Design: Clear, unobstructed paths that accommodate multiple cows.

Holding Pens: Temporary areas where cows wait before milking without overcrowding.

Backing Gates: Gates that gently encourage cows to move forward into the milking stalls.

Customization should also include adjustable features to cater to different cattle sizes and to make allowances for future herd expansion.

Incorporating Efficient Cleaning Systems

Hygiene is paramount in milking parlors to safeguard milk quality and animal health. Portable milking parlors can integrate efficient cleaning systems such as:

Automated Wash Cycles: Pre-programmed cleaning processes that ensure consistent sanitation.

Milk Line CIP (Clean-in-Place) Systems: Cleaning pipelines without disassembly, reducing labor.

Drainage Design: Sloped floors and strategic drain placement to aids in waste removal and water runoff.

With routine cleaning protocols in place, portable milking parlors can maintain high standards of cleanliness to protect milk integrity and animal welfare.

Equipment and Technologies

The proper selection and application of equipment and technologies are critical for the efficient operation of a portable milking parlor. These tools not only contribute to the dairy's operational efficiency but also play a significant role in maintaining milk quality.

Choosing the Right Milking Units

Milking units are the heart of the parlor, directly influencing milking time and udder health. It is essential to select milking machines that are adaptable to a portable setting and provide a consistent vacuum level for safe and efficient milking. The units should be easy to clean and maintain to ensure optimal hygiene and milk quality. Typical components of a milking unit include:

Pulsator: Regulates the on-and-off cycle of vacuum application

Teat cups: Conform comfortably to the teats, made of durable yet gentle materials

Milk tube: Transfers milk to the receiving jar or direct line system

Vacuum pump: Maintains stable vacuum levels throughout milking

Understanding Robotic Milking Systems

Robotic milking machines leverage robotics and dairy management software to automate the milking process, offering precise control and real-time data collection. These systems can improve labor efficiency and are adaptable to varying herd sizes. Key features include:

Automated cow handling and teat cleaning

Customizable milking protocols

Data collection for milk quality analysis and herd management

Reduced stress for animals as they are often free to be milked on their own schedule

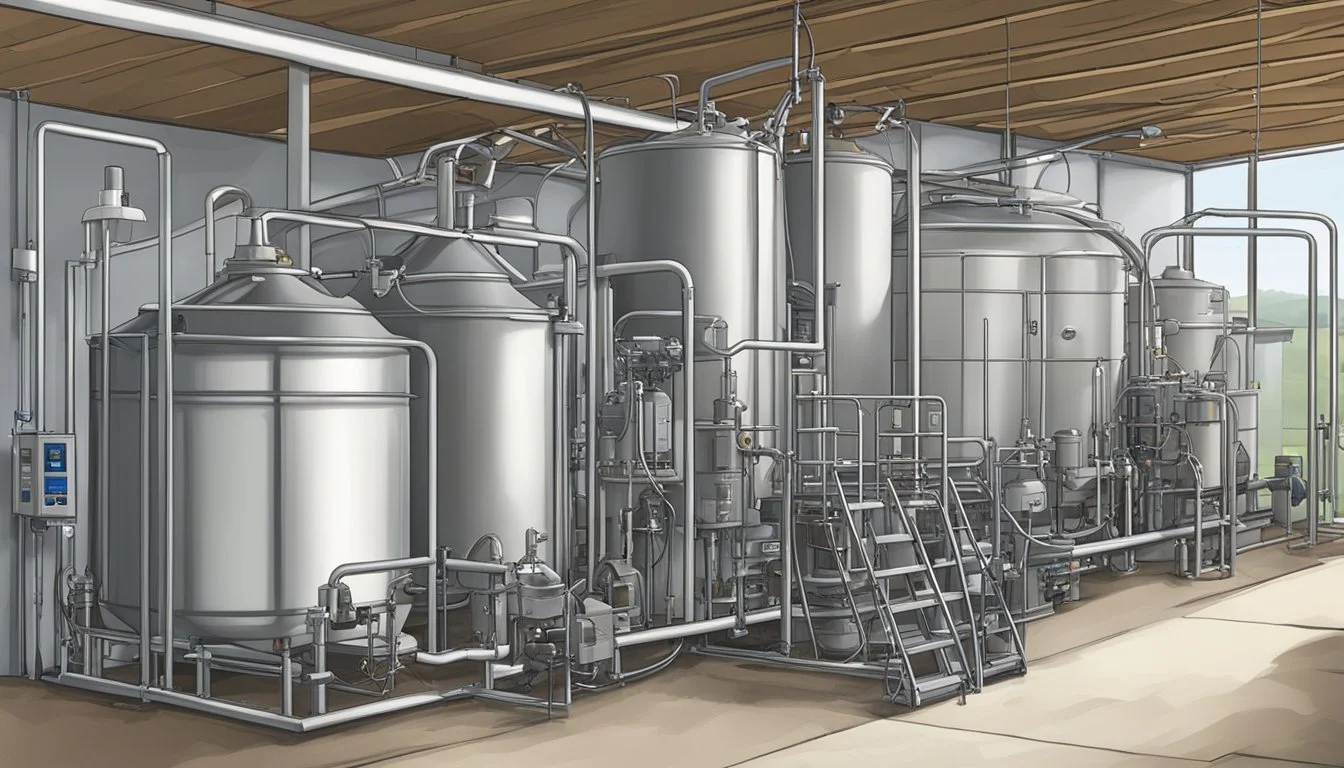

The Importance of Milk Cooling and Quality Control

After milking, rapid and efficient milk cooling is vital to preserve milk quality and prevent bacterial growth. Portable parlors should integrate milk cooling systems that are both effective and energy-efficient. Additionally, portable operations must prioritize quality control mechanisms, such as:

In-line milk meters for accurate yield measurement

Somatic cell count (SCC) monitors to detect milk quality issues

Plate coolers or bulk tank coolers for immediate temperature reduction

In summary, the equipment and technologies chosen for a portable milking parlor must foster a balance between operational flexibility, animal welfare, and the unwavering safeguarding of milk quality.

Operational Aspects of Portable Milking Parlors

Setting up a portable milking parlor involves strategic planning to ensure that labor is effectively managed and the parlor operates with high efficiency. Dairy farmers must consider best practices as well as health and safety guidelines to maintain both animal welfare and employee wellbeing.

Managing Labor and Parlor Efficiency

Effective labor management is vital to maintaining parlor efficiency. A well-designed portable milking parlor can significantly reduce the time employees spend on milking by allowing a streamlined workflow and facilitating easier access to cows. Incorporation of a rapid exit design enhances milking speed, allowing employees to handle larger herds in shorter timeframes. To optimize efficiency:

Allocate roles clearly among employees to avoid overlap.

Train staff thoroughly on operational procedures to ensure rapid and safe milking practices.

Implement a routine that maximizes the use of parlor capacity without overworking labor.

Best Practices for Dairy Farmers

Dairy farmers should follow established best practices to optimize the operation of their portable milking parlors:

Equipment maintenance: Regularly inspect and maintain milking equipment to prevent breakdowns that can delay milking schedules.

Parlor set-up: Place the milking parlor strategically on-site to minimize the distance cows need to travel.

Cleanliness: Uphold stringent cleaning procedures to minimize mastitis risk and maintain milk quality.

Adhering to best practices not only elevates parlor productivity but also ensures the longevity of installed equipment, making the investment more cost-effective.

Health and Safety Considerations

A key component of portable milking parlor operations is upholding health and safety standards to protect both the livestock and the dairy farm employees:

Mastitis prevention: Implement rigorous sanitation protocols to reduce the incidence of mastitis, which can affect milking speed and overall herd health.

Employee training: Offer comprehensive training on parlor safety and emergency protocols to prevent accidents.

Ergonomic design: Choose parlors with designs that minimize physical strain on employees to reduce injury risk.

Dairy farms must prioritize these health and safety aspects to maintain a high standard of operation, ensuring both employee welfare and animal health.

Financial and Market Considerations

In setting up a portable milking parlor, dairy operations must rigorously assess expenses while keeping a keen eye on market dynamics and competition. Both initial investment and the ongoing financial commitment play pivotal roles in the strategic planning of a dairy enterprise.

Cost Analysis and Budgeting

Initiating a portable milking parlor demands a detailed cost analysis and thorough budgeting. An operator might expect to invest between $30,000 and $100,000 for a basic two-sided parallel portable milking parlor. Additions and customizations can raise the cost significantly, potentially up to $300,000. To financially prepare, consider:

Capital Costs: Include the price of the parlor itself, which can vary based on size and features.

Operational Costs: Factor in ongoing expenses such as maintenance, labor, utilities, and transportation.

Reserve Funds: Allocate money for unexpected repairs or market changes.

Foreseeing these expenditures allows a dairy operation to calculate the return on investment and plan for sustainable growth.

Analyzing the Dairy Market and Competition

A dairy business must meticulously analyze the dairy market. Current trends indicate a demand for transparency and efficiency in milk production. Furthermore, knowing one's competitors is vital. Understanding the competitive landscape, including:

Pricing Strategies: How competitors price their products could significantly inform one’s own pricing decisions.

Market Share: Identifying the market share of key players helps in positioning one's dairy products strategically.

Innovation: Adopting innovative practices like mobile parlor systems could provide a competitive edge in a market that values efficiency and adaptability.

These considerations are instrumental in carving out a niche in the dairy market and setting realistic financial goals.

Installation and Maintenance

Setting up a portable milking parlor and establishing a routine for its maintenance ensures that this mobile, often retrofitted system remains robust and functional within a dairy operation's infrastructure.

Setting Up Your Portable Milking Parlor

To install a portable milking parlor, one must first identify an appropriate location that supports the infrastructure required for operation. Installation should consider:

Accessibility: The location must be easily accessible for both the livestock and farmworkers.

Power Supply: An adequate power source is necessary for the milking machines and associated equipment.

Water Access: Availability of clean water is crucial for both the milking process and equipment sanitation.

Flooring: Install non-slip flooring that can withstand the environment and is easy to clean.

After the location is set, the components of the portable milking parlor need to be assembled and properly connected. Follow the manufacturer’s guidelines to ensure:

Milking Units: Each unit is correctly installed and secured.

Vacuum Systems: These are critical for milking; they must be properly connected and calibrated.

Maintenance and Upkeep Schedule

Regular maintenance is vital for the longevity and efficiency of the milking parlor. A consistent upkeep schedule should include daily, weekly, and monthly tasks, such as:

Daily:

Wash and sanitize all milking equipment post-use.

Check for and promptly address any irregularities in vacuum pumps and lines.

Weekly:

Inspect hoses, gaskets, and rubber parts for wear and tear.

Verify pulsator function for optimal performance.

Monthly:

Test and calibrate the vacuum levels and pulsation rate.

Examine electrical connections for safety and functionality.

It's recommended to maintain a log of maintenance activities to monitor the condition and performance of the entire milking parlor. Regular checks can prevent disruptions in the parlor’s operation and safeguard the quality of milk produced.

Innovations and Future Trends

As dairy operations evolve, innovations and technological advancements are pivotal in enhancing productivity and adapting to market demands. Two key areas—emerging technologies in dairy farming and adapting to changing market demands—emphasize the commitment to progressive, efficient agriculture.

Emerging Technologies in Dairy Farming

The dairy farming landscape is being transformed by the integration of robotic systems and mototech solutions. Agricultural robots, also known as 'agribots', are increasingly utilized in portable milking parlors for their efficiency and precision. They offer numerous benefits:

Automated Milking: Robotic milking systems (RMS) allow for 24/7 milking operations, improving overall milk yield and quality.

Health Monitoring: Agribots equipped with sensors monitor cow health in real-time, flagging issues early on to ensure timely intervention.

These systems are not only enhancing milking processes but also optimizing farm management by collecting and analyzing data which leads to informed decision-making.

Adapting to Changing Market Demands

Market demands are shaping the future of dairy farming, influencing the development of portable milking parlors that are:

Flexible: Can be easily adjusted to cater to fluctuating herd sizes and different locations, providing scalability.

Consumer-Driven: Enhance transparency in milk production to meet consumer demands for sustainability and welfare-friendly practices.

As consumers become more interested in the provenance of their milk and the wellbeing of the animals, dairy operations employing innovative milking solutions are likely to gain a competitive edge.

Conclusion

Setting up a portable milking parlor is a strategic decision for dairy operations that value flexibility, efficiency, and scalability. Dairy farmers should consider the size of their herd, the frequency of milking, and their budget when selecting a portable milking system.

Key considerations for a successful setup include:

Size Appropriateness: Ensuring the milking parlor accommodates the current and future herd size.

Efficiency: A system that allows for optimal milking times and animal comfort.

Equipment Quality: Selection of durable and low-maintenance equipment that can withstand the rigors of daily use.

Ergonomics: A design that supports the health and well-being of the milking staff.

It is essential for farmers to investigate different layout options and operational flows to keep the process smooth and stress-free for both the animals and the workers. They need to maintain a clean environment and adhere to sanitation protocols to ensure high-quality milk production.

At the heart of a dairy farm, the milking parlor—portable or otherwise—must be both a reliable and effective component of the dairy production line. With proper implementation, the portable milking parlor can be a cornerstone of a dairy farm's commitment to producing high-quality milk and maintaining animal health, while offering the adaptability to meet the ever-changing demands of the dairy industry.