The Ultimate Guide to Using a Cider Press

Crafting Delicious Homemade Apple Cider and Fruit Juices

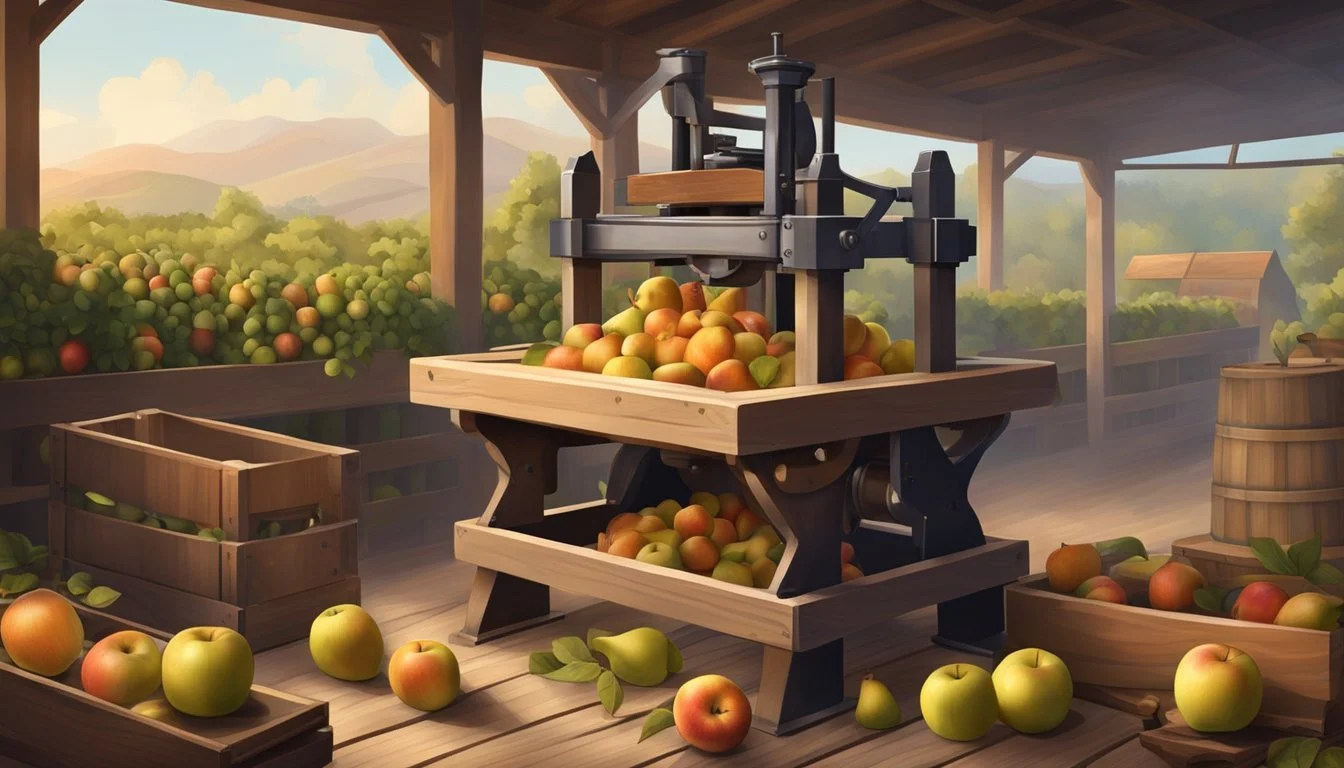

Making homemade apple cider with a cider press is an enjoyable way to create a fresh and flavorful beverage. The charm of this traditional method lies in its simplicity and the exceptional quality of juice it produces. Using a cider press, enthusiasts can turn a bounty of apples into a delicious drink, the quality of which surpasses that of most store-bought options. The process entails grinding the apples into a pulp and then pressing this mash to extract the juice. The resulting cider not only offers a delightful taste but also embodies the essence of autumn's harvest.

The cider press itself is a sturdy device designed to extract the juice from apple pulp efficiently. It is composed of various components, including a pressing plate, a container to catch the juice, and often, a hand crank to facilitate the pressing process. In preparing for pressing, apples are first washed and ground into a coarse pulp. This apple mash is then wrapped in a mesh bag or cloth and placed inside the press. The pressing mechanism applies downward pressure, forcing the fresh apple cider out and leaving behind the dry pulp.

Crafting homemade apple cider using a press is not only about the end product but also the satisfaction of the process. The transformation of whole apples into smooth, amber-hued cider showcases the value of hands-on craftsmanship. Whether one enjoys the cider fresh or fermented into hard cider, the pressing process is a key step in ensuring the character and taste of the beverage are of the highest calibre.

Understanding Cider Pressing

In crafting homemade apple cider and fruit juices, the cider press remains an essential tool. This section will explore the historical technique of cider pressing, the different types of presses available, the components that make up a press, and how apple varieties play a pivotal role in cider quality.

History of Cider Making

Cider making is an ancient practice, with its roots tracing back to Roman times when it was discovered that apples could be fermented to produce an alcoholic beverage. Over the centuries, the method has evolved, but the core process of pressing juice from apples to create cider has remained largely unchanged. The traditional cider press was a staple in many European and early American agrarian communities.

Types of Cider Presses

There are primarily two types of cider presses in use today:

Rack and Cloth Press: Traditional and ideal for larger cider operations, they stack layers of apple mash wrapped in cloth between wooden racks.

Basket Press: More common for home cider makers, consisting of a cylindrical basket whereby the apple mash is pressed from the top by a plate that is turned down manually.

Components of a Cider Press

A typical cider press includes several components:

Grinder or Pulper: This crushes the apples into a fine pulp known as pomace.

Pressing Mechanism: Utilizes pressure to squeeze juice from the pomace. This can range from a simple screw and lever to hydraulic systems.

Collector: Located beneath the pressing mechanism to catch and store the juice as it is extracted from the apples.

The Role of Apple Varieties in Cider

The selection of apple varieties is critical to the cider-making process as they determine the flavor profile of the final product. A blend of sweet, tart, and juicy apples can be used to achieve balanced and rich-flavored cider. Organic apples are often preferred for their natural taste and lack of chemical additives. Sweet apples contribute sugar needed for fermentation, while tart apples add complexity, and juicy apples ensure a bountiful yield of cider from the press.

Preparation for Pressing

The preparation phase is pivotal in determining the quality of the final apple cider. One must meticulously select and cleanse the apples, crush them effectively into pulp, and ensure all equipment is sanitary to secure the desired outcome.

Selecting and Harvesting Apples

When harvesting apples for cider, one should aim for the ripest and freshest fruit straight from the apple tree. Avoid "windfall apples" (those that have fallen to the ground) as they might be bruised or contaminated. When selecting apples for pressing, a mix of both sweet and tart varieties yields a well-balanced cider.

Sweet Apples Include: Fuji, Gala, Honeycrisp

Tart Apples Include: Granny Smith, McIntosh, Jonathan

Cleaning and Preparing Apples

Once harvested, one must thoroughly wash the apples to remove debris and bacteria. During the washing process:

Inspect each apple for bruises and signs of decay.

Remove any spoiled parts to prevent off-flavors in the juice.

Rinse the apples in a solution of water and a fruit-safe cleanser.

Crushing Apples into Pulp

The apples must then be crushed to create a fine apple pulp, which will release the juice during pressing. A mechanical or hand-cranked crusher can effectively break down the apples. The aim is to crush the fruit into a consistency that is neither too coarse, which would yield less juice, nor too fine, which might obstruct the flow during the press.

The Importance of Clean Equipment

Ensuring that all machinery and containers are immaculate prevents contamination and spoilage. All parts of the cider press that will contact the apple pulp or juice should be:

Cleaned: Use a proper cleaning solution

Sanitized: Apply a food-grade sanitizer

Rinsed: Rinse off any cleaning agents with clean water

Making certain that the equipment is free of any previous batch's residue or harmful microbes is essential for a successful press and high-quality cider.

The Pressing Process

The pressing process involves a series of steps that transform crushed fruit into the desired juice, such as apple cider. Precision and careful attention to detail at each stage ensures the extraction of ‘liquid gold’ with maximum yield and clarity.

Assembling the Press

The press, typically composed of sturdy materials like wood or metal, needs to be properly assembled before use. One ensures that the pressing plate is aligned and the screw mechanism functions smoothly. A bucket or container is placed beneath the press to collect the juice.

Layering Apples and Adding Pressure

One begins by placing crushed fruit or pomace within the press, often housed in a nylon bag or strainer for clearer juice. Layers of wooden blocks or racks are then added, followed by the pressing plate. Turning the screw applies pressure, consolidating the contents and aiding the juice extraction.

Collecting the Juice

As the press works on the crushed fruit, the extracted liquid begins to flow. This juice passes through the press into the waiting bucket. One continues to apply pressure until the flow of juice lessens significantly, signaling the completion of juice extraction.

Post-Pressing Clean-Up

After pressing cider, one should disassemble the press for cleaning. All solid remains, or pomace, are removed and the press washed to remove any residual fruit material. Keeping the press clean ensures its longevity and the quality of future batches of cider or juices.

Beyond Pressing: The Next Steps

After pressing apples using a cider press, further steps ensure the juice's clarity, taste, and safety. These post-pressing stages refine the cider for consumption or fermentation into hard cider.

Straining and Filtering the Cider

The freshly pressed juice often contains pulp and sediment. To achieve a clearer cider, one should pass the juice through a straining bag or cheesecloth to remove large particles. Further filtering can be done with finer mesh filters to eliminate finer sediments for a smooth, pure apple juice.

Coarse Strain: Equipment - Straining bag; Description - Removes large pulp and particles.

Fine Filter: Equipment - Cheesecloth; Description - Eliminates finer sediments for clarity.

Options for Sweetening Cider

For those preferring sweeter cider, there are options to enhance the flavor. One can add sugar or honey to the filtered juice, while others may opt for natural methods like blending sweeter apple varieties before the pressing process.

The Pasteurization Process

Pasteurization ensures that the cider is pasteurized and safe for consumption by heating the juice to a specific temperature to kill potential pathogens. This process is particularly important when producing sweet apple cider for immediate consumption and can prevent fermentation for those seeking non-alcoholic options.

Storage and Bottling Techniques

Proper storage is critical to maintain the quality of the cider. Pasteurized cider should be bottled in sterilized containers and can be refrigerated to extend its shelf life. For those making hard cider, the juice must be stored in a clean, airtight container to allow for fermentation, with careful consideration to avoid over-carbonation which can cause bottles to burst.

Sterilization: Technique - Clean bottles; Purpose - Prevents contamination.

Airtight Sealing: Technique - Secure closures; Purpose - Ensures quality and carbonation.

Refrigeration: Technique - Cold storage; Purpose - Preserves fresh cider.

Monitoring: Technique - Regular checks; Purpose - Avoids over-fermentation in hard cider.

Enhancing Your Cider Experience

A truly exceptional cider experience isn't limited to just pressing and consuming the juice; it extends into creative realms of reuse and variation. One can transform apple pomace into resourceful byproducts, innovate with hard cider creations, and master an array of cider recipes and serving techniques.

Alternative Uses for Apple Pomace

After pressing apples for cider, one is left with apple pomace, which has multiple practical uses. This solid residue can be:

Compost: Rich in nutrients, apple pomace can be added directly to a compost pile to enrich garden soil.

Animal Feed: Some may repurpose it as a supplement to livestock feed, ensuring nothing goes to waste.

Additionally, creative culinary uses include making apple butter or apple pomace syrup, both delicious ways to capitalize on the remaining fruit flavors.

Creating Hard Cider and Other Variations

Turning apple cider into hard cider involves the careful management of fermentation. Following a specific tutorial can guide enthusiasts through the process which includes:

Fermentation: The addition of yeast to apple cider and allowing it to ferment for approximately two weeks.

Vinegar: If left to ferment longer, and with proper exposure to oxygen, the hard cider further transforms into apple cider vinegar.

Experimenting with flavors by adding fruits or spices before fermentation allows for a plethora of unique hard cider variations. Practicing these methods safely and effectively does require a certain level of knowledge and attention to detail.

Cider Recipes and Serving Suggestions

Serving cider can be an art in itself. Here are some refined suggestions:

Fresh Cider: Serving Suggestion - Serve chilled, possibly with a cinnamon stick for added aroma.

Mulled Cider: Serving Suggestion - Heat with spices like cloves and allspice for a warming autumnal drink.

Hard Cider: Serving Suggestion - Best enjoyed cold; consider a frosted glass to enhance the crisp taste.

Additionally, incorporating cider into recipes can elevate the flavor profile of various dishes. One can use cider as a base for glazes, reductions, or even incorporate it into baking recipes, allowing the sweet and tart notes of the cider to infuse the dish.

Through thoughtful application of these techniques, one can enhance their cider experience into a multifaceted culinary adventure.

Cider Press Maintenance and Troubleshooting

Maintaining a cider press is crucial to ensure longevity and performance, while troubleshooting helps in addressing common operational issues promptly.

Regular Maintenance for a Long-Lasting Press

Cleaning After Use: One should always clean their cider press following each use. It's essential to dismantle the press components and rinse every part with hot water. Using a mild detergent can help in removing residue, but one must thoroughly rinse to prevent any soap remnants that could affect the flavor of the juices. Materials like stainless steel or coated metals often found in juicer parts are prone to damage if not cleaned properly.

Scrub wooden parts with a brush using hot water, avoiding detergents as they can be absorbed by the wood.

Dry everything completely to prevent the growth of bacteria, which can spoil future batches and degrade the press.

Regular Inspections: Checking the cider press's screw and other mechanical parts for wear is a fundamental part of regular maintenance.

Tighten loose bolts and replace worn-out components.

Oil any moving parts to ensure smooth operation.

Storage: Proper storage is equally important. One should store their press in a dry, cool place away from direct sunlight and cover it to protect from dust.

Common Issues and Solutions

Leakage: If a press is leaking, check all connections and fittings. Tight seals are necessary to prevent juice loss and contamination.

For DIY cider press owners, ensuring all homemade seals are properly fitted and checking for degradation is key.

Poor Juice Yield: If the juicer is not producing as much juice as expected, make sure the fruit is ground finely enough before pressing.

For hard fruit trees like apple, ensure the chunks are small to release maximum juice.

Stuck Screw: The screw is a critical part of the cider press, and it may sometimes become difficult to turn.

Apply food-grade lubricant to the screw thread.

Check for any obstructions or over-tightening that could be hindering movement.

By following a dedicated maintenance routine and being vigilant about troubleshooting common issues, one can guarantee their cider press remains a reliable tool for making homemade apple cider and other fruit juices.

Building Your Own Cider Press

Creating a DIY cider press can be a rewarding project for those interested in homesteading and making their own cider. The process requires careful planning and attention to detail to ensure a functioning and safe cider press.

DIY Cider Press Design and Plans

When embarking on the journey to build a cider press, one must first decide on a design and acquire the appropriate plans. Plans can range from simple, single-tub presses to more complex ones featuring a hand crank and a pressing plate. It is imperative to choose a plan that fits the builder's skill level and the capacity of apple pressing they anticipate.

Popular plan features include:

Hand crank mechanism for crushing apples

Sturdy pressing plate to extract juice

Design for ease of use and efficiency in cider production

Gathering Materials and Tools

The next step involves collecting all necessary materials and tools before starting the assembly. A typical DIY cider press requires wood for the frame, typically 2x4s and a 4x4 for a strong structure. Additional materials might include:

Metal components for the pressing mechanism

Baskets or buckets for holding the apple pomace

Food-grade plastic or stainless steel for surfaces contacting the juice

Essential tools often include:

Saw for cutting wood

Drill for assembling the press

Screws and bolts

Measuring tape and square

Assembly Instructions

With materials and plans at hand, the assembly can commence. It's critical to follow the plans meticulously, starting with the construction of the frame, securing the hand crank mechanism, and ensuring all parts are mounted securely. The builder should carefully assemble the pressing plate in alignment with the frame, to ensure even pressure during the juice extraction process.

Assembly steps in sequence:

Construct the frame according to the dimensions given in the plans.

Install the hand crank or crushing mechanisms.

Fit the pressing plate and ensure it moves freely.

Attach the basket for holding the crushed apples, known as pomace.

Ensure all joints are reinforced and secure.

Safety Tips for DIY Press Making

Safety is paramount when assembling a DIY cider press. Wear protective gear such as goggles and gloves when cutting and drilling wood. Securely fasten all parts to avoid structural failure during use, which could result in injury. Refrain from wearing loose clothing that could get caught in moving parts. Regularly check the press for any signs of wear or damage before each use to maintain a safe cider pressing experience.

Key safety points include:

Wear appropriate safety gear during construction.

Regularly inspect the press for loose fittings or wear.

Ensure stability and sturdiness of the assembled press to prevent accidents.

Seasonal and Regional Considerations

In creating homemade apple cider and fruit juices, the availability of the raw material, namely apples, is subject to seasonal and regional factors. The reader must account for these variations to optimize the quality and flavor of their cider.

Best Time of Year for Cider Making

Apple season typically peaks in the fall, making it the most opportune time for cider making. Apples reach their full ripeness between late summer and late fall, depending on the climate and the variety. Cider makers should plan to harvest or purchase apples in this window when sugars are at their highest and acids are balanced, creating the perfect blend for a robust cider.

Late August to November: Ideal months for the majority of apple varieties in the Northern Hemisphere.

Southern Hemisphere: Harvest typically occurs from late February through May.

Understanding Your Local Apple Varieties

Every apple orchard may offer a different range of apple varieties, and these can impact the taste profile of the cider. Working with local orchards or extension services can aid in identifying the best types of apples for juicing. Common cider apples include:

Tart apples (e.g., Granny Smith): Provide acidity.

Sweet apples (e.g., Fuji, Honeycrisp): Add necessary sweetness.

Bitter apples (historically used for cider making): Contribute depth and complexity.

Specific regional varieties should be researched for their pressing qualities. For example, the Northeastern U.S. is renowned for its McIntosh and Empire apples, while the West Coast is known for its Gravenstein and Gala apples. Each type of apple can influence the cider's character, with considerations such as sugar content, acidity, and juiciness being paramount.

By aligning the cider-making process with these seasonal and regional considerations, one can craft superior homemade fruit beverages.

Resources for Cider Enthusiasts

As cider enthusiasts seek to perfect their craft, resources that offer education and community support are valuable. They provide opportunities to learn how to make apple cider, often through tutorials or by connecting with experienced cider makers.

Educational Workshops and Communities

Many communities offer workshops and classes for individuals interested in cider making. These educational resources vary from backyard tutorials to more formal classes hosted by local community centers or orchards. Local craft cideries often host events and workshops that cover the entire process, from fruit selection to the final bottling.

Books and Guides on Cider Making

For self-paced learning, there are several notable books that serve as comprehensive guides:

"Craft Cider Making" provides essential advice for small scale cider making, combining traditional practices with modern fermentation science.

Additional literature varies in complexity, from introductory texts suitable for beginners to advanced volumes that delve into the chemistry of cider making.

A well-curated selection of these books can be invaluable for both novice and experienced cider makers alike.

Online Forums and Social Networks

Online platforms are a treasure trove for cider enthusiasts. They often harbor active forums and social media groups where members can share advice, success stories, and troubleshooting tips. Websites dedicated to homebrewing and cider-making can offer extensive tutorial content, forum discussions, and articles written by and for community members. Key platforms include:

HomebrewTalk

Reddit's r/cider

These communities allow cider enthusiasts to connect and exchange knowledge, regardless of their physical location.