The Ultimate Guide to Wool Carders

Mastering Fiber Prep for Spinning and Felting

Once the process of sheep shearing is complete, wool carders become an indispensable tool for fiber artists and producers. These devices are crucial for detangling and aligning the raw wool fibers, making them ready for the next stages of wool processing, such as spinning or felting. With the advent of technology, wool carding can be done by hand or with the help of drum carders, which are more efficient and can handle larger quantities of fleece.

Wool carders resemble large, hair brush-like tools with fine teeth that work through the fleece. They serve multiple purposes: from cleaning to blending different fiber types or colors. Thoroughly washed wool yields the best results when carded, as cleaning removes impurities like lanolin, dirt, and debris. This preliminary step ensures the carding process is smoother and the fibers are prepared to transform into high-quality textile products.

Understanding wool carders and how to utilize them effectively is fundamental for anyone looking to engage with wool processing. Whether one opts for manual carding techniques or mechanized alternatives, the carding process is a time-honored link in the chain of turning raw wool into wearable, usable, and saleable woolen goods.

History and Basics of Wool Carding

Wool carding is an essential process in textile manufacturing that dates back to the time when spinning wheels first became prevalent. Carding is the method by which wool fibers are detangled, cleaned, and prepared to be spun after shearing. The process straightens the wool fibers and lays them in the same direction, resulting in a continuous web or sliver suitable for spinning into yarn.

Historically, carding wool was a labor-intensive hand process using two carders, which are brushes with wire teeth. Shepherds would remove the wool during shearing season, and the carding would be one of the first steps to prepare the wool for further use.

Here's a brief overview of the process:

Shearing: Sheep are shorn to collect their wool, which is matted and dirty.

Cleaning: The wool needs to be washed to remove lanolin, dirt, and debris from the fibers.

Drying: After washing, the wool is dried to prepare it for carding.

Carding: The dried wool is then carded using hand carders or drum carders to align the fibers.

In the modern context, carding has been mechanized for efficiency. The carding machines consist of a series of rollers covered in card clothing. They operate to align the fibers and remove any remaining impurities. The ultimate goal of carding is to produce a consistent and uniform batt or sliver that is ready for spinning into yarn.

Carding remains a crucial skill for hand spinners and a vital industrial process in the wool industry. It ensures the quality of the final spun wool and impacts the texture and type of yarn produced.

Different Types of Wool and Their Properties

Wool is a versatile natural fiber that comes from the fleece of various breeds of animals, primarily sheep. The properties of wool can vary significantly depending on the breed of the animal, the characteristics of the fleece, and how the fibers are processed.

Fine Wool:

Merino: Sourced from Merino sheep, this fine wool is renowned for its softness, warmth, and breathability. Fibers are exceptionally thin, making it ideal for luxurious clothing and fine garments.

Cashmere: Coming from the Cashmere goat, these fibers are fine and soft, offering excellent insulation. Despite its thin diameter, it provides substantial warmth without bulk.

Coarse Wool:

Alpaca: Alpaca fibers are obtained from two different breeds—Huacaya and Suri. Huacaya fleece produces a crimped, elastic fiber that is well-suited for knitting, while Suri has a silkier and straight fiber, used in weaving.

Table summarizing the wools:

Type: Fine Wool; Breed: Merino Sheep; Characteristics: Soft, lightweight; Common Uses: High-end clothing

Type: Fine Wool; Breed: Cashmere Goat; Characteristics: Luxurious, warm; Common Uses: Sweaters, scarves

Type: Coarse Wool; Breed: Alpaca; Characteristics: Durable, warm; Common Uses: Coats, linings

Regardless of the type, most wools have the ability to wick moisture away from the body, regulate temperature, and resist odors, making wool fabrics popular for a wide range of climates and uses. The quality of wool fiber is assessed by its diameter (measured in microns), crimp, and length of the locks, as well as the presence of any impurities or vegetable matter that may affect its processing efficiency and end-use quality.

Preparing Raw Wool for Carding

Processing raw wool effectively requires meticulous preparation to ensure the final carded product is of high quality. Proper washing, skirting, grading, and storage techniques are essential steps.

Cleaning and Scouring

Raw wool contains lanolin—a natural grease—as well as dirt and vegetable matter from the pasture. To clean the wool:

Soaking: Submerge raw wool in warm water to loosen dirt and grease. Avoid agitating to prevent felting.

Scouring: Use a gentle detergent designed for wool to wash the fibers. A sequence of multiple washes followed by rinses ensures all contaminants are removed.

Washing: Gently swish the wool in the soapy water.

Rinsing: Rinse thoroughly until the water runs clear, signaling the removal of detergent and lanolin.

Skirting, Grading, and Sorting

Before washing, raw fleece must be prepared:

Skirting: Remove the outer edges of the fleece which are typically dirtier and contain more vegetable matter.

Grading: Assess the quality of the raw fleece, separating fibers based on attributes such as length, strength, fineness, and cleanliness.

Sorting: Segregate fleece into distinct piles, separating clean wool from fibers contaminated with burrs, seeds, or excessive dirt.

Drying and Storage Techniques

After washing and rinsing, raw wool needs proper handling for drying and storage:

Drying: Lay the wool flat or hang it to dry in a well-ventilated space, avoiding direct sunlight to maintain fiber integrity.

Storage: Once completely dry, store the washed wool in a breathable container in a cool, dry place to prevent mold and pests.

These guidelines ensure that raw wool is in optimal condition for carding, leading to the best possible end product.

Wool Carding Tools and Equipment

After shearing, processing wool requires the right tools to transform raw fleece into clean, spinnable fibers. The equipment ranges from manual options like hand cards and blending boards to more sophisticated carding machines and drum carders.

Hand Cards and Blending Boards

Hand Cards are traditional tools resembling large, flat brushes with wire teeth. They are designed for manual carding, often used to prepare woolen fibers for spinning into a soft, airy yarn. A set of Ashford hand cards, known for their quality, typically costs between $50 to $100 depending on the size and materials.

Ashford hand cards: $50 - $100 (price varies)

Wire teeth: Effective for woolen fibers

Creates a rolag: Ideal for hand spinning

Blending Boards function similarly but facilitate the blending of different fibers to create unique textures and colors. They usually feature a flat surface with densely packed pins where fibers are placed and blended using a brush or roller.

Multi-fiber blending: Customizable fiber mixes

Rolag or sliver formation: Versatile output for distinct spinning techniques

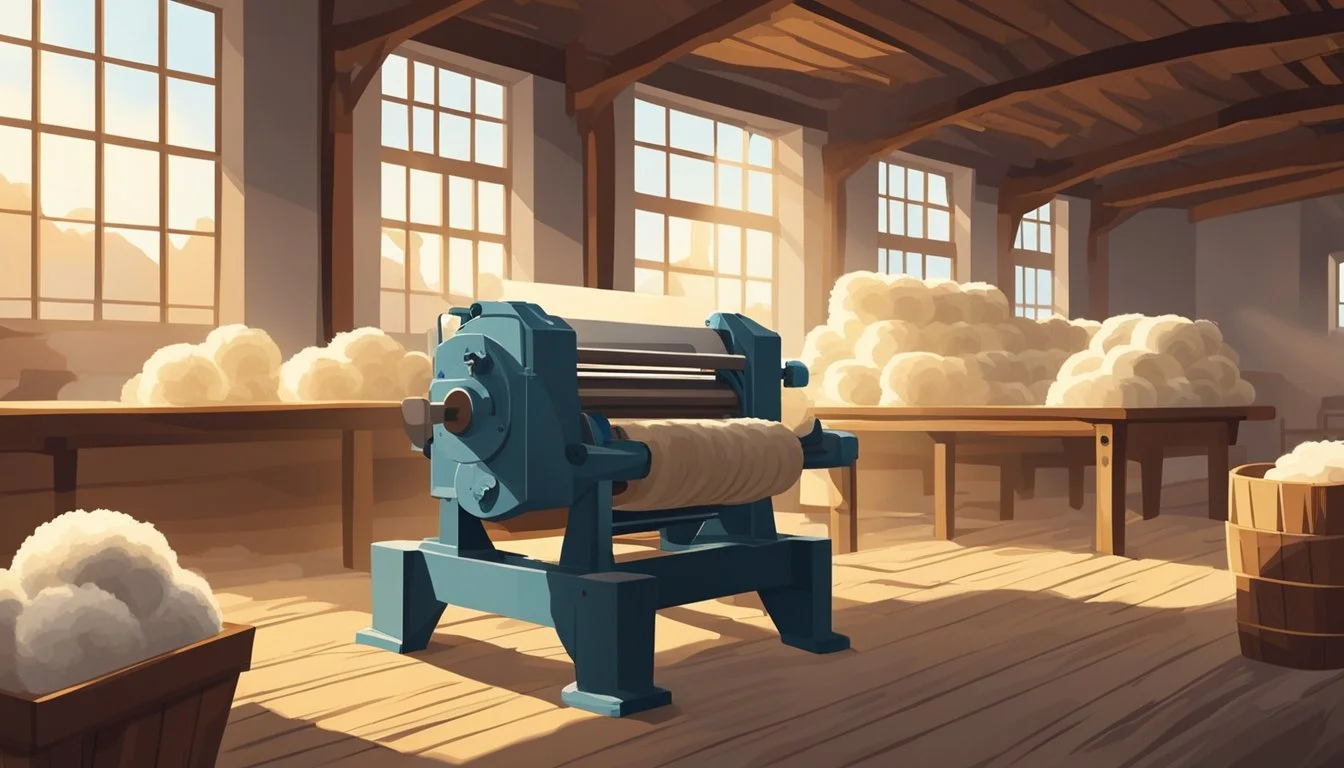

Drum Carders and Carding Machines

Drum Carders utilize two or more cylindrical drums covered in wire teeth to card large amounts of fiber. Renowned models like the Ashford drum carder and the Louet offer durability and efficiency with prices ranging from $500 to over $1,000 based on size and features. Clean, consistent batts or slivers are the output from drum carding, suitable for both hobbyists and professional fiber artists.

Ashford and Louet: $500 - $1,000+

Sizes: Vary to fit the user's need

Material: High-quality output from raw wool

Carding Machines are industrial counterparts, capable of processing wool on a larger scale. While their cost is significantly higher, they automate the carding process, offering a quick solution for commercial production. They yield a continuous web of fibers known as sliver, which is then further processed into yarn.

Industrial carding: High-volume fiber processing

Automated system: Minimized manual labor

Carding Techniques and Processes

Carding transforms raw wool into smooth fibers, ready for spinning. This preparation step aligns fibers, removes debris, and combines locks into a consistent form.

Hand Carding Method

Hand carding is a traditional process using two brushes, known as hand carders, equipped with metal teeth. The wool handler starts by placing locks of wool across one carder until it's evenly distributed. Then, they gently draw the second carder across, combining and detangling the fibers. This method produces rolags, cylindrical rolls of wool, essential for hand spinning.

Steps:

Distribute locks across one carder, fiber tips protruding.

Comb carders in opposing directions.

Roll aligned fibers into rolags.

Using Drum Carders

A drum carder automates carding for larger batches, creating continuous wool batts or a fleece web. The handler feeds fleece locks into the machine, where small and large drums covered with carding cloth detangle and align fibers. The result is a uniform, fluffy batt or a thin web, depending on the settings. Spinners often prefer these for their ability to produce a more considerable amount of prepared fiber quickly.

Output:

Batts: Thick, fluffy sheets.

Webs: Thin, continuous layers.

From Carding to Spinning

Post-carding, the wool becomes either rolags from hand carding or a batt/web from drum carders, and is ready for spinning. Spinners use the fibers in these forms to draft—drawing out and twisting into roving, sliver, or yarn. This drafting is pivotal, determining the yarn’s thickness, strength, and texture. Mastery in fiber carding enhances the spinning process, directly influencing the final handcrafted product.

Transition:

Roving/Sliver: Intermediate stages before yarn.

Spinning: Twisting fibers into yarn using spinning wheel or spindle.

Note: Ensuring cleanliness and proper fiber alignment during carding is crucial for high-quality, easy-to-spin preparations, whether using the direct hand carding method or a drum carder for efficiency.

Understanding Wool Yarns

In the world of wool processing, two distinct yarn types emerge from the spinning process, each with unique characteristics suited for different end uses. The careful transformation of fiber to yarn determines the quality and application of the woolen garments produced.

Types of Wool Yarn

Woolen yarns are typically soft, fluffy, and suitable for creating warm, insulating knits. They consist of shorter fibers that are carded to align in different directions, resulting in a yarn that traps more air and therefore offers better thermal properties. Worsted yarns, on the other hand, are smoother and finer, featuring long, combed fibers that align parallel to each other. This alignment creates a denser and stronger yarn, ideal for garments that require a more refined finish, like tailored suits.

Woolen: Soft, insulating, made from carded fibers.

Worsted: Smooth, strong, made from combed fibers.

The Spinning Process

The spinning process transforms wool fibers into yarn through two principal methods: woolen and worsted spinning. In the woolen method, carded fibers undergo a light and airy drafting, which yields a yarn with a halo effect that is excellent for knitting cozy sweaters. In the worsted method, the fibers are drawn or drafted more tightly after combing, producing a finer and more compact yarn that enhances the durability and appearance of finer knit or woven garments. The spinner's skill in drafting the wool during spinning plays a crucial role in defining the texture and quality of the yarn.

Woolen Spinning: Light drafting, airy yarn, suitable for knitting.

Worsted Spinning: Tighter drafting, finer yarn, ideal for fine knit or woven garments.

Wool Carding for Different End Uses

Wool carding is an essential process that aligns fibers and prepares them for their specific end uses. The type of yarn or felt produced highly depends on how the wool is carded. The preparation varies whether the wool is destined for knitting, crocheting, or felting projects.

Knitting and Crocheting

For those who knit or crochet, carding wool properly is crucial to achieve a smooth and consistent yarn. During the carding process for knitting yarns, the fibers are aligned parallel to each other to ensure strength and uniformity. This is especially important for intricate knitting projects where stitch definition is key.

Fiber alignment: Alignment must be relatively straight and organized.

Spin technique: Fibers should be drawn out carefully during spinning for consistent tension.

Crafters often seek out fine, long fiber wool for a softer and more pliable yarn, suited for garments like sweaters and scarves. Tools such as drum carders can prepare large batches of wool, which is beneficial for spinners who require a steady supply of fiber for their knitting projects.

Felting Projects

In contrast to the requirements for knitting and crocheting, wool prepared for felting projects needs a different approach. Felting relies on the wool fibers' ability to mesh and tangle together, rather than being neatly aligned. The carding process here may be less precise, allowing for a variety of fiber orientations that will aid in the felting process.

Fiber orientation: A random or less uniform fiber alignment is preferable.

Texture: Fibers that are carded for felting typically retain more of their natural crimp and texture.

Typically, wool with a higher micron count, indicating thicker fibers, is selected for felting, as it produces a sturdier end product, suitable for items such as hats, bags, or decorative home crafts. Hand carders and blending boards are often the tools of choice for crafters, as these allow for more artistic and variable blending of fibers and colors.

Tips for Maintaining Carding Equipment

Proper maintenance of carding equipment, whether hand carders or drum carders, is essential for their longevity and performance. Here are some key tips to keep them in top condition:

Hand Carder Maintenance:

Regular Cleaning: After each use, remove any wool remnants from the carder's teeth using a fine-toothed comb or a small cleaning brush designed for this purpose.

Surface Inspection: Check for any bent teeth and gently straighten them using pliers. Avoid using force that can break the teeth.

Drum Carder Maintenance:

Surface Cleaning: Use a small wire brush to clean out fibers from the drum after carding. Focus on the licker-in drum as well as the main drum.

Belt Tension: Check the belt for proper tension and adjust it according to the manufacturer's guidelines to ensure smooth operation.

General Tips for All Carding Equipment:

Lubrication: Occasionally apply a drop of oil to any moving parts that may create friction. Use the oil recommended by the equipment manufacturer.

Storage: Store carders in a dry, clean place to prevent rust and accumulation of dust.

Moisture Control: Always card wool that is completely dry to prevent mildew buildup on your carders.

Maintenance Task: Cleaning; Frequency: After each use; Notes: Crucial for optimal fiber preparation

Maintenance Task: Inspection; Frequency: Monthly; Notes: Look for wear and tear or damaged parts

Maintenance Task: Lubrication; Frequency: As needed; Notes: Based on manufacturer's instructions

Maintenance Task: Belt Adjustment; Frequency: As needed; Notes: Ensure tension is correct for drum carders

Following these maintenance practices helps ensure carding equipment remains functional and efficient, providing clean and well-prepared wool for spinning or felting projects.

Advanced Wool Carding Techniques

In this section, we explore how to enrich the texture and visual appeal of wool through the intricate process of fiber blending.

Blending Fibers for Unique Textures

Blending fibers is a technique that enables the crafter to combine different types of wool and other materials to create unique textures and colors. By using a blending board, carders can mix fibers like silk, angora, and mohair with standard wool to construct batts with various qualities. The method requires a keen sense of creativity and a precise approach to maintain consistency.

Process:

Select Fibers: Choose fibers that complement one another in texture and color.

Layering: Begin with a base layer of wool and gradually add other fibers.

Blending: Use a blending board or drum carder to mix the fibers. Pass the blend through the carder multiple times to achieve a homogeneous mix.

Tips for Optimal Blending:

Maintain Ratios: Keep track of the ratios of each fiber type for consistent results in future blends.

Color Mixing: Experiment with color mixing by carding fibers of different hues to achieve unique shades.

Test Batches: Craft small test batches before committing to larger quantities, ensuring the desired outcome is achievable.

Fiber Suitability: Ensure that all fibers used are appropriate for the intended project, considering factors such as durability and comfort.

By mastering the technique of blending fibers, one can truly tailor the crafting experience to their creative vision, producing a customized end product that stands out in both texture and color.

Wool Dyeing Basics

Dyeing wool transforms it into a vibrant medium for textile creation, and mastering the basic techniques can lead to superior end results. Proper preparation, dye application, and post-dye care are key to achieving uniform color and preserving fiber integrity.

Pre-Dyeing Wool Preparation

Before dyeing, wool must be washed to remove lanolin and impurities. This process, known as scouring, typically involves soaking the wool in hot water with a gentle detergent. Organic options, like those containing bay leaves, can be used for more natural cleaning. After scouring, rinsing thoroughly is crucial to eliminate any residues that might affect dye absorption.

Soak wool in warm (not hot) water with detergent.

Optional: Add bay leaves for an organic wash.

Rinse wool thoroughly to remove all detergents.

Applying Dyes and Fixatives

The dyeing process involves immersing the clean wool in a dye bath. Using the correct temperature and pH levels is essential for fiber bonding with the dyes. Acid dyes are common for wool and require an acidic environment, which can be achieved by adding vinegar to the dye bath. The temperature should be gradually increased to a simmer and maintained to ensure the dye bonds uniformly. Stirring gently helps distribute color evenly. Once the dyeing is complete, the fixative process—a crucial step—secures the dye to the fibers.

Heat dye bath to a simmer, not boiling.

Add acid, like vinegar, for dye to bond to the fiber.

Stir gently to ensure even distribution.

Post-Dyeing Wool Care

After dyeing, the wool should be allowed to cool naturally to room temperature. Rinsing in water then removes excess dye. The water should run clear to indicate that the excess dye has been washed out. Finally, the wool must be dried thoroughly before storage or use. Avoid wringing or twisting the fibers to keep them intact and prevent felting.

Allow dyed wool to cool gradually.

Rinse until water runs clear.

Dry completely without agitating the fibers.

Troubleshooting Common Carding Issues

When processing wool, carders may face issues such as fiber tangles and excessive waste. This section offers solutions to these common problems, ensuring a smoother carding experience.

Resolving Fiber Tangles and Clumps

Carders face common problems when fibers become tangled or form clumps during the carding process. To prevent and resolve these issues:

Preparation: Ensure the wool is properly washed and dried before carding to reduce natural oils and dirt which contribute to tangles.

Technique Adjustment: For hand carders, a lighter touch and slow, steady motions can prevent fibers from rolling into clumps. Ensure not to overload the cards with too much wool at once.

Drum Carder Maintenance: For drum carders, regular cleaning and adjustment of the carding cloth can help remove trapped fibers that cause tangles.

Managing Locks: Disentangling individual locks prior to carding can reduce the occurrence of clumps.

Dealing with Carding Waste

Efficient management of waste is essential to maximize fiber yield and maintain the cleanliness of the final product:

Removal of Plant Matter: Picking out visible vegetable matter before carding and using fine carding cloth to trap smaller particles during carding can reduce the inclusion of plant debris in the fibers.

Regular Cleaning: Clearing out the waste chute or tray often can prevent buildup that leads to jams and inefficient carding.

Utilize Waste Fibers: Waste fibers, often a mix of short, fine, or entangled fibers, can be collected and used for purposes such as felting or stuffing, reducing overall waste.

By addressing these issues, one can improve the quality of carded wool and enhance the efficiency of the carding process, whether using hand carders or a drum carder.

Wool Carding Safety and Ergonomics

When processing wool, the carder's safety and comfort should be prioritized. Here are important considerations to ensure both:

Ergonomics:

Posture: Maintain a proper sitting or standing posture when carding. They should adjust the working surface to elbow height to avoid hunching over.

Movement: Carders should use fluid, natural motions to minimize repetitive strain injuries. For instance, when hand carding, they should use the whole arm to brush, not just the wrist.

Equipment Setup: The carding equipment, whether hand carders or drum carders, should be secured firmly to prevent slippage that could lead to accidents or extra strain.

Safety:

Protective Wear: Wear appropriate gloves to prevent wool fibers from pricking fingers and to provide grip.

Handling: Handle carders, particularly those with sharp teeth, with care to prevent cuts or scrapes. Carders must ensure their fingers are clear of the teeth when the carder is in motion.

Safety Checklist:

Use carders on a stable and non-slip surface.

Secure the carding tools properly before starting.

Keep fingers away from the active carding area.

Check for any loose clothing or jewelry that might get caught.

By adhering to these safety and ergonomic practices, carders can enjoy a smooth carding process, minimize the risk of injury, and improve efficiency.

Economic and Environmental Aspects of Wool Carding

Wool carding, both a critical and labor-intensive process, navigates economic and environmental challenges. Industrial carding machines represent a significant capital investment for wool processors, yet their efficient production justifies the expenditure.

Small-scale operations often utilize hand carders or drum carders, which are more affordable but also labor-intensive. The choice often reflects the budget constraints and scale of the operation. Below is a simplified comparison:

Tool: Industrial Carder; Economic Impact: High investment; Labor Intensity: Low

Tool: Drum Carder; Economic Impact: Moderate cost; Labor Intensity: Moderate

Tool: Hand Carders; Economic Impact: Low cost; Labor Intensity: High

In terms of environmental impact, carding can contribute to sustainability when processors manage their waste properly and opt for organic wool. Organic wool ensures that the sheep are raised without synthetic inputs, and the wool is processed without harmful chemicals, making it a more sustainable choice.

Carding organic wool also reduces the release of synthetic microfibers into ecosystems. Moreover, the durability and biodegradability of wool products underscore wool's environmental merits post-production.

Properly managed carding operations, especially those powered by renewable energy, can minimize the carbon footprint associated with wool processing. The challenge lies in balancing economic viability with sustainable practices—an ongoing quest for the wool industry.

Concluding Thoughts

Wool carders are indispensable in transforming shorn wool into fibers suitable for crafting and spinning. They range from simple hand carders to more complex drum carders, each serving the needs of different crafters. Hand carders are preferred by hand spinners for their control and portability, while drum carders are favored for their efficiency in processing larger volumes of wool.

The process of carding, while straightforward, demands patience and attentiveness to align fibers and remove impurities, setting the stage for high-quality spun wool. Retailers such as The Woolery provide a diverse range of carders, catering to the varied requirements of fiber artists.

Wool carding is more than just a preparatory step; it's the foundation that dictates the texture and quality of the final yarn. For those invested in the craft, investing in a good quality wool carder is not merely an option but a necessity for ensuring the integrity of their work. Whether for personal enjoyment or commercial production, the right carding equipment is a testament to the dedication of the crafter in pursuit of excellence.

When choosing a wool carder, it is important to consider both the scale of production and the desired outcome. The satisfaction of crafting lies in the quality of the material produced, and a wool carder is a critical tool in achieving that high standard.