On-Farm Meat Processing, Butchering and Slaughter in Nevada

Navigating Regulations and Best Practices

On-farm meat processing in Nevada represents a burgeoning frontier for local agriculture, aiming to address the bottlenecks in meat production and offer sustainable solutions for farmers and ranchers. As the demand for locally sourced meats continues to

Overview of On-Farm Meat Processing

On-farm meat processing in Nevada presents unique opportunities and challenges, deeply influenced by state regulations and the effects of the COVID-19 pandemic. It is an evolving sector that plays a critical role in addressing the meat processing bottleneck.

Benefits of On-Farm Processing

On-farm processing can significantly benefit local communities in Nevada. Producers who engage in on-site processing are able to capture more of the food dollar, fostering financial resilience by reducing reliance on fluctuating cattle and beef prices. They tap into a growing consumer demand for local, traceable meat products. Additionally, on-farm slaughter and processing can shorten the supply chain

Setting Up On-Farm Butchering Facilities

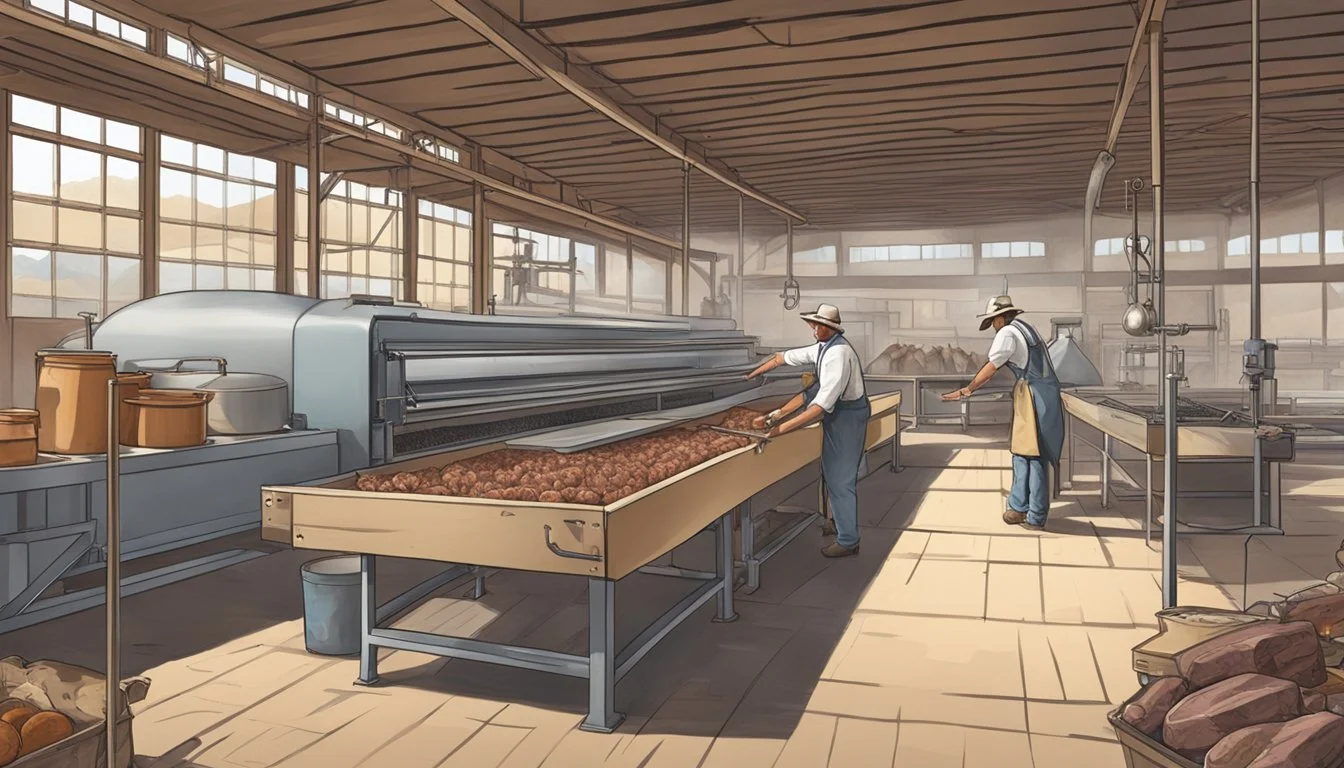

Establishing on-farm butchering facilities in Nevada involves meticulous planning for the infrastructure, specialized equipment, and adopting operational best practices to maintain safety and efficiency during slaughtering and processing.

Infrastructure Requirements

On-farm butchering facilities require a well-designed infrastructure to ensure compliance with safety and sanitation standards. The facility must have:

Adequate space for separate areas designated for slaughtering, processing, and storage

Sanitary surfaces that are easy to clean and made of non-absorbent material

Proper ventilation systems to manage odors and maintain air quality

Waste disposal systems in place to handle by-products and contaminants

Water supply that is sufficient for cleaning and processing needs

Refrigeration units to store meat at safe temperatures post-slaughter

Equipment for Slaughter and Butchering

The right equipment is crucial for operational efficiency and safety. Essential items include:

Stunning tools to humanely render animals unconscious

Knives and saws of various sizes for precise cuts

Scalding tanks or dehairing machines for swine and similarly coated animals

Gambrels or hoists to support carcasses during processing

Stainless steel tables for meat inspection and cutting

Personal Protective Equipment (PPE) to ensure the safety of workers

Operational Best Practices

To run a successful on-farm butchering operation, one must adhere to best practices, including:

Regular training for all individuals involved in slaughter and processing activities

Thorough documentation of all processes to ensure traceability and compliance with regulations

Implementation of Hazard Analysis and Critical Control Points (HACCP) for systematic preventative approach to food safety

Routine inspections and equipment maintenance to uphold safety standards

Efficient workflow design to minimize cross-contamination between different processing stages

Animal Welfare and Handling

On-farm meat processing in Nevada necessitates a strict adherence to animal welfare and handling standards to ensure that the integrity of ethical practices is maintained. This encompasses stress management in livestock and the establishment of rigorous protocols for humane slaughtering.

Stress Management in Livestock

Best Practices: It is imperative for Nevada farmers to implement effective strategies that mitigate stress in livestock. Transportation and holding conditions prior to slaughter significantly impact stress levels.

Cattle and sheep require adequate space and familiar groupings to remain calm.

For poultry, minimizing noise and extreme temperatures is crucial to prevent distress.

Monitoring: Farmers utilize regular observations and handling checks to assess the welfare of cows, sheep, goats, and poultry, adapting practices where necessary to maintain low stress levels.

Protocols for Humane Slaughter

Pre-Slaughter Handling:

Farmers ensure that animals are not subjected to any unnecessary pain or distress during the preparation for slaughter.

Livestock is guided calmly and with minimal force to the slaughter unit.

Slaughter Techniques:

Stunning: Proper stunning methods are enforced to render animals insensible to pain before slaughtering commences, following state and federal regulations.

Equipment: Slaughter equipment is routinely inspected and maintained to ensure efficiency and prevent any undue suffering during the process.

Training and Compliance:

Personnel receive comprehensive training on humane slaughtering techniques.

Operations are regularly audited for compliance with the Humane Methods of Slaughter Act and state-specific animal welfare provisions.

Legal and Liability Considerations

In Nevada, on-farm meat processing, butchering, and slaughter operations are subject to stringent state and federal regulations. These laws are designed to ensure food safety, public health, and animal welfare. Alongside these requirements, operators must also navigate the complexities of liability and insurance to safeguard their businesses.

Understanding State and Federal Laws

Nevada's meat processing establishments need to comply with both state and federal laws. State laws may impose specific requirements on facilities, health, and hygiene standards, while federal laws, primarily enforced by the USDA, mandate inspection and compliance with the Federal Meat Inspection Act (FMIA). It's important for operators to recognize that:

USDA inspection is required for meat intended for commercial sale.

Nevada has adopted the FMIA standards; therefore, state inspections must be equivalent to federal inspections.

Custom slaughter and processing, done for personal use and not for sale, can sometimes be exempt from continuous inspection.

Operators should consult Nevada's Department of Agriculture to verify their compliance with local regulations.

Insurance and Liability for Butchers

It is crucial for butchers and meat processors in Nevada to have insurance coverage tailored to the specific liabilities associated with their trade. Here are key points they must consider:

General liability insurance helps protect against claims related to injuries or property damage caused by the business's operations.

Product liability insurance is important because it covers claims related to the safety and quality of the meat processed and sold.

Workers' compensation insurance is mandated in Nevada for businesses with one or more employees, covering workplace accidents and occupational illnesses.

Operators should work with insurance professionals to ensure that their coverage meets both their liability needs and state requirements.

Environmental Management

Effective environmental management within on-farm meat processing and butchering operations in Nevada is critical. It involves responsible waste disposal techniques and the implementation of sustainable practices to minimize environmental impact.

Waste Disposal

Waste Type Disposal Method Solid Waste (e.g., bones, offal) Composting/Rendering Liquid Waste (e.g., blood, runoff) Sewage treatment systems

In the process of slaughtering and processing, a considerable amount of waste is generated. Nevada farms must employ proper waste disposal mechanisms to mitigate environmental harm. For solid waste, composting serves as a resourceful method, turning slaughter by-products into fertilizer. Likewise, liquid waste requires meticulous management through sewage treatment facilities to prevent water contamination.

Sustainable Practices in Meat Processing

Sustainable practices are essential in on-farm meat processing to ensure the longevity and health of the surrounding environment.

Energy Efficiency: Utilizing renewable energy sources reduces carbon footprint.

Water Conservation: Implementing water-saving technologies within slaughter units helps preserve this vital resource.

Chemical Management: Careful handling and disposal of chemicals prevent soil and water pollution.

Slaughterhouses in Nevada are encouraged to integrate these sustainable methods not only to comply with regulations but also to support the environment and community health. Through vigilance and continuous improvement in these areas, meat processing can align with ecological sustainability goals.

Quality Control and Meat Processing

Quality control in on-farm meat processing is crucial for ensuring the safety and integrity of meat products. In Nevada, farmers and meat processers follow stringent protocols to maintain high standards from butchering to packaging.

Ensuring Meat Quality

Meat quality is assessed through various indicators such as freshness, color, and texture. Farmers and processors in Nevada implement measures to safeguard these attributes, starting from the farm to the final product. Safety is paramount; hence, a Hazard Analysis Critical Control Point (HACCP) plan is integral to the process. Beef and poultry are subject to different quality control checks to address specific risks associated with each type of meat.

To ensure meat quality, processors adhere to the following steps:

Pre-Slaughter Handling:

Livestock are managed humanely to reduce stress, which can negatively impact meat quality.

Feed withdrawal times are strictly followed to ensure a clean gastrointestinal tract.

Slaughter Procedures:

Skilled butchers perform slaughter efficiently to prevent meat spoilage.

Carcass inspection is mandatory to detect and remove any abnormalities.

Storage and Transport:

Meat is chilled to an appropriate temperature immediately after slaughter.

Refrigerated transport preserves meat quality until further processing.

Cut and Wrap Techniques

Cut and wrap techniques are the final steps before meat reaches consumers. Precision and hygiene during these stages are essential to maintaining product quality and ensuring the longevity of the meat. Local farmers employ skilled butchers who are adept at various cuts that maximize yield and satisfy consumer preferences. Furthermore, packaging materials and methods are carefully chosen to preserve freshness and prevent contamination.

Key points in cut and wrap services include:

Cutting:

Butchers make cuts according to standardized guidelines to ensure consistency.

Special care is taken to prevent cross-contamination between different types of meat.

Wrapping:

High-quality, food-grade materials are used for wrapping meat products.

Vacuum sealing is commonly employed to extend shelf life and protect against freezer burn.

Farmers in Nevada collaborate with local butchers and processing plants to provide high-quality, safely processed meat. They continually work to refine these processes, adhering to the best practices in the industry.

Marketing and Selling Processed Meat

For meat producers in Nevada, the pathway to market their processed products effectively is two-fold: adopting direct marketing strategies and forging strong relationships with local meat markets. These approaches help farmers and ranchers navigate post-COVID market disruptions while staying in compliance with regulations.

Direct Marketing Strategies

Producers can leverage direct marketing to sell their meats directly to consumers, bypassing traditional intermediaries. This allows for better control over pricing and a closer connection with the customer base. When selling meat directly from farms, it is imperative that the meat is processed in a facility that meets USDA inspection standards to ensure food safety and compliance. Farmers may sell whole animals or individual cuts, and these products must be accurately labeled to inform consumers.

Sales Avenues:

On-farm stores

Online platforms

Community-supported agriculture (CSA) shares

Producers must focus on clear and compelling product labeling, which should include information like:

Product name

Net weight

Safe handling instructions

USDA inspection legend (if applicable)

Processor's name and address

Collaboration with Local Meat Markets

Building relationships with local meat markets is crucial as they serve as intermediaries between farmers and the broader consumer base. These markets often have established customer traffic and can provide consistent sales volume required for the stability of a farm's meat production business. In collaborations, the terms of the partnership must be transparent, covering aspects like pricing, volume, delivery schedules, and marketing support.

Considerations for Collaborative Partnerships:

Mutual agreement on standards of meat quality

Consistency in supply to meet market demand

Shared marketing efforts to elevate brand presence

Clear communication to manage expectations and responsibilities

Here, producers have the opportunity to leverage the markets' existing infrastructure for processing, storage, and sales, potentially reducing the barriers to entry in the meat market post-processing. These collaborations can mitigate some of the market challenges posed by COVID, as they offer an alternative route to market stability and growth.

Supporting Farmers and Ranchers

In Nevada, farmers and ranchers looking to enhance on-farm meat processing can leverage educational and financial resources tailored specifically for small scale operations. These resources aim to boost local agricultural businesses and contribute to the resilience of the country's food supply chain.

Educational Resources for On-Farm Butchering

Nevada's Cooperative Extension Service offers comprehensive training programs for farmers and ranchers. These programs include:

Workshops and seminars: Covering humane slaughtering techniques, safety standards, and meat processing.

Online learning modules: Focused on best practices for handling livestock, such as beef and dairy cattle, and proper grazing management.

These resources are designed to support local producers in improving product quality, ensuring compliance with health regulations, and sustaining the viability of their businesses.

Financial Resources for Small Scale Operations

Financial aid for on-farm meat processing in Nevada encompasses grants and loans targeting small scale producers to foster growth and independence. Here's a brief overview:

Type of Support Description Grants Non-repayable funds for equipment purchase and facility upgrades. Low-interest Loans Financial products available through local agricultural banks and cooperative funds.

The USDA Meat and Poultry Processing Expansion Program is a notable example, providing monetary support to help small operations scale up and compete in the marketplace. Through such initiatives, farmers and ranchers can secure the necessary capital to invest in their meat processing endeavors.

Innovations in On-Farm Processing

The landscape of meat processing is being reshaped by innovative approaches, particularly in on-farm practices. In Nevada and across the US, technological adoption is driving the industry toward more self-sufficient and versatile processing solutions.

Mobile Slaughtering Units Launch

Nevada has seen the emergence of mobile slaughtering units which bring the processing facilities directly to the farm, mitigating the need for transportation and reducing stress on the animals. These units are self-contained, equipped with the necessary technology to perform slaughtering and butchering services on-site, adhering to USDA standards. Their introduction has provided farmers with greater control over the quality and handling of their meat products.

Key Benefits:

Increased access to processing

Reduced animal stress

Quality control

On-Farm Slaughterhouse Trends in the US

While Nevada is adapting to mobile units, there's a broader trend in the US towards establishing on-farm slaughterhouses. Innovative farmers and ranchers are embracing this trend to gain independence from large-scale processors. These facilities range from small-scale, artisan butcheries to larger, cooperative-owned operations.

Technological Integration:

Advanced meat aging techniques

Enhanced refrigeration systems

Cooperative Models:

Farmer and butcher-owned co-ops

Shared-resource processing facilities

Such trends underscore a move towards localizing meat production and processing, expanding opportunities for producers to maximize their economic resilience.