On-Farm Meat Processing, Butchering and Slaughter in New York

A Guide to Local Practices

On-farm meat processing, butchering, and slaughter constitute important aspects of New York's agricultural landscape. Farmers and processors in New York are equipped with a variety of options when it comes to handling livestock and poultry. State regulations facilitate these activities through specific licensing and exemptions designed to support local agriculture while maintaining food safety standards. For instance, farms processing their own poultry may operate under the 20,000 bird small enterprise exemption, provided their processing numbers do not exceed regulatory thresholds.

In New York State, facilities that do not slaughter livestock or poultry but engage in meat processing operations are licensed under 20-C as commercial kitchens. These kitchens further process meats, ensuring that red meats (What wine goes well with red meat?) come from USDA-inspected slaughterhouses and poultry from registered 5-A facilities. This not only ensures regulatory compliance but also addresses the demand for locally raised and processed meat products.

Butchering and processing of red meat, however, reveal a bottleneck in the local food system due to the limited number of available processing facilities. While the state encourages the growth of this sector through grant funding and technical support initiatives, more efforts are needed to increase the supply of New York-raised meats. This includes creating clear pathways to employment in the industry, thereby establishing a robust infrastructure for meat processing within the state, which can lead to an enriched local food economy and increased self-sufficiency.

Overview of On-Farm Meat Processing

In New York State (NYS), on-farm meat processing is a growing segment in the agricultural sector, providing farmers with increased control over their meat products from farm to table. On-farm processing involves the slaughtering, butchering, and packaging of meat on the premises where the animals are raised. This method of processing offers a variety of benefits including the ability to directly market meat to consumers, which can increase the farmer's share of the final retail price.

USDA regulations play a pivotal role in maintaining food safety standards for meat processing. Farms are required to adhere to these guidelines to ensure that the meat is safe for consumption. In some cases, farmers may operate under a USDA exemption, which enables small-scale producers to process a limited quantity of animals without requiring the presence of USDA inspectors.

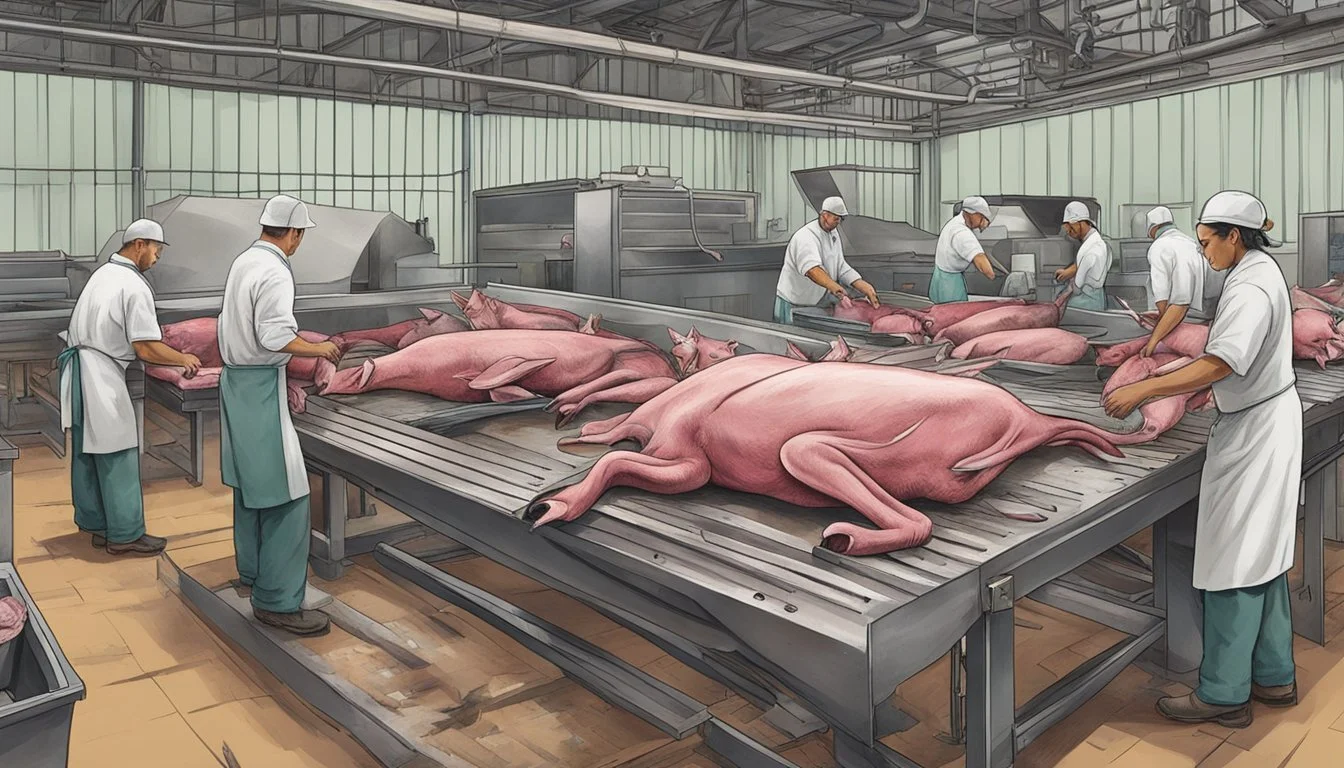

The process typically involves:

Slaughtering: The humane killing of animals for meat consumption.

Butchering: The breakdown of carcasses into smaller cuts of meat.

Processing: The transformation of cuts into value-added products like sausages or smoked meats.

For those without a USDA exemption, utilizing a USDA-inspected facility is crucial to ensure broader market access. Such a facility demonstrates compliance with stringent food safety measures, thereby allowing meat to be sold across state lines and through various retail channels.

It's important for New York farmers to understand and navigate the complexities of slaughtering and butchering within the prescribed legal framework to maintain the integrity of the food system and uphold consumer safety.

Farms seeking to establish or expand their on-farm meat processing operations can take advantage of various grants and technical assistance programs aimed at enhancing the meat and poultry supply chain, as initiated by federal and state agencies.

Regulatory Framework in New York State

In New York State, meat processing, butchering, and slaughter operations are subject to a comprehensive regulatory framework designed to ensure food safety and compliance with both state and federal guidelines. The United States Department of Agriculture (USDA) plays a central role in this framework, especially through the Food Safety and Inspection Service (FSIS), which inspects and regulates meat processing to ensure public health.

State Regulation by the New York State Department of Agriculture and Markets (NYSDAM) works in conjunction with federal oversight to support local food systems and provide guidance for meat processors. For instance, NYSDAM encourages meat processors to leverage available funds aimed at expanding capacity, reflecting the state's support for the growth of small to medium-sized enterprises in the sector.

Facility Inspection

Federal Inspection: Facilities conducting slaughtering and processing must have animals and carcasses inspected by FSIS to certify products for interstate commerce.

State Inspection: NYSDAM has jurisdiction and provides oversight to ensure compliance with food sanitation requirements in farmers markets and other non-federally inspected facilities.

Custom Exempt Slaughterhouse These facilities, known for Freezer Trade, may process livestock and poultry without the need for individual animal inspection by FSIS. They are, however, still subject to facility inspections to maintain compliance with USDA standards.

Licensing Requirements On-farm poultry slaughterhouses in New York that harvest significant quantities (more than 1,000 chickens or 250 turkeys) require an Article 5-A License. Smaller operations may be exempt but have other specific regulations they must follow.

This regulatory environment underscores the commitment to maintaining a safe, sustainable, and locally supported food system within New York State, ensuring consumer confidence in the agricultural products they consume.

Types of Livestock for On-Farm Processing

On-farm meat processing in New York accommodates various types of livestock, each with specific regulations and handling requirements. The selection often includes traditional farm animals as well as game species.

Processing Beef and Pork

Cattle and hogs are two of the most common types of livestock processed on farms. These animals are categorized as red meat providers and are subject to stringent health and safety regulations to ensure food quality and consumer safety.

Cattle: Often raised for beef, cattle are processed for a range of products from steaks to ground meat.

Hogs: Hogs, processed for pork, yield products like chops, bacon, and sausages.

The processing of these animals must adhere to both state and federal guidelines to ensure meat quality and safety.

Poultry and Rabbit Processing

Processing poultry and rabbits on-farm in New York follows specific classifications that may affect selling permissions:

Poultry: This includes chickens, which are often processed under small enterprise exemptions allowing for the processing of up to 20,000 birds.

Rabbits: These can be processed on-farm with fewer regulatory hurdles compared to poultry and red meat.

The facilities handling poultry and rabbits must manage the humane slaughtering and butchering of these animals, taking into account their welfare and the end product's quality.

Processing Game Animals

Game animals such as bison (What wine goes well with bison?) and elk require specialized knowledge for processing due to their size and meat characteristics. Additionally, there are regulatory issues unique to game animals that must be considered, including:

Bison: Though not as common, bison are occasionally processed on farms. Their larger size requires more extensive handling facilities.

Elk: Similar to bison in terms of processing needs, elk are also part of the on-farm processing spectrum.

Farmers must remain compliant with state and federal game processing regulations, which may differ from those applied to domesticated livestock.

Setting Up an On-Farm Processing Facility

Establishing an on-farm processing facility in New York requires careful planning, adherence to regulations, and the implementation of sustainable practices. The key components include developing the necessary infrastructure and managing waste effectively to minimize environmental impact.

Infrastructure Requirements

Successful on-farm meat processing begins with the proper design and set up of the facility's infrastructure. Facility design must consider both the flow of operations and compliance with regulatory standards. Here are the essentials:

Slaughterhouse Area: A designated space for slaughtering that is equipped with stainless steel tables, non-slip floors, and adequate drainage systems.

Processing Equipment: Commercial-grade meat grinders, saws, knives, and refrigeration units. All equipment must meet safety standards and be easily cleanable to prevent contamination.

Inspection Office: Space for onsite USDA inspection personnel, as required for facilities processing over 20,000 birds or engaging in interstate commerce.

Cooling and Storage: Adequate cooling facilities, such as walk-in refrigerators and freezers, to ensure meat products are stored at safe temperatures.

These components are essential for on-farm slaughterhouses to operate safely and to comply with New York's environmental and health regulations.

Waste Management and Sustainability

Waste management is a critical aspect of meat processing due to its potential environmental impact. Sustainability practices and effective sewage treatment are integral:

Solid Waste: Solid waste material, such as bones and offal, should be disposed of or repurposed according to state guidelines. Options include rendering or composting when permitted.

Liquid Waste: Waste water, including blood and other fluids, requires proper treatment before it can be released. On-site sewage treatment infrastructure or approved off-site facilities must be used to prevent contamination of local water systems.

Sustainability Practices:

Water Use Reduction: Install low-flow systems and water recirculation practices.

Renewable Energy: Consider solar panels or wind turbines to power facility operations.

Byproduct Utilization: Take advantage of byproducts for pet food or as feed in agricultural settings, reducing waste and creating additional revenue streams.

Facility operators must work closely with regulatory agencies to ensure that waste management systems comply with environmental regulations and to promote sustainability within the industry.

Financial Aspects and Funding Opportunities

In New York, on-farm meat processing entities, including small processors and mobile operations, have various financial aspects to consider. Operational costs for these businesses typically encompass equipment acquisition, maintenance, staffing, and compliance with regulations. Insurance is imperative to safeguard against potential losses and liabilities.

Funding opportunities are available to support these entities. Historically, the U.S. Department of Agriculture (USDA) has offered grants to enhance the meat and poultry processing infrastructure. For instance, the USDA's Meat and Poultry Processing Expansion Program (MPPEP) provides financial assistance for construction and equipment costs.

Funding Source Funding Scope USDA MPPEP Grants $250,000 - $10 million American Rescue Plan Funds Varied investment in processing capacity

Investment in on-farm processing can benefit from these federal opportunities, which aim to increase competition in the marketplace and enhance the food supply chain's resiliency.

For mobile slaughter and mobile poultry processing units, grants may be utilized to fund the necessary equipment, allowing them to deliver services directly to farms, thus reducing facility overheads. Small processors can secure funds for expanding operations, which may include integrating advanced technologies or increasing output.

It's essential that applicants meet eligibility requirements and adhere strictly to the outlined use of funds, as these grants are competitive and require detailed planning and justification.

New York's food system stakeholders are encouraged to capitalize on these funding avenues to invest in efficient and safe meat processing, thereby strengthening their operational foundations and contributing to a robust agricultural economy.

Operational Protocols for Safety and Quality

The protocols for on-farm meat processing, butchering, and slaughter in New York are designed to ensure the highest standards of food safety and meat quality. They incorporate scientifically grounded procedures and are closely aligned with USDA regulations.

Food Safety Principles

Food safety in on-farm meat processing entails a series of stringent controls to prevent contamination and ensure consumer health. Protocols include:

Sanitation: Facilities must maintain impeccable cleanliness, routinely disinfecting surfaces and equipment.

Temperature Control: Meat must be kept at safe temperatures during processing and storage to inhibit bacterial growth.

Cross-Contamination Prevention: Separation of raw and cooked products is mandatory to avoid cross-contamination.

Pest Control: Operations should implement proactive pest management strategies, such as sealing openings and utilizing air curtains.

In addition, staff training on hygienic practices is essential. Employees must understand and follow proper handwashing, equipment use, and personal hygiene protocols.

Quality Control and Meat Science

Quality control measures are critical to maintaining the integrity of meat products. Key aspects include:

Ante-mortem and Post-mortem Inspections: Animals are examined both prior to and following slaughter to detect any diseases or abnormalities that could affect meat quality.

Stress Reduction: Livestock management before slaughter is pivotal; stress can adversely affect meat quality, so animals are treated humanely to prevent toughening of meat.

Curing and Storage: Accurate methods of curing and properly regulated storage conditions are critical for extending shelf life and preventing spoilage.

Scientific principles guide these processes to maximize meat safety and palatability. Research in meat science contributes to optimizing tenderness, flavor, and nutritional content while adhering to health standards.

Insurance and Liability Considerations

When operating an on-farm meat processing, butchering, or slaughter operation in New York, owners must carefully address insurance and liability considerations to safeguard their business. It is imperative that they acquire General Liability insurance to protect against third-party claims of bodily injury or property damage. For example, injuries might arise from accidents such as slips and falls, or customers could become ill from consuming spoiled or contaminated meat products.

The ownership and operation of meat processing facilities are governed by various legal requirements that extend to health, sanitation, and waste disposal. Entities are also expected to adhere to facility or building specifications as mandated by state and federal regulations.

Meat processing plants are considered an attractive business opportunity, but entrepreneurs should be mindful of their liability. Businesses with a 20-C license are permitted to sell products processed at 20-C facilities, ensuring compliance with regulatory standards. The liability extends to ensuring that red meat is slaughtered and inspected at a USDA slaughterhouse, and that poultry comes from a registered 5-A facility.

Key Insurance Policies:

General Liability Insurance: Vital for covering accidents resulting in bodily harm or property damage.

Product Liability Insurance: Needed to address claims related to the consumption of meat.

Legal Requirements:

Compliance with USDA standards for red meat and 5-A standards for poultry.

Adherence to health and sanitation regulations, as well as waste disposal laws.

Owners must also consider the potential for agri-tourism on their farm or ranch as part of their marketing strategy, which might necessitate additional insurance coverage to address the increased risk exposure.

In summary, it's crucial for businesses in the on-farm meat processing sector to ensure they are sufficiently insured and legally compliant to mitigate risks and protect their interests.

Educational Resources and Extension Programs

In New York, individuals interested in on-farm meat processing, butchering, and slaughter have distinct educational resources and extension programs available. These offerings primarily equip participants with the necessary skills and knowledge to navigate the complexities of meat processing, while adhering to the state's regulations.

Cornell University Outreach

Cornell Cooperative Extension serves as a key resource for individuals looking to enter or improve within the field of on-farm meat processing. It operates as a partnership between county, state, and federal governments and is an integral part of the Cornell University system. This extension provides practical education that bridges the gap between Cornell’s research findings and community implementation.

The Cornell Small Farms Program is specifically designed to cater to the educational needs of small farmers and processors in New York. These services include but are not limited to:

Training Workshops: Hands-on instruction in meat processing and butchering techniques.

Regulatory Guidance: Information on state and federal regulations pertaining to meat processing to ensure compliance and safety.

Business Development: Programs aiding in the creation and expansion of small-scale meat processing enterprises.

Through these initiatives, participants gain access to comprehensive materials, expert consultations, and a network of professionals dedicated to sustainable agriculture and community resilience.

Local Food Movements and Consumer Awareness

Recent years have witnessed a surge in consumer demand for local food, including meat from local farms. Spearheaded by the 'eat local' movement, there is heightened consumer awareness about the origins of food and the economic, environmental, and social benefits of supporting local agriculture. This movement is grounded in a confidence that purchasing locally produced food fosters community resilience and ensures traceability and freshness.

Consumer Trends indicate that people are increasingly seeking information about the food they consume, prioritizing products that are marketed with transparency in regard to their production and supply chain. The local food movement has been instrumental in educating consumers about the impact of their food choices, leading to a greater interest in how and where their food is processed.

Product Marketing has adapted to these consumer trends, with producers emphasizing locality and sustainable practices as key selling points. This marketing taps into the consumer desire for food with identity, story, and place. Farmers and retailers of locally-sourced meat have thus found it beneficial to highlight the local aspect of their products to attract discerning buyers.

Consumer Priorities in Local Food Provenance Sustainability Support for Local Economy Freshness and Quality

The local food movement's focus extends to the realm of on-farm meat processing, where consumers are showing interest in supporting small-scale operations that align with their values. These operations often exemplify transparency and can provide detailed information on the handling and processing of the meat, further meeting the consumer demand for clarity and quality in their food choices.

Impact of COVID-19 on Meat Processing

The advent of COVID-19 brought significant challenges to the meat processing industry in New York. The industry, vital for both livelihoods and food supply, had to swiftly adapt to maintain operations under the new health guidelines and constraints. With processing facilities often characterized by close-quarter working conditions, the spread of the virus among workers led to heightened health concerns, necessitating operational changes.

Industry Response and Operational Changes

Processing plants implemented several measures to address the health risks:

Enhanced sanitation protocols: Frequent cleaning and disinfection routines became standard.

Physical distancing: Where possible, spaces were reconfigured to provide more distance between workers.

Personal protective equipment (PPE): The use of masks and shields was mandated to mitigate transmission.

Testing and contact tracing: Regular health assessments were conducted to identify and isolate affected individuals.

Disruptions and Adaptations

The pandemic caused disruptions in the supply chain as the infection rate impacted manpower:

Staff shortages: High infection rates led to a reduced workforce, slowing down production lines.

Intermittent closures: Some facilities faced temporary shutdowns for deep cleaning and quarantine measures.

Despite disruptions, the industry showcased resilience by:

Automating processes: Investment in technology to reduce dependency on manual labor.

Diversifying supply sources: To mitigate the risk of a single point of failure.

The industry's response to COVID-19 underpins the critical role flexibility and crisis management play in ensuring food security amidst global challenges. Meat processors continue to adapt, aiming for a balance between public health and economic sustainability.

Case Studies from Other States

In Oregon, the landscape of meat processing includes various models such as USDA-inspected red meat slaughter/cut & wrap shops. Several of these entities offer co-packing services, an option that allows ranchers to have their meat processed and packaged by another company. Oregon also boasts a number of licensed exempt poultry/rabbit slaughterhouses, with some providing co-packing.

Mobile slaughter units have become a pivotal element in rural regions. These units, often housed in large trucks, bring the capability of slaughtering animals directly to the farm. A mobile unit typically has the capacity to process 25-30 beef and 30-40 hogs per week.

State Facility Type Capacity Oregon Red Meat Co-packers 13 USDA-inspected Poultry Processors 2 USDA-inspected Exempt Poultry Slaughterhouses 19 Licensed General Mobile Slaughter Units 25-30 beef, 30-40 hogs weekly

Entities like Foothills Local Meat/Butcher Bars in North Carolina serve as effective case studies beyond Oregon's market. They exemplify how specialized local and pasture-raised meats can be marketed and distributed within a region.

When comparing to New York State, where red meat processing faces bottlenecks, these case studies illustrate alternative avenues for livestock production and processing. The on-farm slaughterhouse model or mobile units present a means to alleviate some of the pressures on the traditional meat processing infrastructure in New York State and elsewhere.