On-Farm Meat Processing, Butchering, and Slaughter in Pennsylvania

Navigating Regulations and Best Practices

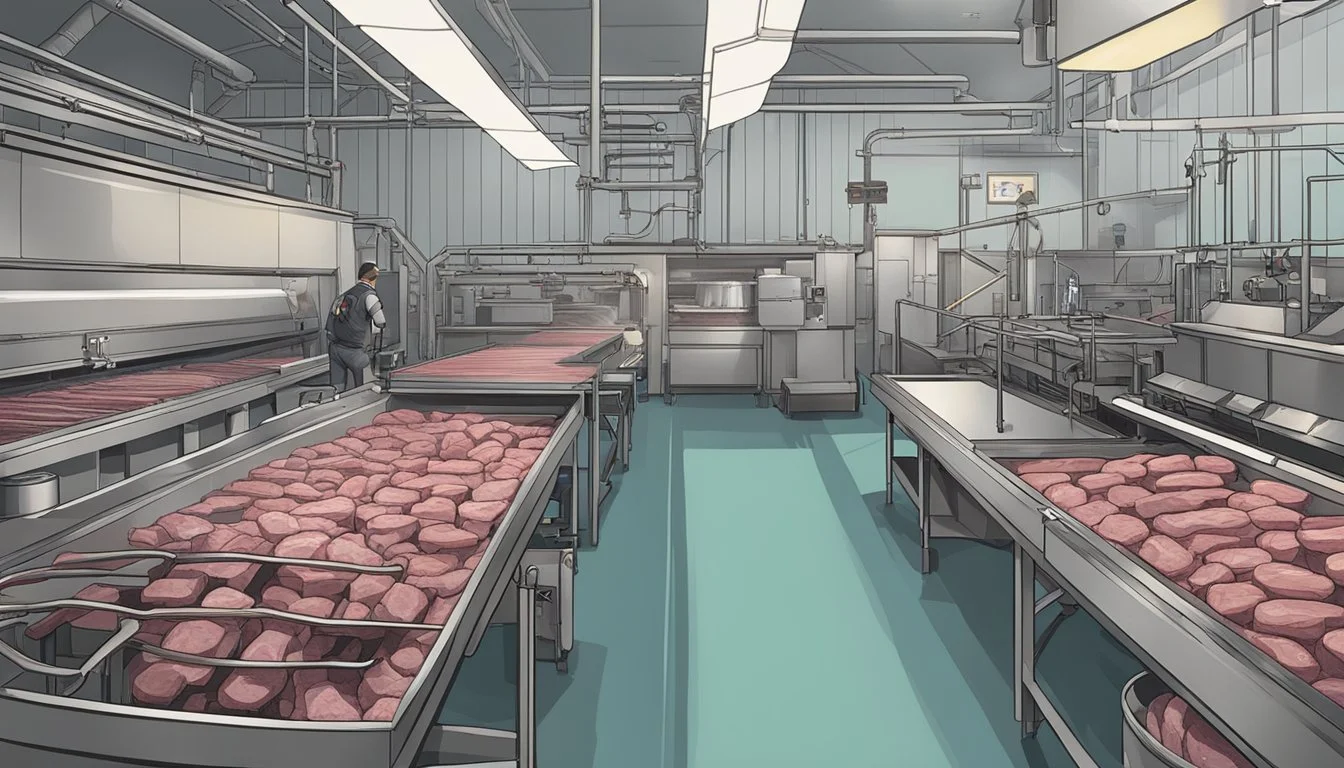

On-farm meat processing in Pennsylvania encompasses a vital set of activities that adhere to specific regulations and standards to ensure the safety and quality of meat products. At the core of these operations is the slaughter of livestock, a process that falls under stringent oversight to maintain public health and animal welfare. Producers operating in Pennsylvania must obtain the necessary licenses and inspections as mandated by state and federal authorities. This adherence to regulations is critical for both small-scale and large-scale operations, whether the meat is destined for local farmers' markets or larger distribution chains.

The state's agricultural stance on the processing of domestic animals integrates well-established practices with oversight by entities such as the Pennsylvania Department of Agriculture. These regulations cover establishments that process meat, which not only includes the act of slaughter but also the subsequent transformation of meat into various products fit for sale, such as ground meats and smoked sausages. Facilities are required to handle meat through a regulated process that could involve cutting lamb carcasses into boneless roasts or the grinding of trim into ground meat, as seen in livestock farms supplying meat to local markets.

As the industry navigates the complexities of meat and poultry hygiene laws, Pennsylvania-based meat processors are expected to operate with a clear understanding of such legislation. The Pennsylvania Meat and Poultry Hygiene Law of 1968, for example, outlines the definitions and requirements that processors must meet, which may include federal inspection services to ensure public safety and product quality. The framework set by these guidelines ensures that meat processing and slaughter activities are conducted responsibly, sustaining the market's demand for transparency and trust in locally sourced products.

Legal Framework for Meat Processing

The intricate legal framework that governs meat processing includes both federal and state regulations, which are designed to ensure food safety and public health. The USDA plays a significant role, alongside Pennsylvania's state-specific policies and exemptions that tailor the regulatory environment for local meat processors.

Federal and State Meat Inspection Laws

Federal law mandates that meat processors adhere to strict inspection protocols to ensure consumer safety. In Pennsylvania, both the United States Department of Agriculture (USDA) and the Pennsylvania Department of Agriculture (PDA) are responsible for overseeing the enforcement of these laws. Meat establishments must engage with these agencies to maintain compliance and operate legally. Meat that has been inspected and approved is marked as such to communicate conformity with safety standards.

USDA Regulations and Inspection Requirements

The USDA ensures that meat processing facilities comply with health and sanitation standards. All meat sold commercially must pass USDA inspection to be considered an approved source. This includes antemortem inspections, postmortem examinations, and the continuous monitoring of processing operations. The USDA also sets requirements for facility design and waste disposal to protect both the quality of the meat and the environment.

Policies Impacting Pennsylvania Meat Processors

Regulations specific to Pennsylvania are enforced by the Pennsylvania Department of Agriculture, which licenses meat establishment operations within the state. These local policies might include additional labeling requirements, business operational standards, and handling procedures that work in conjunction with federal regulations to maintain a safe supply chain.

Exemptions and Special Regulations

Certain exemptions apply, such as those for farmers processing limited quantities of meat for personal use, known as the personal use exemption. Small-scale producers that do custom slaughtering or processing can also benefit from more relaxed regulations under specific USDA exemptions. These exemptions, however, have conditions that must be met, including limitations on the sale of the meat and the necessity for meat processed under exemption to come from an approved source if distributed.

Setting up On-Farm Meat Processing

When establishing an on-farm meat processing facility in Pennsylvania, it's essential to carefully choose a location, understand regulatory requirements, and procure proper equipment for efficient operation.

Choosing a Site and Constructing Facilities

Selecting the right site is crucial for a successful on-farm meat processing operation. One must consider factors like accessibility for delivery trucks, waste management systems, and proximity to markets. Construction of the building should comply with state and federal guidelines to ensure food safety and worker health. Essential considerations include:

Ample space for separate areas dedicated to slaughter, processing, and storage

Adequate drainage and waste disposal systems

Surfaces and materials that are easy to clean and sanitize

Obtaining Licenses and Permits

To operate legally, on-farm slaughterhouses in Pennsylvania must obtain relevant licenses and permits. The process involves:

Developing written Sanitation Standard Operating Procedures (SSOPs).

Conducting a hazard analysis and creating a validated Hazard Analysis and Critical Control Point (HACCP) plan.

Securing a Federal Grant of Inspection or a state equivalent, subject to on-site review by FSIS inspection personnel.

Producers should consult with the Pennsylvania Department of Agriculture for specific state requirements.

Equipment and Infrastructure for Slaughter and Butchering

An on-farm slaughterhouse must be equipped with the necessary tools and infrastructure for humane slaughter and efficient butchering. Core components include:

Stunners or other humane slaughtering devices

Bleeding and scalding tanks

Dehairing or skinning equipment

Evisceration tables and cooling facilities (chillers or refrigerated storage)

Cutting tables and meat processing tools

Each piece should be designed for ease of cleaning and maintaining strict hygiene, in keeping with food safety standards.

Managing On-Farm Slaughter Operations

In Pennsylvania, managing on-farm slaughter operations involves strict adherence to best practices in animal welfare, meticulous handling and transportation of livestock, and compliance with health and food safety regulations to ensure the production of safe and high-quality meat products.

Best Practices for Animal Slaughter and Welfare

The wellbeing of cattle, sheep, goats, swine, and poultry during on-farm slaughter is paramount. Best practices dictate that all animals should be humanely handled and slaughtered to minimize stress and pain. Operators must be trained in:

Proper stunning techniques: Effective stunning methods must be used to render animals insensible to pain before slaughter.

Humane handling: Animals should be moved calmly and without undue stress.

Stress reduction: Facilities should be designed to reduce noise and maintain a calming environment.

Ensuring animal welfare not only aligns with ethical standards but also positively impacts meat quality.

Handling and Transportation of Livestock

Efficient handling and transportation of livestock are essential to maintain the integrity of the meat supply chain. Operators should implement:

Biosecurity protocols: To prevent the spread of diseases, like those related to COVID-19, strict biosecurity measures must be observed.

Transportation standards: Livestock must be transported safely and without overcrowding, considering the needs of different species.

A well-managed transport system ensures animals arrive in optimal condition for slaughter, maintaining animal welfare and meat quality.

Health and Food Safety Regulations

Adherence to health and food safety regulations is critical in on-farm slaughter operations. Regulatory aspects include:

Inspection compliance: Both federal and state meat inspection laws govern on-farm slaughter practices. Operators must ensure their facilities pass these inspections.

Sanitation protocols: Facilities must be kept clean, with special attention to areas where animals are killed and meat is processed.

The coronavirus pandemic has underscored the importance of disease prevention measures to ensure consumer safety and the ongoing availability of local meat supply.

Post-Slaughter Processing

After slaughter, meat processing in Pennsylvania involves specific steps to ensure the meat is safe, palatable, and ready for consumption or sale. These steps include butchering techniques, packaging and storage methods, and the creation of value-added products to meet consumer demands.

Butchering Techniques and Meat Cutting

The skillful butchering of meat is essential to maximize yield and quality. Beef and poultry are commonly processed in Pennsylvania, with butchering techniques differing by animal. For beef, standard cuts include steaks, roasts, and ground meat, while poultry is often divided into breasts, thighs, wings, and drumsticks. Butchers must understand meat science to adequately separate chops and other cuts, ensuring tenderness and flavor.

Key Processing Steps:

Beef:

Steaks (T-bone, ribeye, sirloin)

Roasts (chuck, brisket)

Ground beef

Poultry:

Breast

Wings

Thighs

Drumsticks

Packaging, Storage, and Preservation

Proper packaging and storage are critical to maintain the integrity and safety of meat products. Meat is often vacuum-sealed to prevent spoilage and extend shelf life. Coolers and freezers are utilized for storage, with temperatures strictly monitored to prevent bacterial growth. Smoked meat products require specific preservation techniques, including curing and smoking, which impart flavor and further protect against spoilage.

Packaging Techniques:

Vacuum sealing

Modified atmosphere packaging

Storage Conditions:

Refrigeration: 32°F to 36°F

Freezing: 0°F or below

Value-Added Products and Specialisation

The production of value-added products in Pennsylvania allows processors to cater to niche markets and increase profitability. Specialty items may include smoked sausages, jerky, and custom-prepared cuts. Such specialization requires expertise in meat science and an understanding of consumer preferences. Butchers and processors often offer services like custom cutting, enabling consumers to request specific meat preparations.

Specialty Products:

Smoked sausages

Marinated cuts

Jerky

Services:

Custom cutting

Meat product development

Market Access and Distribution

To effectively distribute and market on-farm processed meat in Pennsylvania, producers need to understand the intricacies of local and regional markets, employ strategic marketing, and navigate the direct-to-consumer supply chain dynamics.

Navigating Local and Regional Meat Markets

Producers in Pennsylvania can tap into a variety of market channels, ranging from local community markets to larger agricultural markets. A sheep farm, for instance, may opt to distribute its lamb products through farmers' markets where they can engage directly with consumers. It's critical for producers to factor in the regional demand, competition, and specific market requirements. Compliance with regulations, such as obtaining a Meat Establishment License from the Pennsylvania Department of Agriculture, is mandatory to ensure market access.

Marketing Strategies for On-Farm Processed Meat

Developing effective marketing strategies for on-farm processed meat involves branding and positioning products in a way that appeals to the target audience. Farmers should highlight the localness and quality of their meat products, leveraging these characteristics as selling points. Suitable marketing materials and online presence can also elevate a farm's profile among potential customers, including restaurants, local groceries, and individual consumers.

Direct-to-Consumer Sales and Supply Chain Dynamics

Direct-to-consumer sales enable farmers to build relationships with their neighbors and the surrounding community, fostering consumer trust and loyalty. This approach can reduce the number of intermediaries in the supply chain, potentially leading to better profit margins. Clear communication regarding availability, pricing, and delivery methods is vital. Additionally, adapting to current supply chain dynamics, such as integrating online sales, can further expand a farm's reach.

Mobile Slaughterhouse Units

Mobile slaughterhouse units, designed to facilitate on-farm meat processing, provide Pennsylvania ranchers with a more flexible approach to butchering and slaughter. These units are equipped to maintain the same standards as stationary facilities, with the added benefit of transportation to the farm site.

Advantages of Mobile Slaughtering

1. Convenience for Farmers: Farmers can have animals processed on their property, reducing stress for livestock and eliminating transportation costs.

Time-saving: Mobile units significantly cut down the time required to transport animals to slaughterhouses.

Reduced Animal Stress: Processing animals in their familiar environment reduces their stress, potentially improving meat quality.

2. Direct-to-Consumer Sales: Ranchers can streamline the process of selling meat directly to consumers by shortening the supply chain.

Market Expansion: By facilitating on-site processing, ranchers can serve local markets more efficiently.

Customer Assurance: Consumers often prefer meat from animals that have been humanely handled and slaughtered; mobile units can provide this transparency.

Compliance with Regulations for Mobile Units

1. USDA-Certified Facilities: Mobile slaughter units operating in Pennsylvania must comply with USDA regulations to be deemed USDA-certified facilities.

Inspection Requirements: These facilities are subject to regular inspections to ensure they meet federal standards for safety, sanitation, and operation.

Exemption Scenarios: Some mobile units may be exempt from inspection if they only serve individual families, non-profit organizations, or owners of the animals being processed.

2. Pennsylvania Laws: State-specific regulations also apply to mobile slaughter units to ensure public health and safety.

Licensing: Operators in Pennsylvania require proper licensing to maintain the legal operation of mobile units.

Record-Keeping: Comprehensive records must be maintained in accordance with state and federal law, documenting all aspects of the slaughter and processing.

Integration with Existing Farm Operations

1. Low Impact on Farm Operations: These units are designed to seamlessly integrate with existing farm structures and operations with minimal disruption.

Space Efficiency: Mobile slaughterhouse units require less space than permanent structures, allowing ranchers to better utilize their land.

Operational Flexibility: Farms can schedule slaughtering based on their specific needs and livestock readiness, optimizing meat production cycles.

2. Partnership Opportunities: Working with mobile unit operators can lead to collaborative efforts within the agricultural community.

Shared Resources: Ranchers without the financial means to own a mobile slaughterhouse unit can still benefit from them through community shared-resource models.

Educational Value: The presence of these units on farms offers an educational opportunity to the public, demonstrating sustainable farming practices.

Industry Trends and Challenges

The meat processing industry in Pennsylvania is facing a complex interplay of challenges and trends, with COVID-19, the shift towards sustainable meat production, and industry consolidation each playing significant roles.

Impact of COVID-19 on Meat Processing

The COVID-19 pandemic severely disrupted the meat processing sector, with smaller processors experiencing unprecedented strain due to a sudden increase in demand. Labor shortages and heightened safety concerns further complicated operations, as businesses grappled with maintaining consistency and meeting health protocols to safeguard against the virus's spread.

Sustainable Practices and Pasture-Raised Meat

Consumers have shown an increasing preference for pasture-raised meat, leading to the adaptation of more sustainable practices. The demand for locally sourced meats is on the rise, benefiting small processors and pasture-based farms. These entities are however facing pressure to scale up while maintaining their commitment to both animal welfare and ecological sustainability.

Consolidation in the Meat Processing Industry

The trend of consolidation within the industry poses a significant challenge for smaller processors. Large corporations dominate, with a notable percentage of the market share, leaving limited room for small independent processors to compete. Consolidation has led to the centralization of slaughter and butchering facilities, which can impact local supply chains and reduce options for farmers.

Support and Training Resources

For individuals and businesses in Pennsylvania involved in on-farm meat processing, a robust support system and comprehensive training resources are crucial. These entities provide essential guidance for butchering and slaughtering to comply with health, safety, and quality standards.

Pennsylvania Department of Agriculture Support

The Pennsylvania Department of Agriculture (PDA) offers various resources to ensure compliant and efficient on-farm meat processing operations. They have outlined requirements for USDA inspection to ensure meat products meet federal standards. For those operating custom slaughterhouses, the PDA provides oversight and assistance to maintain custom exemption status, allowing them to process meat for owners of the livestock, not for retail sale.

USDA inspection guidance: Detailed process descriptions for obtaining a federal grant of inspection and developing requisite sanitation and safety plans.

Custom slaughterhouse support: Information on sewage treatment and other regulations specific to Pennsylvania.

Education and Outreach Programs

Penn State Extension serves as a valuable resource for on-farm meat processors, providing education and training. These programs focus on everything from the meat processing techniques to business management.

Meat Specialist Guidance: Expert advice from meat specialists to help improve process efficiency and product quality.

Workshops and Certifications: Training on regulations and best practices for safe meat processing.

Training Topics Description Sanitation Procedures Cleanliness and maintenance of processing areas. Product Handling Proper techniques to ensure meat safety and quality. Regulatory Compliance Understanding federal and state meat processing laws.

Professional Associations and Expertise

Professional associations offer further support and expertise for Pennsylvania's meat processors. These organizations provide networking opportunities, and access to industry best practices, and promote collaboration among processors.

Pennsylvania Association of Meat Processors (PAMP): A platform for meat processors to share knowledge and advocate for industry interests.

Consultations and Support: Tailored advice for specific challenges related to on-farm butchering and slaughter.

Through these subsections—assistance from the Pennsylvania Department of Agriculture, educational opportunities from Penn State Extension, and the collective knowledge of professional associations—meat processors in Pennsylvania have access to a comprehensive infrastructure designed to promote excellence in on-farm meat processing.