What Are the Considerations for Cattle Feed Storage?

Best Practices for Maximizing Feed Quality

Cattle feed storage is a critical component of managing a livestock operation. Proper storage conditions are essential for preserving the nutritional value and ensuring the safety of the feed. Feed that is compromised due to poor storage conditions can lead to reduced animal performance, economic losses, and can even pose health risks to the livestock. Therefore, farmers and ranchers must consider various factors to maintain the quality of stored feed.

Moisture control is paramount as it prevents the growth of mold and bacteria, which can contaminate cattle feed and cause health issues in the herd. The storage area should be designed to keep feed dry and protected from the elements. Additionally, pest management is another important consideration; rodents and insects can not only consume and contaminate feed, but also carry diseases. Implementing measures to deter pests is crucial in maintaining the integrity of the feed.

Beyond environmental factors, the logistical aspects of feed storage, such as the ease of access, handling, and distribution, are also important for efficient farm operations. Adequate space for storage, efficient feed retrieval systems, and organization are factors that can affect day-to-day operations. Considering these various factors can lead to improved feed quality, financial savings, and healthier cattle.

Fundamentals of Feed Storage

Proper feed storage is crucial for maintaining the nutrition and health of livestock. Understanding the different types of feedstuffs and the optimal storage conditions is key to preserving the quality of animal feed.

Importance of Proper Feed Storage

Proper feed storage is essential as it directly influences the nutritional value and safety of the feed consumed by livestock. Inappropriate storage can lead to spoilage, nutrient degradation, and the proliferation of contaminants such as mold and pests, which can compromise animal health and productivity.

Types of Feedstuffs

Livestock feed includes a diverse range of feedstuffs, each with specific storage needs. Forages and grain-based feeds are common, with other coproducts used depending on the dietary requirements of the animals. The formulation of animal feed must account for the nutritional balance necessary to ensure the well-being and growth of livestock.

Storage Conditions and Their Impact on Feed Quality

The quality of stored feed is heavily dependent on the conditions in which it is kept. Feed should be stored in a dry, covered area to protect it from moisture, while also being shielded from excessive heat and direct sunlight. Additionally, ensuring a clean storage area free from pests is necessary to prevent the introduction of contaminants into the feed. Proper inventory management, including the practice of "first in, first out," helps in maintaining the quality and reduces the waste of feedstuffs.

Storage Solutions

Effective cattle feed storage solutions maintain feed quality, minimize waste, and ensure easy access for daily operations. This requires careful consideration of containers and facilities, location, and methods to maximize shelf life.

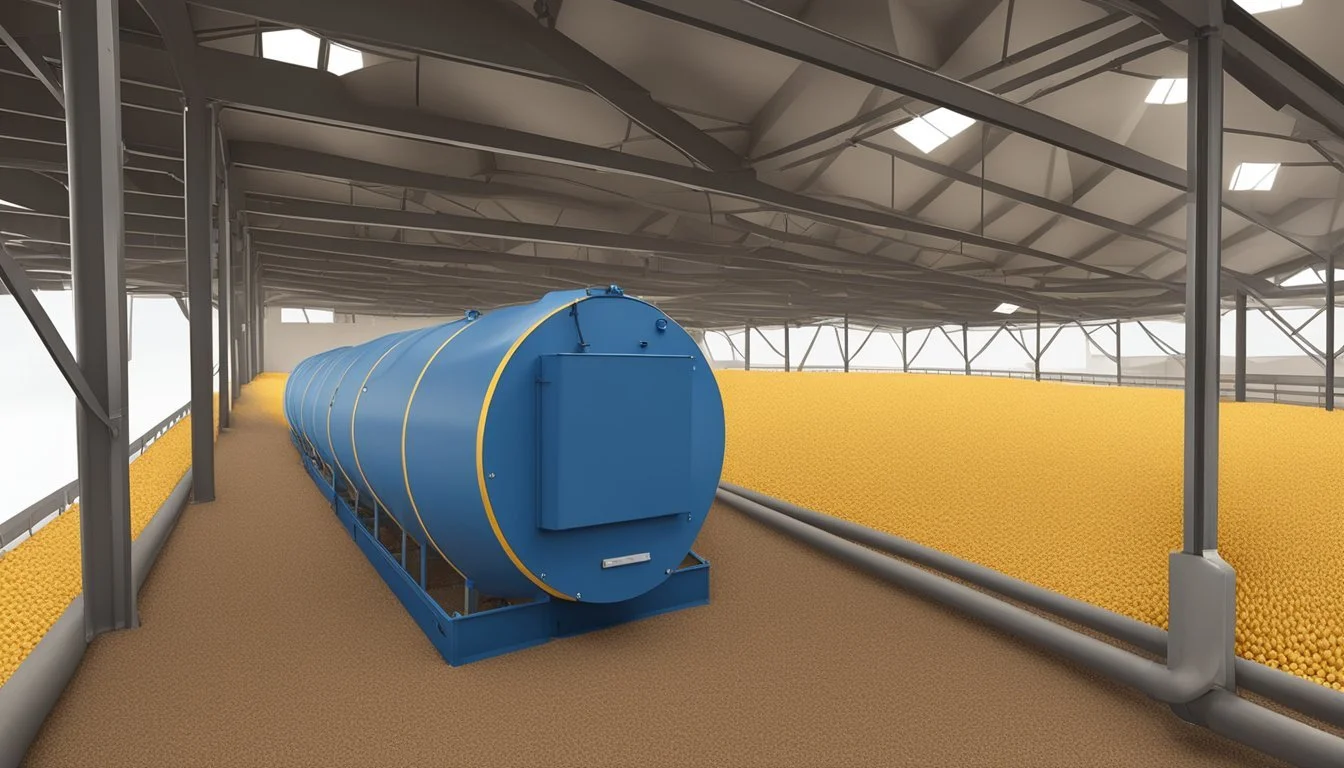

Types of Containers and Facilities

Selecting the right type of container is paramount in safeguarding the quality of cattle feed. For grains and pellets, feed bins made of heavy-duty plastic or metal are common, as they offer protection from moisture and pests. Silage is often stored in tanks or concrete bunkers, where it can ferment in a controlled environment. Large-scale operations may utilize silos or storage facilities with auger systems for efficient handling and distribution.

Choosing the Right Location

The location of feed storage is just as critical as the container used. Facilities should be placed on a well-drained area to prevent water accumulation, which can affect feed quality. It is essential to situate storage facilities away from areas prone to flooding or excessive moisture. Furthermore, storage sites must be easily accessible for both filling and feed distribution to ensure efficient farm management.

Maximizing Shelf Life Through Optimal Storage

To maximize the shelf life of cattle feed:

Grains should be stored in a cool, dry place to prevent mold and spoilage.

Hay must be kept dry to avoid decomposition and nutrient loss, with covered storage in a barn or under tarps as viable options.

Silage requires an airtight environment to preserve its nutritional value and prevent spoilage. Techniques such as plastic wrapping or using silage-specific containers can be employed.

Ensuring feed rotation is practiced can also extend the shelf life, using the oldest feed first to maintain its quality and nutritional value.

Moisture Control

Effective moisture control in cattle feed storage is essential to preserve feed quality and prevent spoilage. Managing the moisture content and proper storage infrastructure are pivotal to maintaining the integrity of cattle feed.

Impact of Moisture on Feed Quality

Feed quality can be severely compromised by improper moisture levels. High moisture fosters mold growth and spoilage, leading to nutrient loss and potential health risks for cattle. When moisture content rises above certain levels, typically around 12-14%, the risk of deterioration escalates significantly. To ensure optimal feed quality, the percent moisture must be carefully monitored and regulated.

Moisture Content Management

Controlling moisture content involves both the addition and removal of moisture to achieve an ideal state. Adjusting feed moisture to the correct levels can be attained through techniques such as SmartMoisture inclusion, which retains desired moisture levels while enhancing pellet durability. Strategic use of ingredients and conditioning agents can help bind moisture within the feed, reducing the risk of dry-out and spoilage.

Ventilation and Insulation Solutions

A key component of moisture control in feed storage is the ventilation system. Adequate ventilation prevents condensation and accumulation of stale air, both of which can elevate feed moisture content and promote mold. Proper insulation of storage facilities also contributes to maintaining a consistent climate and reducing temperature fluctuations that can lead to condensation. Utilizing traps and bait as part of pest control can help to maintain a clean environment and further protect the feed from additional moisture and contamination as advised for best practices in livestock feed storage.

Feed Composition and Nutritional Value

Cattle feed storage requires careful consideration of the nutritional value and the balance of proteins, energy, vitamins, and minerals. The feed composition impacts the livestock's health and productivity, making nutrient analysis and the inclusion of supplements fundamental to effective feed management.

Nutrient Analysis and Feed Quality

Feed quality is critically determined by its chemical and nutritional composition. Nutrient analysis is essential in understanding the nutritional value provided by various feedstuffs. This process typically involves measuring the concentrations of crude protein (CP), fiber, fat, and energy within the feed. Accurate knowledge of these components helps in formulating diets that meet the specific needs of cattle during different stages of growth, lactation, or gestation. Feed composition tables, like those from Beef Magazine, can guide producers in mixing feed with optimal CP levels for their livestock's diet.

Role of Vitamins, Minerals, and Supplements

The balance of vitamins and minerals in cattle feed is pivotal for maintaining animal health and enhancing its growth and production capabilities. These nutrients support various biological functions, including immune response, reproductive health, and metabolic processes. A cattle's need for vitamins like A, D, E and minerals such as phosphorus, calcium, and magnesium varies, and it's usually adjusted according to the animal’s age, weight, and production goals.

Supplements can be added to the cattle's diet to ensure the nutritional requirements are met, especially when forage quality is low or during high-stress periods like weaning or transport. Commercially available supplements come in various forms, such as blocks, tubs, or loose minerals, and should be selected based on the precise needs of the cattle as indicated by nutritional management guides. Balanced supplementation is crucial, as an excess or deficiency of vitamins and minerals can lead to health issues and decreased productivity.

Safety and Hygiene

Ensuring safety and hygiene in cattle feed storage is crucial to prevent contamination, spoilage, and growth of mold and bacteria. It involves strict cleanliness protocols, regular maintenance, and diligent quality control practices.

Preventing Contamination and Spoilage

The storage area must be sealed properly to ward off pests and moisture, which are primary contributors to contamination and spoilage. Regular checks for leaks or cracks in the storage containers help in identifying and addressing potential problems early on. Using clean and dry scoops and containers is essential to minimize the risk of introducing mold and bacteria into the feed.

Cleanliness Protocols for Feed Storage

Storage areas should be clean and free from debris. Implement a regular cleaning schedule and ensure all staff are trained in proper cleaning techniques. Adequate air circulation is necessary to keep the area dry, as damp conditions encourage mold growth. Record the cleaning sessions to monitor the cleanliness and hygienic condition of the storage facility.

Maintenance and Quality Control Practices

Regular maintenance is needed to ensure feed bins and silos are in good condition. Quality control entails inspecting feed upon delivery and throughout its storage for any signs of deterioration. Samples should be taken periodically and tested for quality control, checking for moisture content, mold presence, and signs of spoilage. Tools and equipment used in handling feed should also undergo routine sanitization.

Proper maintenance and quality control are indispensable for preserving the safety and nutritional quality of cattle feed.

Pest and Deterioration Management

Effective management of pests and prevention of feed deterioration are critical to maintaining the quality of cattle feed. Ensuring feed is stored properly can protect animal health and prevent financial losses due to spoiled feed.

Protecting Feed from Pests and Rodents

To safeguard livestock feed from pests and rodents, it's imperative to store the feed in a dry, covered area. Utilizing pest control measures such as traps or bait can effectively manage pest populations. For example, feed storage should include insect screens and rodent-proof barriers to prevent infestations. Regular cleaning of the storage area also plays a vital role in minimizing the attraction to pests that can lead to contaminated feed.

Preventing Deterioration of Livestock Feeds

Feed deterioration often results from exposure to moisture, which can lead to mold growth and nutrient loss. To prevent this, it is essential to store feed in containers that are elevated off the ground to facilitate airflow and reduce moisture uptake. Additionally, protecting feed from excessive heat and direct sunlight helps in preserving its nutritional quality and prevents the growth of mold, thereby reducing the risk of feeding animals spoiled feed that could harm their health.

Feed Management and Delivery

Effective feed management and delivery are crucial in maintaining the quality of feed while minimizing waste and ensuring that livestock receive the right nutrients. These processes are integral to the success of a cattle feeding program.

Effective Feed Rotation Strategies

Rotation is key to keeping cattle feed fresh and nutritionally robust. Feed rotation involves structuring the delivery of feed so that the oldest stock is used first, following the "First In, First Out" (FIFO) approach. This strategy reduces the risk of feed spoilage and nutrient degradation over time. Producers should routinely monitor their feed storage solutions to ensure that storage conditions are optimal for feed longevity.

Feed Delivery Systems and Handling

The choice of feed delivery systems can significantly impact feed quality and ease of distribution. Feeders must be designed to allow for uniform access and minimize feed waste; they also need to be easy to clean to prevent mold and contamination. Feed handling must also incorporate systems for proper feed use and animal safety. For instance, routine maintenance checks are essential to spot and correct issues such as sharp edges on corroded feeders.

Calculating Storage Volume and Turnover Rate

Determining the appropriate storage volume and turnover rate is critical to manage feed inventories efficiently. Feed storage calculations should account for the herd's size, the feeding rate, and the type of feed. A well-calculated turnover rate ensures a continuous supply of fresh feed while reducing excess inventory that could result in waste. Furthermore, implementing feed mixing and feed additives requires precise calculations to maintain balanced diets and reduce excess stocking of component ingredients.

Economic Considerations

Implementing effective strategies for cattle feed storage is vital to manage costs and maintain profitability. Operators should consider the economic impact by minimizing feed waste, assessing labor and storage expenses, and choosing cost-effective storage solutions.

Reducing Feed Waste to Lower Costs

Feed waste significantly affects the overall feed cost per ton; hence, strategies to reduce waste are crucial. Proper storage facilities can maintain feed quality by protecting against moisture and pests, which in turn prevents spoilage. For example, feed storage should be near the feed trough and hay rack to reduce the time and energy spent on moving the feed, ultimately cutting down on waste and expenses.

Assessing Labor, Handling, and Storage Expenses

Labor costs can account for a sizable portion of feed-related expenses. Evaluating the time taken for feed handling can identify areas for improved efficiency. Feed systems should be designed to minimize labor, for instance, choosing a storage system that simplifies loading and unloading can reduce man-hours. Handling limitations, like equipment constraints or storage access, should also be considered, as they can impact labor efficiency.

Evaluating Cost-Effectiveness of Storage Options

The price and cost-effectiveness of storage solutions vary widely. When selecting a feed storage option, one must weigh the initial investment against potential savings over time. Durable, high-quality storage options may have a higher upfront cost, but they can be more cost-effective in the long run due to reduced feed waste and maintenance needs. Calculating the cost per ton of feed over the storage facility's lifespan can aid in determining the most economically sound choice.

Advanced Storage Technologies

Advancements in cattle feed storage technologies have markedly boosted farm efficiency. These developments include a range of sophisticated measures aimed at preserving feed quality and nutrient value.

Innovative Storage and Preservation Methods

Airtight containers have become a staple in protecting protein meals and premixes from moisture and pests, thereby extending shelf life and maintaining nutritional integrity. Systems like climate-controlled facilities employ cutting-edge technologies to regulate temperature and humidity, crucial factors in preventing feed spoilage. Moreover, self-feeders designed with innovative dispensing mechanisms not only preserve the feed but also offer controlled and on-demand access to livestock, enhancing feed utilization rates.

The Role of Research in Feed Storage Advancements

Research in feed storage technologies focuses on the continuous improvement of storage conditions and the development of smart systems. Scientists and engineers work on integrating advanced technologies like IoT sensors and data analytics to create storage solutions that can monitor conditions in real time and alert farmers to any potential issues. This research also explores novel materials and designs for containers that deliver improved airtight sealing capabilities, which is pivotal in the storage of volatile or highly perishable feed ingredients.