Aging Beef

The Art of Enhancing Flavor and Tenderness

Dry-aged beef (What wine goes well with beef?) is a culinary technique that enhances the flavor and tenderness of fresh meat by allowing it to rest under controlled conditions. This process is not to be confused with the age of the animal, but rather the time the piece of meat is stored post-slaughter. If you're looking for a way to take your expensive meat to the next level, there are two primary methods. When it comes to dry-aging beef the two approaches are dry aging and wet aging, each offering distinct characteristics and benefits to the dry-aged meat.

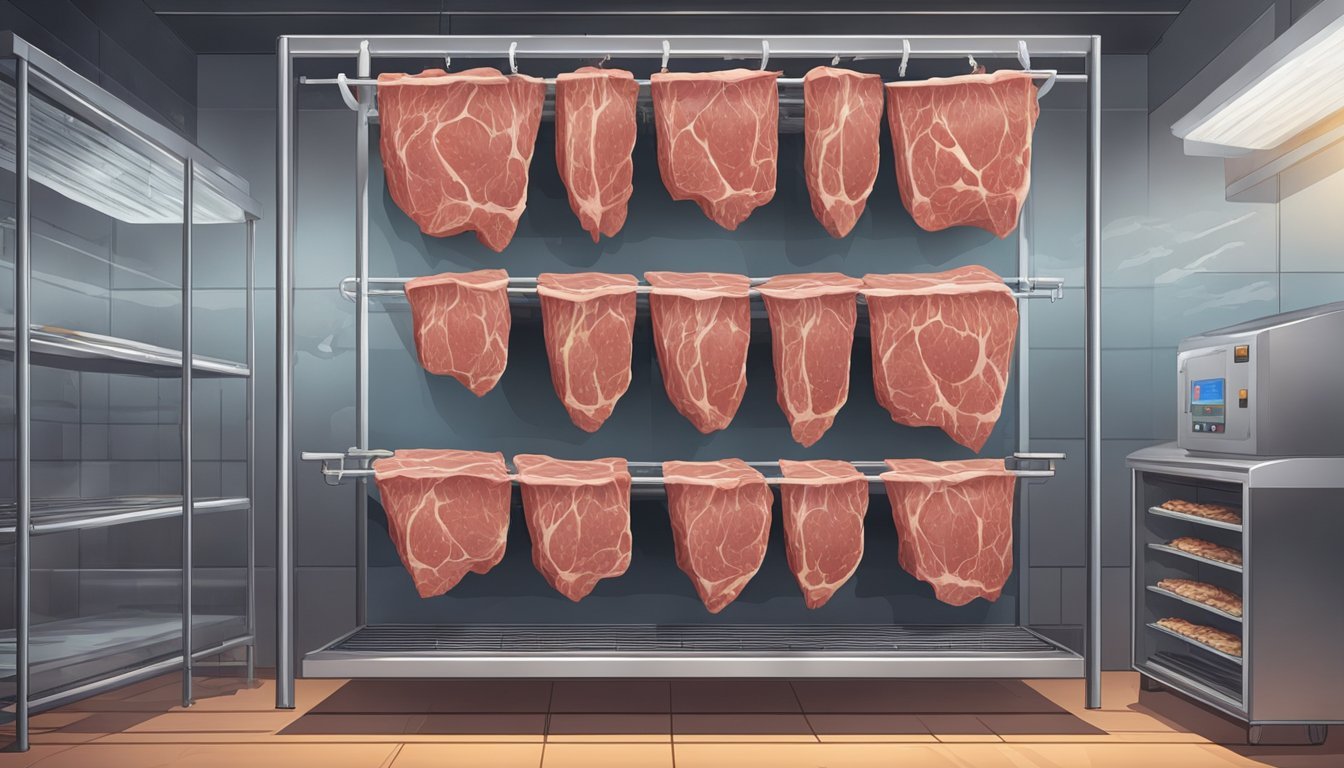

The drying process involves hanging meat in a controlled environment where humidity, temperature, and air circulation are carefully monitored. This approach to aging meat is an expensive process compared to wet aging. The absence of protective wrapping allows moisture to evaporate from the dry-aged piece of beef that allows its flavor to shine through and facilitate the activity of natural enzymes that break down connective tissue. As a result, dry-aged beef develops a richer, more complex flavor and cuts of tender beef that is highly prized among culinary enthusiasts.

Wet aging, on the other hand, involves sealing the beef in a vacuum-packed bag, which retains moisture and allows the meat to age in its own juices. This process requires a shorter period of time than dry aging and helps to prevent the weight loss from evaporation, making it cost-effective for many distributors. Wet-aged beef tends to be more subtle in flavor compared to its dry-aged counterpart that has a much more intense flavor, yet it retains a notable increase in tenderness.

When you decide to age meat, these methods play a crucial role in transforming freshly slaughtered beef, which can initially taste metallic and less intense, into a succulent and flavorful product that appeals to the palate of discerning diners.

History and Basics of Aging Beef

Aging beef is a traditional process that enhances the meat's flavor and tenderness. It exists in various forms, such as dry and wet aging, each with distinct methodologies and results.

Traditional Methods

Dry Aging: This process dates back to the mid-20th century when butchers realized that hanging sides of beef at cool temperatures for several weeks resulted in a product that was more tender and tasteful. As the beef dries, collagenolytic enzymes aid in breaking down the collagen in the meat, which can intensify the meat's natural flavor and make it more succulent. This is where they discovered a dry-aged steak is much more superior than fresh steaks.

Controlled Environment: Dry aging requires a controlled environment with specific temperature, humidity, and airflow.

Duration: The duration of aging ranges from days to several weeks, and sometimes longer.

Unique Flavor Profile: The meat develops a complex, nutty flavor profile due to fungal and bacterial action on the meat's surface during aging.

Modern Practices

Wet Aging: Wet aging is a newer method, becoming prevalent since the 1970s with advances in vacuum sealing technology. In wet aging, beef is aged in vacuum-sealed bags which accelerates the aging process and retains the meat's moisture.

Vacuum Sealing: Beef is sealed airtight, preventing moisture loss and protecting from bacterial growth.

Time Efficiency: This method is quicker than dry aging, often just a few days to a couple of weeks.

Widespread Adoption: Due to its convenience and the reduced risk of product loss, wet aging has become the dominant mode of aging beef in many parts of the world.

Both methods serve to enhance tenderness and influence the flavor of the beef, and they are utilized by meat purveyors and restaurants to cater to different consumer preferences.

Dry Aging Process

Properly dry-aged meat allows the beef's flavor and tenderness by allowing natural reactions by collagenolytic enzymes. It requires specific conditions and careful selection of meat, with a duration that varies according to desired outcomes.

Dry-Aging Room Conditions

For dry-aging beef, a controlled refrigerated environment is crucial. Key conditions to maintain include:

Temperature: Ideal range is between 34°F to 38°F (1°C to 3°C). This keeps the meat from spoiling without freezing it, which would halt the aging process.

Humidity: Around 85% humidity is recommended to reduce water loss without fostering bacterial growth.

Air Circulation: A constant airflow, often achieved by a small fan, helps keep the environment around the beef consistent and prevents pockets of warmer air that could lead to spoilage.

Choosing the Right Meat

The cut of beef selected for dry aging should have a high degree of marbling (fat content), as this contributes to both flavor and tenderness. This is why one would commonly see dry-aged steaks and other fatty cuts of beef are usually used. More premium cuts, like ribeye or sirloin, are often used because they benefit significantly from the dry aging process.

Duration of Dry Aging

The length of time needed for dry-aged meat can range from 15 to 28 days, though in certain cases it may extend to several weeks. During this period, enzymes break down muscle tissue, which improves both texture and taste. The extended time also concentrates the beef's flavor as moisture evaporates.

Wet Aging Techniques

Wet aging beef is a controlled process of enhancing meat's tenderness and flavor through natural enzymatic breakdown. It requires precise temperature regulation and appropriate packaging to ensure safety and quality. So before you salivate on those wet-aged steaks, there are certain things to consider before you turn that big cut of fresh meat to glorious cuts of bliss.

Vacuum Sealed Wet Aging

Wet aging is commonly conducted using the cryovac or vacuum packaging method. In this technique, beef ages in a securely sealed plastic bag that creates an oxygen-free environment. This sealed packaging is crucial as it prevents spoilage and bacterial growth, while allowing the enzymes to tenderize the meat. Traditionally, vacuum sealed wet aging is performed on whole loins or primals rather than individual steaks, as larger pieces are more stable during the aging process.

Key Steps:

Beef must be sealed immediately after butchering in vacuum packaging.

The packaged beef is then stored in a refrigerated space.

Duration: Recommended aging time spans from 30 to 60 days, depending on the desired level of tenderness and flavor concentration.

Refrigeration Considerations

Refrigeration is paramount in the wet aging process. The refrigerated environment must maintain a consistent temperature just above freezing—between 36°F and 38°F—to optimize enzyme activity without risking meat spoilage or freezing which would halt the aging process. Maintaining a high humidity level, usually around 85%, is equally important to minimize moisture loss from the beef.

Factors to Monitor:

Temperature: Essential to be kept constant to prevent spoilage.

Humidity: High humidity levels are preferred to ensure minimal moisture loss.

By adhering to these practices with precision, one can ensure that beef is wet aged successfully, resulting in a more tender and mildly flavored cuts of meat.

Effects of Aging on Beef Quality

Aging beef is a crucial process that enhances its quality characteristics. Key aspects influenced by aging include tenderness and texture, flavor development, and moisture and weight loss, all of which directly affect the palatability and consumer satisfaction of the final product.

Tenderness and Texture

The tenderness of beef increases during the aging process. The breakdown of proteins and connective tissue within the muscle breaks down, primarily due to the activity of endogenous proteases. These are enzymes naturally present in the meat that degrade proteins over time. As connective tissue breaks down, particularly the protein collagen, the beef becomes more tender. The texture of the meat is thus transformed, making it more enjoyable to consume.

Flavor Development

Beef flavor intensifies and becomes richer through aging. The breakdown of both fat and protein during the enzymatic processes contributes to the enhancement of beef flavor and aroma. Such changes are tied to the release and interaction of amino acids and sugars, which form new flavor compounds. Specifically, longer periods of dry aging can lead to the development of distinctive nutty and savory flavors that are highly sought after by consumers.

Moisture and Weight Loss

During the aging process, moisture loss occurs, leading to a reduction in the weight of the beef. This weight loss can have a positive effect on the beef's taste and texture because the flavors become more concentrated, which, when coupled with the reduction in excess water, results in a more pronounced flavor profile and improved texture. Moisture loss is particularly significant during dry aging, as the meat is exposed to air, which enhances evaporative loss.

Health and Safety Concerns

Ensuring the safety of aged beef revolves around meticulous attention to preventing spoilage and controlling bacteria or microbial growth. The process must be managed precisely to avoid health risks associated with improperly aged meat.

Preventing Spoilage and Bacteria Growth

Spoilage in aged beef is primarily the result of bacterial activity, which can be controlled by maintaining appropriate temperature conditions and careful monitoring of the aging process. It is essential to store beef at temperatures below 40°F (4°C), which inhibits the proliferation of spoilage organisms and pathogenic bacteria. Smell can be an indicator of spoilage; a sour or off-odor often signifies bacterial growth and potential spoilage.

Key Temperature Thresholds to Remember:

Below 40°F (4°C): Essential for safe storage.

Above 140°F (60°C): Recommended temperature to kill most bacteria during cooking.

Effective aging of beef requires carefully controlled humidity and air flow to prevent the outer layers of the meat from drying too quickly, which can harbor bacteria on the surface. Safe practices include:

Regular monitoring of temperature and humidity.

Inspection for unusual odors or textures, which can indicate spoilage.

Best Practices for Handling Aged Meat

When handling aged beef, it is imperative to maintain sanitary conditions to avoid cross-contamination. All utensils, cutting boards, and surfaces need to be cleaned and sanitized before and after contact with the meat. Additionally, one should:

Wear disposable gloves and change them frequently, especially between handling different food items.

Use separate utensils for raw and cooked meat to prevent cross-contamination.

Beef aging, when done correctly, does not pose greater health risks than fresh meat. Adhering to these procedures is critical to ensuring the microbiological safety of aged beef, contributing to a product with enhanced flavor and tenderness that is safe to consume.

Preparing and Cooking Aged Beef

Aged beef offers a depth of flavor and tenderness unavailable in standard cuts. Properly preparing and cooking this delicacy accentuates these qualities, making the dining experience exceptional.

Trimming and Cutting

Before cooking, aged beef requires careful trimming to remove the desiccated exterior that forms during the aging process. The chef should only leave the edible and flavorful meat. They must use a sharp knife, trimming away the hard and discolored outer layers to reveal the richly colored meat beneath. For cutting, precision is key; steaks should be sliced to an even thickness, typically about 1.5 to 2 inches, to ensure uniform cooking.

Cooking Techniques for Enhanced Flavor

When cooking aged beef, techniques that promote a flavorful sear without overcooking are pivotal.

Searing: Achieve a caramelized crust by searing the steak over high heat. Cast-iron skillets are ideal for this.

Resting: Before slicing, let the steak rest for approximately 5 minutes per inch of thickness to allow juices to redistribute.

Quick Cooking Methods:

Pan Frying: Brief cooking on each side to develop taste and maintain tenderness.

Grilling: Quick exposure to high heat produces a flavorful exterior. Direct and indirect grilling methods both work well.

Broiling: Positioning the steak near the broiler element can result in a quick and flavorful sear.

Choosing the right cooking method enhances the inherent qualities of aged beef, resulting in a steak that is both tender and delectably flavored.

Choosing Beef Cuts for Aging

When selecting beef for aging, it's essential to choose high-quality cuts with substantial marbling and size that can withstand the moisture loss during the aging process.

Popular Cuts for Dry Aging

Dry aging enhances beef's flavor by a concentration of flavor from the loss of moisture and tenderizing the tougher muscle fibers. The most suitable cuts for proper aging are those with a significant amount of marbling and a protective outer layer of fat which aids in preventing excess moisture loss and spoilage. Examples of the type of beef you can use are:

Prime Rib: Known for its rich marbling and beef palatability.

Ribeye: Offers a balance of flavor and tenderness; ideal for dry aging.

New York Strip: Also known as strip steak, it has a tight texture and robust flavor.

Sirloin: Less commonly aged, but can yield good results if it's top-grade and well-marbled.

Prime rib, known for its high marbling, offers a tender texture and is considered excellent for aging, making it highly suitable for a premium dining experience. The ribeye also boasts high marbling but has a slightly firmer texture, yet it still ranks as excellent in terms of aging suitability. Moving to the New York Strip, it features moderate to high marbling with a tighter grain, earning a very good rating for aging suitability. Lastly, the sirloin presents variable marbling and is firmer in texture; its aging suitability is good, provided that it is of top-grade quality.

Selecting Cuts for Wet Aging

Wet-aged beef is a process where cuts of beef are aged in a vacuum-sealed bag, retaining moisture and allowing enzymes to break down the muscle tissue, which enhances tenderness. Ideal cuts for wet aging usually include:

Steak cuts like sirloin or beef loin, which benefit from the tenderness induced by wet aging.

Cuts that may not have enough protective fat for dry aging, making them more suitable for the wet method.

List: Characteristics of Wet Aging Suitable Cuts

Less outer fat needed due to the protective vacuum-seal.

Uniform in shape and size for even aging and tenderness.

Adequate thickness to ensure the cut retains its structure and does not become overly soft.

Advanced Aging Techniques

Advanced aging techniques in beef leverage the application of specialized methods and ingredients to amplify flavor and tenderness. These techniques go beyond traditional methods, incorporating modern innovations for optimizing the aging process.

Using Enzymes and Additives

Natural enzymes play a crucial role to, for example, a well-aged steak, primarily by breaking down muscle tissue to enhance tenderness and flavor in the wet or dry-aging process. The controlled addition of enzymes, such as proteases, can expedite this process. For instance, Koji—a type of fungus used in Asian cuisine to ferment soybeans (how long do soybeans last?)—is rich in natural enzymes and when applied to beef, accelerates the tenderization and develops unique umami flavors. Enzymes are typically used in wet aging methodologies, where the meat is vacuum-sealed and the enzymes are allowed to work within this controlled environment.

Key Enzymes:

Proteases

Lipases

Collagenases

Experimental Aging Methods

Experimental aging methods are at the frontier of culinary innovation in the beef industry. They include the utilization of dry aging bags, which allow for making dry-age beef at home without the need for professional equipment. These bags are breathable, allowing moisture to escape while forming a protective barrier around the cuts of meat, mimicking the environment of traditional dry aging without the risk of contamination.

Dry Aging Bag Benefits:

Moisture reduction & concentrated flavor

Protection against contaminants

Moreover, dry-aging meat using ultrasonic waves or varying humidity and temperature controls within aging chambers presents new possibilities in manipulating and accelerating the aging process, potentially leading to the discovery of novel flavor profiles and textures in beef.