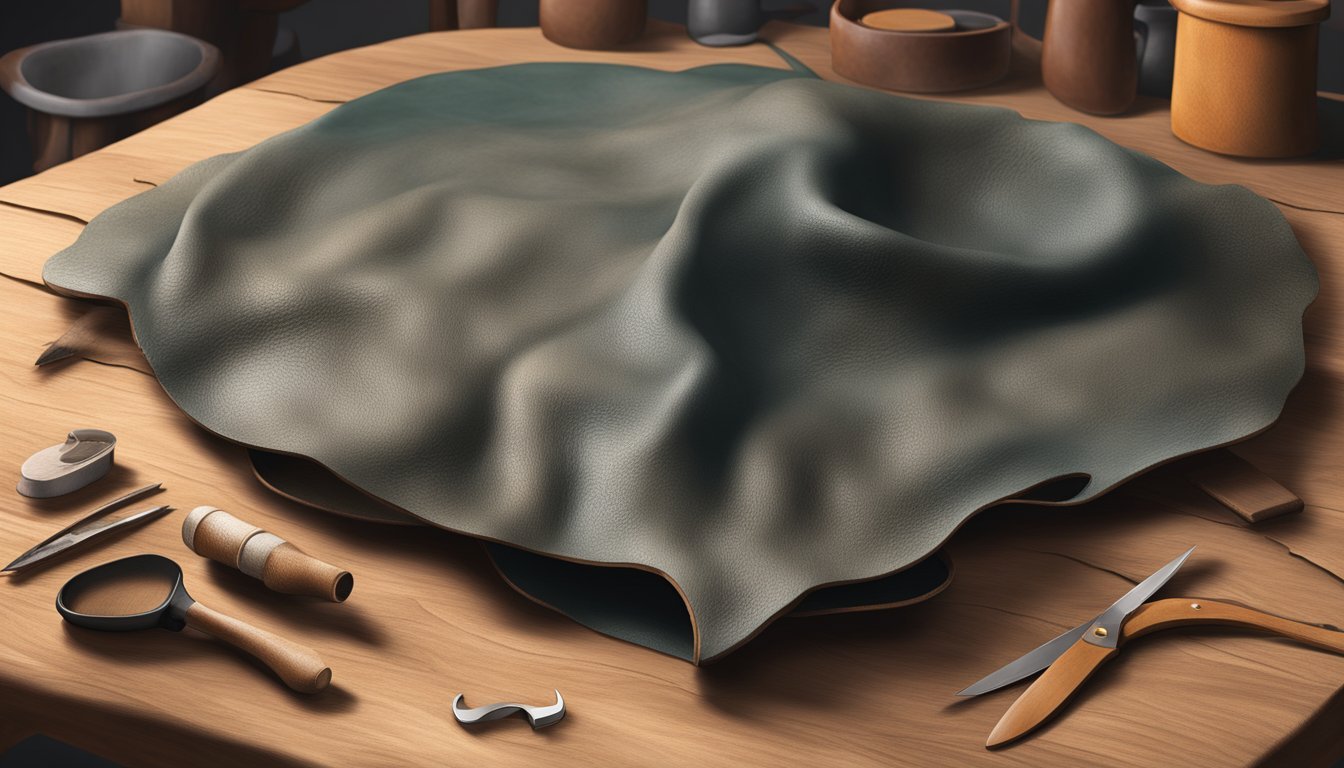

The Art of Making Deer Hide Leather from Kitchen Scraps

A Step-by-Step Guide

The process of converting deer hide into leather is an ancient craft that transforms a byproduct of hunting and meat processing into a durable and versatile material. Deer leather, known for its softness and strength, has been utilized historically in a variety of products and projects. Modern crafters continue to embrace the unique qualities of deer hide, seeking sustainable and resourceful methods to create leather using household byproducts.

In a society increasingly attuned to sustainability, the art of making deer hide leather from kitchen scraps stands out as a resourceful technique. It enables craft

Understanding Deer Hide

Deer leather, crafted from the hide of deer, is renowned for its unique texture and qualities. It stands out in the leather industry for its fine balance between durability and suppleness.

Types of Deer Leather

Buckskin: Traditionally smoked and produced from the hides of male deer, known for exceptional softness.

Deer Hide: Generic term covering all leather made from deer, regardless of processing method.

Deer Hide Characteristics

Deer leather is characterized by a bold grain pattern and a thick collagen fiber layer, enhancing its strength. Its texture is softer and more supple than many other types of animal hide, due to the nature of the deer's lifestyle, which involves regular movement through various terrains. The fur on a deer hide, often removed during processing, is initially a natural insulator and protector for the animal.

Comparing Deer Leather to Other Leathers

When one contrasts deer leather with other leathers, several aspects stand out:

Quality Deer Leather Other Leathers Softness Extremely soft Soft to rigid, variable Durability Durable Range from delicate to highly durable Flexibility Highly pliable Less pliable Texture Distinct grain Varies Breathability High Low to moderate

Deer leather is often more breathable, making it ideal for clothing where airflow is beneficial. It is strong and more durable against wear compared to some other leathers, yet remains notably supple, providing a comfortable fit in garments and accessories.

Preparation of Raw Materials

In crafting deer hide leather using kitchen scraps, meticulous preparation of raw materials is pivotal. This involves sourcing natural tanning agents from kitchen waste, adequately treating the hide, and gathering the essential tools for processing.

Sourcing Kitchen Scraps for Tanning

Kitchen scraps rich in tanning agents, such as eggshells and banana peels, contain essential oils and acids that can contribute to the leather tanning process. Firstly, one needs to dry these materials thoroughly, reducing moisture to create a potent tanning mixture. For example, eggshells can be ground into a fine powder and act as a mild lime alternative, providing the necessary alkalinity for breaking down the hide.

Cleaning and Curing the Hide

The hide requires a thorough cleaning to remove flesh and debris, a process known as fleshing. Post-fleshing, the hide must be cured with salt to extract excess moisture. This curing step is crucial to prevent decay and prepare the hide for tanning. A well-cured hide has significantly reduced water content, ensuring that the tanning agents from kitchen scraps penetrate effectively.

Tools Required for Preparing the Hide

A table highlighting the essential tools for hide preparation is outlined below:

Tool Usage Sharp Knife To flesh the hide and remove excess tissues. Salt To cure the hide and draw out moisture. Flat Surface For stretching and drying the hide. Buckets For soaking the hide in various solutions.

These tools are necessary for ensuring that the hide is properly prepared, which is the foundation for the subsequent steps in making deer hide leather with kitchen scraps.

The Tanning Process

Turning deer hide into leather with kitchen scraps provides a unique and sustainable approach to tanning. Using natural and chemical methods, tanners can produce durable leather with a reduced environmental impact.

Natural Tanning Methods

Natural tanning involves using ingredients readily available in most kitchens, such as vinegar. In this process, the deer hide is soaked in a mixture that often contains acidic elements. The natural acids in vinegar help to preserve the hide and prepare it for further tanning stages. It's a method respected for both its simplicity and environmental friendliness.

Chemical Tanning with Kitchen By-products

Chemical tanning with kitchen by-products can be achieved using substances like pickle, which is a solution made from vinegar and salt. While not as heavy-duty as industrial methods involving chromium, the pickling process using kitchen scraps creates a less toxic environment. This method serves as a bridge between cleaning the hide and the actual tanning process, allowing the hide to absorb tannins more effectively in the subsequent stages.

Finishing the Tanned Leather

Once the hide has undergone tanning through natural or chemical means, the finishing process begins to enhance its durability and appearance. Here, the tanned leather might be oiled, dyed, or waxed to achieve the desired finish. Every step is crucial to ensure the leather's longevity and aesthetic quality, leaving it soft, supple, and ready for use in various products.

Shaping and Treating the Leather

Crafting deer hide leather from kitchen scraps involves meticulous cutting and shaping, followed by several treatments to strengthen, soften, add color, and create texture. The leather must be handled with care, ensuring the right temperature and use of oils to maintain its quality.

Cutting and Shaping Techniques

To cut and shape deer leather properly, one starts by stretching the hide on a flat surface, dampening it with water to make it pliable. Using sharp tools, they trim the leather to the desired shape, taking care not to compromise its natural strength. Consistent temperature control during this phase is crucial to prevent the hide from becoming brittle.

Trimming:

Use a sharp knife to cut the leather.

Follow the desired pattern closely.

Stretching:

Secure the hide on a frame to keep it taut.

Gradually apply tension to avoid tears.

Strengthening and Softening Treatments

After shaping, the hide receives treatments to enhance durability and make it supple. Crafters apply natural oils, working them into the hide with a sponge. These oils not only condition the leather but also influence its final texture, preparing it for further embellishment.

Conditioning with Oils:

Types: Neatsfoot oil, mink oil.

Application: Use a sponge to rub the oil evenly into the hide.

Softening Techniques:

Hand-stretch the leather to encourage flexibility.

Repeat the oil treatment as needed for increased suppleness.

Dyeing and Adding Texture

The final touches involve dyeing and texturing the leather. Crafters select dyes that complement the natural tone of the deer hide, applying them evenly to achieve a uniform color. Methods such as embossing or using tools to create patterns impart unique textures to the leather's surface.

Applying Dyes:

Test the dye on a small area first.

Use a sponge for an even application across the hide.

Texturing:

Tools like stamps and rollers create patterns.

The texture affects both the look and feel, adding a unique finish to the leather.

Each treatment step is crucial in transforming deer hide into quality leather, suitable for various crafting needs, ensuring it remains durable, functional, and aesthetically pleasing.

Creating Finished Goods

Turning deer hide scraps into finished products combines traditional techniques with the precision of modern crafts. It's where raw materials transform into fashion statements and functional items, capturing the essence of handmade quality.

Handmade Deer Leather Products

Deer leather, known for its durability and fine grain, is ideal for a variety of handmade products. Fashion items like belts and straps benefit from its strength, whereas smaller goods such as coasters and wallets favor its aesthetic appeal. One may often find artisans crafting bespoke upholstery for furniture, exhibiting deer leather's versatility within home décor.

Customization and Personalization Tips

Personalization elevates the intrinsic value of deer leather goods. To personalize items like a belt, lacing techniques or embossing initials onto the surface can make each piece unique. In fashion, applying customized patterns or incorporating specific color thread choices in the stitching process showcases the individual's style and attention to detail.

Sewing and Assembling Techniques

The assembly of deer hide leather goods relies on proficient sewing methods. Using a sewing machine suitable for leather is key, often requiring a walking foot and nylon or polyester thread for resilience. Hand-stitching is also prevalent, with a focus on strong, even stitching that ensures longevity and a polished finish. When joining larger sections, such as in upholstery, a consistent seam allowance and patterning acumen are paramount for professional results.