How Industrialization Changed Our Meat

The Evolution of Production and Consumption

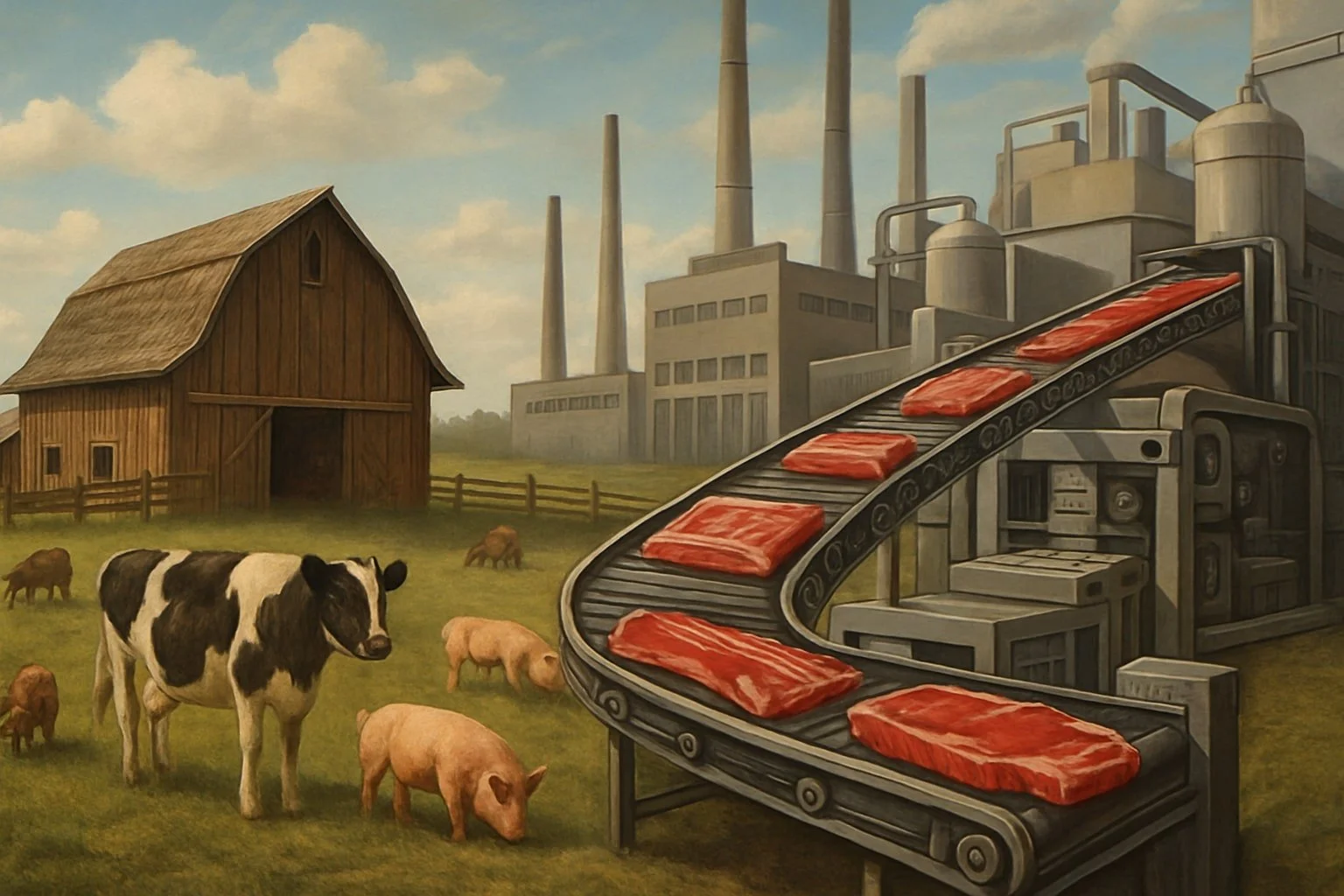

Industrialization dramatically changed the way meat is produced, processed, and delivered, shifting it from local and small-scale operations to a global, highly standardized industry. The late 19th and 20th centuries saw the rise of large-scale farms and processing plants, which prioritized efficiency, consistency, and cost reduction.

These changes made meat more widely available and affordable but also introduced concerns about animal welfare, environmental impact, and standardization of taste. The transformation of meat production continues to affect consumer choices and shapes debates around sustainability, ethics, and food quality.

The Rise of Industrialization in Meat Production

Industrialization changed meat production in the United States by increasing efficiency, shifting production to larger scales, and transforming traditional farming practices. These developments led to widespread changes in the structure of agriculture and the food system.

Historical Context and the Industrial Revolution

The origins of industrialized meat production trace back to the late 19th and early 20th centuries. As the Industrial Revolution altered manufacturing and transportation, meat packers and processors adopted new technology to handle greater volumes of livestock.

Railroads and refrigeration made it possible to move meat long distances. Urbanization created large new markets. These factors pushed meat production away from local, small-scale operations toward larger centralized facilities.

The rise of urban populations demanded consistent meat supply, which further drove factories to adopt mass production techniques drawn from other industries.

The Shift from Family Farms to Factory Farming

In the early 20th century, most meat production in the United States took place on family-owned farms. Over time, the industry moved toward large corporate-owned facilities with a focus on maximizing output and reducing costs.

Factory farming emerged as a dominant model in animal agriculture by the second half of the 20th century. These large-scale operations concentrated thousands of animals in confined spaces.

According to available data, by the 1990s, less than 0.05% of dairy farms produced nearly 10% of all U.S. milk, and very small fractions of broiler and hog farms accounted for a major share of production. This consolidation gave a few large companies control over much of the meat industry.

Mechanization and the Assembly Line

Meat production embraced mechanization to boost efficiency and standardize processes. Assembly line methods adapted from automotive manufacturing let plants process vast numbers of animals quickly.

Slaughterhouses adopted specialized machinery such as carcass splitters, conveyor belts, and industrial cutting tools. This reduced labor costs and helped meet growing consumer demand.

The assembly line broke down complex tasks into smaller steps. Workers repeated the same step continuously, speeding up food production and transforming meatpacking into a high-output industry. For example:

Mechanization Milestone Impact Conveyor Belt Processing Faster throughput Specialized Cutting Equipment Consistent product sizes Refrigeration and Cold Storage Year-round supply, long shelf life

These developments established the foundation for modern large-scale meat production and distribution systems.

Major Changes to Production and Processing

Industrialization brought sweeping and permanent shifts in meat production. Advances in breeding, processing, and animal management have shaped the way meat is produced, distributed, and consumed in the modern era.

Livestock Production and Breeding Practices

The adoption of selective breeding programs greatly increased the efficiency of livestock production. Producers began favoring animals with rapid growth rates, better feed conversion, and greater meat yield.

Breeds like the Angus for beef or the Landrace for pork became popular due to their desirable traits. Artificial insemination and genetic testing improved herd consistency and uniformity.

Smaller, diverse family farms gave way to larger, specialized operations focused on productivity. The USDA and industry groups established standards to maintain quality and track animal lineage, making large-scale genetic improvement possible.

Meat Processing and Packaging Innovations

Technological progress in meat processing has transformed how meat reaches consumers. The introduction of refrigerated transport in the late 19th century enabled shipping of fresh meat over long distances without spoilage.

Assembly-line techniques in processing plants streamlined butchering and deboning, reducing labor costs and increasing volume. Innovations like vacuum packaging and modified-atmosphere packaging extended shelf life and improved food safety.

Modern meat packaging is designed for convenience, reducing exposure to contaminants and helping standardize portions. Stringent USDA inspections and quality control protocols maintain consistency and help prevent outbreaks of foodborne illnesses.

Feedlots and Intensive Animal Husbandry

Feedlots, or concentrated animal feeding operations (CAFOs), are a defining feature of industrial meat production. Livestock is moved from pastures to feedlots, where animals are grouped in confined areas and given carefully formulated grain diets.

Key characteristics of feedlot operations:

High stocking density

Mechanized feed delivery systems

Regular veterinary oversight

This model supports rapid weight gain and efficient use of feed resources. Intensive animal husbandry practices focus on disease prevention, controlled environments, and minimizing loss. Critics point to concerns over animal welfare, waste management, and antibiotic use, which remain subjects of regulation and debate.

Economic Impacts of Industrialized Meat

Industrialization has reshaped how meat is produced, distributed, and sold. These changes have altered pricing, market structures, and local economic dynamics across countries like the United States and Canada.

Cost, Scale, and Economies of Scale

Industrial meat production has sharply reduced unit costs through automation and consolidation. Large processing plants can handle thousands of animals per day, lowering the per-pound price of beef or poultry.

Producers achieve significant economies of scale by purchasing feed, equipment, and veterinary care in bulk. This enables lower retail prices for consumers in the U.S. and Canada. However, smaller producers struggle to compete with the low costs enjoyed by massive corporations.

Labor costs in industrial plants are tightly controlled. Workers often face repetitive, demanding tasks to drive efficiency and cut overall expenses. This focus on cost efficiency can lead to price volatility when supply chain disruptions occur.

Distribution and Globalization

Modern distribution systems rapidly move meat products from large-scale facilities to both domestic and international markets. Highly coordinated logistics networks use cold storage, refrigerated transport, and centralized hubs.

This has enabled North American meat companies to expand globally. The globalization of meat supply chains means products raised in the United States or Canada are available in markets worldwide. It also means local markets face imported competition.

Trade agreements and international standards affect access to foreign markets. The globalization of meat has increased the industry’s complexity and exposed it to risks such as trade disputes and disease outbreaks.

Marketing and Consumer Behavior

Meat companies invest heavily in marketing to shape consumer preferences. Branding emphasizes traits like safety, convenience, or perceived value, especially for prepared and processed meats.

Promotional strategies—ranging from retail discounts to ad campaigns—influence demand and encourage high consumption patterns. Convenience products such as pre-cooked chicken or ground beef have become staples of the average U.S. household.

Consumer behavior has shifted toward purchasing meat from supermarkets instead of local butchers. This change reflects both the convenience of large retailers and the influence of national advertising on buying habits.

Impact on Local Economies

The rise of industrial meat has profoundly affected local economies in North America. Small processors and butchers often cannot match the scale or pricing of multinational corporations, leading to widespread closures.

In many rural areas, a large meatpacking plant can become one of the few major employers. This creates some local jobs, but often at lower wages and with fewer protections than before the industry consolidated.

When small farms and processors exit the market, local communities lose economic diversity. Profits increasingly flow to national or international firms rather than staying in the region, reducing the share of economic benefits that remain local.

Effects on Meat Quality and Consumption

Industrialization led to significant changes in how meat is produced, processed, and consumed. These transformations have had lasting impacts on the characteristics and nutritional profile of meat, as well as on eating patterns, especially regarding beef.

Taste and Texture Alterations

The rise of industrial meat production introduced standardized feeding practices and faster animal growth.

These changes affected both taste and texture. Factory-farmed animals are often fed grain-heavy diets rather than natural forage, resulting in meat with milder flavors and less marbling compared to pasture-raised meat.

Texture also shifted due to accelerated growth rates. Modern beef and pork tend to have a softer, sometimes less varied texture, because animals are slaughtered at younger ages. Tenderness is often achieved through processing methods such as mechanical tenderization and the use of brines or additives.

Traditional vs. Industrial Meat:

Trait Traditional Industrial Diet Grass/pasture Grain/processed Flavor Rich, distinctive Mild, uniform Texture Firm, varied Soft, consistent

Protein Content and Nutrition

While industrial production keeps meat widely available and affordable, it can alter nutritional value. Protein content per serving remains similar in both traditional and industrial meats, but the quality of fats and micronutrients changes.

Grain-fed meat tends to have a higher proportion of omega-6 fatty acids and lower omega-3s than grass-fed meat. Industrial beef can be higher in saturated fat, which is a concern for some consumers.

Vitamin and mineral levels—such as vitamin E, zinc, and iron—may be lower in heavily processed or intensively farmed meat. Additives or preservatives may also be present in processed products, affecting the overall nutritional profile.

Beef Consumption Trends

The industrial revolution brought increased efficiency and scale to beef production and distribution. As a result, beef became more accessible to a broader portion of society rather than being reserved for wealthier classes.

Beef consumption rose sharply, especially in industrialized nations throughout the 19th and 20th centuries. However, recent decades have seen a shift as health and environmental concerns influence consumer choices.

Key statistics:

19th century: Beef was a symbol of wealth, but became widely consumed as processing and refrigeration improved.

Modern era: High consumption rates in the U.S. and parts of Europe, though some decline is seen as plant-based options gain popularity and awareness of health/environmental impacts grows.

Food Safety, Regulation, and Public Health

Industrial meat production led to new challenges in preventing contamination and safeguarding health. The introduction and regulation of antibiotics, frequent inspections, and evolving food safety laws have reshaped the way meat is monitored and controlled.

Food Safety Advancements

The scale of meat production increased the risk of foodborne illness, making safety improvements essential. Modern slaughter facilities adopted practices such as hazard analysis and critical control points (HACCP) to reduce contamination from bacteria like Salmonella and E. coli.

Technological advances in refrigeration and packaging helped extend shelf life and keep products safer during shipping and storage. Faster distribution networks reduced the time from processing to retail.

Routine microbial testing, sanitation protocols, and employee hygiene training have become standard. These measures aim to keep pathogens in check and provide a safer meat supply for consumers.

Regulatory Oversight by USDA and Other Agencies

Federal oversight expanded after early 20th-century scandals in meatpacking. The Federal Meat Inspection Act and the Pure Food and Drug Act introduced standards for inspection and cleanliness.

The US Department of Agriculture (USDA) is the main agency regulating meat safety in the United States. It provides continuous inspection of red meat processing and sets requirements for sanitation and labeling.

Other agencies, like the Food and Drug Administration (FDA), play a complementary role, especially for processed foods. Regulatory frameworks evolve in response to new risks, such as emerging pathogens and international trade issues.

Use of Antibiotics and Public Health Concerns

Industrial meat producers often rely on antibiotics to promote growth and prevent disease in crowded conditions. This practice increases the potential for antibiotic-resistant bacteria, which can enter the food supply and cause hard-to-treat infections in humans.

A 2024 review highlighted rising antibiotic resistance links to livestock antibiotic use. Public health groups and scientists call for stricter regulation and limits on non-therapeutic antibiotic applications in meat production.

Some countries have banned growth-promoting antibiotics, while in the US, the USDA and FDA issue guidance but face pressure to enforce stronger rules. Consumers and advocacy groups continue to push for transparency and safer practices.

Environmental and Sustainability Challenges

Industrialized meat production requires significant resources, generates large quantities of waste, and drives much of the world’s agricultural emissions. Its rapid growth over the past century impacts air, water, land use, and the global climate.

Environmental Impact and Pollution

The industrial system depends heavily on feed sourcing, including monoculture crops like corn and soy. Millions of acres of land are cleared to cultivate these crops, reducing natural habitats and affecting biodiversity.

Manure from concentrated animal operations is a leading source of water pollution. Nutrient runoff leads to algal blooms and dead zones in rivers and coastal waters. Air pollution also rises from ammonia and particulate matter, which can harm respiratory health in both humans and animals.

Large-scale processing also generates significant solid waste, including packaging materials, and increases the use of fossil fuels for transportation and refrigeration. The accumulation of these pollutants presents a persistent challenge for communities near meat-producing regions.

Sustainability of Industrial Meat Production

Sustaining industrial meat output requires large amounts of water, grain, and energy. According to recent studies, industrial systems often use more resources per calorie of meat than many plant-based alternatives.

Resource intensity affects not just producers, but regions dependent on local water supplies and arable land. Overuse of these resources can deplete groundwater, erode soils, and reduce the land’s ability to recover for future generations.

Barriers to more sustainable practices include economic pressures, entrenched infrastructure, and the need for consistent large-scale supply. Solutions exist—such as improved manure processing and feed efficiency—but have not been widely adopted due to costs and complexity.

Climate Change and Population Growth

Meat production is a major contributor to greenhouse gas emissions, with livestock responsible for significant outputs of methane, nitrous oxide, and carbon dioxide. Estimates suggest animal agriculture may account for up to 18% of global emissions, especially as demand for meat grows worldwide.

As global population rises, so does meat consumption, placing greater strain on ecosystems and the climate. Increased production amplifies emissions, land conversion, and water consumption.

Adapting to these challenges involves managing growth to avoid overwhelming environmental thresholds, addressing emissions across the supply chain, and considering shifts toward diets less reliant on resource-intensive animal products.

Animal Welfare and Ethical Considerations

The shift to industrial animal agriculture brought major ethical debates, especially around the treatment of livestock and regulatory approaches to welfare. Production systems changed rapidly, often creating stark differences in animal living conditions and welfare monitoring.

Conditions in Factory Farming and Feedlots

Factory farms often confine large numbers of animals—such as pigs, chickens, and cattle—in limited spaces to maximize production efficiency. Feedlots are used particularly in the beef industry, where cattle are housed in dense pens and fed grain-based diets to increase growth rates.

Key conditions found in industrial settings:

High stocking densities

Restricted movement for animals

Limited access to natural behaviors

Reliance on antibiotics to manage disease in crowded environments

Many animals face physical and psychological stress. Chickens in battery cages may not be able to spread their wings. Sows in gestation crates experience limited mobility for most of their lives. These conditions have sparked criticism from animal rights groups and consumers who are concerned about welfare standards.

Animal Welfare Standards

Regulations and welfare standards differ widely between regions and production systems. Some countries have introduced legal minimums for space, lighting, and enrichment, while others rely mostly on voluntary compliance or third-party certifications.

Common welfare measures and audits include:

Standard Description Space Requirements Minimum area per animal Environmental Enrichment Opportunities for natural behaviors Health Monitoring Regular veterinary inspections Humane Slaughter Animal handling at end of life

Many producers participate in welfare assurance programs to improve transparency. However, gaps remain in enforcement and reporting, leading to ongoing debates about how best to ensure humane treatment across all industrial animal agriculture systems.

Innovations and the Future of Meat Production

Meat production is undergoing rapid transformation with the development of new protein sources and more efficient processing technologies. Advances in cultivated meat and bioreactor technology are shaping the next era of the meat industry.

Cultivated Meat and Alternative Proteins

Cultivated meat, created by growing animal cells in controlled environments, is moving closer to commercial viability. Companies are scaling up production from laboratory samples to industrial levels, addressing challenges like cost, texture, and nutritional standards.

The alternatives are not limited to animal cells. Plant-based and fermented proteins have gained traction, with products mimicking the taste and texture of traditional meats. This shift is driven by consumer health concerns, demand for sustainable options, and a push to reduce the environmental impact of animal agriculture.

Regulatory pathways are becoming clearer in some regions, making it easier for new products to enter the market. Market adoption still depends on overcoming hurdles related to price, consumer acceptance, and large-scale manufacturing.

Key drivers:

Sustainability goals

Health trends

Innovation in cell culturing and plant-based methods

Bioreactors and Technological Advances

Bioreactors are central to scaling up cultivated meat. These vessels provide the precise conditions required for cell growth, including temperature, nutrients, and oxygen. Advances in bioreactor design are allowing for higher yields, improved efficiency, and reduced contamination risks.

Automation and advanced materials are increasingly integrated into meat processing facilities. Flexible production lines adapt to diverse formulations, from ground meat to structured cuts, meeting both industrial needs and shifting consumer preferences.

The ability to monitor and control bioreactor conditions in real time has accelerated progress in cultivated meat. Companies are now able to optimize cell growth and resource usage, making production more cost-effective and consistent.

Emerging trends:

Continuous monitoring

Scalable designs

Integration with traditional processing systems