On-Site Livestock Processing with a Mobile Slaughter Unit

Essential Tips for Homesteaders

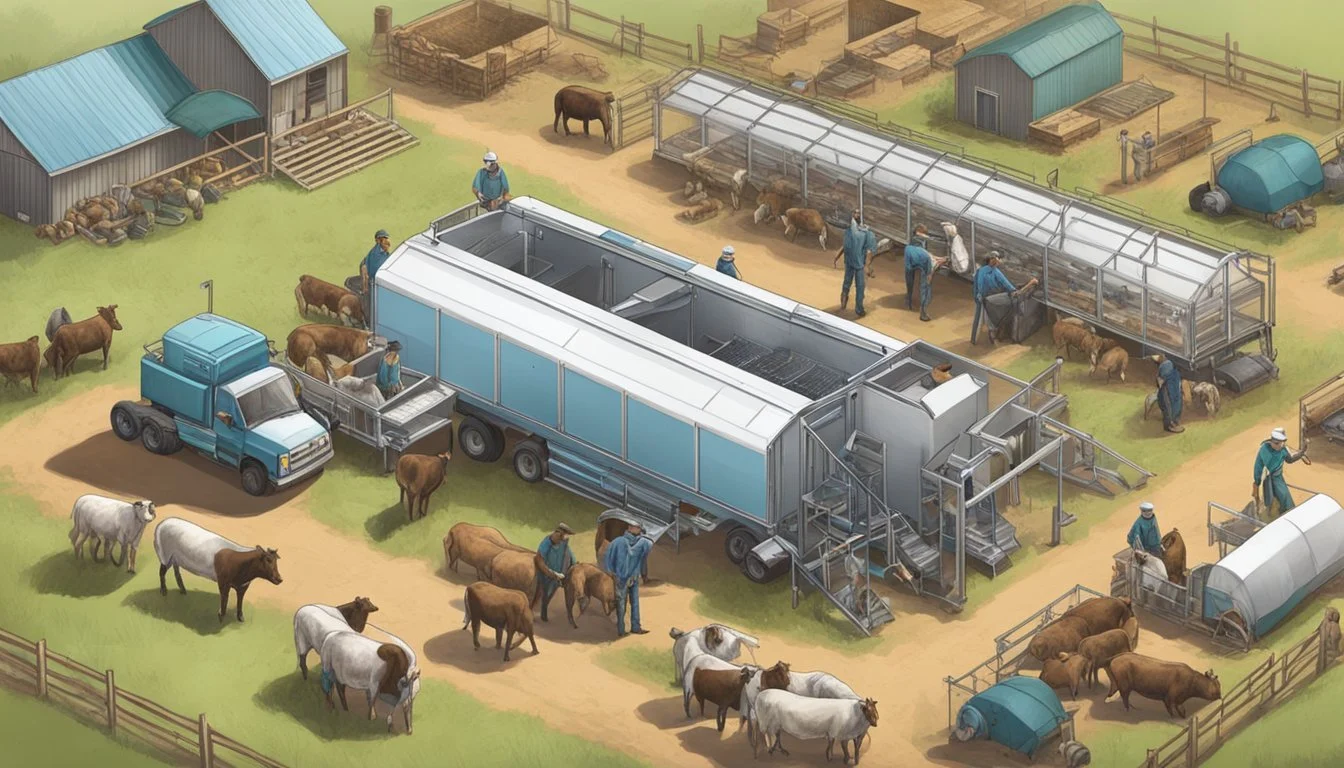

On-site livestock processing is a critical component for homesteaders aiming for self-reliance and control over their food sources. Mobile slaughter units provide a practical and efficient method for processing animals in a manner that aligns with this lifestyle. They offer a flexible solution by eliminating the need to transport livestock off the property, thereby reducing stress for both the animal and the producer. This approach not only supports animal welfare but also ensures the meat is fresh and the entire process is transparent.

Homesteaders view mobile slaughter units as a bridge between traditional animal rearing practices and modern regulatory compliance. These units are designed to meet the safety standards required for meat processing, aligning with Food Safety and Inspection Service (FSIS) regulations. Equipped with the necessary tools for slaughtering and butchering, mobile units can offer services from farm to farm or at regional collection points, opening up market possibilities for small-scale producers and contributing to the local economy.

Beyond the point of slaughter, these units reinforce the homesteading ethos of sustainability and community. By maintaining control over the entire lifecycle of livestock, homesteaders can ensure the integrity of their food, from pasture to plate. Mobile slaughter services also play a role in educating the community about responsible meat consumption and the significance of supporting local production systems. This holistic approach to livestock processing is not just about meat production—it reflects a commitment to ethical practices, quality food, and the sustainability of homesteading as a way of life.

Understanding Livestock Processing

In the realm of homesteading, effective livestock processing is paramount for ensuring the transition from live animal to consumable meat is safe, humane, and of the highest quality. This involves a solid grasp of animal husbandry and an understanding of how mobile slaughter units operate.

Basics of Animal Husbandry

Animal husbandry is the cornerston of producing high-quality meat. Those involved in the raising of animals must possess holistic knowledge and skills that span the entire lifecycle of livestock. Paramount to this process are:

Nutrition: Providing a balanced diet ensures healthy growth and impacts meat flavor.

Healthcare: Routine veterinary care and vaccinations prevent disease, which is vital for animal welfare and meat safety.

Environment: Proper space and clean conditions reduce stress and the spread of pathogens.

Understanding how to manage these elements effectively directly relates to the quality of meat after processing.

Mobile Slaughter Unit Essentials

Mobile Slaughter Units (MSUs) bring the butchering process directly to the farm, minimizing animal stress and potentially improving meat quality. Key components of a successful MSU include:

Equipment: Fully-equipped MSUs house all necessary tools for slaughtering and initial meat processing. This ranges from stunners for humane killing to refrigeration for immediate cooling of carcasses.

Stunner: Humanely renders the animal unconscious

Knives: For skinning and eviscerating

Saws: For carcass splitting

Hooks: To hang and move carcasses

Refrigeration Unit: Chills meat to prevent spoilage

Regulations: Compliance with food safety standards set by entities like the USDA ensures sanitary conditions and safe end products.

Skills: Butchers must possess the technical ability to properly and humanely slaughter livestock, as well as clean and process carcasses into meat cuts efficiently.

Logistics: The MSU must be well-planned in terms of scheduling and location to ensure efficient service to regional producers.

Familiarity with these essentials is crucial for anyone considering on-site processing with an MSU. It allows homesteaders to maintain control over the entire process, often resulting in a more personal and potentially sustainable approach to meat production.

Preparation for Processing

Before initiating the on-site processing of livestock, one must ensure that all necessary equipment is on hand and strict sanitation and safety protocols are in place. This is crucial to maintaining the integrity of the meat and ensuring compliance with health guidelines.

Gathering Necessary Equipment

For Farming and Slaughter Operations:

Stunning Tool: For humane dispatching.

Knives: A variety of sizes for different cuts.

Scalding Tank: Set to the appropriate temperature for defeathering poultry.

Plucking Machine: If available, to expedite feather removal.

Buckets: To contain offal and keep the work area clean.

For Butchering and Processing:

Cutting Surfaces: Durable and sanitized.

Meat Saw: For cutting through bone.

Vacuum Sealer or Wrapping Material: To package the meat appropriately.

Sanitation and Safety Guidelines

Cleaning Protocols:

Hot Water: Access to a sufficient supply for cleaning and sanitizing equipment.

Food-Grade Cleaners: Use approved substances to prevent contamination.

Safety Measures:

Personal Protective Equipment (PPE): Gloves, aprons, and eyewear must be worn.

Sanitation Plan: Develop and follow a standard operating procedure for the sanitization of all tools and surfaces before and after use.

Implementing these careful preparations is critical for the successful operation of a mobile slaughter unit and ensuring the safety and quality of the meat produced.

Processing Techniques

The processing techniques involved in on-site livestock processing with a Mobile Slaughter Unit (MSU) must comply with regulations while ensuring humane handling and the maintenance of meat quality. Homesteaders value the ability to process animals quickly and efficiently, minimizing stress and maximizing product integrity.

Humane Handling and Slaughter

It is critical that animals are handled with care before and during slaughter to minimize stress, which impacts meat quality. Slaughter should be performed immediately after animals are restrained. Poultry can be placed in killing cones to keep them calm and restrict movement during the process, resulting in a quick and humane end. For other livestock, proven methods such as captive bolt stunning should be used to ensure a humane and instantaneous death.

Skinning and Dressing Procedures

Dressing begins once an animal has been humanely slaughtered. This involves skinning, eviscerating, and preparing the carcass for cooling. Skinning must be done with precision to avoid contamination, and all incisions should be clean to prevent bacteria entry. Homesteaders processing chickens at home may scald and pluck feathers before evisceration. Afterward, they should ensure that the carcass is free from feathers, dirt, and debris.

Post-Processing Meat Care

After dressing, the focus shifts to preserving meat quality. Carcasses should be promptly cooled to inhibit bacterial growth - a crucial step in extending shelf life and maintaining flavor. Meat must be stored at proper temperatures and, if necessary, processed further into cuts or packaged for sale or personal use. Timely and careful handling post-processing is essential for ensuring that the meat remains safe and high quality for consumption.

Storage and Preservation

Proper storage and preservation are critical to maintaining the quality and safety of meat processed by mobile slaughter units. A homesteader should prioritize efficiency in these methods to ensure the longevity and taste of their products.

Meat Curing Methods

To enhance flavor and longevity, one can apply various curing methods. Dry curing involves applying salt and seasonings directly to the meat surface. The meat then undergoes a resting period in controlled conditions to allow the cure to penetrate evenly. Wet curing, alternatively known as brining, submerges meat in a saltwater solution often enhanced with spices, sugar, and nitrates.

Dry Curing:

Apply salt and seasonings directly to meat.

Rest meat in controlled conditions.

Wet Curing (Brining):

Submerge meat in a spiced saltwater solution.

Utilize refrigeration during the brine period.

These methods not only impact the taste but also contribute to the preservation by inhibiting bacterial growth.

Freezing and Packaging

Freezing is a common preservation method that mitigates the growth of microorganisms. For optimal quality, meat must be frozen quickly to minimize ice crystal formation, which can negatively affect texture and moisture content. The storage temperature should remain constant at 0°F (-18°C) or lower.

Efficient packaging is key to preventing freezer burn and extending storage life. Vacuum-sealed packaging is preferred as it removes air and prevents oxidation.

Freezing:

Freeze meat rapidly.

Maintain a consistent temperature of 0°F or lower.

Packaging:

Use vacuum-sealing to remove air.

Prevent oxidation to avoid quality degradation.

Proper freezing and packaging practices ensure meat retains its quality during extended periods of storage.

Regulatory and Ethical Considerations

When considering on-site livestock processing using a Mobile Slaughter Unit (MSU), it is crucial for homesteaders to understand the legal landscape and the ethical ramifications of their operations.

Legal Requirements for Slaughter

The successful operation of a Mobile Slaughter Unit requires adherence to a set of strict regulations. In the United States, all meat sold commercially must be processed at a facility inspected by either the state or the U.S. Department of Agriculture (USDA). These regulations are enforced to ensure food safety and public health.

Federal Inspection: MSUs must comply with USDA's Food Safety and Inspection Service (FSIS) regulations.

State Regulations: Some states, such as Oklahoma, have specific codes, like sections 35:37-3-6 through 35:37-3-14, that lay out additional requirements.

Sanitation and HACCP Plans: Operators must maintain a Hazard Analysis and Critical Control Point (HACCP) plan, identifying potential contamination points and establishing procedures to mitigate these risks.

Pest Control: They are required to implement effective pest management practices to avoid contamination.

These measures are in place to ensure that the process is safe and that the product is fit for consumption.

Ethical Implications of Meat Processing

Ethical considerations in meat processing underscore the homesteader's responsibility towards humane handling and sustainability.

Humane Slaughter Act: This act mandates the proper treatment and humane handling of all food animals slaughtered in USDA-inspected facilities.

Sustainability Practices: More broadly, homesteaders are expected to uphold sustainable agriculture practices, which encompass:

Animal Welfare: Ensuring the ethical treatment of animals throughout the process.

Environmental Impact: Minimizing the ecological footprint of their operations by effectively managing waste and reducing transportation needs.

By upholding both legal and ethical standards, homesteaders contribute to a responsible and sustainable food system.

Economic and Market Insights

On-site livestock processing with mobile slaughter units is reshaping the homestead economy and the meat market. It introduces efficiencies and opens up new avenues for market engagement, contributing to economic growth.

Homestead Economics

A homesteader's decision to employ a mobile slaughter unit (MSU) is driven by the desire to maximize economic outcomes. They find that MSUs reduce transportation costs and stress on the animals, which can lead to a better-quality product. This on-site processing capability can lead to increased revenue through direct sales to the consumer, and potentially a higher share of the consumer dollar. The investment in a mobile unit can be balanced against these benefits.

Cost Savings: Reduction in transportation and logistics costs.

Quality Control: Direct oversight of the slaughtering process can maintain high-quality standards.

Revenue Streams: Direct-to-consumer sales offer increased revenue potential.

Understanding the Meat Market

The meat market operates within the larger context of the economy, influenced by GDP growth, trading dynamics, and open market regulations. On a micro scale, MSUs empower producers to tap into local food movements, catering to consumers demanding local, sustainably sourced meat and poultry. Such trends play a role in shaping regional economic growth. The flexibility MSUs provide allows producers to respond to market demand quickly and effectively, potentially stabilizing small farm incomes.

Market Trends: Consumer preference for local and sustainably sourced products.

Regulatory Environment: Compliance with local and federal regulations that may affect market access.

Economic Impact: Contribution to local economies through job creation and retention.

By leveraging MSUs, homesteaders can explore economic opportunities within the meat market's intricate landscape while adhering to regulations and responding to evolving trading and market conditions.

Advanced Techniques and Innovations

The evolution of mobile slaughter units reflects a blend of innovation and industrialization in modern farming. These advancements significantly increase the efficiency of on-site livestock processing, providing scalable solutions and employing automated equipment.

Automated Processing Equipment

Mobile slaughter units now embrace automated processing equipment which serves to streamline the slaughtering process. For example, some units implement automated conveyance systems that assist with the movement and handling of livestock. This significantly reduces labor costs and helps maintain consistent product quality. Moreover, stations within the unit that perform evisceration and skimming can be semi-automated, allowing for faster and more hygienic processing. These technological advancements ensure the delivery of safe and wholesome products to the market while adhering to necessary regulations.

Exploring Scalable Solutions

Investing in mobile slaughter units presents a scalable solution for producers. The modular nature of these units allows for them to be upgraded or adjusted based on demand and throughput. For example, producers can start with a basic setup for small-scale operations and later introduce additional modules to increase capacity or broaden their services. This flexibility also enables producers to adapt to changing market conditions with relative ease, thus fortifying the link between local agriculture and regional markets. The growth potential of these units is a testament to the adaptability and resourcefulness of modern farming techniques.

Cultural and Environmental Impact

Mobile Slaughter Units (MSUs) are changing the landscape of livestock processing with significant implications for society and the environment. These units bridge the gap between traditional slaughter methods and sustainable agricultural practices.

Agriculture and Society

Mobile Slaughter Units provide an alternative for small-scale farmers and homesteaders, allowing them to process animals on-site rather than transporting livestock to distant facilities. This approach respects the cultural fabric of smaller agricultural communities by supporting local economies and preserving farming traditions. Shortening the distance animals travel reduces stress for the animals and aligns with ethical slaughter practices, which are increasingly important to consumers.

Local Employment Opportunities: MSUs can create jobs within the community.

Cultural Traditions: On-site processing supports family-run farms, where methods are passed down through generations.

Global Food Systems and Sustainability

MSUs play a role in the global effort to reduce the environmental footprint of food production. Food sustainability is directly linked to practices that minimise waste, conserve resources, and maintain ecosystem health. MSUs can support these goals through:

Waste Reduction: Contained processing results in better waste management.

Resource Conservation: Reduced transport means less fuel consumption and lower emissions.

By situating slaughter activities closer to the source, MSUs alleviate some of the strain on the environment and contribute to a food system that can better accommodate rising demands without compromising future sustainability.

Environmental Impact: Localised processing minimises transportation pollution and habitat disruption.

Scalable Sustainability: MSUs offer scalable solutions that can adapt to varying farm sizes and production levels.

Expanding Horizons and Future Practices

The advancement of on-site livestock processing technology is a stepping stone toward sustainable practices in space exploration and colonization. The integration of mobile slaughter units and the role of livestock management are critical for the self-sufficiency of future interstellar communities.

Space Farming: An Interstellar Outlook

Space farming is anticipated to be a cornerstone of life support systems on planetary outposts and space stations. Agriculture in space environments requires innovative solutions to address the challenges of limited space and resources. Mobile slaughter units are one aspect of this, providing a modular and flexible option for livestock processing.

Constraints:

Space and weight are premium considerations on any spacecraft or space habitat;

The closed-loop systems will necessitate highly efficient recycling of all byproducts, including those from livestock.

Innovations may include:

Hydroponic and aeroponic systems for plant-based nutrition;

In-vitro meat production, reducing the need for live animals while still providing protein.

The Role of Livestock in Future Colonies

Livestock has multiple roles in human societies, from food sources to companionship, and this is not expected to change in future colonies. They will contribute to the ecological balance by recycling waste into fertilizers and providing raw materials for various purposes.

Terraforming efforts:

Livestock could play a part in terraforming activities by contributing to the development of a balanced ecosystem on planets such as Mars;

Their presence can help establish a sense of normality and continuity from Earth.

Role in colonies:

Livestock must be managed efficiently due to potential limitations in space and resources;

Ethical considerations become paramount when breeding animals in confined interstellar environments, necessitating the use of humane processing techniques like those offered by mobile slaughter units.