The Ultimate Guide to Choosing the Perfect Livestock Scale Platform

Key Considerations for Weighing Large Animals

Selecting the right livestock scale platform is an essential decision for anyone involved in the management of large animals. Accurate weighing is foundational to animal health, precise feeding, breeding, and marketing decisions. In the farming and veterinary industries where the measurement of weight is a regular and necessary action, a dependable scale can be the difference between profit and loss, as well as an indicator of an animal’s well-being.

A well-chosen livestock scale platform ensures that farmers and veterinarians can carry out efficient and reliable weight monitoring. Different models cater to specific needs, ranging from mobile units that can be utilized across various locations, to more permanent installations that can handle the daily demands of heavy use. Considering elements such as maximum weight capacity, the size of the platform, durability, and ease of use is crucial when making this investment.

Livestock scales must also withstand the rugged environment of a working farm or ranch. As such, the materials and construction of the scale should be scrutinized to ensure longevity and consistent performance. With the right scale, owners and caretakers can track growth patterns, administer medications with accuracy, and make informed decisions about each animal's health and productivity.

Understanding Livestock Scales

Selecting the right livestock scale is essential for the accurate management of animal health and farm profitability. There are a variety of scales designed for different needs, such as stationary and portable options, with key features that ensure precision and durability.

Types of Livestock Scales

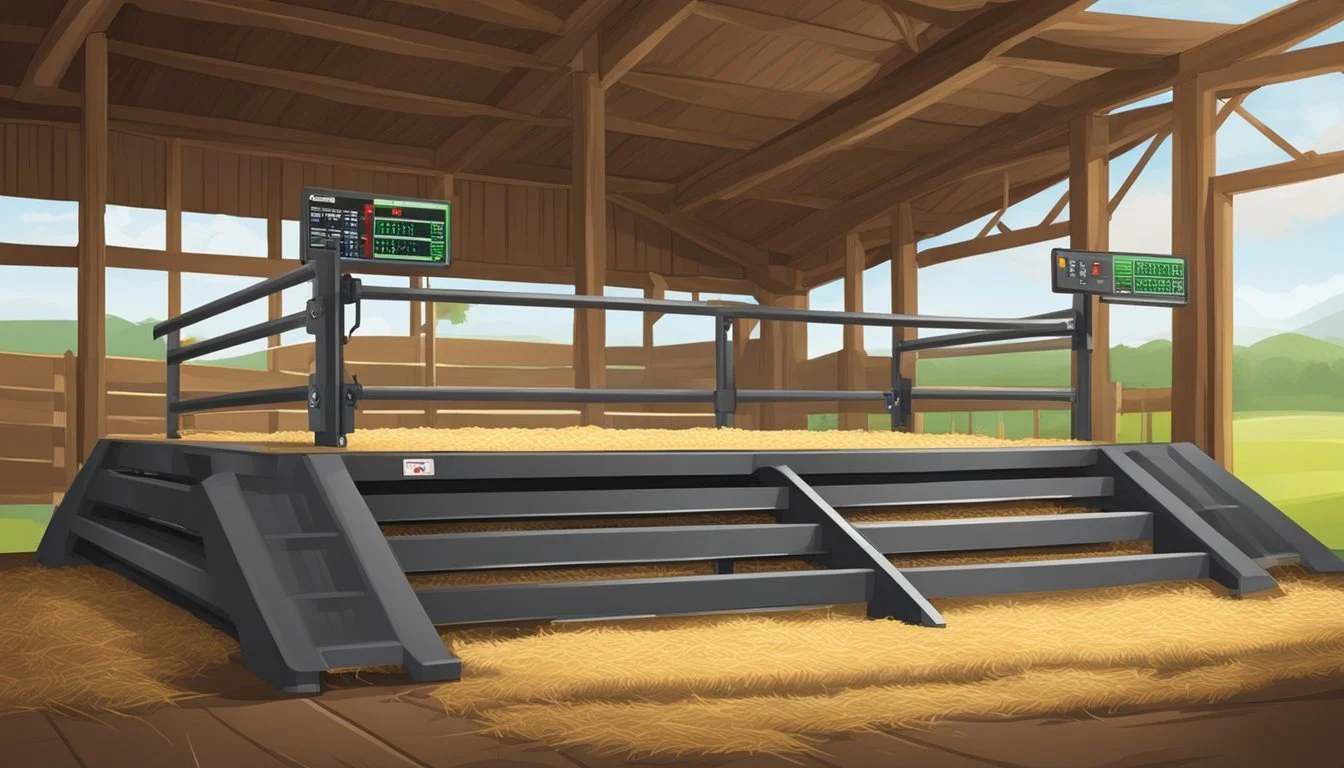

Stationary Livestock Scales: These are typically more robust and constructed for permanent installation. They're often integrated with squeeze chutes for safe and secure animal weighing.

Electronic Stationary Scales: Offer digital accuracy and can sometimes be connected to herd management software.

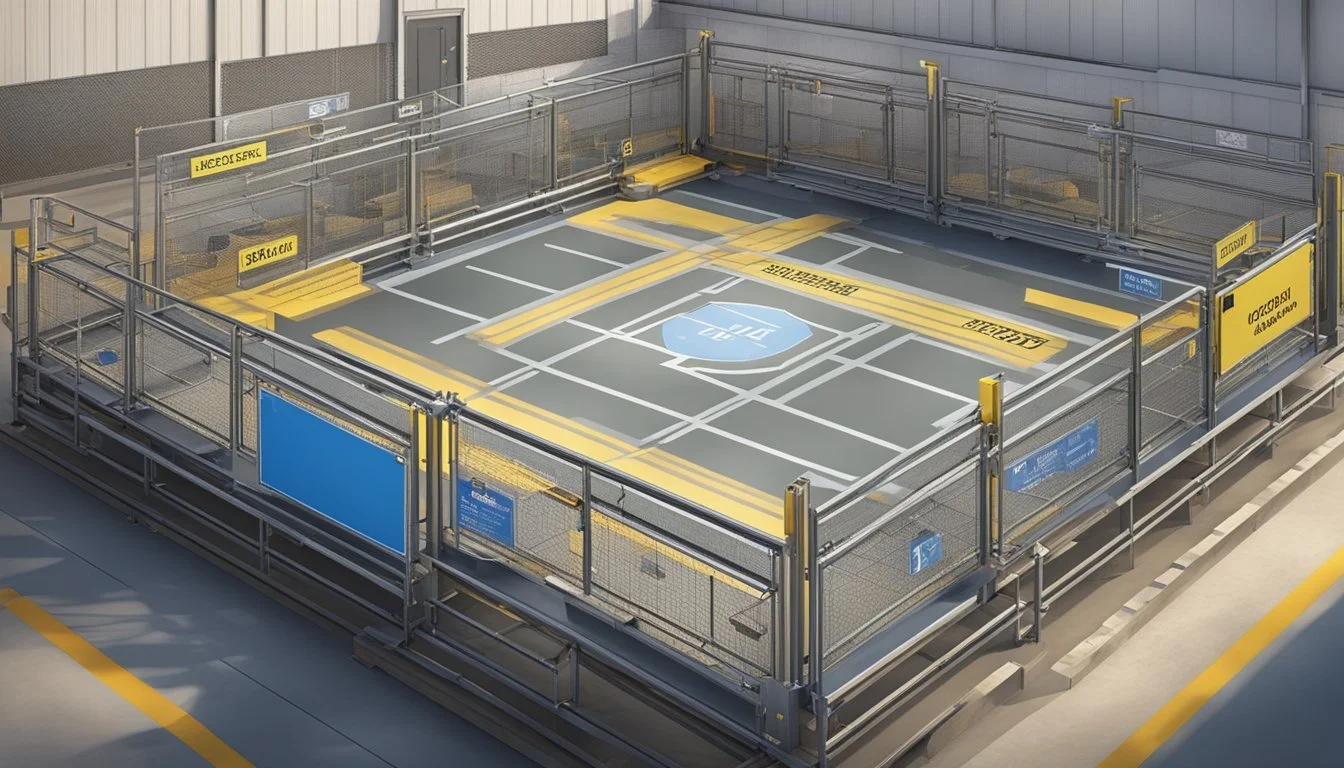

Portable Livestock Scales: Designed for flexibility, these can be moved as needed across different locations on a farm. They may come with platforms or cages and are suitable for a variety of farm animals.

Mechanical Portable Scales: Focus on simplicity and ease of use, often requiring no power source.

Electronic Portable Scales: Provide electronic readouts and might include battery operation for field use.

Key Features of Quality Livestock Scales

Durability: A quality livestock scale must withstand heavy use and varied weather conditions.

Material: Often made from steel or other heavy-duty materials.

Design: Should have animal safety features to prevent injury during weighing.

Precision: Accuracy is crucial, as it affects feed ratios, medication dosages, and breeding decisions.

Accuracy: Look for scales that provide accurate readings, crucial for effective livestock management.

Readout: Clear digital or analog displays that allow for quick and easy weight recording.

Importance of Accurate Weight Measurements

Health Management: Regular and precise weight tracking is significant for monitoring animal health and development. Scales provide valuable data that can influence nutritional adjustments and medical treatments.

Financial Efficiency: Accurate weight measurements are critical in optimizing profits. They inform decisions on market timing, feed efficiency, and breeding practices.

Understanding the key aspects of livestock scales, their types, essential features, and the importance of accurate weight measurements, equips farmers and ranchers with the knowledge to select the best equipment for their operations. Whether it's a stationary or portable scale, durability and precision are paramount for maintaining a successful and sustainable livestock management system.

Factors to Consider When Choosing a Livestock Scale

When selecting a livestock scale, it is paramount to assess several critical factors to ensure accurate weighing of large animals, with focus on the scale's capacity, construction quality, ease of operation, and logistical setup.

Scale Capacity and Size

The capacity of a livestock scale is a crucial aspect, as it must be capable of handling the maximum weight of the animals it will weigh. Scales come in various sizes and weight limits, and choosing one that meets the peak weight requirements, with some additional capacity, is essential for accurate measurements.

Maximum weight capacity: Ensure the scale can accommodate your heaviest animal, plus a buffer.

Platform size: The scale's platform should be sufficiently large to comfortably fit the animal without risk of injury or escape.

Material and Build Quality

The durability of a livestock scale is significantly influenced by its build materials. Scales are often constructed from steel or concrete, which provide the robustness needed for heavy-duty use in varying environmental conditions.

Steel: Often used for its high tensile strength and resilience.

Concrete: May offer a more stationary option for permanent weighing locations.

Ease of Use and Maintenance

A user-friendly livestock scale is imperative for efficient operation. Ease of use not only includes the simplicity of obtaining weight measurements but also the routine maintenance required to keep the scale functioning accurately.

Calibration: Regular calibration ensures ongoing precision.

Cleaning: Scales with fewer crevices and complex parts are easier to clean and maintain.

Portability and Installation

Portable scales are advantageous for ranchers who need to weigh animals at multiple locations. The scale's design should allow for straightforward setup, disassembly, and transport without compromising stability and accuracy.

Portability: Look for scales that offer ease of movement, possibly with wheels or trolley systems.

Installation environment: Consider the location and environment where the scale will be used, ensuring it can withstand local conditions.

Enhancing Farm Management with Accurate Weighing

Accurate weighing plays a pivotal role in effective farm management, providing crucial data for making informed decisions. By utilizing precision scales, farmers can closely monitor livestock health and growth, refine breeding programs, manage feed efficiently, and strategically select animals for culling.

Monitoring Health and Growth

Health Monitoring: Regular weight checks are instrumental for tracking the health of livestock. Sudden weight loss or poor weight gain can be indicators of health issues or disease. Accurate scales enable farmers to detect such problems early, allowing for prompt treatment response and minimizing the spread of illness.

Growth Tracking: Precise weight measurements track growth rates, ensuring animals are developing according to expected benchmarks. Data on weight gain informs nutritional adjustments and can indicate the general well-being of the livestock.

Optimizing Breeding Programs

Reproductive Performance: A livestock scale is a valuable tool for monitoring the weight of breeding stock. Ideal body condition is essential for optimal reproductive performance, and weight is a proxy measure for assessing this condition. Accurate weighing ensures breeding stock are at their peak condition for successful conception.

Breeding Management: Weight data can also help in selecting genetically superior animals, contributing to a more productive and profitable breeding program. Animals that consistently reach weight milestones may be prime candidates for breeding.

Managing Feed Efficiency

Feed Efficiency: Optimizing feed efficiency is about ensuring animals receive the right amount of feed for their weight to achieve the desired growth. Accurate scales guarantee precise feeding, which can lead to substantial cost savings and enhanced animal welfare.

Feed Adjustments: Monitoring weight gain against feed consumption provides insight into feed conversion ratios. Adjustments can be made to the diet to maintain an efficient and cost-effective feeding regimen, supporting sustainable farm management practices.

Making Informed Culling Decisions

Effective Culling: Making culling decisions based on accurate weight measurements ensures that only the least productive animals are selected for sale or slaughter. This improves the overall productivity of the herd.

Profitability and Sustainability: Judicious culling based on precise weight data contributes to the farm's profitability and sustainability. It ensures that resources are invested in animals most likely to provide returns, whether through sales or breeding success.

Livestock Scale Technology and Innovation

Innovations in livestock scale technology have significantly improved measurement techniques offering farmers and ranchers more accurate weight measurements and data integration. This section explores the types of scales, technology enhancements, and the use of electronic identification (EID) in livestock management.

Digital vs. Mechanical Scales

Digital scales have progressively phased out mechanical scales due to their precision and ease of integration with other technologies. Digital scales feature advanced load cells that translate pressure into electrical signals, which a digital indicator then converts into a weight reading. This process results in a high level of accuracy when weighing large animals.

Mechanical Scales: Often require calibration and can be susceptible to wear and tear.

Digital Scales: Known for:

Precision: Offer finer measurements with reduced error margins.

Convenience: Simplify the weighing process with instant digital readouts.

Advancements in Weighing Technology

Weighing technology has seen considerable advancements, especially with the incorporation of sophisticated load cells and software capabilities. Load cells are critical components of modern scales, acting as transducers to ensure dependable readings.

Enhancements include:

Improved durability to withstand the rigorous farm environment.

Data management systems that allow for effective tracking and analysis.

Electronic Identification (EID) Integration

The integration of Electronic Identification (EID) with livestock scales is a transformative innovation. EID facilitates the recording of individual animal weights linked to their unique identification tags, streamlining data collection and accuracy.

EID Systems enable:

Rapid identification: Immediate detection of animals as they are being weighed.

Efficient record-keeping: Weight data can be stored and managed digitally, minimizing the potential for human error.

Integrating EID with livestock scales not only enhances accurate weight measurements but also improves overall livestock management by offering detailed and accessible data for each animal. This technology represents a significant step forward in livestock weighing practices.

Safety and Welfare Considerations

When selecting a livestock scale platform, one must prioritize the animals' safety and well-being. These considerations are foundational in mitigating stress and injury, thereby ensuring that weighing procedures are both humane and effective.

Reducing Stress and Ensuring Animal Safety

The process of weighing large animals should impose minimal stress. Reliable livestock scales are designed with safety features that simplify the process. Chutes and squeeze chutes are integral to guiding animals onto the scale with ease, preventing unnecessary stress or agitation. When designing or choosing a chute, one should ensure smooth operation and a fit that prevents an animal from turning around or escaping, without causing undue restriction.

Design Features for Animal Comfort

The comfort of animals during the weighing process is paramount. Anti-slip surfaces are one such design feature; they provide traction that prevents slips and falls, thereby reducing the potential for injury. Surfaces should be firm yet yielding, minimizing discomfort underfoot. Additionally, the sides of the platform should shield the animal from external stimuli to promote calmness and ease during weighing.

Financial Aspects of Livestock Weighing

Investing in a livestock scale can be crucial for a rancher's financial success. It is essential to understand not just the upfront costs, but also the return on investment, while precision weighing can significantly enhance ranch profitability.

Understanding Costs and Return on Investment

When ranchers consider the purchase of a livestock scale, they need to account for the initial expenditure and the ongoing maintenance costs. The initial cost includes the price of the scale itself and any installation fees. Ongoing costs might consist of calibration, repairs, and potential replacement of parts. However, a livestock scale can quickly become profitable by increasing the efficiency of the ranch operation. Legal for trade scales are cost-effective investments because they ensure that sales based on weight are accurate and certified, preventing losses from discrepancies.

A clear understanding of return on investment (ROI) is crucial. ROI is calculated by considering the profits gained from accurate weighings against the input costs of both purchase and upkeep. A precise livestock scale reduces treatment cost and wasted medications, as treatments can be administered based on exact weights rather than estimates. This accuracy not only optimizes animal health management but also leads to better market pricing, directly impacting profit margins.

Enhancing Profit through Precision Weighing

Precision weighing is a powerful tool for ranchers seeking to maximize profits. By providing accurate weight data, a livestock scale helps ranchers make informed decisions on feeding, breeding, and selling. This reduces the risk of financial loss due to under or over-estimating animal weights, which can lead to underselling valuable weight or overfeeding.

Adequate weighing practices can also identify issues with animal health earlier, allowing for more timely and cost-effective treatments. Considering that the cost of medication can be significant, accurate dosing—made possible by precise weighing—can lead to substantial savings. Moreover, with reliable weight information, ranchers can avoid the legal and financial repercussions that come from non-compliance with legal for trade regulations. Compliance with these regulations is not just a legal requirement but also bolsters the credibility and profitability of ranch operations.

Choosing the Right Livestock Scale for Your Operation

When selecting a livestock scale for an agricultural operation, it's essential to focus on accuracy, durability, and adaptability to different animal sizes. Each scale has distinctive features that cater to varying needs, from cage designs to large platforms.

Comparing Popular Livestock Scale Models

B-TEK Small Animal Livestock Scale: Designed for versatility, this scale provides reliable weighing for various small to medium-sized animals. The platform is of a modest size, which makes it appropriate for non-commercial operations or smaller pens.

Adam Equipment Pallet Beam Livestock Scale: Known for its durability, this model offers a larger platform suitable for weighing cattle and other large animals. The beam design facilitates ease of movement and durability, making it ideal for frequent use in dynamic farming environments.

Mobile Livestock Scale: These scales are known for their portability and are ideal if the weighing platform needs to be moved between locations. They often come with wheels and a braking feature for stability during use.

Features to Consider:

Scale capacity and sensitivity: Ensure the maximum weight capacity fits the type of animals being weighed.

Platform size: Large platforms accommodate bigger animals, while small platforms are suitable for smaller livestock.

Construction materials: Strong materials like stainless steel can withstand the demands of heavy and frequent use.

Ease of use: Consider how simple the scale is to operate, including ease of loading and unloading animals.

Case Studies: Real-World Applications

Farm Management: A cattle farm implemented the Adam Equipment Pallet Beam Livestock Scale to efficiently manage herd weight. The large platform accommodated their large breed cattle, and the durability meant frequent use did not wear out the system quickly.

Zoos and Animal Sanctuaries: Mobile scales have been effectively used in zoos where it's crucial to transport the scale between different enclosures without stressing the animals. The cages that come with these scales ensure animal safety during the weighing process.

Veterinary Practices: Small to medium-sized platform scales such as the B-TEK Small Animal Livestock Scale are a staple in veterinary settings. The scale's size and accuracy are suitable for regular health assessments of a variety of animals.

Notable Application Details:

Efficiency: Accurate weight measurements lead to better feed management and health monitoring.

Adaptability: Adjustable and portable features provide flexibility for diverse environments.

Safety: Designs with animal safety in mind prevent injuries during the weighing process.

Installation and Setup

When installing a livestock scale platform, the key factors are preparing the site and ensuring the setup for accurate weighing. Selecting the right location and following precise steps for installation can lead to a system that consistently provides reliable measurements.

Preparing the Site for Scale Installation

Before installing a scale, it's essential to choose an ideal location. The site should be easily accessible and level, with consideration given to the environment to ensure the scale operates correctly throughout temperature fluctuations.

Accessibility: Ensure the site is easily accessible for the animals and equipment.

Level Ground: Level the installation area to prevent inaccuracies due to uneven surfaces.

Environment: Select a location that protects the scale from extreme weather conditions.

Setting up for Accurate and Reliable Weighing

The setup process varies depending on whether the scale is permanent or portable. The following steps outline the standard procedure for both types of scales.

Permanent Scale Setup:

Anchor the scale and components such as the squeeze chute to a concrete foundation.

Connect load bars or load cells to the scale platform, ensuring they are properly secured.

Portable Scale Setup:

Assemble the scale near the handling area; it should be on firm, level ground.

Attach the weigh scale indicator and ensure the portable platform is stable.

For both setups, testing the calibration with known weights is crucial to validate that the scale provides accurate measurements. Regular maintenance checks are recommended to prolong the life and accuracy of the livestock scale.

Maintenance and Troubleshooting

Proper maintenance ensures the durability and longevity of a livestock scale platform, while effective troubleshooting maintains its precision and reliability. These are crucial practices for the optimal performance of scales in varying environments and temperatures.

Routine Maintenance for Longevity

Daily and Weekly Checks

Inspect scale platform for cleanliness; remove debris and waste to prevent damage.

Verify that cables are secure and undamaged to prevent signal interference.

Monthly and Seasonal Tasks

Test for accuracy with known weights to ensure consistent performance.

Check for corrosion, particularly in metal components, which could compromise the durability of the scale.

Environmental Considerations

Protect electrical components from extreme temperatures and moisture to prevent malfunctions.

Calibrate the scale regularly, adhering to manufacturer’s guidelines, to preserve its measurement accuracy.

Troubleshooting Common Issues

Display Errors or Inconsistencies

Examine the power source and cables for secure connections.

Reset or recalibrate the scale according to the manufacturer's manual to resolve discrepancies.

Fluctuating Readings

Ensure the scale is on a level and stable surface as uneven grounding can cause inaccurate measurements.

Check the load cells for signs of overload or damage, which can affect the scale’s ability to weigh correctly.

Unresponsive Scale

Confirm all components, including load cells and indicators, are properly connected.

Consult the manufacturer’s troubleshooting guide for specific error codes or indicators that are displayed.

Legal and Compliance Considerations

When selecting a livestock scale, compliance with legal requirements and industry standards is paramount. Accurate and legal-for-trade scales are crucial for maintaining trust in trade and animal management practices.

Regulations and Standards for Livestock Scales

Legal for Trade: Scales that are deemed "Legal for Trade" must meet rigorous testing and certification standards. They are required to provide precise and reliable measurements, which are legally acceptable for determining sales and trade values.

Compliance with Accuracy Standards: Livestock scales must conform to specific accuracy requirements as laid out by regulatory bodies. The accuracy of scales ensures fair transactions for both buyers and sellers and maintains standardization across the industry.

Regulations: Livestock scales are subject to local, national, and international regulations which can vary by region. For instance, in the United States, the National Institute of Standards and Technology (NIST) provides guidelines for scales used in commerce. Users must ensure that their livestock scales comply with these guidelines to avoid legal and financial repercussions.

It is the responsibility of each entity operating with livestock scales to stay informed and adhere to all pertinent regulations and standards. Regular maintenance and calibration are essential to uphold the scale’s accuracy and legal standing.

Conclusion

Selecting the right livestock scale is an essential part of farm management. Key considerations include maximum weight capacity, durability, ease of use, and stability. When evaluating options, farmers should consider:

Capacity: Ensuring the scale can handle the maximum expected weight of their animals.

Durability: Opting for scales constructed with materials that can withstand farm environments.

Stability: Choosing models with features like braking on casters to maintain safety during the weighing process.

Ease of Use: Assessing the scale's user interface for efficient operation.

Noteworthy models include the PEC Livestock Cattle Chute Scale Kit, which is lauded for its robustness and adaptability to various livestock types. For cattle, Selleton's livestock weighing equipment is praised for its precision and convenience, featuring ramps for easy animal loading. Adam Equipment’s pallet beam livestock scale is recognized for its rugged design, whereas Happybuy digital livestock scale is often suggested for smaller livestock due to its compact and portable nature.

Regular weighing is pivotal for monitoring health and productivity. Farmers should integrate accurate weighing systems into their routine to make informed decisions regarding feed rations, breeding, and market timing. With the right scale, farmers can ensure optimal growth rates, enhance the efficiency of their operations, and drive profitability.