The Ultimate Guide to Using a Handheld Tree Tap

Mastering Maple Syrup Production

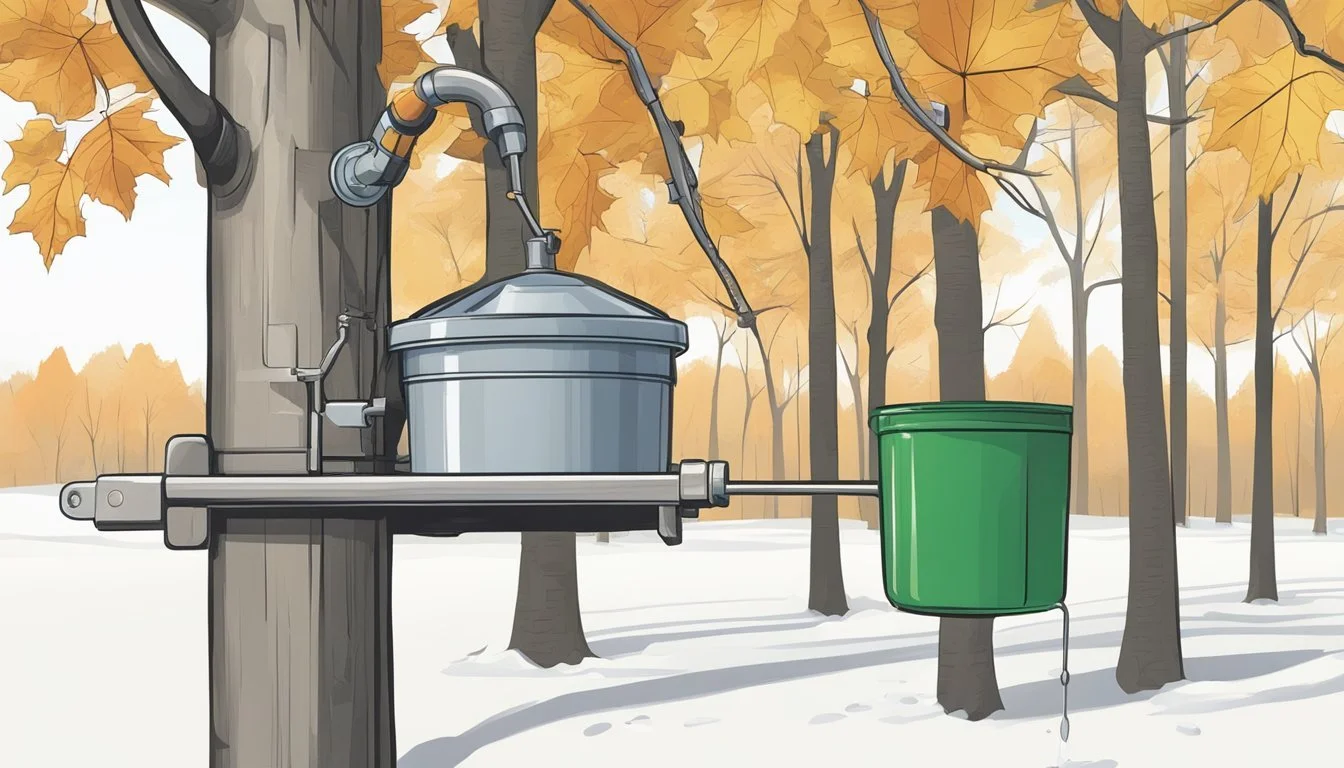

Tapping maple trees and transforming sap into syrup is a time-honored tradition that has been practiced for centuries. It requires precision and a thorough understanding of the natural processes at play. The purity of the end product, maple syrup, is a direct result of careful tapping techniques and proper handling of the sap collected from maple trees. Maple syrup production starts with identifying the right trees, typically sugar maples, known for their high sugar content. Mature trees with a diameter of at least 10 inches at chest height are ideal for tapping as they can sustain the process without significant harm.

Handheld tree taps, or spiles, are essential tools for accessing the sweet sap. Upon inserting these taps into drilled holes in the maple trees, sap begins to flow, guided by the rising temperatures of late winter and early spring. It's critical to tap at an upward angle to facilitate the gravity-led drip of sap out of the tree and into the collection vessel. The depth of the tap hole is also pivotal; it should not exceed 2 inches to ensure the tap accesses the area of active sap flow while minimizing damage to the tree. Tapping at the correct time and using the proper techniques not only increases sap yield but also preserves the health of the maple trees for future seasons.

Understanding Maple Trees

In the endeavor of maple syrup production, recognizing the correct tree species and understanding the natural cycle of sap flow are foundational steps. Optimal tree health and seasonal fluctuations greatly influence sap yield.

Identifying Maple Species

Maple trees, particularly species such as sugar maple (Acer saccharum), black maple (Acer nigrum), red maple (Acer rubrum), and silver maple (Acer saccharinum), are commonly tapped for syrup due to their high sugar content. The sugar maple stands out as the most preferred due to its sap's ideal sugar concentration.

Sugar Maple: High sugar content, dense crown, robust size

Black Maple: Similar to sugar maple, slightly lower sugar content

Red Maple: Adaptable, but lower sugar content than sugar maples

Silver Maple: Fast-growing, lower sugar content, early sap flow

Tree Health and Selection

A healthy tree is paramount for a sustainable tapping process. Trees should have a diameter of at least 12 inches (30 cm) and be free of disease and significant damage. Adequate sunlight and a robust crown with vibrant leaves indicate good tree health. Prioritize mature trees that have been well-established in their environment.

Seasonal Timing for Tapping

Sap tapping seasons in North America typically fall between late winter and early spring when daytime temperatures rise above freezing and nighttime temperatures drop back below. These temperature fluctuations cause pressure changes inside the trees, facilitating sap flow. The season's start and duration are influenced by regional weather conditions.

Northeastern: Late February

Midwestern: Early March

Southeastern: FebruaryMaple Tree Anatomy and Sap Production

Maple trees are deciduous, meaning they shed their leaves annually. The process of sap production is influenced by photosynthesis during the warmer months, where sugar gets stored in the tree's roots. As spring temperatures start to fluctuate, this sugar is converted into sap and begins to flow through the xylem system of the tree, which can then be tapped and collected for syrup production.

Tools and Equipment for Tapping

The process of tapping trees for maple syrup requires specific tools and equipment to ensure a successful harvest. Each tool plays a crucial role, from drilling the tap hole to collecting and storing the sap.

Selecting the Right Drill

Drill: A cordless drill is preferred for its portability and ease of use in the field. For tapping maple trees, users should select a drill bit size that corresponds to the type of spile they will be using, typically between 5/16-inch to 7/16-inch in diameter.

Types of Taps and Spiles

Taps and Spiles:

Metal Spiles: Durable and traditional, metal spiles are commonly used.

Plastic Spiles: These may offer the advantage of being lighter and sometimes easier to clean. To install spiles, one would use a rubber mallet to gently tap them into the drilled holes without damaging the tree.

Containers and Storage Solutions

Containers for Collection and Storage:

Buckets: Often used for sap collection, they should be food grade if the sap is intended for syrup production.

Lids: For the buckets, to keep out debris and contaminants.

Tubing Systems: An alternative to buckets, where a network of tubing connects multiple taps to a central collection container.

Storage Containers: These should be airtight and large enough to hold the collected sap until it can be processed into syrup.

By utilizing the correct tools and equipment, one ensures the efficiency and purity of the maple syrup production process.

The Tapping Process

The tapping process is a critical series of steps in maple syrup production. Detailed attention to drilling technique, spile insertion, sap monitoring, and tree health ensures a successful harvest.

Drilling the Tap Hole

Drilling the hole for the tap is a precise task. Select a spot on the maple tree's trunk, keeping in mind the previous year's tap holes and potential disease sites. The hole should be drilled at a slight upward angle to facilitate sap flow, at a depth of about 1.5 to 2.5 inches into the tree. It's important to use a clean, sharp drill bit to minimize damage to the tree bark and to clear out wood shavings immediately to prevent infection.

Inserting the Spiles

Once the hole is drilled, a spile, which serves as the conduit for sap flow, must be carefully inserted. Position the spile against the hole and gently tap it into place using a hammer or mallet. The spile should fit snugly; overtightening can damage the tree and affect sap collection. Make sure that the spile is secure and there is no leakage around it.

Monitoring Sap Flow

Monitoring sap flow is essential during the tapping season. Sap flow can vary due to temperature fluctuations and tree health. Place a collection container below the spile and check it regularly. Optimal sap flow occurs when daytime temperatures rise above freezing with colder nights, and monitoring these changes can maximize yield.

Preventative Measures for Tree Health

Protecting the health of the maple tree during tapping is paramount. Use smaller diameter drill bits (1/4", 5/16", or 7/16") to reduce the impact on the tree. Trees should be at least 12 inches in diameter before they are tapped. Rotate the tap hole location each year to allow old tap holes to heal and avoid tapping into frozen wood, as this can cause tree splitting.

Sap Collection and Handling

Efficient sap collection and handling are vital for producing high-quality maple syrup. This involves utilizing the correct techniques, maintaining strict sanitation protocols, and understanding the variables that affect sap yield and flow rates.

Sap Collection Techniques

Sap collection requires precision to ensure the tree's health and optimize sap purity. Drill a tap hole no more than 2 inches deep at an upward angle to facilitate sap flow. This procedure taps into the xylem, where sap transport occurs predominantly in the outermost wood. Collectors traditionally use buckets or bags affixed to the tree to gather the sap. Buckets should be covered to protect the sap from environmental contaminants like debris and insects.

Daily Collection: When temperatures rise above freezing during the day and drop below at night, sap flow is optimal, necessitating daily collection to prevent spoilage.

Correct Tap Placement: The number of taps per tree depends on its diameter; generally, a tree must be at least 10 inches in diameter to support a single tap.

Sanitation and Contamination Prevention

Hygiene is critical in maple syrup production to preserve sap quality and prevent spoilage. Before the season begins and between uses, all equipment used in sap collection should undergo thorough sterilization. Use a solution approved for food surfaces and rinse equipment properly to remove any residual cleaning agents.

Clean Buckets and Covers: Ensure buckets and covers are free of residues and foreign matter.

Regular Cleaning Schedule: Establish a cleaning schedule correlating with the frequency of sap collection to reduce the risk of contamination.

Use of Food-grade Materials: All containers should be made of food-grade materials that do not alter the sap's flavor or sugar content.

Sap Yield and Flow Rates

The yield of sap can fluctuate greatly due to tree size, tapping methodology, and environmental conditions. An average taphole can produce between 5 to 15 gallons of sap. Under favorable conditions, this yield can significantly increase. However, over-tapping can lead to reduced sap flow and potential tree damage.

Tap Holes: Limit the number of tap holes based on the tree's size to prevent undue stress.

Flow Rates: Colder nights and warmer days stimulate sap flow; monitoring weather patterns can aid in predicting peak flow times.

Measurements: Measuring sap yield and flow rates can help producers optimize tapping strategies for future seasons.

By meticulously managing sap collection and handling, producers can enhance yield, maintain the maple syrup's natural flavor, and provide a safe and delicious product.

From Sap to Syrup

Transforming sweet sap into the cherished liquid gold known as maple syrup involves a meticulous process where precision ensures the highest quality of the end product. The process encompasses the boiling of sap, its filtration, and the grading that determines its unique flavor profile.

The Boiling Process

The boiling process is the pivotal step in maple syrup production. Once sap is collected, it must be boiled down to increase the sugar concentration and to achieve the right consistency. Typically, 40 gallons of sap are needed to produce one gallon of syrup. Boilers or evaporators carefully heat the sap, allowing water to evaporate, leaving behind concentrated syrup. The point at which syrup forms is meticulously observed; a temperature of about 7.1°F (4°C) above the boiling point of water indicates that the syrup is ready.

Filtering and Refining Sap

After boiling, the syrup contains impurities that need to be removed. Filtering is a crucial step that removes these impurities, ensuring the syrup's clarity and smoothness. Initially, a coarse filter removes large particles, and then a finer filter further purifies the syrup. The filtering process can be as simple as using cheesecloth or as sophisticated as employing a commercial filter press. A filtered, clear syrup is free from sediment and ready for the final steps of refinement.

Grading and Flavor Profiles

Maple syrup is graded based on its color and flavor profile. The grading system ensures a standard for quality and taste. There are several grades, each reflecting the time in the season when the sap was harvested and its resultant flavor.

Grade A Golden and Delicate Taste: Light in color with a mild, delicate flavor, derived from sap collected early in the season.

Grade A Amber and Rich Taste: A full-bodied flavor with a medium amber color, a common choice for consumers.

Grade A Dark and Robust Taste: Darker, with a more robust flavor, typically harvested later in the season.

Grade A Very Dark and Strong Taste: The darkest grade with a strong, pronounced flavor, often used for cooking.

The characteristics of homemade maple syrup can vary, but by adhering to this process and these guidelines, producers can create a high-quality product that is as delightful as it is natural.

Storing and Enjoying Maple Syrup

After successfully collecting sap from the sugar maple and processing it into maple syrup, one must understand the proper storage methods to retain quality and discover various uses and pairings to fully enjoy this natural sweetener.

Proper Storage Techniques

When it comes to storing maple syrup, the key elements are temperature control and minimizing exposure to air. Glass is the recommended storage container to preserve the syrup's flavor and color. Here are the specific storage steps:

Refrigeration: Once opened, maple syrup should be stored in the refrigerator to prevent spoilage. An airtight container is essential to avoid prolonged air exposure, which can deteriorate the syrup's quality.

Freezing: For long-term storage, maple syrup can also be kept in the freezer. The syrup will not freeze solid but will maintain its viscosity and quality.

Containers: Glass containers are preferable to plastic as they don't allow oxygen to permeate, which can cause the syrup to darken and lose flavor.

Maple Syrup Uses and Pairings

Maple syrup is incredibly versatile, with its uses extending well beyond the breakfast table. Here's a brief overview of how it can be enjoyed:

Breakfast Items: Naturally, maple syrup is the perfect complement to pancakes and waffles. Pour it over oatmeal or yogurt for an additional touch of sweetness.

Savory Dishes: Use it as a glaze for meats like bacon, ham, or chicken. It pairs well with spicy and savory flavors, offering a nuanced sweetness to dishes.

Desserts and Baked Goods: Substitute maple syrup for sugar in baking, adding its rich flavor to cookies, cakes, and pies.

In recipes, it's essential to note that maple syrup is sweeter than sugar, so adjustments may be necessary when using it as a substitute.

Pairings should accentuate the unique flavor profiles found in different grades of maple syrup, from the light and delicate to the deeply robust, allowing this natural delicacy to enhance a wide array of culinary creations.

Understanding the Industry

Maple syrup production is a craft that intertwines the history and tradition of North America with modern agricultural practices and sustainability concerns. This guide focuses on aspects from the rich background of this industry to its evolution into a sustainable agriculture practice.

History of Maple Syrup Production

The history of maple syrup begins with the indigenous peoples of North America, who first discovered that the sap from maple trees (primarily Acer saccharum, or sugar maple) could be processed into a sweet substance. European settlers adopted these methods, and maple syrup became a staple. Throughout the United States, maple syrup production has evolved, yet it still retains elements of its traditional roots.

Pre-Colonial: Indigenous methods of sap collection, such as using birch bark containers.

Colonial: Introduction of iron pot boiling by European settlers.

19th Century: Invention of the tin spout which improved sap collection.

20th & 21st Century: Integration of modern technology, including tubing systems and vacuum pumps.Current Trends and Sustainability

The maple syrup industry has observed recent trends toward sustainability and high-yield production. Innovations such as tubing systems with vacuum, efficient energy use in sap boiling, and tapping guidelines to ensure tree health are at the forefront.

Acer saccharum remains the most tapped maple due to its high sap sugar content.

Other species like Acer rubrum (red maple) and Acer nigrum (black maple) are also used, contributing to the diverse maple syrup offerings.

Sustainability practices in maple syrup production include:

Limiting the number of taps per tree to avoid over-tapping.

Stewardship programs to maintain forest health.

Research into tree health for long-term viability of the maple syrup industry.

The industry continues to embrace these practices, with producers in states like Vermont leading the way in implementing guidelines that promote sustainable and profitable syrup production.

By understanding both the historical roots and modern developments of maple syrup production, one gains appreciation for the delicate balance between tradition and innovation in this industry.