The Ultimate Guide to Using a Portable Scissor Lift

Safely Elevating Maintenance in Homesteading

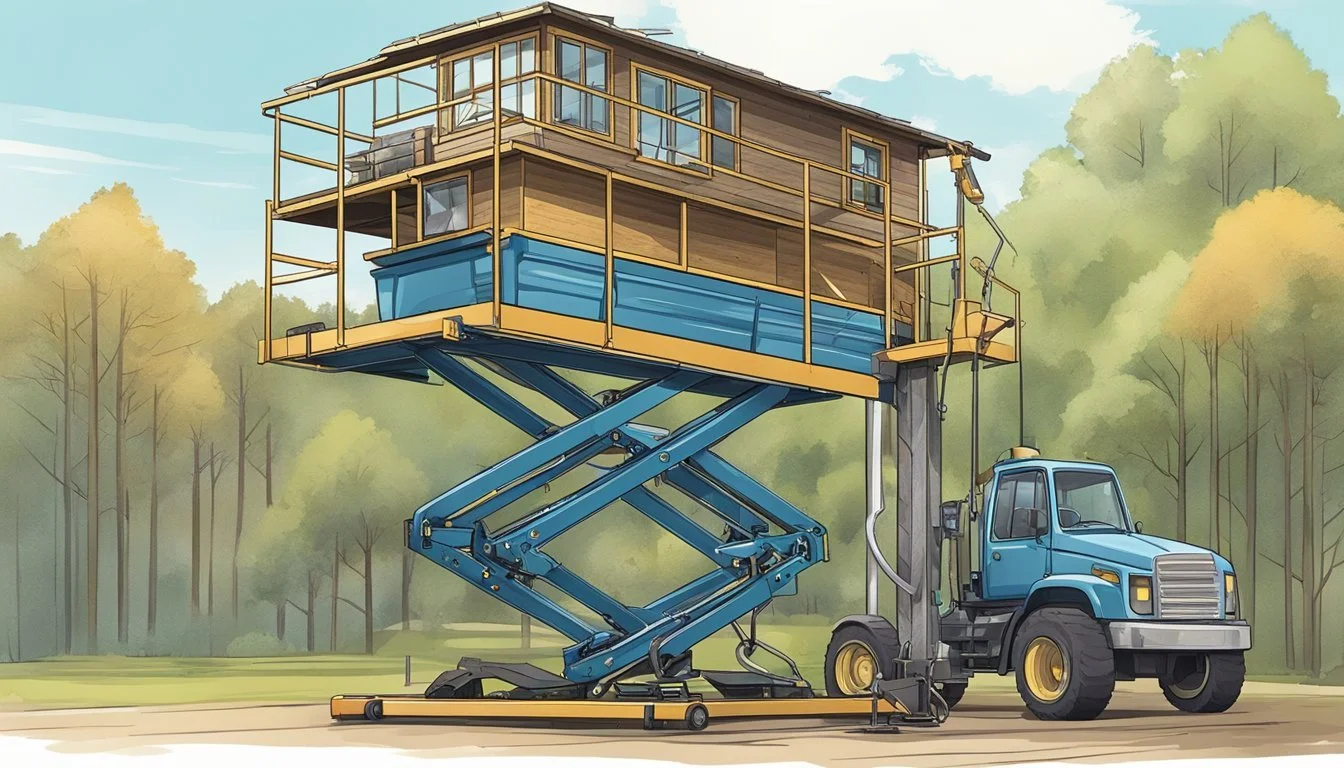

In the realm of homesteading, ongoing maintenance tasks require a blend of tradition and modern technology. Among the innovative tools at one's disposal, portable scissor lifts are proving themselves to be invaluable. These devices provide a stable and efficient means to access elevated areas, whether it's for pruning fruit trees, repairing facades, or installing overhead irrigation systems. With their sturdy design, scissor lifts ensure safety and accessibility, making them ideal for a variety of maintenance tasks around the homestead.

Unlike ladders or scaffolding, scissor lifts offer a mobile and secure platform that can be easily maneuvered across uneven terrain, common in rural settings. The lift's simple operation allows for rapid elevation to the desired height, enabling maintenance work to be carried out with greater precision and less physical strain. Regular upkeep of homestead buildings and equipment is streamlined, as scissor lifts make it possible to reach difficult areas without compromising on safety.

Scissor lifts are also a time-efficient solution for homesteaders. The ease of setting up and operating these lifts directly contributes to a more productive maintenance schedule. By integrating scissor lifts into routine maintenance tasks, homesteaders can allocate more time to other essential activities, thereby balancing the demands of modern upkeep with the self-sufficient ethos of homesteading life.

Understanding Scissor Lifts

In the realm of elevated maintenance tasks, scissor lifts are essential due to their stability and ease of use. They vary in power source and size, catering to different operational necessities.

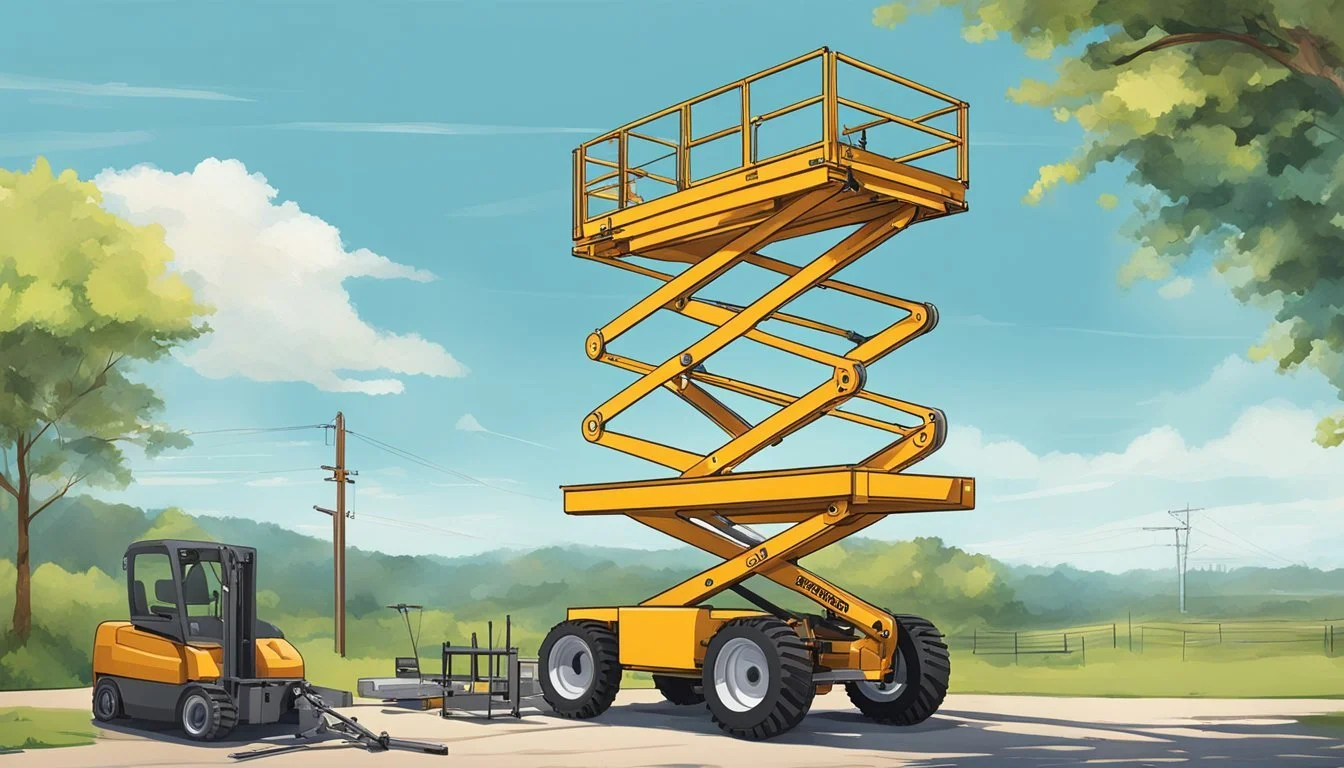

Types of Scissor Lifts

Scissor lifts can be broadly categorized based on their power source and intended use environment:

Electric Scissor Lifts: Ideal for indoor use due to their quiet operation and lack of emissions.

Diesel-Powered Scissor Lifts: Suited for outdoor tasks, these lifts can handle rougher terrain and larger loads.

Hydraulic Scissor Lifts: They use hydraulic fluid to power the lift mechanism, offering smooth and consistent elevation.

Compact Scissor Lifts: These are designed with smaller dimensions, making them perfect for tight spaces.

Rough Terrain Scissor Lifts: Equipped with enhanced features such as reinforced tires and 4-wheel drive to navigate uneven surfaces.

Key Components and Functionality

At its core, a scissor lift includes the following elements:

Platform: The surface on which personnel or equipment is placed for elevation.

Base: Provides stability and contains the machinery that controls elevation.

Lifting Mechanism: Utilizes a series of linked, folding supports in a crisscross 'X' pattern, known as the pantograph. The mechanism can be powered by:

Electricity

Diesel

Hydraulics

The functionality of a scissor lift revolves around the vertical elevation of the platform, offering a stable aerial work space compared to alternatives like ladders or scaffolding. These are typified by the following operational features:

Vertical Lift: Offers direct upward motion, which is ideal for tasks that require vertical access, such as maintenance work.

Aerial Lifts: Scissor lifts are a subset of aerial lifts, which include other machinery like boom lifts. However, scissor lifts provide a larger work platform and typically allow for a higher weight capacity than comparable vertical or boom lifts.

Safety and Training

To ensure a safe working environment while using portable scissor lifts, homesteaders must adhere to stringent safety protocols and engage in comprehensive operator training. It is vital to understand and implement regulations while being prepared for any emergencies.

Safety Protocols and Regulations

Occupational Safety and Health Administration (OSHA) mandates specific guidelines for the safe use of scissor lifts. These include:

Guardrail Systems: Scissor lifts must have sturdy guardrails in place to prevent falls, as fall protection is a key concern in elevated tasks.

Personal Protective Equipment (PPE): Operators must wear PPE such as hard hats, safety harnesses, and goggles.

Regular Inspections: Lifts must be inspected routinely for any mechanical or structural issues.

Load Capacities: Heeding the manufacturer’s load capacity recommendations is essential to prevent tip-overs.

Abiding by these regulations ensures the safety of the operator and those around the lift.

Operator Training and Certification

Proper training and certification are paramount for operating a scissor lift:

OSHA Certification: Operators should undergo an OSHA-approved training program to ensure they are qualified.

Safe Operation Training: In-depth knowledge on the operation of lifts, including control familiarization, smooth maneuvering, and correct positioning, is crucial.

Practical Assessment: After theoretical training, operators must demonstrate their abilities through a supervised practical test.

This comprehensive approach to training ensures operators are confident and competent in safe lift operations.

Emergency Procedures

Developing and understanding emergency procedures can mitigate risks in urgent situations:

Emergency Stop: Operators must know the location and function of the scissor lift’s emergency stop feature.

Evacuation Plan: A clear plan for rapid and safe descent in case of power loss or equipment failure should be established.

First Aid: Operators should be trained in basic first aid and know how to access emergency medical services if needed.

These procedures are critical for quick and effective response to any unexpected incidents.

By upholding safety protocols, ensuring rigorous operator training, and establishing clear emergency procedures, homesteaders can safely perform elevated maintenance tasks using portable scissor lifts.

Preparation for Use

Before utilizing a portable scissor lift for elevated maintenance tasks, it is imperative that operators conduct thorough preparations to ensure safety and efficiency. These preparations involve a careful assessment of the work site, a detailed pre-use inspection of the lift, and the implementation of necessary stabilization measures.

Site Assessment and Positioning

The initial step involves evaluating the site where the scissor lift will be used. Operators should:

Identify potential hazards such as uneven ground, overhead obstructions, or nearby power lines.

Check wind speed to ensure it is within safe operating limits for the lift.

Determine an appropriate area for positioning the scissor lift, ensuring it is level and free from debris.

Pre-Use Inspection

Before operation, a comprehensive pre-use inspection is crucial to identify any defects or issues that may compromise safety. Operators should examine:

Controls to confirm they are in working order.

Rails to ensure they are secure and intact.

All safety devices, including brakes and emergency stops.

If any defects are found, the lift must not be used until they are rectified.

Stabilization Measures

To maintain the stability of the scissor lift during use:

The lift should be deployed on solid ground with the base fully retracted to maximize stability.

The brakes must be engaged to prevent any potential movement of the lift.

Extendable stabilization arms, if available, should be used according to the manufacturer's guidelines.

Operating the Scissor Lift

Operating a scissor lift efficiently and safely requires understanding its controls and adhering to safety protocols. The following information details how to maneuver the scissor lift and ensure the safety of both the operator and the equipment when working at heights.

Controls and Maneer Wing

Scissor lifts typically feature a control panel with a joystick for steering and buttons or switches for raising and lowering the work platform. To start the lift, the operator inserts the key into the ignition and turns it, activating the power to the controls. Steering is straightforward: the operator maneuvers the lift using the joystick, moving it in the desired direction. The lift should be positioned carefully, ensuring the base is retracted for stability before any elevation changes.

For raising and lowering the aerial work platform, the operator uses the corresponding controls, often a switch or joystick toggle, to adjust the platform to the desired height. During this process, it is crucial to continuously check for overhead obstructions such as utility wires or tree branches to avoid accidents.

Work Platform and Lift Safety

Safety is paramount when operating a scissor lift. Before use, operators must wear appropriate Personal Protective Equipment (PPE), including a safety helmet and safety footwear. The work platform is surrounded by guardrails, which provide fall protection for the operator and any tools or materials.

When working, it is essential to maintain a stable position on the work platform, keeping the lift stationary and ensuring it is on a flat surface to prevent tipping. After completion of the elevated tasks, the lift should be safely lowered, and the power source disconnected for shutdown. Before leaving the lift, the operator should check that the work platform is fully retracted and the lift is parked in a designated area.

By following these guidelines, homesteaders can operate scissor lifts confidently and conduct maintenance tasks effectively and safely.

Maintenance and Inspections

The longevity and safe operation of a portable scissor lift rely on adherence to rigorous maintenance routines and thorough inspections. Ensuring that each component functions correctly is vital for homestead elevated maintenance tasks.

Routine Maintenance Procedures

For consistent performance and safety, routine maintenance procedures should be diligently followed. These include:

Battery Inspection and Care: Batteries should be checked for proper fluid levels and charging conditions.

Lubrication: All moving parts, particularly the scissor mechanism and pivot points, require regular lubrication to maintain smooth operation.

Brake and Hydraulic Systems: Brakes must be tested for responsiveness, and hydraulic systems should be inspected for leaks or changes in fluid levels. It's imperative to use the correct fluid type as specified by the manufacturer.

Cleaning: Regularly cleaning the lift can prevent the build-up of debris that may interfere with mechanical components.

Identifying and Addressing Common Defects

Identifying common defects during inspections can prevent accidents and costly repairs. Key areas of focus include:

Structural Components: Check for signs of wear or damage to the lift's arms, platform, and base. Any structural defect requires immediate attention.

Controls and Emergency Stops: All control functions need to be operating correctly. Emergency stop mechanisms should be tested regularly to guarantee they are functioning as intended.

Safety Devices and Alarms: Devices such as tilt sensors, limit switches, and alarms must be in working order to ensure they accurately detect and communicate hazards.

By maintaining compliance with established standards and addressing defects promptly, one ensures that a portable scissor lift remains a safe and reliable tool for elevated maintenance tasks.

Practical Applications

Portable scissor lifts are indispensable tools for various elevated tasks in homesteading, from maintenance to storage arrangement. They offer a stable platform to work at height, streamlining efficiency and ensuring safety.

Maintenance and Repair Tasks

For tasks involving ceilings, light fixtures, and ventilation systems, portable scissor lifts allow individuals to reach high areas safely. They are particularly useful for:

Replacing or repairing light fixtures and ceiling components

Conducting maintenance on overhead structures without the need for precarious ladders

Inventory and Warehousing Usage

In the realm of warehousing and inventory management, these lifts facilitate:

Easy access to high storage areas for inventory audits

Safe and efficient stocking or retrieval of items on elevated shelves

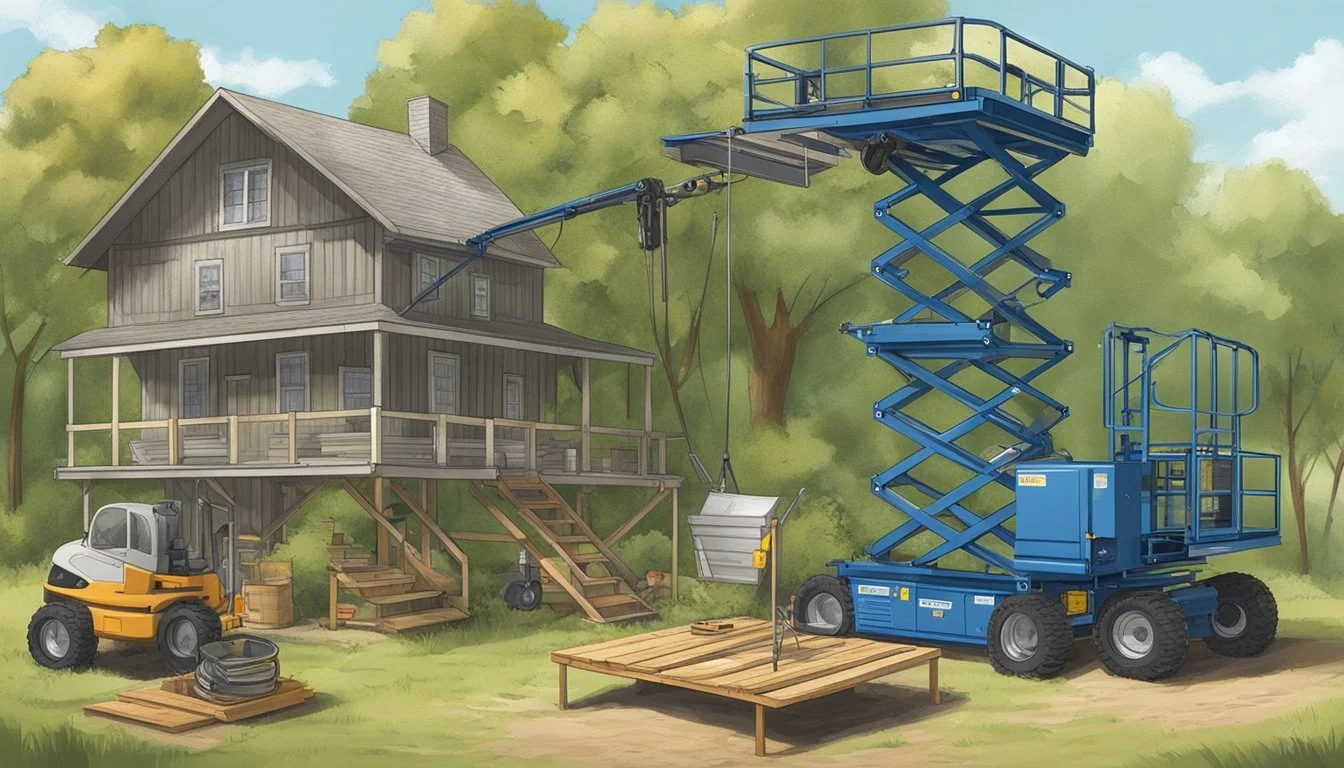

Construction and Decorating Projects

Scissor lifts are also vital in construction and decorating scenarios where they serve to:

Provide a stable platform for painting or decorating activities that occur at a height

Assist in tasks such as installing drywall or setting up structural frameworks during construction projects

Considerations for Purchasing

When homesteaders contemplate adding a portable scissor lift to their maintenance arsenal, recognizing the imperative to align this investment with their specific infrastructure needs and regulatory responsibilities is paramount.

Assessing Needs and Specifications

Before embarking on a purchase, they must thoroughly assess the lift's intended use. For tasks within the construction industry that demand a compact lift, specifications such as height reach, weight capacity, and platform size must correspond to construction projects at hand. For instance, a lift that extends up to 25 feet and supports between 500 to 1,000 lbs might suffice. Lists and tables can be utilized for specification comparison to simplify the decision-making process.

Height Reach: Ensure the lift meets the maximum elevation requirements.

Weight Capacity: Choose a lift that safely carries the combined weight of workers and their tools.

Platform Size: Opt for a platform that allows comfortable movement for involved tasks.

Safety Features and Compliance

Compliance with safety standards is not negotiable; therefore, purchasers must seek lifts equipped with essential safety features to protect users from potential hazards. Compliance with standards such as OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute) is a testament to the lift’s dedication to safety. Features like guardrails, emergency stop buttons, and stability sensors should be non-negotiable.

Guardrails: Integral for fall prevention.

Emergency Features: Such as stop buttons and safety alarms.

Evaluating Cost and Value

A clear understanding of the lift's life cycle cost, which encompasses the purchase price, maintenance expenses, and potential resale value, provides insight into its overall value proposition. Homesteaders should not only look at the upfront cost but also consider the total cost of ownership in the context of the lift's contribution to productivity and efficiency in maintenance tasks. Affordability should not compromise quality, especially for devices critical to safety and production.

Initial Purchase Price: Evaluate if the investment aligns with the budget and expected utility.

Maintenance Costs: Factor in regular servicing and potential part replacement.

Resale Value: Consider future resale opportunities to recoup part of the investment if needs change.

By factoring in these detailed considerations, homesteaders can ensure that their investment into a portable scissor lift is well-suited to their property maintenance needs, compliant with safety regulations, and economically justified.

Legal and Industry Standards

In ensuring elevated maintenance tasks on homesteads are executed safely and legally, it is paramount to understand and adhere to Occupational Safety and Health Administration (OSHA) regulations and industry best practices. Compliance with these guidelines minimizes risks and enhances the safety of operations involving portable scissor lifts.

OSHA Guidelines and Compliance

The Occupational Safety and Health Administration (OSHA), a regulatory authority, mandates specific standards for the safe operation of scissor lifts. OSHA’s standards for scissor lifts in the construction industry focus on preventing accidents through fall protection and secure operation.

Key OSHA Standards:

29 CFR 1926.453(b)(2)(v): Requires guardrails on scissor lifts to prevent falls.

29 CFR 1926.451(g)(1): Obligates employers to provide fall protection for employees on a scaffold more than 10 feet above a lower level.

OSHA also regulates training for operators, underlining that they must understand:

Model-specific scissor lift nuances.

Recognition and avoidance of potential hazards.

Failure to comply with OSHA regulations can lead to penalties and increased risk of workplace injuries.

Best Practices in Elevating Work Platforms

Aligning with industry standards ensures not just compliance, but also operational efficiency and safety. Here are a few best practices recommended for safe use of elevating work platforms like portable scissor lifts:

Pre-Operational Checks: Thoroughly inspect the scissor lift for any malfunction before use.

Stable Positioning: Always place the lift on firm and level ground to prevent tip-overs.

Awareness of Surroundings: Operators should be cognizant of overhead power lines and any other potential hazards.

It is crucial for anyone using scissor lifts to be trained in and adhere to these best practices. This ensures a safe work environment not just for the operators but for all personnel on the property.

Conclusion

Portable scissor lifts are a practical solution for homesteaders seeking to perform elevated maintenance tasks safely and efficiently. These devices provide a stable platform, making them preferable over ladders or scaffolding. When using a scissor lift, operators should prioritize safety by following the manufacturer's guidelines and adhering to OSHA's fall protection standards.

Key considerations for safe and effective scissor lift operation include:

Stabilization: Ensure the lift is used on level and firm ground.

Training: Operators must be knowledgeable about the lift’s functions and safety features.

Inspection: Regularly check the scissor lift for any signs of wear, damage, or malfunction.

Fall Protection: Use railings and, if required, safety harnesses to prevent falls.

Maintenance tasks such as changing light fixtures, painting, or trimming trees are simplified with a scissor lift. However, users must remain vigilant of their surroundings to prevent accidents, especially when working near drop-offs or overhead obstructions.

Remember to store your scissor lift properly when it is not in use, protecting it from the elements and ensuring it is ready for operation the next time it is needed. By following these guidelines, homesteaders can safely maximize the utility of portable scissor lifts for various maintenance tasks.