The Ultimate Guide to Honey Bottling Tanks

Mastering Efficient Honey Processing and Bottling

Honey bottling tanks are vital components in the journey from hive to jar, representing the final step in the honey processing sequence. For beekeepers, the choice of an appropriate bottling tank is crucial for achieving an efficient and hygienic transfer of honey. These tanks not only streamline the filtration process but also serve as interim storage solutions, maintaining honey's purity before it is decanted into its final packaging. Understanding the specifications and features of different bottling tanks helps beekeepers optimize their operations and ensure that the honey's quality is preserved.

The process of extracting and bottling honey includes several stages, from uncapping the wax seals of the honeycomb frames to spinning out the honey using an extractor. Once extracted, the honey is often allowed to settle in a bottling tank, which is designed with a spigot or honey gate at the bottom to facilitate easy and controlled pouring. Tanks come in various materials, including food-safe plastic and stainless steel, each offering different benefits. For example, stainless steel tanks are highly durable and can withstand the rigors of beekeeping while ensuring a non-reactive environment for honey.

Beekeepers looking for an efficient way to bottle their honey should consider the size and design of the bottling tank. A sufficient size will accommodate the output from their hives, and features like a honey gate will enhance the ease of filling jars. It's important for beekeepers to ensure that their selection complies with food safety standards, thus guaranteeing the wellbeing of consumers while enjoying the natural sweetness of their carefully harvested honey.

Fundamentals of Honey Processing

Effective honey processing is a critical step in honey production and requires adherence to best practices in beekeeping and extraction. The process starts with uncapped honey, where beekeepers remove the wax caps from honeycombs using tools like hot knives or uncapping forks.

Extraction follows, generally accomplished by spinning the frames in a honey extractor, using centrifugal force. Interestingly, gravity also plays a role in the extraction process as it helps facilitate the flow of honey from the frames.

Next, filtering and straining come into play to remove impurities. A double sieve setup is commonly used, which consists of a coarser mesh on top of a finer mesh, ensuring that most contaminants are removed. Here's a simple breakdown of this process:

Uncapping: Removal of the wax seal from capped honey cells.

Extraction: Using a centrifuge or manual spinner to release honey.

Filtering: Passing through sieves to eliminate debris.

The gravity straining method involves letting honey slowly pass through sieves, relying on gravity rather than forced filtration. This preserves the integrity of the honey while ensuring purity.

Storage and settling are critical too. Honey is typically stored in a honey bucket or tank to allow air bubbles and small particles to rise to the top. Raw honey can be bottled immediately after straining, or it may be allowed to settle further, which helps in achieving a clearer product.

Proper processing creates honey that highlights the natural flavors and benefits that consumers expect while ensuring a shelf-stable product when properly contained.

Honey Harvesting Techniques

Before honey can be bottled, it requires efficient harvesting techniques that ensure quality and ease of processing. These steps are critical as they influence the final product's purity and taste.

Extraction Methods

Honey extraction from the beehive is a careful process that utilizes specific tools. Typically, beekeepers use an extractor, a centrifugal device, to spin uncapped frames, forcing honey out of the comb by centrifugal force. The method is effective and commonly used because it preserves the comb's structure, allowing bees to reuse it, thereby saving their energy for honey production instead of comb reconstruction.

Extraction can be performed using:

Manual Extractors: Operated by hand crank; suitable for small-scale apiarists.

Electric Extractors: Powered by electricity, these are ideal for commercial beekeeping operations due to their efficiency in handling a large number of frames.

Wax Cap Removal

Every honeycomb cell is sealed with a wax cap, created by the bees to preserve the honey's quality. Unsealing these caps, a process known as uncapping, is necessary before extraction. Tools used for uncapping vary but can include:

Hot knives: Electrically heated knives that melt through the wax cappings.

Uncapping forks: Handheld tools with tines that are dragged along the surface to pull off the wax.

Uncapping machines: More sophisticated devices suitable for larger operations; they often use rollers or chains to remove the wax cap efficiently.

Each method aims to minimize damage to the frames and can be chosen based on the scale of the operation and the beekeeper's preference. After uncapping, the frames are ready to be placed in an extractor, where the honey can be harvested for the next bottling steps.

Choosing the Right Honey Bottling Tanks

Selecting an appropriate honey bottling tank is crucial for beekeepers, as it directly affects the efficiency of honey extraction and storage processes. The ideal tank should pair high-quality materials with the right capacity to meet a beekeeper's current and future needs.

Materials and Build Quality

When evaluating honey bottling tanks, the material plays a pivotal role in longevity and safety. Stainless steel tanks are highly recommended due to their durability and resistance to corrosion. Beekeepers should ensure the grade of stainless steel is food-grade, typically 304 stainless steel, to maintain the purity of the honey. The construction should also include features like a secure lid, a controllable honey gate valve, and, in some cases, a heated bottom for easier processing.

Build quality is evident in features such as rubber seals to preserve freshness and prevent leaks, as well as latches for securing the lid during storage. Tanks should have a smooth interior surface to facilitate easy cleaning, and ideally, should be designed to drain completely, leaving no honey behind.

Capacity and Scalability

Capacity is another factor that beekeepers must consider. The size of the tank should correspond to the beekeeper's level of production. For a small-scale beekeeper, tanks can range from 8 gallons to 26 gallons, ensuring that the tank won't be overly cumbersome for their operation. Larger operations might require tanks up to 40 gallons or more.

Scalability is about anticipating growth. Beekeepers should ponder their long-term goals, choosing a tank size that allows for increased production without necessitating an immediate upgrade. While a larger tank might have a higher price initially, it may be more cost-effective in the long run. Tanks often come in the following capacities, catering to various scales of operation:

8 gallons

13 gallons

18 gallons

26 gallons

40 gallons and above

In summary, when beekeepers select a bottling tank, one must consider the materials and build quality for a durable and safe honey processing experience, in addition to matching the capacity with their current and potential future needs to ensure sustainable scalability.

The Bottling Process Explained

When bottling honey, precision and cleanliness are paramount. The process requires a methodical approach to ensure that honey is packaged in a sterile environment, maintaining its quality and purity.

Preparation and Sterilization

Before bottling honey, it is crucial to sterilize all equipment. This includes the bottling tanks, jars, and any other tools that will come into contact with the honey. Proper sterilization eliminates potential contaminants. The equipment can usually be sterilized using hot water or appropriate chemical solutions recommended for food safety.

Filling Honey Jars and Bottles

Filling honey jars and bottles is done with the help of a spigot attached to a bottling tank or a specialized filling machine. These systems allow for precise control of honey flow to minimize air bubbles and effort during the process. Bottling should be done in a clean environment to ensure the honey stays pure from the tank to the final container.

Steps for Filling:

Uncap the tank: Open the spigot gently to start the honey flow.

Fill the containers: Place jars or bottles under the spigot and fill them to the desired level, avoiding overfilling.

Applying Lids and Labels

Securing lids onto jars and bottles should be done immediately after filling to avoid any contamination. Lids must fit snugly to create an airtight seal, extending the honey's shelf life. Afterward, labels are applied to the containers, displaying necessary information such as product origin, weight, and branding.

Checklist for Lids and Labels:

Ensure lids are cleaned and fit properly.

Apply labels straight and free of wrinkles for a professional appearance.

By following these steps, honey producers can efficiently process and bottle honey while upholding quality standards.

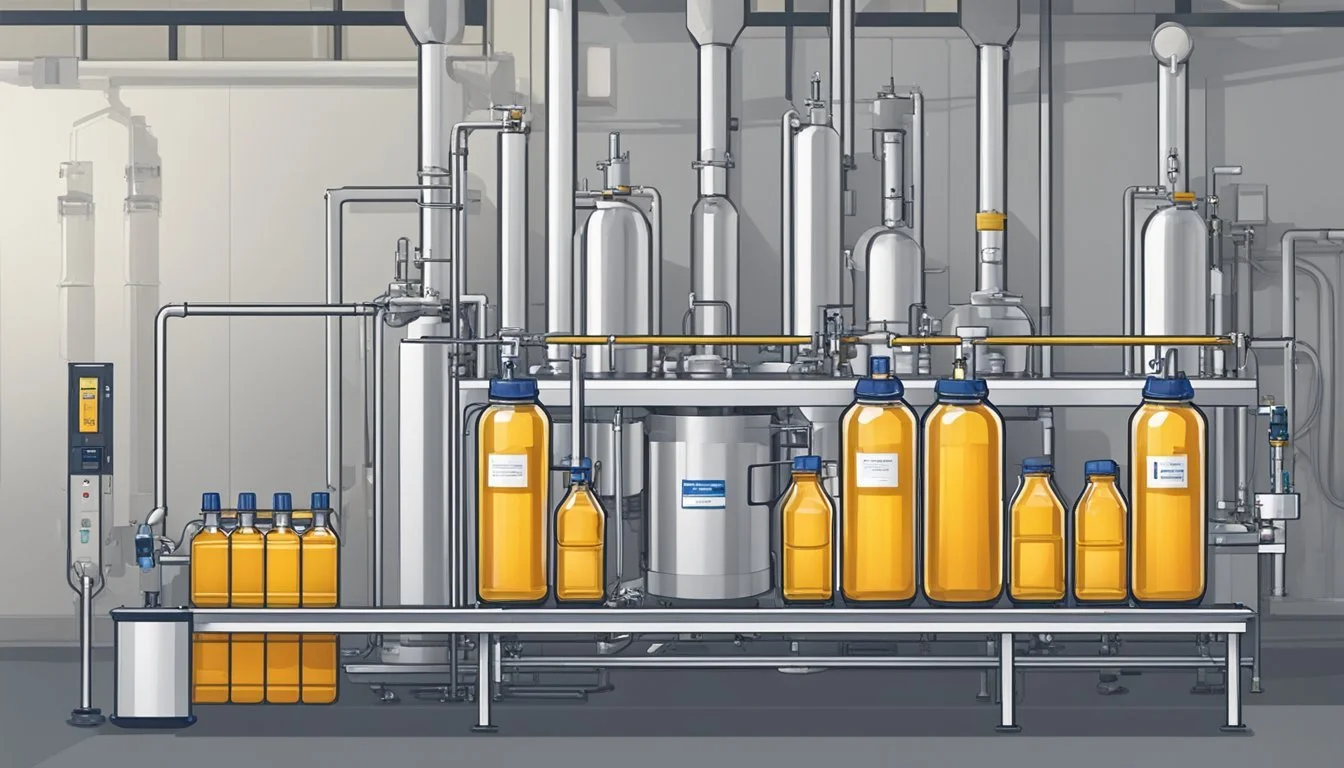

Advanced Bottling Equipment

In the realm of apiculture, advanced bottling equipment plays a pivotal role in enhancing the efficiency of honey processing and bottling. Specifically designed to streamline operations, these tools cater to the needs of larger honey production setups where precision and speed are paramount.

Heated Bottling Tanks

Heated bottling tanks are essential for maintaining honey at a consistent, fluid condition that facilitates efficient bottling. The controllable heating elements ensure the honey remains at an optimal temperature to prevent crystallization and maintain its natural properties. Tanks also often feature a honey gate valve, which allows for precise control during dispensing.

Key features include:

Temperature Control: Ensures honey stays at the desired temperature for easy bottling

Uniformity: Maintains consistent heat distribution for quality product handling

Automated Bottling Systems

For beekeepers looking to expedite the bottling process, automated bottling systems are the ideal solution. They often incorporate conveyance systems and filling machines which can be adjusted to fill containers of various sizes with remarkable accuracy. These systems dramatically decrease the time and labor involved in the bottling phase, increasing the overall production rate.

Advantages include:

Efficiency: Streamlines the filling process, saving time and minimizing effort

Consistency: Delivers uniform quantities of honey, ensuring each container is filled accurately

Notably, while heated bottling tanks and automated systems represent significant advancements in honey processing technology, many beekeepers may initiate their operations with a simple plastic bucket. These buckets, equipped with a honey gate valve, provide an affordable and basic tool for gravity-assisted honey bottling, suited for beginners or small-scale operations.

Storage and Preservation of Bottled Honey

Proper storage and preservation are crucial to maintaining the quality and longevity of honey after bottling. This section will cover the optimal environmental conditions for storing bottled honey to ensure it retains its natural flavor, consistency, and beneficial properties.

Environmental Factors for Storage

Temperature: The ideal storage temperature for honey is between 50-70°F (10-21°C). Temperatures above 70°F may cause honey to darken and lose its aroma and flavor, while temperatures below 50°F can lead to crystallization.

Humidity: A humidity level below 60% is preferable to prevent fermentation and preserve the honey's quality. Excess moisture can lead to spoilage and reduce shelf life.

Light: Honey should be stored in a dark place as exposure to light can degrade its quality. It is best to store honey in opaque containers to minimize light penetration.

Container Material: Honey should be stored in food-grade containers. Glass jars are ideal as they do not impart any odors or flavors and allow for easy inspection of the honey. If using plastic, ensure it is BPA-free.

Seal: Ensure containers are airtight. A proper seal keeps moisture out and prevents honey from absorbing any external odors.

Quality Control and Testing

Quality control and testing are crucial for ensuring that honey retains its natural properties and meets industry standards. They utilize precise instruments and techniques to maintain the integrity of the product from the hive to the bottle.

Measuring Moisture Content

Beekeepers employ a refractometer to measure the moisture content of honey. This tool is essential because the humidity levels directly influence honey's shelf life and susceptibility to fermentation. Honey typically has a moisture content between 17% and 18%. Beekeepers must ensure it does not exceed 20%, as higher moisture can lead to spoilage. The refractometer provides a quick and accurate measurement, which is instrumental for maintaining quality.

Ensuring Purity and Authenticity

To guarantee honey's purity, testing for the presence of propolis and pollen is essential. These substances are natural components of honey and indicators of its authenticity.

Pollen Analysis: Pollen helps in identifying the floral sources of the honey, confirming its origin. A microscopic analysis can determine the types of plants the bees have visited, which in turn can be used to verify labeling claims.

Propolis Content: The amount of propolis can also indicate the honey's purity. As a natural bee product, it possesses antibacterial properties and its presence further confirms that the honey has not been overly processed or adulterated.

Marketing Bottled Honey

After harvesting and bottling, honey producers must turn their attention to the competitive market. A strong branding strategy and adherence to legal standards are both pivotal for success.

Branding and Label Design

Branding is the cornerstone of any successful product, and honey is no exception. A producer should develop a unique identity for their honey that resonates with consumers. This identity is conveyed through the design and information presented on the label. The label serves not only as the first point of contact with customers but also as a means to distinguish the product from competitors. Careful consideration should be given to:

Visual Elements: Utilizing appealing color schemes, fonts, and imagery that reflect the honey's quality.

Informative Content: Providing details such as the type of honey, origin, and any unique selling points, which can educate consumers and pique their interest.

Legal Considerations for Selling Honey in the USA

When selling honey in the United States, producers must navigate a series of legal requirements to ensure that their product meets federal and state regulations. These regulations generally concern the accuracy of labels and the quality of food products. Key legal considerations include:

Label Accuracy: Making sure that labels accurately reflect what's in the jar, including net weight, ingredients, and the producer's contact information.

Health Claims: They must refrain from making unproven health claims about their honey, as these could be misleading and result in penalties.

By focusing on attractive, truthful branding and by complying with the legal standards, honey producers can effectively position their products in the marketplace.

Sustainable Beekeeping Practices

In the realm of sustainable beekeeping, efficiency and resourcefulness are paramount. Beekeepers are not only tasked with harvesting honey but also with ensuring that all by-products are used optimally to minimize waste.

Reducing Waste and Utilizing Beeswax

Beekeepers aim to reduce waste by carefully managing the resources produced by beehives. Beeswax, a valuable by-product of the honey extraction process, is meticulously collected and preserved. To make the most of the wax, beekeepers may employ cheesecloth or similarly appropriate materials for filtering, capturing fine particles and impurities that could otherwise contaminate the beeswax.

After harvesting, the purified beeswax finds a multitude of uses, such as in the production of candles, cosmetics, and even in furniture care. The judicious use of all hive by-products underscores the commitment to sustainable beekeeping practices, ensuring that every element of the hive's output is utilized in an environmentally responsible manner.