The Ultimate Guide to Using a Rebar Cutter and Bender for Homesteading Projects

Efficient Techniques for Self-Sufficiency

For homesteaders tackling construction projects, the ability to manipulate steel reinforcement bars, commonly known as rebar, is a valuable skill. Rebar provides structural support to concrete in a variety of homebuilding and landscaping projects, ranging from simple garden paths to more ambitious outbuildings. A rebar cutter and bender is a tool that allows one to efficiently cut and bend these bars to the required specifications, ensuring that the rebar fits perfectly into the construction design.

Using a rebar cutter and bender requires an understanding of the tool's capabilities. Modern portable rebar cutters enable quick and precise cutting of the steel bars. These tools can typically handle rebar of various grades and diameters, crucial for adhering to the specifications of each unique project. Additionally, rebar benders allow the user to bend the bars to the desired angles. This capability is essential for creating stirrups, hooks, and other complex shapes needed in reinforced concrete structures.

The selection of a rebar cutter and bender should be guided by the specific needs of the homesteading projects one anticipates undertaking. Factors such as the grade and size of the rebar used, the volume of work, and the level of portability required will influence the choice of tool. High-quality cutters and benders not only provide clean cuts and precise bends but also contribute to the longevity of the tool and the safety of the user.

Understanding Rebar Fundamentals

Rebar, or reinforcing bar, is a common steel bar used extensively in construction to increase the tensile strength of concrete in structures. This steel reinforcement is essentially the skeleton within concrete, which is otherwise strong in compression but weak in tension.

Composition and Types: Rebars are typically made of carbon steel and come in a variety of grades which determine their yield strength, that is, the minimum stress that leads to permanent deformation.

Grade 40 has a minimum yield strength of 40,000 psi.

Grade 60 reflects a yield strength of 60,000 psi, being more common.

Grade 75 and higher are also available for projects requiring even greater tensile strength.

Dimensions: The diameter of rebars is measured in eighths of an inch. For example, a number 4 rebar is 4/8 or 1/2 inch in diameter. Standard diameters range from #3 (3/8 inch) to #11 (1 3/8 inches).

Patterns: Rebars are characterized by their surface patterns — ridges or deformations — which help the bars grip the concrete. This structural relationship prevents the bars from slipping and improves the overall stability of the reinforced structure.

Best Practices for Usage: Selecting the correct grade and size of rebar is critical to the integrity of a project. It should be kept clean and free from any contaminants that could impair the bond with concrete. As corrosion is a concern with steel, proper concrete coverage is essential to protect the rebar from the elements.

By understanding these rebar fundamentals, one ensures the foundational rigidity and resilience required for any homesteading project involving concrete structures.

Selecting the Right Rebar Cutter and Bender

Selecting an appropriate rebar cutter and bender is vital for efficient, precise, and safe homesteading projects. It is important to find a tool that meets the specific needs of your tasks while staying within your budget and offering durability and ease of use.

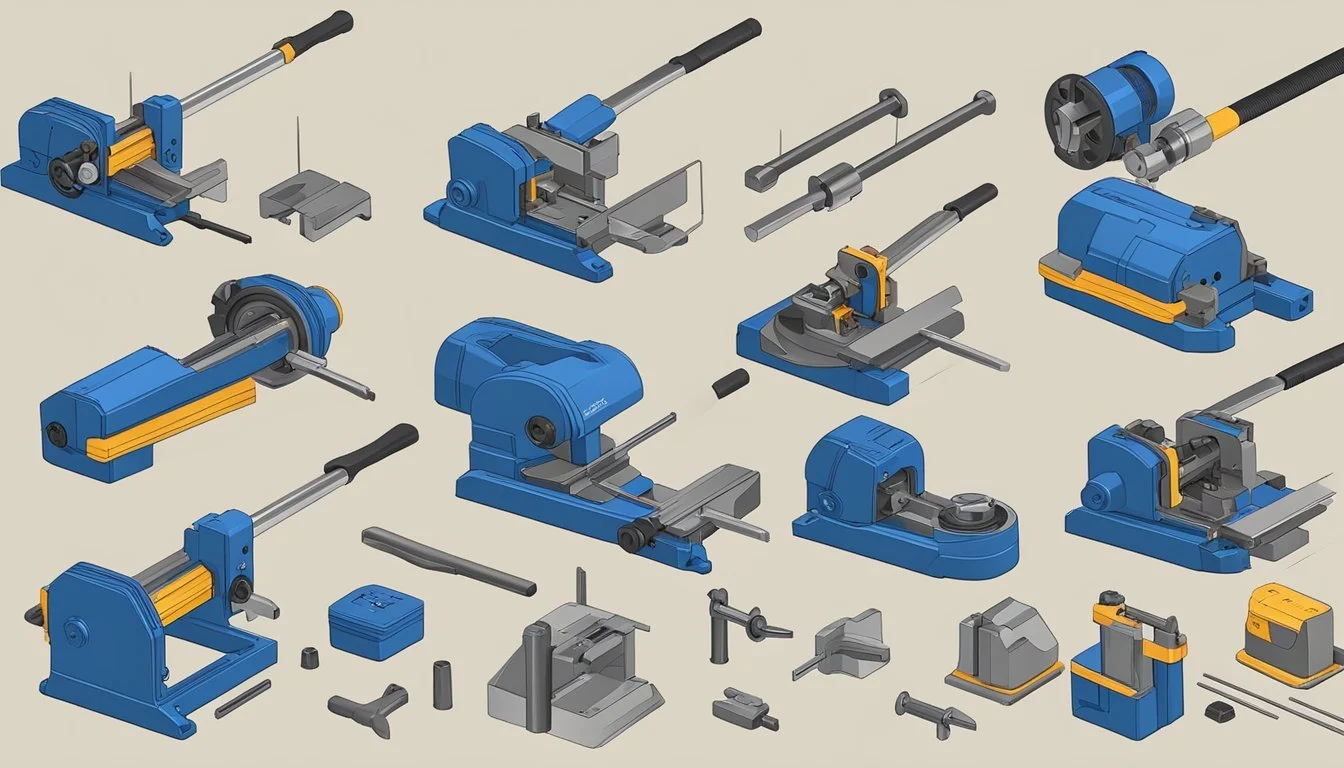

Evaluating Rebar Cutters

When evaluating rebar cutters, consider the cutting capacity which typically ranges from 3/8-inch to 5/8-inch for common models. Manual rebar cutters are cost-effective and portable but require physical effort to operate. Electric rebar cutters offer speed and ease of use but may be less portable. For larger projects, hydraulic rebar cutters provide the power needed to cut through thicker rebar but can be more expensive and less portable due to their weight.

Choosing Rebar Benders

Rebar benders are categorized by the bending angle they can achieve and the mechanism they use. Manual rebar benders are budget-friendly and offer control for precision but may be labor-intensive. Electric rebar benders are fast and efficient, often featuring a variable speed trigger for better control, suitable for repetitive tasks requiring consistent results.

Factors to Consider When Buying

When purchasing a rebar cutter and bender, consider:

Durability: Look for robust construction that can withstand your project demands.

Efficiency: High-speed and power contribute to faster completion of tasks.

Portability: Compact and lightweight models are easier to move around your homestead.

Precision and Accuracy: Ensure the tool delivers consistent performance.

Manufacturer: Choose reputable brands known for quality and good customer service.

Top Brands on the Market

Metabo: Known for professional-grade tools and electrical efficiency

Hitachi: Known for innovation and durable construction

BN Products: Known for specializing in cutting and bending tools

Klutch: Known for reliability and cost-efficiency

Product Reviews

The Metabo HPT Electric Rebar Bender and Cutter combines bending and cutting, suitable for grade 60 rebar, and is praised for its speed.

BN Products MBC-16B 1 Manual Bender/Cutter is recognized for high-degree bends, manual operation, and a solid construction.

The Klutch Rebar Cutter and Bender is noted for its dual functionality, compact design, and being a budget-friendly tool for occasional use.

Retailers like Amazon, Home Depot, Harbor Freight, and Lowe's frequently stock these tools, providing a variety of options for both professional contractors and homestead DIY enthusiasts.

Safety Protocols for Rebar Handling

Ensuring safe handling practices when working with rebar is critical, especially for those involved in homesteading projects. Adhering to safety protocols can significantly reduce the risk of injuries. These protocols encompass wearing the appropriate personal safety gear and strictly following operational safety measures.

Personal Safety Gear

One should not underestimate the importance of personal safety gear when working with rebar. It is essential to protect oneself from potential injuries caused by the rebar's sharp edges, as well as from the operation of heavy machinery.

Gloves: Always wear heavy-duty gloves to protect the hands from cuts and abrasions. Gloves should be durable and have a good grip to handle rebar effectively.

Safety Gear: Besides gloves, other safety gear includes steel-toed boots, safety glasses, and hard hats. These provide a comprehensive layer of protection against various risks.

Operational Safety Measures

A systematic approach to operating rebar cutters and benders will enhance safety and efficiency. Proper use of equipment is key in preventing accidents.

Pressure: Always monitor the pressure applied by the rebar cutter or bender. Avoid using excessive force to prevent the machine from malfunctioning and causing potential harm.

Handling: Carefully handle and support the rebar during bending and cutting operations. Make sure the rebar is securely in place before proceeding to avoid slippage and unintended movement.

Support: When operating a rebar bender or cutter, it should be firmly secured and supported. This ensures stability and reduces the risk of the equipment toppling over during use.

Preparing for Cutting and Bending

Before diving into construction projects, it's crucial to set up your workspace correctly and understand the tools and techniques for cutting and bending rebar. Precision is key, as the strength of your structure can depend on the accuracy of these elements.

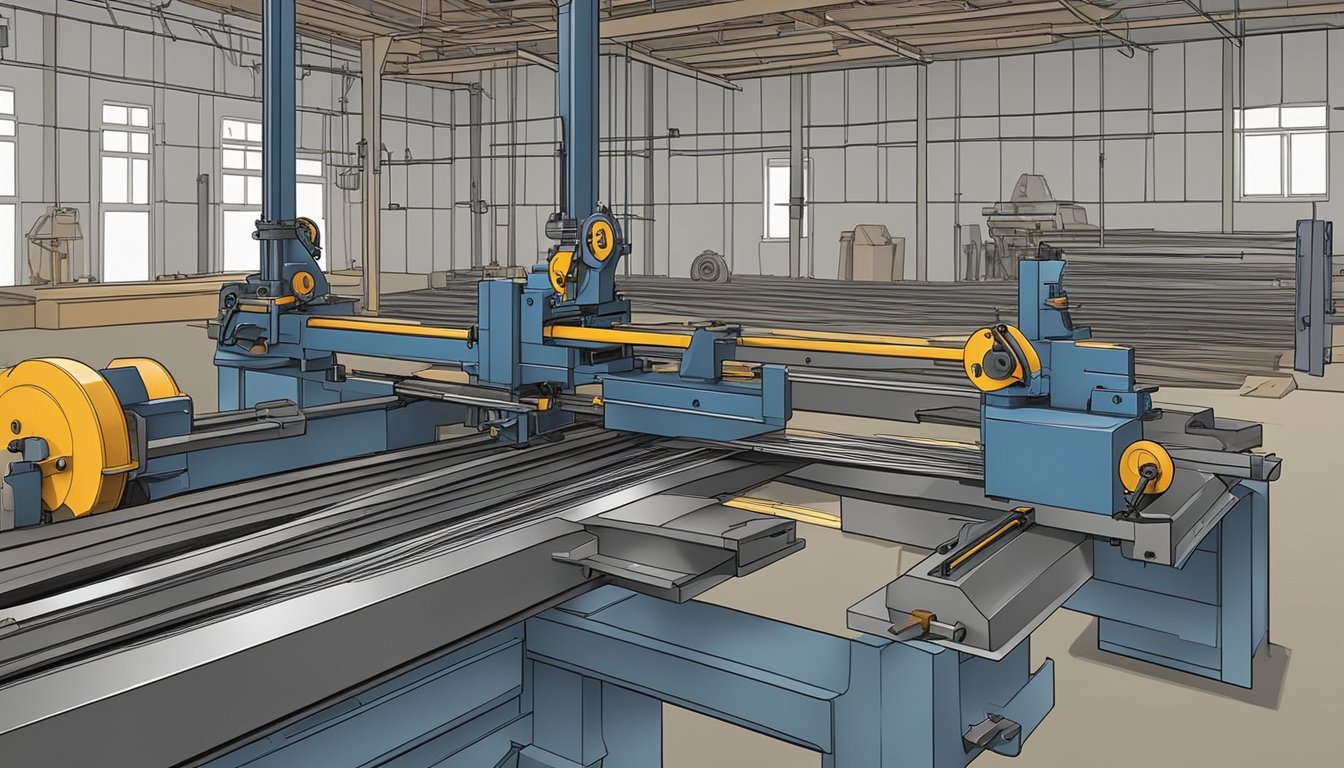

Workspace Setup

The workspace should be organized, well-lit, and have enough room to maneuver long lengths of rebar easily. Ensure the area is clear of debris and that all tools and safety equipment are within reach. A sturdy workbench with a mounted rebar cutter and rebar bender will save time and increase efficiency.

Organization: Clearly labeled tool stations.

Lighting: Adequate overhead and task lighting.

Space: Ample room for handling and storing rebar.

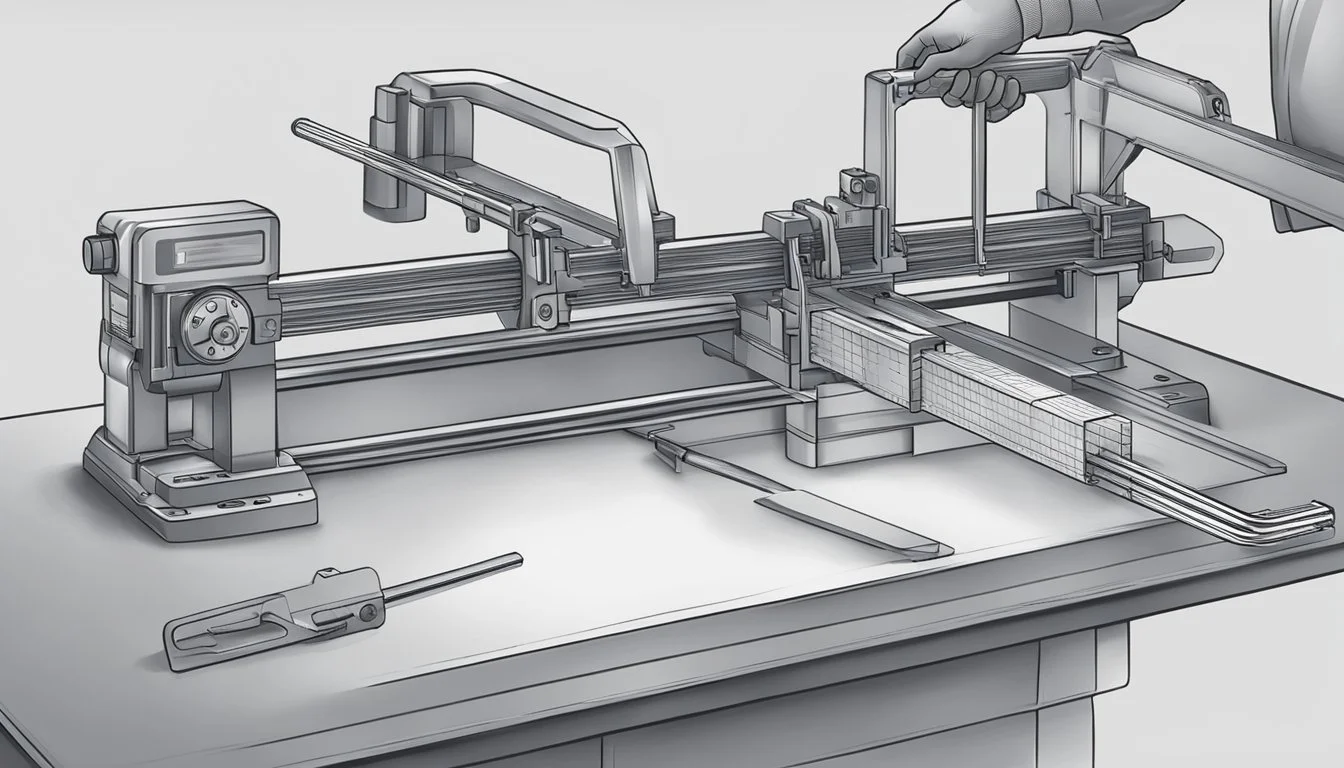

Rebar Measurement and Marking

Accurate measurement and marking are essential for precision cuts and bends. Utilize a tape measure to determine the required length and mark the rebar using a permanent marker. Double-check measurements to avoid errors that could compromise the structural integrity of your project.

Equipment Needed: Tape measure, permanent marker, protractor (for measuring angles).

Measurement Tips: Always measure twice, cut once.

Cutting and Bending Techniques

Rebar can be cut and bent manually or with powered equipment, depending on the volume of work. Rebar cutters offer a quick way to snip rebar to size, while rebar benders can shape rebar into the desired angle and degree with precision. Typically, rebar is bent to angles more than 90 degrees.

For Cutting:

Manual: Use a rebar cutter with a long handle to apply ample leverage for a clean cut.

Powered: Operate the machine, keeping a safe distance and following all safety protocols.

For Bending:

Manual: Employ a manual bender, positioning the rebar at the marked point and applying pressure to achieve the angle required.

Powered: Use a power bender, ensuring the rebar is securely in place and bending to the prescribed degree.

Always wear protective gear during these processes to prevent injury.

Manual vs. Electric Tools

When considering rebar cutters and benders for homesteading projects, the decision between manual and electric tools hinges on factors such as volume of work, precision requirements, and available budget.

Comparing Manual Tools

Manual benders and cutters are cost-effective and portable, requiring no power source to operate. They are typically operated by hand or with mechanical assistance. For instance, manual rebar cutters like hacksaws can be slow, but they are straightforward to use. Pliers provide a grip and leverage advantage, yet may require more force and time than their electric counterparts. The typical manual bending tool allows one to shape rebar with direct physical input, which can be sufficient for small-scale projects. However, with manual rebar cutting, the cutting speed is inherently slower, and the effort involved increases with the rebar's thickness.

Key Attributes of Manual Tools:

Cost: Generally lower upfront investment

Portability: No reliance on power; can be used anywhere

Effort: Higher physical exertion, especially for thick rebar

Speed: Slower cutting and bending speeds

Electric Tools Advantages

Electric rebar cutters and benders often include a brushless motor, providing a blend of efficiency, durability, and low maintenance. These tools enhance productivity with faster cutting and bending speeds. The electric rebar cutter effortlessly slices through rebar with precision and consistent force, drastically reducing the manual effort and time involved. Electric rebar benders allow for quick angle adjustments and can typically handle a heavier workload than manual benders, making them ideal for larger or more frequent projects.

Key Advantages of Electric Tools:

Efficiency: Higher cutting and bending speeds with less effort

Precision: Consistent results with less potential for user error

Workload: Suitable for larger and more frequent bending and cutting tasks

Convenience: Often include features such as preset angles for repetitive tasks

Advanced Techniques in Bending and Cutting

When tackling complex homesteading projects, understanding advanced techniques in bending and cutting rebar can elevate one's craftsmanship. These methods ensure precision and foster the creation of both aesthetic and functional elements.

Creating Complex Shapes

Creating curved shapes with rebar requires a methodological approach. An indexing head on a bender can facilitate this process, as it allows for bending at various degrees with high precision. The user can set the indexing head to the desired angle to achieve consistent curved shapes. Here are the steps they could follow:

Determine the desired shape: Establish the number of bends and the angle at which each bend should occur to form the shape.

Set the indexing head: Align the indexing head with the marked measurements on the rebar, which represent the bending points.

Bend the rebar incrementally: To avoid over-bending, one should make gradual bends, checking the angle after each pass.

For more intricate designs involving multiple bends, it's advisable to use a bending chart or software that can pre-calculate the bend sequences for accuracy.

Ensuring Accuracy and Consistency

Accuracy and consistency are paramount in cutting and bending rebar to maintain the integrity of a structure. The following practices should be adopted:

Measure Twice, Cut Once: Before any cut, double-checking measurements with a tape measure is essential to prevent material waste and ensure that pieces fit correctly.

Use of Stop Blocks: A stop block can be clamped into place to ensure each piece of rebar is cut to the exact same length.

Bending Tools: One may use a manual rebar bender equipped with calibrated markings that indicate the degree of the bend. It's critical to apply steady and consistent pressure when bending to avoid rebar deformation.

For both bending and cutting, one should regularly maintain their tools to prevent inaccuracies caused by worn-out equipment. Regular calibration and sharpening, where applicable, ensure that the applied techniques bear the desired results.

Maintenance and Longevity of Tools

Proper maintenance ensures the longevity and durability of rebar cutters and benders. Adhering to regular maintenance practices and measures to extend tool life is critical for their optimal performance in homesteading projects.

Regular Maintenance Practices

Daily Cleaning: Every use should conclude with removing debris and dirt from the rebar cutter and bender. This prevents the buildup of materials that can interfere with the tool's functionality.

Lubrication: Apply lubricant to moving parts regularly to reduce friction and wear. Check the manufacturer's guide for specific lubrication points.

Inspection: Before and after use, inspect the tools for any signs of wear or damage. Pay attention to the cutting blades and bending dies for dullness or cracks.

Storage: Store the tools in a dry environment to prevent rust and corrosion. They should be kept away from the elements and organized to avoid accidental damage.

Extending Tool Life

Use Correctly: Always use the rebar cutter and bender as intended by the manufacturer. Avoid overloading the tools beyond their capacity as it leads to premature wear.

Calibration: Regularly check and adjust the calibration settings to ensure precision in cuts and bends. Misalignment can cause unnecessary stress on the tool components.

Replacement Parts: When parts do show significant wear, replace them promptly with compatible, high-quality parts. Using worn parts can cause further damage to the tool.

By following these guidelines, one can maintain their rebar cutter and bender in top condition, thereby maximizing durability and extending the tools' lifespan for homesteading projects.

Project Ideas for DIY Enthusiasts and Pros

Utilizing a rebar cutter and bender empowers DIY enthusiasts and construction professionals to tackle an array of projects with precision and efficiency. These tools are pivotal in ensuring structural integrity, especially when dealing with concrete structures.

Residential Construction Projects

For those looking to get involved in constructing residential buildings, a rebar cutter and bender is indispensable. These individuals can undertake tasks such as:

Laying foundations with accurately bent reinforcement bars to ensure the stability of the structure.

Erecting concrete walls and columns, where the rebar can be custom-fitted to enhance their load-bearing capabilities.

Structural Enhancements

Rebar is crucial in reinforcing concrete, enhancing its tensile strength, which is essential for both new constructions and the fortification of existing structures. Projects in this domain include:

Reinforcing concrete slabs and driveways to prevent cracking and shifting.

Upgrading patio spaces with custom rebar grill designs for extra durability and aesthetic appeal.

Agricultural and Homesteading Implementations

Rebar cutter and bender tools serve a critical role in developing agricultural and homesteading projects, such as:

Constructing greenhouses with rebar frames to withstand adverse weather conditions.

Creating custom fencing and gates for livestock enclosures, where precision-cut rebar ensures the proper dimensions and strength.

Conclusion

In this guide, the emphasis has been on the practical benefits of using a rebar cutter and bender for homesteading projects. These tools not only increase efficiency but also enhance safety and versatility while being cost-effective for construction tasks.

Recap of Key Points

Safety: Rebar cutters and benders reduce the risk of injury compared to manual cutting and bending, making them a safer choice for both amateurs and construction professionals.

Efficiency: The tools streamline workflows, enabling users to perform rebar cutting and bending tasks more quickly than manual methods.

Versatility: Users can manipulate various sizes of rebar for different applications, thanks to the adjustable settings.

Cost-Effectiveness: Investing in these tools can save money in the long run through reduced labor costs and time savings.

Final Recommendations

For those in the construction industry or individuals tackling homesteading projects, incorporating a rebar cutter and bender is recommended. It is beneficial to select a model that is appropriate for the scale of the work—from handheld portable options to larger, more industrial models. Secure handling procedures should be adhered to, ensuring the user's safety and the longevity of the equipment.