The Ultimate Guide to Using a Portable Loading Ramp

Efficient Livestock Trailer Loading Tips

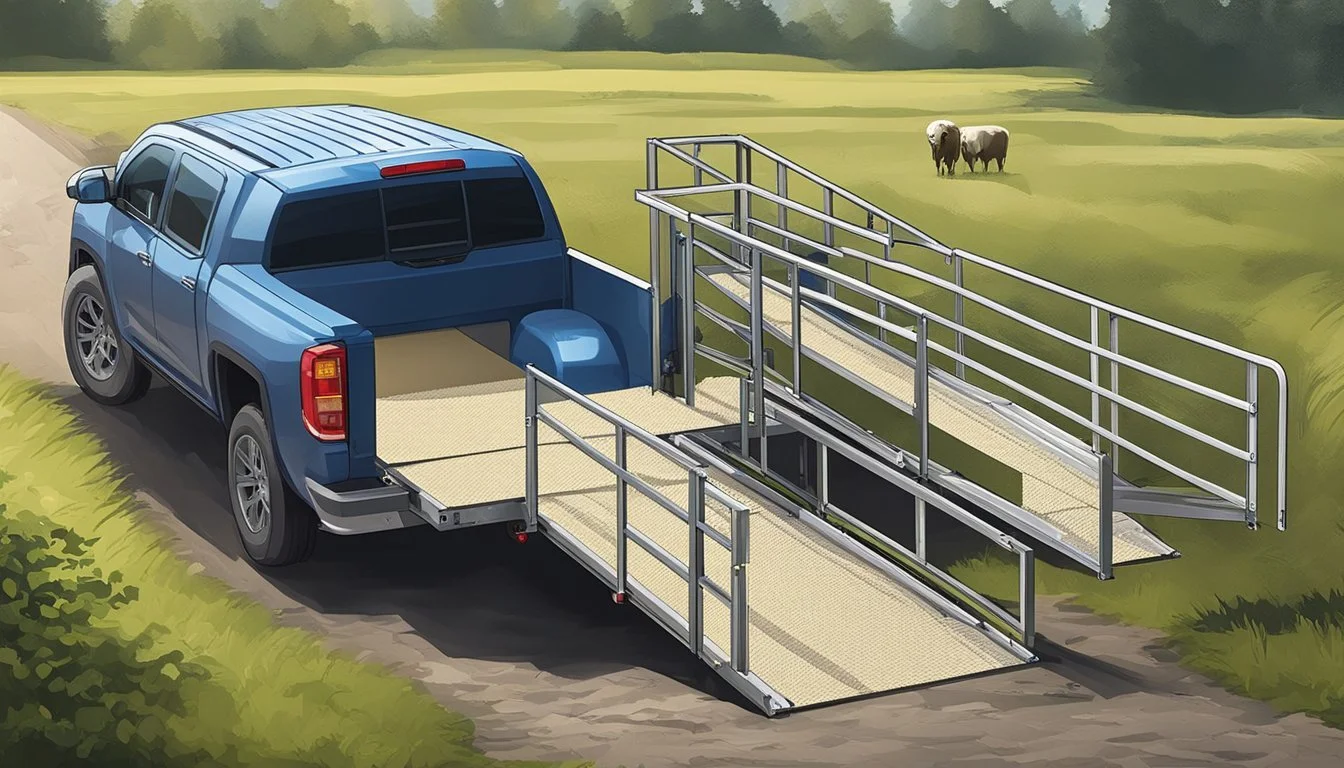

Efficient and safe loading of livestock onto trailers is a critical component of modern farming and ranching operations. A portable loading ramp is an essential tool that facilitates the transportation of animals like cattle with minimal stress and injury risk for both the livestock and handlers. These ramps are engineered to accommodate various trailer heights and are designed to ensure a smooth transition for animals from the ground to the trailer.

The design of portable loading ramps includes features such as adjustable heights, fully sheeted sides, and ample width to prevent animals from turning around or slipping, thus promoting a low-stress environment. The portability aspect allows for flexibility in different settings and eases the process of moving the ramp to meet the needs of different loading sites. With proper training and exposure, cattle can become accustomed to these ramps, which further maximizes efficiency and supports the overall welfare of the herd during the loading procedure.

Safety remains a top priority when using a portable loading ramp. Manufacturers are continuously refining their designs to include safety measures that comply with industry standards and legal requirements. Handlers are advised to follow best practices to mitigate risks, such as ensuring the ramp is securely connected to the trailer, checking for stable footing, and maintaining a calm and controlled approach to encourage cooperative behavior from the cattle.

Fundamentals of Portable Loading Ramps

When handling livestock, the right portable loading ramp is vital for efficient and safe loading onto trailers. The following information will guide users through the basics of these ramps, including their variety, how to understand them, and determining the appropriate size for specific needs.

Understanding Loading Ramps

Portable loading ramps offer a flexible solution for loading and unloading livestock from various vehicles to trailers. They are designed to be mobile, which allows them to be used in different locations and under a range of conditions. A key feature of any loading ramp is its loading height, which should match the vehicle to ensure a smooth transition of livestock.

Types of Portable Loading Ramps

There are primarily two types of portable loading ramps:

Straight Ramps: These ramps are linear without any curvature and are suitable for vehicles with a minimal height difference.

Arched Ramps: Arched ramps have a curved design, which helps in loading animals into higher vehicles by preventing the ramp's midsection from touching the vehicle undercarriage.

Determining the Correct Ramp Size

When selecting a portable loading ramp, size is critical. Here are the main factors to consider:

Capacity: Ensure the ramp can handle the weight of livestock and handlers.

Length: The ramp should be long enough to provide a gentle incline, reducing stress on animals during loading.

Width: It should be wide enough to accommodate the largest animal, ensuring they don’t feel confined, which could lead to hesitancy or resistance.

Choosing the correct ramp size helps in maintaining animal welfare and worker safety during the loading process.

Materials and Construction

In the realm of portable loading ramps for livestock, material choice and construction design are fundamental to the functionality and longevity of the ramp. These considerations directly impact safety, durability, and the capacity to handle varying weights of livestock.

Importance of Durable Materials

The selection of durable materials is crucial for portable loading ramps as they are subject to considerable wear and tear. Livestock ramps endure not only the heavy load of animals but also exposure to the elements and aggressive use. Durable materials extend the lifespan of ramps and ensure consistent performance under heavy-duty applications. High-quality construction materials provide resistance to corrosion, which is particularly important as ramps often come into contact with animal waste and harsh cleaning agents.

Comparing Steel and Aluminum Ramps

Steel Ramps: Often preferred for their strength, steel ramps are well-suited for situations requiring high weight capacities. Steel provides superior resistance to structural deformation under the stress of loading heavy livestock. Its robust nature, however, contributes to a heavier ramp, which can impact portability.

Advantages: High strength, lower cost

Disadvantages: Heavier, prone to corrosion

Aluminum Ramps: These are valued for their lightweight properties and resistance to rust, making them easier to move and more durable in certain weather conditions. Aluminum ramps, while not as strong as steel, are still sufficient for many livestock applications and offer a good balance between portability and strength.

Advantages: Lightweight, corrosion-resistant

Disadvantages: Lower strength than steel, typically more expensive

Understanding Weight Capacity

It's imperative to consider the weight capacity of a portable loading ramp. Manufacturers specify the maximum weight that ramps can safely support, and this is a direct reflection of the materials and construction quality. Exceeding these capacities can result in ramp failure, endangering both livestock and handlers. Therefore, it is recommended to choose a ramp with a weight capacity that well exceeds the typical load to account for any unforeseen excess weight.

Setting Up for Safe Operations

Ensuring a safe environment is pivotal during the loading of livestock onto trailers. Detailed preparation and meticulous attention to safety measures reduce the risk of accidents and injuries.

Preparing the Loading Area

The loading area should have a level, non-slip surface to maintain stability and prevent slips. It's critical to check the slope of the area; it must be minimal to avoid undue stress on the livestock during ascent. They also ensure the space is clear of any obstructions that could pose a hazard.

Checklist for Area Preparation:

Ensure the ground is level and stable.

Verify the presence of non-slip surfaces.

Assess the slope; it should be as flat as possible.

Remove potential obstacles from the area.

Securing the Ramp

To secure the ramp, they must properly attach safety chains or other securing devices to the trailer to prevent movement during loading. The ramp itself should be checked for any damages such as cracks or weak spots that could jeopardize its integrity.

Ramp Security Measures:

Attach safety chains firmly to the trailer.

Inspect the ramp for any signs of damage before use.

Using Spotters for Guidance

Spotters play a critical role in guiding the livestock onto the trailer safely. They position themselves where they can clearly see and direct the movement, ensuring the animals ascend the ramp correctly and enter the trailer without incident.

Guidance Protocol:

Use a spotter to guide the livestock up the ramp.

The spotter should have an unobstructed view of the animals and the ramp.

Clear communication between the spotter and loader is essential.

Loading Techniques and Best Practices

The proper loading of livestock onto trailers is vital for ensuring animal welfare and operational efficiency. This section details the methods and best practices for handling livestock during loading, the use of gates and side panels, and strategies to optimize efficiency.

Handling Livestock During Loading

When loading cattle, one must approach the task with calmness and patience, as stress-free handling is key to preventing injury to both the livestock and handlers. Trained personnel should guide the animals onto the ramp, using barriers strategically to direct movement. Livestock should never be rushed or forced aggressively, as this can lead to resistance and potential harm.

Effective Use of Gates and Side Panels

Gates and side panels are crucial for safely guiding livestock into a trailer. They should be positioned to create a clear path for the animals, minimizing distractions and areas where they might veer off course. These barriers must be sturdy and secure, as animals may press against them during loading.

Proper setup of gates and panels:

Ensure gates swing freely and latch securely.

Position side panels to prevent escape and reassure the animals with a visual barrier.

Optimizing Loading Efficiency

To optimize loading efficiency, plan and prepare the site layout in advance. This will ensure smooth movement of the cattle from holding areas to the loading ramp. Streamlining the process reduces loading time and decreases stress on the livestock.

Steps for efficient loading:

Pre-arrange the holding pens to align with the ramp.

Schedule loading to minimize waiting time and congestion.

Train staff in loading procedures to maintain a steady flow of movement.

Maintenance and Care

Proper maintenance and care are pivotal for ensuring both the longevity and safe operation of a portable loading ramp used for loading livestock onto trailers. A well-maintained ramp fosters reliability and durability.

Regular Inspection Routines

Inspect Your Ramp: Scheduling regular inspections is vital. They must assess structural integrity, welds, and surfaces for any signs of wear or damage. Indicators to look for include cracks, corrosion, or any deformities that could compromise the ramp's strength.

Weekly checks for superficial damage

Monthly in-depth examinations of structural components

Immediate inspection post any incident that might cause damage

Cleaning and Upkeep

Clean the Ramp: Maintaining a ramp in a clean state extends its life. Remove debris, dirt, and any spillages promptly.

Daily sweeping to clear surface dirt

Bi-weekly washing with appropriate cleaners to remove stubborn stains or spill residues

Prevent Slipping: Ensuring the ramp remains free from substances that could cause slipping is crucial for operator safety.

Apply non-slip coatings as necessary

Check and maintain traction surfaces regularly

Long-Term Durability Strategies

Care for Moving Parts: Regular lubrication of all moving parts—hinges, levers, wheels—is required.

Use appropriate grade lubricants

Follow manufacturer guidelines for lubrication intervals

Protective Measures: Implement procedures to protect the ramp from harsh weather and overloading.

Use ramp covers or store under shelters when not in use

Adhere to the ramp's weight capacity limits without exceptions

Expert Assessment: Engage with professionals for annual maintenance review and repair.

Have certified technicians conduct annual maintenance

Keep maintenance logs for reference and warranty purposes

By following these maintenance and care guidelines, a portable loading ramp can sustain its functional integrity and continue providing undeniable value in the safe and efficient loading of livestock.

Advanced Ramp Features

When dealing with livestock, the advanced features of portable loading ramps are critical for safe and efficient operation. These features are designed to provide enhanced safety for animals and ease of use for handlers.

Enhanced Non-Slip Surfaces

High-quality portable loading ramps often incorporate non-slip surfaces to ensure maximum traction for livestock during loading and unloading. This is particularly important in adverse weather conditions, where surfaces can become slippery. An example of such a system includes surfaces with textured patterns or rubber coatings that increase the friction beneath the animals' hooves, significantly reducing the risk of slips and falls.

Hydraulic and Adjustable Systems

Modern portable loading ramps may come equipped with hydraulic systems for easy height adjustment. These systems allow handlers to perfectly align the ramp with the trailer, accounting for varying trailer heights and ground levels. Here are some specifics on hydraulic and adjustable features:

Ease of Use: Simply operated with a hand pump or an electric motor.

Versatility: Accommodates different vehicle heights.

Time Efficiency: Rapid elevation changes as compared to manual adjustments.

Specialized Ramps for Specific Projects

For loading livestock, it is crucial to use specialized ramps that cater to the needs of specific animals, like a cattle loading chute. These ramps often have features designed to handle the particular behavior and requirements of the livestock type, including:

Siderails: Higher rails to prevent cattle from jumping off.

Width: Adequate space for animals to move up and down without stress.

Durability: Strong materials that can withstand repeated use by heavy animbals.

Each of these advancements in ramp technology plays a crucial role in streamlining the process of loading livestock onto trailers while prioritizing animal welfare and handler safety.

Logistical Considerations

When integrating portable loading ramps for livestock trailers, attention must be paid to compatibility with trucks and trailers, the specificity of loading vehicles and heavy equipment, and the efficiency of warehouse and bulk loading procedures.

Integrating with Trucks and Trailers

The connection between the portable ramp and the receiving semi-trailer or truck is critical for safe loading and unloading of livestock. Ramps should be adjustable to match the height of different vehicles and have secure locking mechanisms to ensure a tight, gap-free fit.

Securement: Ramps must be secured with chains or appropriate connectors.

Height Adjustment: The ramp incline should be minimal to prevent stress on animals during ascent or descent.

Loading Vehicles and Heavy Equipment

Loading vehicles such as tractors or loaders and heavy equipment onto trailers via portable ramps requires stability and strength.

Weight Capacity: The ramp must support the weight of the heaviest equipment.

Traction: Surfaces should offer grip to prevent slips, especially under wet conditions.

Warehouse and Bulk Loading

Efficient movement of cargo into warehouses or onto transport for bulk loading hinges on the accessibility provided by the ramp.

Ramp Width: Wide enough to accommodate varying sizes of pallets and bulk containers.

Smooth Transitions: Level-off areas at the top of ramps aid forklifts and carts in moving cargo on and off trailers.

Ensuring that portable ramps are properly integrated with transport vehicles, capable of loading heavy equipment, and conducive to warehouse operations is fundamental to maintain a safe and efficient loading process.

Safety Precautions and Tips

When it comes to using a portable loading ramp for loading livestock onto trailers, prioritizing safety precautions is crucial to minimize the risk of injuries and ensure a smooth operation. These tips focus on maintaining stability, adhering to safety protocols, effective management, and preparedness for emergencies.

Avoiding Common Injuries

To prevent common injuries, one must ensure the stability of the portable ramp. This includes routine checks for any signs of damage, such as cracks, bends, or rust. It's imperative to select a ramp that is appropriate for the specific task, considering the weight and size of the livestock being loaded. Additionally, keeping the ramp's angle low aids in reducing the likelihood of accidents, which is especially significant when handling livestock, as sudden movements can lead to instability.

Stability Checks: Perform daily inspections of the ramp's surface and structure.

Appropriate Selection: Choose ramps designed to support the type and weight of livestock to be loaded.

Emergency Procedures

In the event of an emergency, having clear procedures in place is essential. This includes having easy access to first-aid equipment and ensuring that all personnel know how to use it. Additionally, emergency contacts should be clearly displayed, and all workers must be familiar with the process for contacting veterinary services if livestock are injured during loading. Safety equipment, such as safety straps or chains, should be regularly checked to ensure they are in proper working condition.

First-Aid Readiness: Maintain a fully stocked first-aid kit and ensure all personnel know its location and usage.

Emergency Contacts: Display veterinary and emergency service contacts prominently at the loading site.

Training and Management

Effective management involves providing comprehensive training to all personnel involved in the loading process. Training should cover loading procedures, handling techniques, and use of safety equipment. Everyone must understand the importance of these safety measures, as proper training reduces the risk of accidents. Regular safety meetings and refresher courses can keep safety protocols top of mind for all involved.

Comprehensive Training: Train staff in specific procedures for handling livestock during loading.

Regular Refreshers: Hold frequent safety briefings to reinforce best practices and protocol adherence.

Conclusion

In the use of portable loading ramps for livestock, adhering to best practices is paramount for the safety of both the animals and handlers. The choice of ramp should align with the specific requirements of the task, considering factors such as weight capacity and adjustability to accommodate different livestock sizes.

Key Takeaways:

Safety: It is the number one priority. Ensuring ramps meet safety standards reduces the risk of injury.

Efficiency: Portable loading ramps provide an efficient method for loading livestock onto trailers, saving time and reducing stress for the animals.

Operation: The use of a hydraulic system can greatly enhance the precision and ease of ramp adjustment.

Durability: Selecting a robust ramp made from high-quality materials ensures longevity and reliability in use.

Ramp installation and maintenance are crucial for optimal performance. Handlers must be trained comprehensively on usage techniques and emergency procedures. Signs should be placed around facilities to remind staff of safety protocols.

Over time, adherence to these guidelines will foster a secure environment for livestock handling. Users who stay informed, prioritize animal welfare, and commit to regular ramp assessments will benefit from an improved loading process. The integration of well-designed, portable loading ramps is a step towards advanced livestock management practices.