On-Farm Meat Processing, Butchering, and Slaughter in Florida

Key Regulations and Practices

In Florida, on-farm meat processing opens a pathway for farmers to diversify their operations and add value to their livestock. Through this self-reliant approach, producers can directly cater to the growing local food movement, where consumers are increasingly interested in sourcing meat from known, responsible practices. On-farm butchering and slaughter not only offer a more intimate connection from farm to table but also allow farmers to bypass some of the logistical challenges and costs associated with using off-site processing facilities.

To participate in on-farm meat processing, Florida livestock owners must navigate a framework of state and federal regulations. These guidelines ensure food safety and animal welfare, while still supporting small-scale operations. In particular, the "custom exemption" as outlined by the USDA-FSIS provides a legal avenue for farmers to slaughter and process their meat for personal consumption, for the owner's household, non-paying guests, and employees.

Adhering to regulations, while embracing on-farm processing, gives producers control over every aspect of the meat production process—from raising the animal and overseeing its diet, health, and welfare, to the final step of processing. This level of oversight is appealing to consumers who prioritize transparency in their food sources, thereby fostering a deeper trust between local farmers and their communities.

Overview of On-Farm Meat Processing in Florida

On-farm meat processing in Florida allows livestock owners to control the quality of their meat through personal oversight. This processing includes various methods of on-farm slaughter and the utilization of custom exempt slaughterhouses.

Defining On-Farm Meat Processing

On-farm meat processing involves the slaughtering of animals and the subsequent butchering of their meat directly on the premises of a farm. In Florida, livestock owners have two primary avenues for legally processing their meat: slaughtering the animals themselves, or delivering them to a custom exempt slaughterhouse for processing. Custom exempt slaughterhouse processing is a practice regulated by the USDA-FSIS (United States Department of Agriculture - Food Safety and Inspection Service), where the meat cannot be sold and must be used exclusively by the owner’s household, non-paying guests, and employees.

Historical Context and Current Trends

The history of on-farm meat processing in Florida mirrors the state’s agricultural development. Traditionally, farmers and ranchers practiced on-farm slaughter as a way to ensure a direct supply of meat to the family table. Today, while on-farm processing is less common than commercial operations, it continues to be an important aspect for small-scale farmers and homesteaders who value self-sufficiency and local food systems. Current trends include an increased interest in local, sustainably raised meat, which has encouraged some farmers to consider on-farm processing to meet the demand for such products. Entities like the University of Florida have even established Meat Processing Centers to support educational and research endeavors in line with USDA-FSIS guidelines.

Regulatory Framework

The regulatory framework for on-farm meat processing in Florida is governed by a complex web of federal and state regulations to ensure food safety and public health.

Federal vs. State Regulations

Federal regulations are established by the United States Department of Agriculture's Food Safety and Inspection Service (FSIS) and provide overarching guidelines that must be followed nationwide. These include the Federal Meat Inspection Act, which mandates inspection of all meats intended for commercial sale. Under this federal umbrella, state regulations may operate but cannot be less stringent than federal requirements. States can maintain their own meat inspection programs, but these must be equivalent to the federal standards to receive the "at least equal to" status.

Key Agencies and Oversight

The Food Safety and Inspection Service is the federal agency responsible for ensuring that the nation's commercial supply of meat is safe, wholesome, and accurately labeled. At the state level, the Florida Department of Agriculture regulates food safety for meat processing facilities within the state. Meat processing facilities in Florida can choose to be either federally inspected by FSIS or state-inspected; however, USDA-inspected facilities can sell their products across state lines, while state-only inspected facilities are limited to intrastate commerce.

Florida Specific Regulations

In Florida, regulations specific to on-farm meat processing are enforced by the Florida Department of Agriculture, which monitors compliance with both federal and state regulations. The state provides a "Custom Exempt Slaughter" option, allowing owners to slaughter their livestock themselves or deliver it to a custom exempt slaughterhouse. However, the resulting meat cannot be sold and is strictly for the owner’s personal consumption. For those wishing to sell meat, they must do so through USDA-regulated channels to ensure the meat is safe for public consumption and meets all food safety standards.

Food Safety and Inspection Protocols

Ensuring the safety of meat products through rigorous inspection protocols is crucial. This section outlines the specific protocols and systems in place to maintain high standards in food safety and meat inspection processes.

Hazard Analysis and Critical Control Points (HACCP)

HACCP is a systematic preventive approach to food safety that identifies physical, chemical, and biological hazards in production processes. Meat processors in Florida must develop and follow an HACCP plan that includes:

Hazard Analysis: Identifying potential hazards that could occur in the food production process.

Critical Control Points: Establishing points in the process where risks can be controlled or eliminated.

Meat processors are required to monitor these control points and maintain records to verify that the HACCP system is functioning effectively.

Inspector Roles and Responsibilities

Food safety inspectors are responsible for enforcing the Federal Meat Inspection Act (FMIA) and associated regulations. Their roles include:

Conducting on-site inspections to evaluate the sanitary practices and operational procedures.

Ensuring that meat products are processed under sanitary conditions to prevent contamination.

Evaluating the implementation of HACCP plans and verifying compliance with food safety regulations.

Inspectors provide oversight and ensure that meat processing facilities adhere to legal and food safety standards.

Documentation and Compliance

Proper recordkeeping is a vital aspect of meat processing and inspection. All facilities must maintain detailed records, including:

Records of HACCP plan implementation and monitoring logs.

Documentation of actions taken when deviations occur.

Evidence of corrections to procedures to ensure continued compliance.

Compliance with these recordkeeping requirements is essential for traceability and verification that the meat processing operations maintain food safety standards.

On-Farm Slaughter and Exemptions

In Florida, on-farm slaughter and meat processing are subject to specific exemptions from federal inspection, provided certain criteria are met. These exemptions are crucial for small-scale livestock and poultry producers, enabling them to operate within specific regulatory boundaries.

Understanding Custom Exemptions

Custom exemptions allow livestock owners to have animals slaughtered and processed for personal use without the meat undergoing continuous federal inspection. These are applicable when the meat from the livestock slaughtered is not intended for sale. Meat processed under a custom exemption must be marked "not for sale" and can only be consumed by the owner, the owner’s family, and non-paying guests. In Florida, custom exempt operators manage facilities where these services are provided, ensuring compliance with the custom slaughter exemption standards.

Eligibility Criteria for Exemptions

To qualify for custom exemptions, a poultry producer or livestock owner must adhere to guidelines that govern on-farm slaughter. For poultry, there is a notable 20,000-bird exemption where producers can slaughter and process up to this number of birds annually for direct sales within the state. These sales can occur directly to consumers or to hotels, restaurants, and retail stores, provided they are within intrastate commerce.

Retail exempt facility: Such entities can sell meat processed at a USDA-inspected facility, yet they are limited in the volume they can market directly to consumers.

On-farm slaughter: This is generally reserved for personal consumption unless falling under a designated exemption bracket.

Limitations and Prohibitions

Despite the allowances, exemptions come with specific limitations:

Meat from custom exempt facilities must be used solely by the individual or family who owns the animal and cannot be sold.

Meat sold under the 20,000-bird exemption must meet state guidelines and cannot cross state lines, as it is not federally inspected.

Advertising for the sale of meat processed under these exemptions is strictly regulated to ensure it does not mislead consumers about the nature of the processing.

These exemptions aim to balance food safety with the practicalities of meat science and small-scale farming. They respect the exemption process while providing guidelines for poultry producers, custom exempt operators, and retail exempt facilities, ensuring public health and product quality.

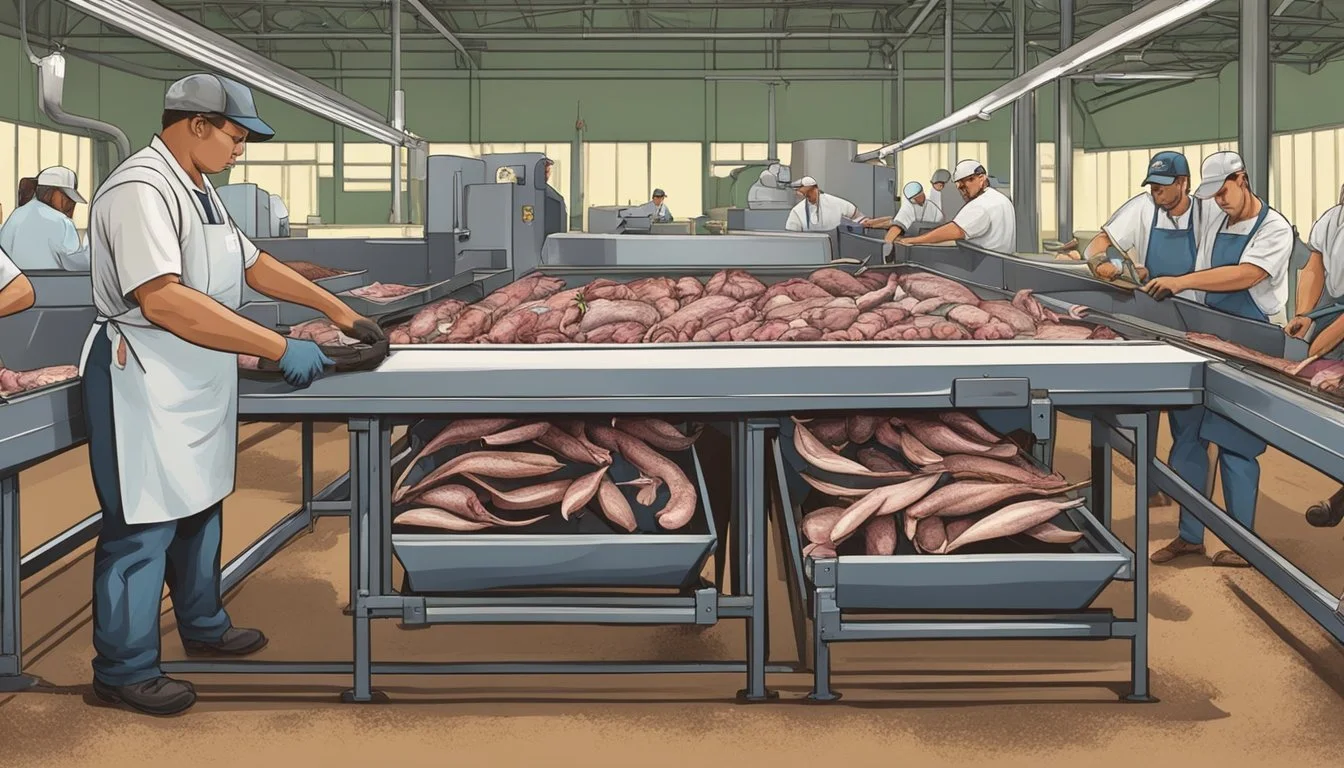

Slaughtering and Processing Operations

In Florida, the operations involved in on-farm slaughtering and meat processing are diversified, involving both mobile and fixed facilities, with an aim to address the needs of various species, including livestock, poultry, and cattle. These operations facilitate not just the humane slaughtering of animals but also provide opportunities for further processing and value-adding to the meat products before they reach the market.

Mobile Slaughter Units

Mobile slaughter units represent a flexible solution for on-farm processing in Florida, proving particularly beneficial for farmers with small herds of cattle or poultry. These units travel directly to the farm, reducing animal stress by eliminating the need for transportation to distant facilities. Species-specific mobile processing units are equipped to handle different types of livestock, ensuring compliance with regulations and humane treatment during slaughter.

Pros:

Reduced animal transportation stress

Convenience of on-site processing

Adaptability for different livestock species

Cons:

Limited processing capacity

Requisite adherence to USDA regulations

Fixed On-Farm Facilities

Fixed on-farm facilities offer farmers control over the entire slaughter and meat processing operation. These designated structures are required to meet stringent sanitary standards, as well as adhere to regulations laid out by federal and state agencies. Facilities are often designed for processing a specific species such as beef cattle, providing tailored equipment and environments conducive to effective and humane processing.

Facility Requirements:

Proper restraint and stun areas

Sanitation protocols

Compliance with humane handling regulations

Further Processing and Value-Adding

Following primary processing, Florida's on-farm facilities may also engage in further processing and value-adding activities. These processes transform basic meat cuts into ready-to-cook or ready-to-eat products, and can include smoking, curing, or packaging the meat. Such value-added products are a way for farms to differentiate themselves in the market, catering to niche demands or premium segments.

Processing Techniques:

Smoking

Curing

Sausage making

Packaging

Each of these touring points represents an integral part of a complex system designed to deliver safe, high-quality meat products from Florida farms to the consumers' tables.

Business and Marketing Approaches

In Florida, the success of on-farm meat processing relies on astute business and marketing strategies. These strategies include pinpointing specific target markets and fostering relationships with various end users, alongside leveraging alternative sales channels to distribute the product effectively.

Identifying Target Markets

For meat processors in Florida, the first step in developing a strong marketing plan is to identify key target markets. This could include local restaurants, hotels, and retail stores seeking high-quality, farm-raised meats. Establishing a clear understanding of the demands within these markets allows processors to tailor their offerings. Farmers should also consider targeting Community Supported Agriculture (CSA) members, who value local and sustainably sourced products.

Building Relationships with End Users

Once target markets are identified, building and maintaining relationships with end users becomes paramount. Meat processors should focus on forming partnerships with restaurants and hotels that prefer sourcing their meats from local farms. This not only ensures a stable customer base but also can create a niche market, satisfying the demand for farm-to-table dining experiences. Establishing trust with these entities by ensuring consistent quality and reliable delivery is essential.

Alternative Sales Channels

Exploring alternative sales channels can offer Florida meat processors additional revenue streams. For example:

Farmers' markets: They provide direct access to consumers and can foster personal connections between the producer/grower and the end user.

Online platforms: They can widen the reach, allowing customers to place orders directly for home delivery.

Subscription models: Initiating a meat subscription service can promise steady business and a loyal customer base.

Institutions like schools and hospitals also present opportunities, but these generally require adherence to specific supply and safety standards. By incorporating a mix of sales channels, meat processors can expand their market presence and enhance their business resilience.

Impact and Challenges

On-farm meat processing in Florida has significant repercussions for the local economy, public health, and environmental sustainability. These effects have been particularly highlighted by the recent challenges posed by global events.

Economic Impacts on Local Communities

Local Economy: On-farm meat processing can bolster Florida's economy by providing jobs and keeping money within local communities. When farmers choose to process meat on-site, they generate employment opportunities for butchers and support staff. Furthermore, by selling directly to consumers or through local food services, farms contribute to a circular economy where money spent on local products stays within the community.

Retail Meat Sales: Small-scale farms engaged in on-farm processing often sell their products directly to consumers, commanding higher prices due to direct marketing. However, the costs associated with ensuring quality and adhering to regulations can reduce margins. Custom processors are integral to this local supply chain, as they often provide services to multiple small farmers, enabling retail meat sales at a more sustainable scale.

Challenges Posed by COVID-19 Pandemic

Supply Chain Disruption: The COVID-19 pandemic introduced major disruptions to meat processing, primarily due to worker illness, leading to reduced processing capacity. In Florida, this emphasized the importance of local on-farm processing as central processing facilities faced closures or slowed operations, creating bottlenecks in the meat supply chain.

Public Health Concerns: Outbreaks of COVID-19 in larger meat processing facilities underscored the need for more controlled, smaller-scale processing operations. On-farm processing units, where they can ensure adherence to health protocols, presented a potentially safer alternative to large, crowded processing plants, lessening the risk of widespread contagion.

Sustainability and Ethical Considerations

Meat Quality and Animal Welfare: On-farm processing is generally perceived to offer superior meat quality, as stress in animals during transport to slaughter can negatively affect the quality of the meat. Ethical considerations also come into play, with a shorter supply chain allowing for more oversight of animal welfare standards.

Environmental Footprint: Smaller-scale, on-farm processing operations are believed to have a reduced environmental footprint compared to large centralized facilities. This is due to a decrease in transportation requirements and the potential for incorporating sustainable practices such as waste repurposing and energy-efficient equipment. However, achieving the delicate balance between operational efficiency and sustainability remains a challenge for many Florida farms.

Resources and Support Networks

In Florida, on-farm meat processors have access to a variety of resources and support networks aimed at enhancing their operations. These include educational materials to ensure compliance with safety regulations and associations offering professional guidance.

Educational Resources and Training

The Niche Meat Processor Assistance Network (NMPAN) serves as a key resource for on-farm meat processing education. They provide webinars, videos, and information on topics such as Mobile Slaughter and Processing (MSU) operations, which are vital for those looking to expand or establish mobile processing units.

USDA Grants: Processors can receive support through USDA grants and must develop Sanitation Standard Operating Procedures (SSOPs) and a HACCP plan. The USDA conducts on-site reviews to ensure regulatory compliance.

Professional Associations and Support Groups

The American Association of Meat Processors (AAMP) is North America’s largest meat trade organization. It supports small to medium-sized meat businesses, including those involved in on-farm processing. Membership provides crucial industry contacts and resources.

NMPAN also acts as a support network, connecting processors with regulatory specialists, such as those within the Department of Agriculture, for personalized assistance. These specialists provide processors with regulatory guidance, helping them navigate the complexities of meat processing regulations.

By utilizing these educational materials and support groups, on-farm meat processors in Florida can maintain high standards of safety and quality, while also ensuring regulatory compliance.

Conclusion

In this section, the crucial elements associated with on-farm meat processing within the state of Florida are underscored, notably centering on the projection of this sector's evolution.

Future Outlook for On-Farm Processing in Florida

The trajectory for on-farm processing in Florida shows signs of evolution, thanks in part to a growing emphasis on local food systems and transparency in meat production. Custom meat operations, under the custom exemption, reflect a significant part of this sector. They are pivotal for farmers who wish to sell meat directly to consumers without a USDA inspection, provided the meat is not for resale and is for personal consumption.

Local regulations in Florida require that farmers engaging in animal slaughter for custom meat must either perform the slaughter on their premises or utilize custom exempt slaughterhouses. They must also ensure that the products are not sold in the conventional marketplace. This pathway continues to draw attention, mirroring a national trend towards more intimately scaled, locally-focused meat production akin to practices found in states like New Jersey, albeit with tailored local protocols.

Addresses and names of the custom exempt slaughterhouses are essential for networking and trust-building between consumers and producers. The clarity in documentation and transparency in operations position these entities as cornerstones for future expansion in the local meat processing industry.

The on-farm processing landscape in Florida is anticipated to adapt and respond to changes in consumer preferences, regulatory adjustments, and market demands. Those involved in this industry must navigate a complex web of statutes and expectations, balancing the needs for safety, quality, and economic viability. The informed farmer or entrepreneur stands well-placed to leverage Florida's evolving marketplace for on-farm butchery and meat processing.