On-Farm Meat Processing, Butchering, and Slaughter in Georgia

A Guide to Local Operations

On-farm meat processing in Georgia offers an alternative to traditional slaughterhouses by allowing farmers to process livestock directly on their property. This approach to butchering and slaughter not only shortens the supply chain but also provides the producer with greater control over the quality and handling of their meat products. By addressing demands for local and responsibly raised meat, on-farm processing is becoming a more common practice among Georgia farmers.

Establishing an on-farm slaughter facility involves navigating various regulations and obtaining the proper licensing. In Georgia, farmers must comply with state and federal rules, which include obtaining a mobile meat license from the Georgia Food Safety Division if off-farm sales are intended. The facilities must be designed to ensure sanitary conditions and proper handling of animals to meet health standards and reduce stress for the livestock.

The popularity of on-farm butchering in Georgia reflects a national trend where farmers and consumers are increasingly interested in local food systems. This model empowers farmers to have a hand in all stages of meat production, from raising the livestock to processing and marketing. Despite challenges such as capital investment and adherence to regulations, on-farm meat processing is a burgeoning component of Georgia's agricultural landscape, providing an essential service to small-scale farmers and local markets.

Understanding On-Farm Meat Processing

On-farm meat processing involves the slaughter and butchering of livestock on the premises where they are raised. This process requires adherence to regulations and an understanding of the methods and rationale behind it.

Basics of Meat Processing and Slaughter

Meat processing and slaughter refer to the methods used to transform livestock into ready-to-cook meat products. The process includes several steps, starting from the humane slaughter of the animal and followed by skinning, eviscerating, and sectioning the carcass into appropriate cuts. Compliance with USDA regulations is crucial at every stage to ensure food safety and quality.

On-Farm Butchering Essentials

On-farm butchering requires specific knowledge and tools to ensure the meat is processed safely and efficiently. Essential equipment includes knives, saws, and meat grinders. Producers must be aware of two categories of meat based on regulatory compliance: "custom" for personal use and "state-inspected" where USDA inspectors or state equivalents oversee the process, thus permitting the sale of the meat.

Rationale for On-Site Processing

On-site processing offers producers control over their meat products and can potentially provide financial resilience amid fluctuating market prices. It allows for direct marketing of meat products and can cater to the increasing consumer demand for locally sourced and processed meats. Furthermore, this approach helps avoid the bottleneck in meat processing capacity, often experienced by centralized facilities.

Regulations and Compliance

The landscape of on-farm meat processing in Georgia is shaped by stringent regulations and compliance standards, primarily designed to ensure food safety and public health.

USDA Regulations and Food Safety

The United States Department of Agriculture (USDA) sets federal regulations governing livestock and poultry slaughter as well as meat processing. Establishments that undertake these activities must adhere to USDA guidelines, which focus on food safety and sanitary operations. USDA regulations require daily inspection of federally regulated slaughter and processing facilities to ensure compliance. Farmers' Market Sales: Facilities processing meat must comply with USDA inspection requirements even if the product is destined for farmers' markets.

State Specific Guidelines: Georgia

In Georgia, the Georgia Department of Agriculture (GDA) mirrors federal mandates and may impose additional state-specific regulations to manage meat processing activities. They conduct daily inspections of state facilities and routine inspections of exempt establishments. Establishments must also follow GDA regulations for livestock and poultry slaughter as well as for meat processing. The state oversees meat compliance and maintains standards consistent with, and sometimes exceeding, federal food safety requirements.

COVID-19: Modifications or temporary guidelines may be established in response to public health emergencies such as the COVID-19 pandemic.

Farmers' Legal Considerations

Farmers and owners of meat processing facilities in Georgia need to be informed about legal considerations including health and sanitation regulations, waste disposal, and building requirements specific to meat processing. Compliance with the Food Safety and Inspection Service (FSIS) is crucial for the legal operation of mobile slaughter units (MSUs) and on-farm processing activities.

Exemptions and Sales: Federal regulation allows for certain producer/grower exemptions. Understanding these exemptions and how they apply to sales to hotels, restaurants, institutions, and retail stores is essential for legal operation.

Farmers must navigate a complex web of laws that dictate every aspect of on-farm meat processing, from animal handling and slaughter to processing and sale of the meat products. Compliance with these laws not only ensures public health but also the viability of the local meat industry in Georgia.

Animal Welfare and Ethics

In Georgia, the practices of on-farm meat processing and butchering are closely regulated to ensure the welfare of animals and adherence to ethical standards. The focus is on implementing humane slaughter practices and reducing stress for livestock throughout the process.

Humane Slaughter Practices

Georgia's regulations mandate that slaughter methods should induce immediate unconsciousness in animals before death to minimize suffering. Stunning techniques are a critical aspect of humane slaughter and include methods such as captive bolt pistols, electric stunning, and gas stunning. These methods are constantly monitored for their efficiency and effectiveness in providing a quick and painless transition for the animal.

Captive Bolt Pistol: Delivers a forceful strike to the animal's skull, causing immediate unconsciousness.

Electric Stunning: Uses controlled electric currents to render the animal unconscious quickly.

Gas Stunning: Involves the use of gas mixtures like carbon dioxide to sedate the animal before slaughter.

Reducing Stress for Livestock

Minimizing stress for livestock during their final moments is a key element of animal welfare. Stressful conditions can affect not only the moral considerations of slaughtering but can also directly impact the quality of the meat produced. Strategies for reducing stress in livestock include:

Providing comfortable holding areas with adequate space.

Ensuring gentle handling by trained personnel.

Designing facilities that facilitate a calm and direct movement towards the slaughtering area.

Avoiding loud noises or sudden movements that can startle the animals.

By implementing these measures, farmers and processors in Georgia aim to uphold a high standard of animal welfare and ethical responsibility in on-farm meat processing, butchering, and slaughter.

Economic and Market Considerations

The movement toward on-farm meat processing in Georgia reflects a response to market demands and economic incentives. Local farmers seeking to maximize income and maintain a competitive edge are increasingly exploring on-farm slaughter and butchering.

Market Access for Small Processors

Small processors in Georgia face unique challenges and opportunities in gaining access to markets. The ability to process meat on-site allows for direct sales to consumers, which can lead to increased local market penetration and enhanced brand recognition. However, it also requires navigating state and federal regulations to ensure access to broader markets. The presence of fewer small-scale slaughter facilities can limit their reach, making it vital to understand and overcome these barriers to ensure successful market access.

Financial Impact on Farmers

For Georgia farmers, on-farm meat processing can significantly affect their financial bottom line. It eliminates the need for costly transportation to external processing plants and can quickly adapt to changing market demands. This agility can result in a higher income due to shortened supply chains and the added value of selling processed meat. Nevertheless, the initial investment in establishing an on-site slaughter facility can be substantial, and ongoing operational costs must be meticulously managed.

Grants and Funding Opportunities

Grants and federal funding have become more accessible, encouraging economic development in Georgia's meat processing sector. Programs like those announced by the USDA aim to support the expansion of processing capacity and improve the competitiveness of the meat and poultry processing industry. These funding opportunities provide financial assistance critical for small processors to overcome the capital-intensive nature of establishing and expanding on-farm processing capabilities. Access to these grants can facilitate infrastructure upgrades, job creation, and sustainable economic development within local meat markets.

Facilities and Equipment

In Georgia, the approach toward on-farm meat processing facilities necessitates a balance between functional design and the inclusion of essential equipment. Key considerations are ensuring compliance with USDA regulations and optimizing the process flow to enhance efficiency.

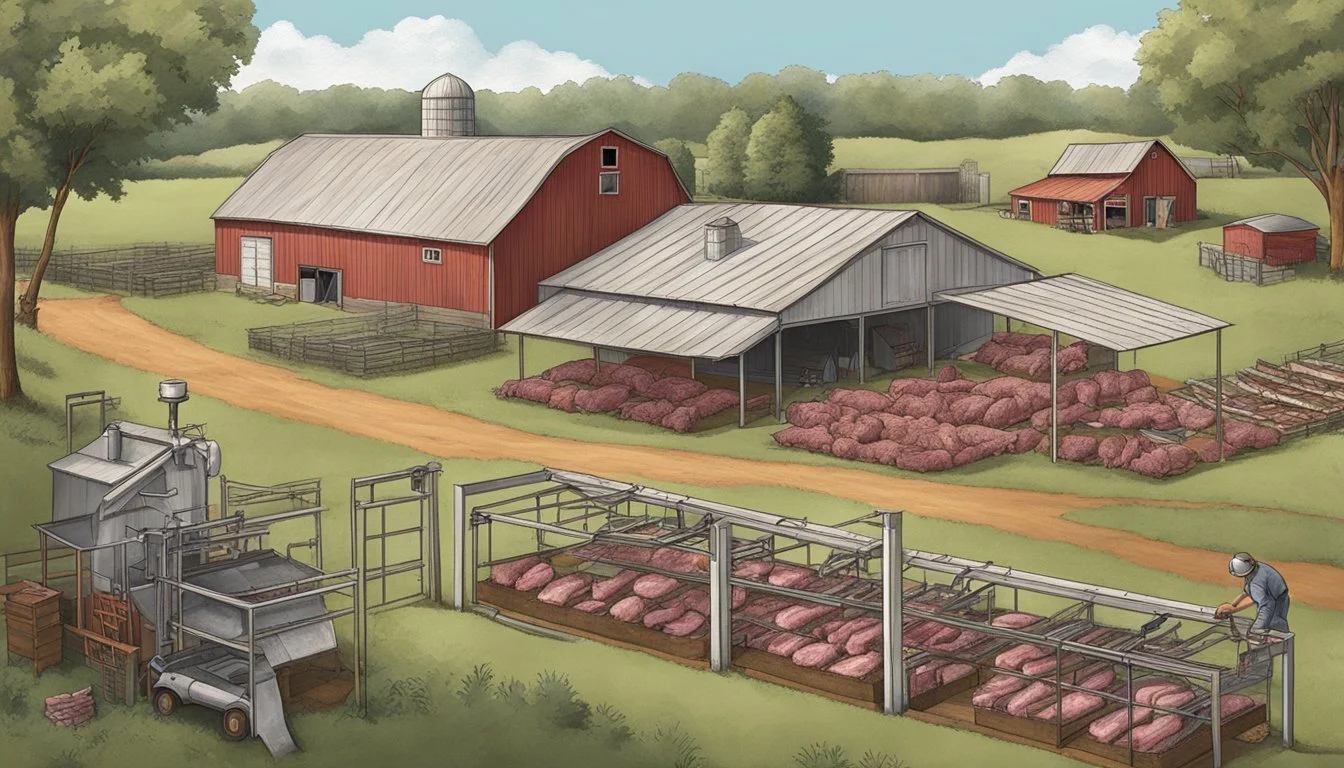

Designing a Slaughter Facility

A well-designed slaughter facility in Georgia should adhere to USDA compliance, which encompasses the integration of a Hazard Analysis Critical Control Point (HACCP) plan. The design must facilitate efficient animal movement and minimize stress to ensure humane handling, with distinct areas for different processing stages: killing, bleeding, scalding and dehairing (for swine), eviscerating, and chilling. The facility should be equipped with stainless steel tables, washable walls and floors, adequate drainage, and refrigeration systems to maintain meat quality and safety.

Key equipment within the slaughter facility includes:

Stunning devices: to ensure humane slaughter

Bleeding and processing tables: for efficient draining and butchering

Scalding tanks and dehairing machines (for swine processing)

Chilling units: crucial for meat preservation post-processing

Packaging equipment: for proper meat wrapping and storage

Mobile Slaughter Units and Their Advantages

Mobile slaughter units (MSUs) offer a versatile solution to on-farm processing in Georgia as they enable producers to process animals directly on the farm, significantly reducing animal stress and transportation costs. These units are essentially self-contained slaughter facilities on wheels, often taking the form of a trailer that can be moved from one farm to another.

Advantages of using MSUs include:

Flexibility: MSUs provide processing services to multiple farms, suiting small-scale operations.

Regulatory compliance: They can be designed to meet USDA standards, ensuring that meat is processed safely and legally.

Lowered investment: Instead of constructing fixed facilities, MSUs represent a lower capital cost option for farmers just starting with on-farm processing.

Managing Processing Bottlenecks

In Georgia, addressing the processing bottlenecks in meat production is crucial for maintaining a stable and efficient meat supply chain. Focusing on expanding processing capacity and fostering collaborations and co-ops are two strategies to manage and mitigate these challenges.

Expanding Processing Capacity

Expanding processing capacity is a direct approach to alleviate bottlenecks. Small processors are often at the heart of the issue due to limited operational capabilities. Investment in infrastructure is one strategy, potentially increasing throughput by adding cutting lines or extending operating hours. Training initiatives to enhance workforce skills can also lead to a more proficient processing operation, ultimately increasing the volume of meat that can be handled.

Key Investments:

Modern equipment

Facility expansions

Workforce training programs

Collaborations and Co-Ops

Collaborations and co-operative models present another viable solution to processing capacity challenges. By pooling resources, small processors can achieve a scale of operations that reduces per-unit costs and improves bargaining power for supplies and services. These co-ops could help streamline the logistical aspects of meat processing, allowing member farmers to focus on rearing livestock while the co-op handles processing and distribution.

Co-Op Advantages:

Shared resources reduce individual costs

Centralized services streamline processing

Enhanced market access for members

Through these collective steps, the processing expansion can be realized, benefiting producers and consumers alike by ensuring a more reliable meat supply.

Techniques and Best Practices

Proper techniques and adherence to best practices in on-farm meat processing are crucial for ensuring high-quality meat and maintaining safety standards. These elements are foundational for successful butchering and processing livestock effectively.

Butchering Techniques and Meat Quality

Dry Aging: For enhancing flavour and tenderness, meat is hung in a controlled environment for several days to several weeks allowing enzymes to break down muscle tissue.

Sharp Tools: Sharp knives and proper butchering equipment ensure clean cuts and reduce the risk of contamination or uneven butchering that could compromise meat quality.

Correct Slaughter Method: Utilizing approved and humane slaughtering methods not only aligns with ethical standards but also affects the quality of meat. Stressful conditions can lead to poor meat quality, whereas calm and humane practices help maintain the integrity of the muscle fibers.

Safety and Hygiene in Meat Processing

Personal Hygiene:

Clean attire

Regular hand washing

Equipment Sanitization:

Immediate cleaning post-use

Regular maintenance checks

Facility Standards: Facilities must follow strict hygiene standards such as proper waste disposal, adequate ventilation, and pest control measures.

Food Safety Protocols:

Temperature control to prevent bacterial growth

Cross-contamination prevention through designated cutting areas

Adhering to these techniques and best practices significantly impacts the quality of meat products and the safety of the processing environment. It ensures that on-farm meat processing in Georgia meets the required food safety regulations and consumer expectations for high-quality meat.

Community and Environmental Impact

On-farm meat processing in Georgia has tangible impacts on community development and the environment, entwined with local economies and climate considerations.

Supporting Local Economies

On-farm processing can bolster the financial backbone of rural communities. It directly contributes to the local economy by creating jobs and circulating money within the community. For example, when farmers process meat on their land, they can often bypass intermediary steps, keeping a greater share of the profits local. This cycle of reinvestment encourages rural development and can lead to further business opportunities.

Job creation in processing and related services

Increased income retention within the community

Expansion possibilities for ancillary local businesses

Additionally, on-farm processing facilities can strengthen relationships with neighbors and nearby residents by offering fresh, locally-sourced products, emphasizing the farm-to-table connection.

Climate Considerations for On-Farm Processing

The environmental impact of on-farm processing centers on its potential to mitigate climate change. By reducing the need for transportation of livestock to remote processing facilities, on-farm processing can lower carbon emissions. This localized approach aligns with efforts to meet climate goals by minimizing the environmental footprint of meat production.

Key Environmental Points:

Reduced transportation: Lowers greenhouse gas emissions

Localized waste management: Potentially limits pollution of waterways and lands

However, it's crucial for these on-farm operations to implement sustainable waste management practices to prevent environmental degradation. Comprehensive manure management and appropriate waste disposal are essential to protect local ecosystems.

In Georgia, supporting environmental stewardship in on-farm processing not only helps in meeting climate actions but also preserves the state's natural beauty for future generations and maintains a healthy habitat for wildlife.

Industry Developments and Future Outlook

The Georgia on-farm meat processing sector anticipates growth, driven by a focus on sustainability and technological innovation, to meet future demand and challenges.

Trends in Sustainable Meat Processing

Georgia's meat processing industry is increasingly adopting sustainable practices in response to consumer demand and regulatory pressures. They are exploring avenues like on-farm slaughtering to shorten the supply chain reducing transportation emissions and stress on animals. Additionally, there's an emphasis on waste reduction through composting and recycling by-products, which aligns with the broader goal of creating a more circular economy within the sector.

Research and Technological Advances

Research in Georgia has focused on enhancing meat quality and safety through technology. Adoption of advanced refrigeration and packaging techniques has improved shelf life and reduced food waste. Cutting-edge biotechnology research is also underway to develop safer and more effective methods of disease prevention, potentially increasing overall production efficiency. The state is seeing more investments in automation and data analytics to optimize process flows and traceability, preparing the industry for the future.

Additional Resources and Expert Insights

In Georgia, on-farm meat processing is both a burgeoning trend and a complex undertaking, demanding a depth of knowledge in regulations, animal husbandry, and meat science. A network of established educational resources and hands-on training opportunities facilitate these requirements for farmers and producers.

Educational Material from Top Institutions

Ohio State University and Ohio State University Extension provide a wealth of information pertinent to on-farm meat processing. Their extension programs are particularly valuable, offering comprehensive guides that encompass:

Regulatory compliance for meat processing

Best practices in animal welfare

Understanding of meat quality and safety

Farmers can access these materials directly through the university's websites or through cooperative extension offices in Georgia.

Workshops and Training Opportunities

Farmers seeking practical, hands-on experience have various workshops and training sessions at their disposal. These workshops are designed to deliver expert knowledge and skill-building lessons in:

Slaughtering techniques;

Butchery and meat processing;

Business management for meat processing.

Workshops provided by educational institutions like Ohio State University often collaborate with industry experts to ensure that the curriculum remains up-to-date and relevant. Local agricultural agencies may also host events, focusing on Best Management Practices (BMPs) and cutting-edge processing technologies.