On-Farm Meat Processing, Butchering, and Slaughter in Alabama

A Comprehensive Guide

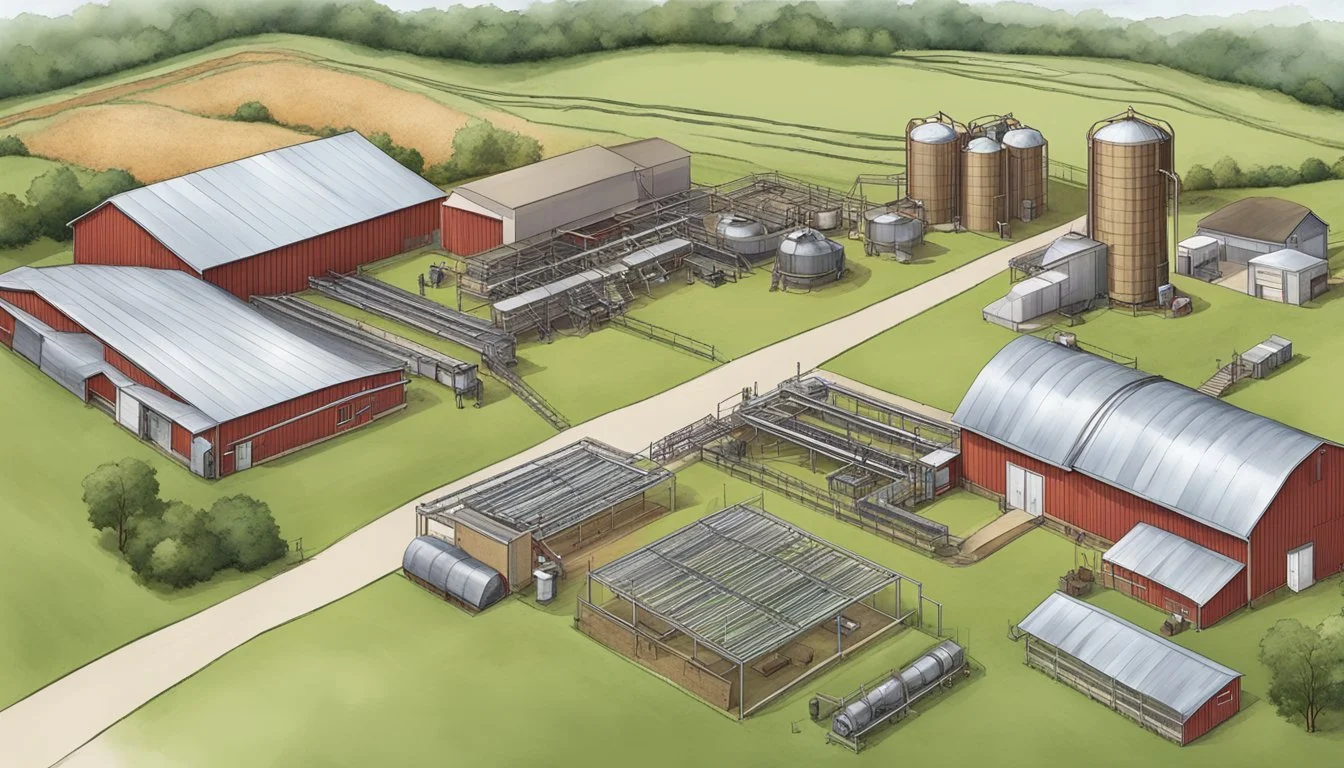

In the state of Alabama, a movement towards on-farm meat processing is shaping the landscape of livestock slaughter and butchery. This trend towards localized processing embraces a model where the resources of a farm are used to handle the processing and butchering of meat on site, providing farmers with direct control over the quality and handling of their products. With this approach, Alabama's producers are capitalizing on the growing consumer interest in locally sourced and processed meats, leveraging the increased traceability and transparency that on-farm processing offers.

While on-farm meat processing presents numerous advantages, it also requires adherence to stringent regulations to ensure food safety and animal welfare. In Alabama, facilities involved in such activities must navigate the complexities of state and federal laws, including those overseen by the Alabama Department of Agriculture and Industries and the United States Department of Agriculture's Animal and Plant Health Inspection Service. These entities ensure that meat products are safe, wholesome, and correctly labeled, serving as essential partners for farmers in complying with the regulations.

Adopting on-farm processing in Alabama is not without its challenges, which range from significant capital investments to mastering the regulatory landscape. Despite the hurdles, some Alabama producers have found success, establishing on-farm processing as a viable option to strengthen their economic resilience. The process allows farmers to add value to their products while meeting the demands of a market increasingly concerned with the origins and handling of meat.

The Importance of On-Farm Meat Processing

On-farm meat processing in Alabama encompasses both safety and economic aspects, particularly in relation to beef and poultry. It ensures meat quality while contributing to local economies.

Food Safety and Quality Control

On-farm processing gives farmers direct control over the safety and quality of their meat products. This control is critical in ensuring that beef and poultry meet established safety standards, thereby minimizing the risk of foodborne illnesses. Alabama producers are able to implement a stringent safety protocol throughout the butchering and slaughtering process, often exceeding what is required by industry regulations.

Traceability: On-farm processing facilities maintain detailed records, allowing for complete traceability from farm to table.

Hygiene Practices: Strict hygiene practices are enforced to ensure that meat products are handled in a clean and sanitized environment.

Benefits to Local Economy

The operation of on-farm meat processing facilities contributes noticeably to Alabama's local economy. By having the capacity to process meat on-site, farmers can circumvent bottlenecks at larger processing facilities, reducing delays and potentially increasing their profit margins.

Job Creation: New on-farm processing roles provide employment opportunities within the community.

Economic Circulation: Money spent on local meat processing tends to stay within the community, fostering economic growth.

By focusing on both food safety and economic benefits, on-farm meat processing in Alabama presents a viable approach to meat production that sustains local communities and ensures high-quality, safe consumer products.

Understanding Alabama's Regulations for Meat Processing

Alabama's meat processing regulations are designed to ensure food safety and public health. The state operates a Meat and Poultry Inspection Program that aligns with federal standards, and businesses involved in meat processing must adhere to strict licensing and compliance requirements.

State Meat Inspection Program

Alabama administers a State Meat Inspection Program that functions in accordance with the Federal Meat Inspection Act (FMIA). This program requires that all slaughtering and processing establishments within Alabama meet regulations that are "at least equal to" those set federally. These standards help to maintain a food supply that is safe, wholesome, and correctly labeled and packaged.

The key responsibilities of the State Meat Inspection Program include:

Inspecting all slaughter and processing facilities within the state.

Ensuring that state laws, regulations, and procedures related to meat inspection are diligently followed.

Compliance with these regulations is necessary for any business that wishes to operate within the state in the realm of meat processing.

Licensing and Compliance

For a meat processing or slaughter facility to operate legally in Alabama, they must obtain the proper licensing and comply with state regulations. To this end, the Alabama Agriculture and Industries Department outlines specific procedures and requirements for businesses.

Important aspects of licensing and compliance include:

Submitting to regular inspections to verify adherence to health and safety standards.

Ensuring proper sanitary conditions and humane handling during slaughter.

Entities engaging in custom slaughter or processing operations must also follow specific code sections, namely Code of Ala. § 2-17-27. Facilities are urged to be attentive to these laws to avoid penalties and ensure the integrity of their operations.

The Process of Slaughtering Livestock

The slaughtering of livestock on Alabama farms involves stringent procedures designed to ensure humane treatment and high-quality meat production. These processes are regulated to minimize stress and adhere to specific techniques tailored to different types of animals.

Humane Handling and Stress Reduction

To ensure the welfare of livestock pre-slaughter, farms must prioritize humane handling and stress reduction. It is well-established that stress can negatively affect the quality of meat, making this a critical component of the slaughter process. For cattle and sheep, this entails the use of a chute system to limit physical movement. Hogs might require different handling techniques due to their different physiques and behaviors.

For cattle: Restrained in a chute to limit movement

For sheep: Similar handling as cattle, with species-specific considerations

For hogs: May be guided individually or in small groups to provide a sense of security

Slaughter Techniques for Various Animals

The method of slaughter must be chosen with regard to the species in question to ensure a quick and painless end. Alabama farms generally employ two main methods of stunning: mechanical and chemical.

Mechanical Stunning:

Non-penetrating concussion (especially for euthanasia and Halal-compliant methods): A mushroom-style head device may be used, rendering the animal unconscious without penetrating the skull.

Penetrating (commonly used for cattle and sometimes for hogs): Pneumatic or cartridge stunners are employed where a bolt is driven into the brain.

Chemical Stunning:

CO₂ chambers (often used for hogs): An effective CO₂ stun requires at least 70% concentration in the chamber to ensure unconsciousness without pain.

Each technique has been studied and refined to minimize the stress on animals, which includes cattle, hogs, and sheep, contributing to the humane aspect of the slaughter process.

Mobile Slaughter Units in Alabama

In Alabama, the use of mobile slaughter units presents a viable solution for farmers to process meat on-site in a regulated and efficient manner.

Advantages of Mobile Slaughter

Mobile slaughter units bolster local economies by providing farmers the ability to process meat directly on their property. This leads to reductions in transportation costs, minimizes stress on the animals, and allows the farmers to oversee the entire process, ensuring quality and integrity of the product. These units come equipped with the necessary tools for slaughtering and butchering, usually following USDA regulations to maintain food safety standards. By using mobile units, Alabama farmers can access broader markets, selling their meat as local, freshly-processed products which often command higher prices.

The flexibility of these units contributes to their advantages:

Ease of scheduling: Farmers can arrange processing around their own timelines.

Reduced waste: On-site processing can decrease waste, as remains can be more easily repurposed as compost or other by-products.

Customization: Units can be tailored to specific needs, handling various types and sizes of livestock.

Island Grown Farmers Cooperative Model

The Island Grown Farmers Cooperative (IGFC) model represents a successful case study in the deployment of mobile slaughtering units. This cooperative approach involves several farmers pooling resources to use a shared mobile slaughter facility. It provides a framework that can be replicated in Alabama to support local agricultural communities.

Key elements of the IGFC model include:

A cooperative structure where farmers have shared ownership and investment in the unit.

The unit operates under USDA inspection, guaranteeing meat processed is eligible for sale across state lines.

IGFC offers training and support for farmers, ensuring adherence to safety and quality standards.

Alabama's agricultural community can look to the IGFC model for a roadmap on implementing mobile slaughtering units effectively, with emphasis on compliance, education, and cooperation among farmers.

On-Farm Butchering Techniques

On-farm butchering in Alabama requires skillful application of techniques that ensure the quality and safety of meat. Proper cutting, packaging, and understanding of meat science are essential for the best results.

Cutting and Packaging

Before butchering, it's important to have a clear plan for cutting and packaging, ensuring each step complies with health and safety standards. They begin by breaking down the animal into primary cuts: the chuck, rib, loin, round, flank, short plate, brisket, and shank for beef, for example. This is followed by fabricating these into retail cuts, such as steaks and roasts, which are then trimmed of excess fat and sinew.

Cutting should be precise to maintain the integrity of the muscles and optimize the meat's market value. After cutting, the meat is immediately packaged to preserve freshness. Vacuum-sealed packaging is commonly used for its ability to extend the shelf life of the product while protecting it from contaminants.

Aging and Meat Science

Aging is a crucial step that impacts the tenderness and flavor of meat. There are two main methods: wet aging and dry aging. Wet aging involves vacuum-sealing the meat in its own juices for several days to weeks, while dry aging requires hanging the meat in a controlled environment, where enzymes naturally tenderize the muscle tissues. It is vital to control the temperature, humidity, and airflow during the aging process to prevent spoilage and encourage desirable changes in the meat's structure.

Meat science encompasses understanding the changes in meat through age and processing. Butchers must comprehend how these changes affect texture, flavor, and safety. The enzymatic activity within the muscle fibers changes the meat's properties, and butchers apply their knowledge of these processes to optimize quality during butchering and aging.

Challenges and Solutions in Meat Processing Bottlenecks

In Alabama, the meat processing industry faces significant challenges involving supply and demand, particularly exacerbated by the COVID-19 pandemic. Addressing these issues requires an understanding of both the capacity constraints and the health implications on the industry.

Capacity and Demand Imbalances

The meat processing industry in Alabama has encountered considerable difficulties due to a disparity between slaughtering capacity and farmer demand. Mobile slaughtering units offer a potential solution by increasing on-farm processing capabilities, thus alleviating the pressure on fixed facilities. One solution being considered is the development of more on-farm facilities to ensure that farmers have greater control over the processing phase, thereby improving the supply chain resilience.

Key Issues:

Overloaded processing systems

Limited processing appointments for farmers

Increasing direct-to-consumer sales

Potential Solutions:

Expansion of mobile slaughtering units

Investment in on-farm processing infrastructure

Policy support for small-scale processors

COVID-19 Pandemic Implications

The COVID-19 pandemic has further strained the meat processing sector, with large plants experiencing temporary shutdowns leading to a ripple effect throughout the supply chain. During these closures, smaller local butchers became overwhelmed, creating an extensive backlog. Many livestock producers faced the prospect of scheduling butchering up to a year in advance, or in severe cases, resorting to euthanizing excess animals.

Impact of COVID-19:

Shutdowns of large processing plants causing supply disruptions

Increased demand on small, local butchers

Farmers facing extended wait times for meat processing

Response to COVID-19:

Adapting production lines to enhance safety and maintain operations

Incentivizing the diversification of processing capacity across facilities of various sizes

Encouraging development of alternative supply chains to distribute the processing load

Implementing these solutions requires the cooperation of farmers, processors, and policymakers to establish a more balanced and resilient meat processing infrastructure in Alabama.

Ethical and Environmental Considerations

In Alabama, on-farm meat processing, butchering, and slaughter raise distinct ethical and environmental challenges that require careful management and consideration to ensure sustainable practices and humane treatment of livestock.

Genetic Selection and Animal Welfare

Genetic Selection involves breeding livestock for specific characteristics to improve productivity and quality of meat. However, it must be balanced against Animal Welfare concerns. The conscious selection of genetics that do not compromise animal well-being is essential. It is incumbent on producers to ensure that traits such as disease resistance and stress tolerance are prioritized, thereby enhancing the resilience and health of the animals throughout their lifecycle, including during the slaughtering process.

Climate and Weather Impacts on Slaughter Operations

The operation of on-farm slaughter facilities is affected by Alabama's varying climate, with particular emphasis on Rain events. Heavy rainfall can impact the logistics of slaughtering, creating challenges in maintaining humane treatment and hygienic conditions. Careful scheduling and infrastructure design can mitigate rain-related disruptions, ensuring both ethical and environmental standards are maintained. Erosion control and water management systems must be in place to handle stormwater runoff, protecting local ecosystems from contamination and ensuring compliance with environmental regulations.

The Business of Meat Processing

In the state of Alabama, the business of meat processing on farms is a crucial link between local farmers and consumers. By focusing on developing strong relationships with the community and staying alert to market trends, these businesses can thrive.

Building a Customer Base

The success of on-farm meat processing in Alabama is heavily reliant on a strong customer base. Farmers need to prioritize product quality and safety to build trust and a loyal clientele. Local marketing efforts, such as participating in farmer's markets and community events, facilitate connections with consumers seeking fresh, locally processed meat. Additionally, direct sales strategies like subscription services and online platforms are increasingly effective in reaching consumers interested in supporting local agriculture.

Farmers may also benefit from collaborations with local restaurants and grocery stores, which can reinforce their product’s presence in the meat market and broaden their reach. Establishing a recognizable brand and maintaining a transparent relationship with customers is paramount.

Navigating Market Fluctuations

Market fluctuations present both challenges and opportunities for Alabama's meat processing businesses. Farmers and processors must remain vigilant and adaptable to changes to sustain their operations.

Understanding consumer trends is essential. Demand for certain cuts or types of meat can change rapidly, and processors must adjust their practices accordingly. Economic variables such as feed costs, fuel prices, and regulatory changes also impact the bottom line. Remaining informed about these fluctuations allows for more strategic decision-making.

Adaptation strategies might include diversifying product offerings, investing in efficient processing equipment, or altering inventory based on seasonal demands. Staying connected with statewide and national agricultural organizations provides insights and support, helping the farmer respond effectively to the shifting meat market landscape in the country. Additionally, engaging with community networks supports the resilience of the business, buffering it against market pressures.

In conclusion, the intersection of building a stable customer base and navigating market fluctuations embodies the business acumen required for successful meat processing operations in Alabama. With a focus on quality, community engagement, and market awareness, farmers contribute to a robust local economy and the broader agricultural fabric of the USA.

Legal Aspects and Liability Concerns

In Alabama, on-farm meat processing is subject to specific legal requirements designed to protect consumers, ensure food safety, and manage risk for farmers. Operators should be well-versed in state and federal laws, insurance policies, and risk management strategies relevant to meat processing activities.

Insurance and Risk Management

Farmers engaged in on-farm processing must obtain appropriate insurance coverage to mitigate risks associated with the operation. This coverage typically includes:

General Liability Insurance: Protects against claims of bodily injury or property damage.

Product Liability Insurance: Covers damages related to the products sold.

Property Insurance: Safeguards against damage to the processing facilities.

Insurance serves as a crucial risk management tool, preserving the financial stability of the farm in the event of accidents or regulatory action.

Understanding Farmer Protections

Alabama farmers operating on-farm processing facilities should become familiar with state and federal regulations that impact their operations, including:

Custom Exemption Laws: Federal law allows certain small-scale processing activities to be exempt from continuous inspection if processing animals for an owner's personal use, household guests, or farm employees.

Poultry Exemption: Small poultry producers in Alabama may be exempt from some federal regulations under specific circumstances, such as processing fewer than 20,000 birds per year.

State Food Safety Guidelines: They must adhere to state-level food safety guidelines, ensuring products are safe for consumption.

Farmers bear the responsibility for ensuring their operation complies with these laws to avoid legal consequences and to secure their business continuity.

Case Studies: Successful On-Farm Meat Processing

This section explores specific instances where farms have turned to innovative on-farm meat processing to add value to their products and meet local demand.

Wisconsin Models of Innovation

In Wisconsin, local farms have established themselves as models of innovative meat processing. Farms are integrating processing facilities directly on their properties, allowing for greater control over the quality of meat produced. Notably, these farms often process a variety of meats, including beef carcass, dairy cows, bulls, steers, and even game animals like buffalo and elk. The streamlined process from farm to processing on-site ensures fresher products and a shorter supply chain.

Diversified Farms and Added Value

Farms that diversify their operations by adding meat processing capabilities often see increased value. By processing their own meats, they are able to respond to consumer demand for locally sourced and transparently processed products. They capitalize on the growing niche markets for specialty meats, such as grass-fed beef and organic products. This addition not only boosts farm income but also supports the local economy and creates new job opportunities in the community.