On-Farm Meat Processing, Butchering and Slaughter in Oklahoma

A Comprehensive Guide

On-farm meat processing in Oklahoma represents a critical segment of the agricultural industry, allowing local farmers to take control of the entire production cycle of their livestock, from rearing to slaughter. These operations provide a means for producers to directly market their meat to consumers, highlighting fresh, locally-sourced products. They must adhere to strict regulations that ensure food safety and animal welfare, while still offering the scalability to cater to various operation sizes. For example, in Oklahoma, pork, beef, and poultry farmers can conduct on-farm slaughter and meat processing within set guidelines, such as the limitation for poultry growers to slaughter and sell up to a maximum of 2,500 turkeys or 10,000 chickens per year.

The state’s regulations are designed to uphold food safety without placing undue burden on small-scale producers. Facilities used for on-farm meat processing are subject to approval to guarantee cleanliness and proper handling. This balance attempts to protect consumers while fostering a sustainable local food system. For direct marketing of meat and poultry, farmers can sell slaughtered carcasses directly to consumers on the farm, provided they stay within defined annual limits, such as 1,000 chickens or 250 turkeys, thus enabling consumers to purchase meat that they can trust has been processed under regulated conditions.

Considering the rising consumer interest in the origins of their food, on-farm meat processing in Oklahoma not only bolsters the local economy but also connects the consumer to the source of their food. The state has undertaken educational initiatives to support the workforce in this sector, with programs aimed at enhancing skills in meat processing. This focus on education assures a steady flow of knowledgeable workers adept in both the art and science of butchery, strengthening the on-farm meat processing industry in Oklahoma.

Understanding On-Farm Meat Processing

On-farm meat processing in Oklahoma involves the butchering and processing of red meat and poultry directly at the farm. This section provides a detailed overview of the essential aspects of on-farm slaughter and processing, with a focus on the regulatory framework and operational standards that ensure food safety and quality.

Basics of Meat Processing

On-farm meat processing encompasses the steps necessary to transform livestock into market-ready meat products. For Oklahoma farmers, this typically means converting cattle, pigs, and poultry into various cuts of meat following specific procedures that aim to minimize waste and ensure quality.

Legal Framework Governing Slaughter in Oklahoma

In Oklahoma, on-farm slaughter is regulated by the Oklahoma Department of Agriculture, Food, and Forestry, under Title 35, Chapter 37 of state regulations. These rules align with federal standards set by the Poultry Products Inspection Act and are supervised by the Food Safety and Inspection Service (FSIS).

On-Farm Slaughter Operations

On-farm slaughter operations in Oklahoma can range from traditional setups to the utilization of mobile slaughter units. Both must comply with USDA-FSIS guidelines if meat is to be sold, which require an inspector present during processing. Farms may also register for slaughter exemptions if selling meat directly to consumers.

Safety and Sanitation Policies

Farmers engaged in on-farm processing must develop and adhere to stringent safety and sanitation policies to protect both workers and consumers. These include facility cleanliness, proper handling of meat, and waste disposal, in line with both state and federal food safety guidelines.

Certifications and Inspections

Regular certifications and inspections are mandatory to ensure compliance with USDA and Oklahoma regulations. This includes periodic checks by a USDA or state inspector and obtaining a certificate of registration affirming adherence to specific requirements for meat processing on the farm.

Compliance and Reporting

Compliance with state and federal laws is non-negotiable for meat processors. They must maintain meticulous records, handle meat safely, and report to the relevant authorities as stipulated by the USDA and Oklahoma agriculture departments.

Marketing and End-User Segmentation

Processed meat from on-farm operations is marketed to various segments, including direct-to-consumer, as well as to restaurants, hotels, institutions, schools, and the Hospitality, Restaurant, and Institutional (HRI) sectors. Marketing strategies often highlight the freshness and local sourcing of farm-processed meats.

Socio-Economic Impact of On-Farm Processing

The socio-economic impact of on-farm processing in Oklahoma is significant. It can drive local economies, support farmers, ranchers, and creates a resilient food supply chain, especially noted during the COVID-19 pandemic, which presented challenges to traditional meat supply channels.

Industry Structure and Market Channels

The industry structure and market channels within the on-farm meat processing sector in Oklahoma are pivotal for the state's agricultural economy. They directly influence the scope and efficiency with which meat products are brought from farm to table.

Livestock Types and Meat Categories

Oklahoma's livestock sector comprises cattle, swine, sheep, goats, and rabbits, with cattle being the most prominent in terms of volume. The state's meat categories span across poultry and red meat, catering to a diverse consumer base with various preferences.

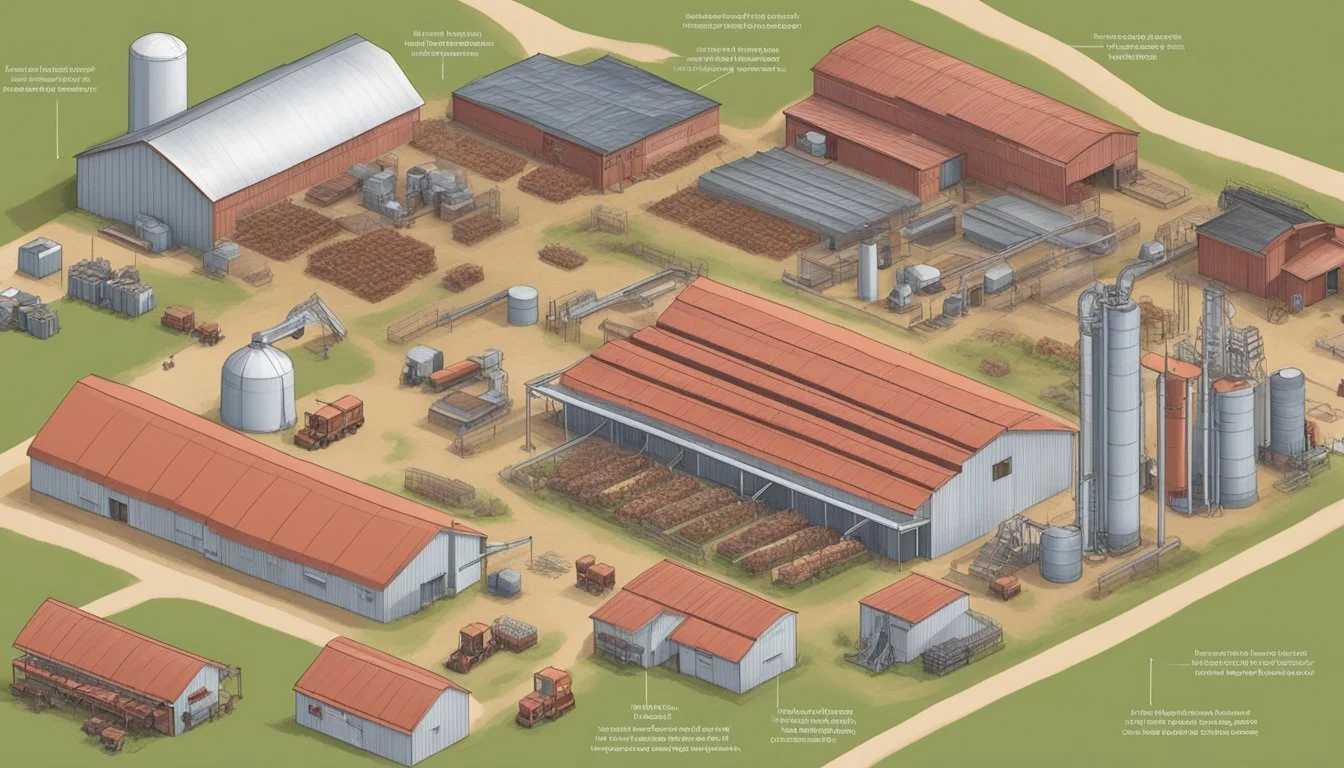

Processing Facilities and Their Roles

State-inspected and federal establishments are the two primary types of slaughter and processing facilities in Oklahoma. State-inspected facilities cater to local markets, while federal establishments must meet USDA standards to ship across state lines. Mobile slaughter units have also emerged, offering enhanced flexibility, especially for small-scale ranchers and farmers.

Distribution and Marketing Channels

The distribution of meat from slaughter to sale operates through several channels:

Retail stores

Distributors and meat brokers

Public warehousemen

Restaurants, hotels, and institutions, including schools

The presence of these channels ensures the flow of meat products across different market segments, maintaining the supply chain despite potential disruptions.

Direct-to-Consumer Sales

Direct interaction with consumers has gained ground, with producers engaging in farmers' markets and community-supported agriculture (CSA). This model strengthens relationships between producers and consumers and often allows farmers to receive a better price for their products.

Business Models for Niche Markets

The emergence of the Niche Meat Processor Assistance Network and the Island Grown Farmers Cooperative highlight tailored business models that assist markets such as organic, grass-fed, and locally sourced meat products. These models help producers navigate market complexities and cater to specific consumer demands.

Supply Chain Disruptions and Adaptations

The meat industry has faced challenges, especially during the COVID-19 pandemic, which caused disruptions in the traditional supply channels. Meat processors were compelled to quickly adapt, often turning to local markets and exploring alternative marketing and distribution strategies to sustain their operations and support local ranchers and farmers.

Regulatory Compliance

In Oklahoma, on-farm meat processing is governed by a set of clear regulatory frameworks designed to ensure public health and food safety. Compliance with these regulations is essential for any operation that aims to slaughter and process meat.

State Versus Federal Regulations

The Oklahoma Department of Agriculture, Food, and Forestry (ODAFF) and the USDA's Food Safety and Inspection Service (FSIS) both play significant roles in the oversight of meat processing. While federal establishments require continuous USDA-FSIS inspection, state inspection is an option under the Talmadge-Aiken Act if equivalent standards to FSIS are met. Establishments in Oklahoma can operate under state inspection provided they do not engage in interstate commerce.

Permits and Licensing

To legally process meat in Oklahoma, facilities must obtain relevant permits and licenses issued by both state and federal authorities. Operators must apply to the ODAFF for a state-inspected permit or seek federal approval for a USDA-FSIS regulated establishment. Each type carries specific operational guidelines and oversight.

Inspection Criteria and Standards

Both state inspectors and federal inspectors from USDA-FSIS ensure compliance with strict inspection criteria and standards. This includes examining all animals before and after slaughter to prevent diseased meat from entering the food supply. Establishments considered "custom exempt" are not subjected to continuous inspection but are still reviewed for sanitary operations and proper labeling.

Health and Safety

Health and safety parameters are strictly enforced by both the ODAFF and the FSIS. These include proper sanitation of the facility, adequate disease control measures, and the secure handling of meat products. In Oklahoma, an inspector must be present in all federally established slaughter and processing plants to oversee compliance with these health and safety regulations.

Operational Best Practices

In the pursuit of ensuring the highest standards of on-farm meat processing in Oklahoma, it is critical to implement strategic operational best practices. These practices focus on meat processing techniques, the use of advanced equipment and technology, adherence to stringent animal welfare and ethical standards, and sound environmental management.

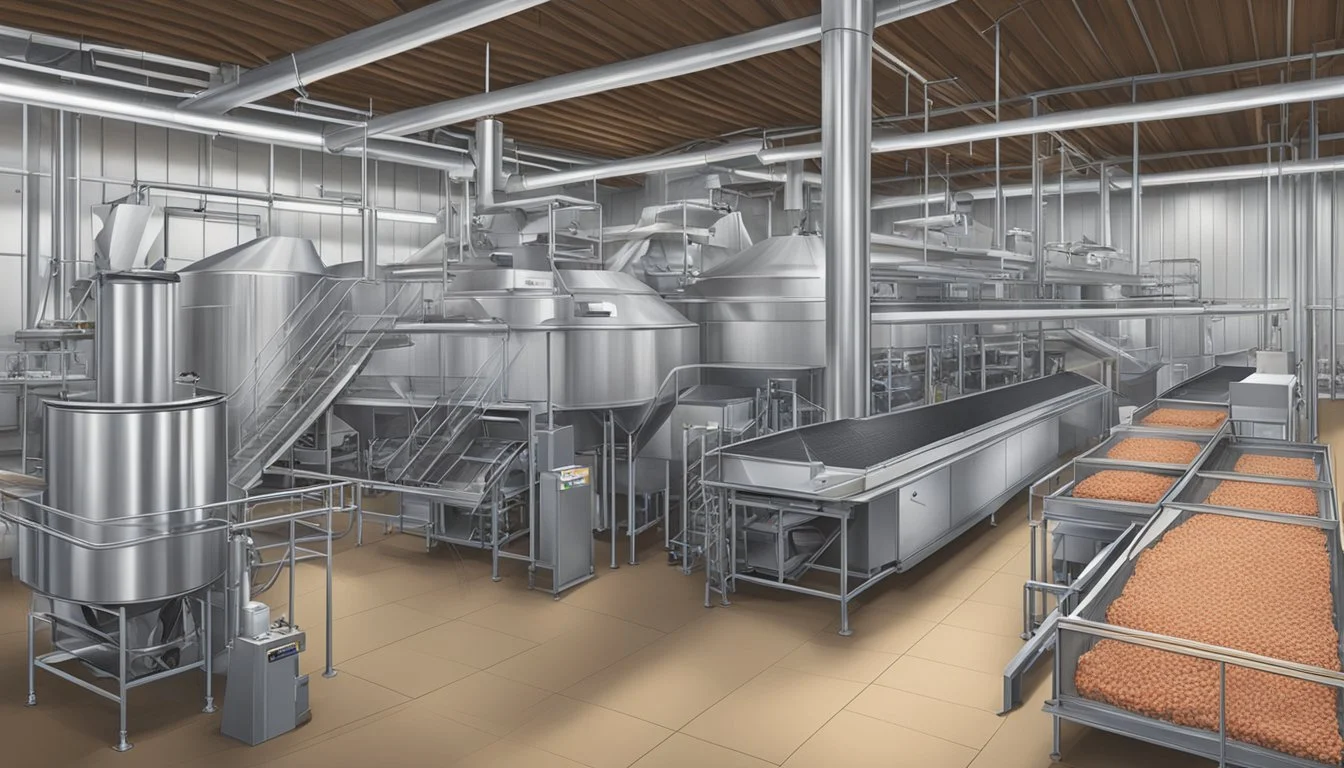

Meat Processing Techniques

The procedures for processing meat on-farm require a comprehensive understanding of meat science to ensure that the final product is safe and of high quality. In Oklahoma, farmers must follow set protocols to slaughter up to 2,500 turkeys or 10,000 chickens annually with the appropriate facilities. Techniques for effective slaughter include:

Stunning: Animals are rendered unconscious humanely before slaughter to avoid distress.

Exsanguination: A swift and precise process that ensures swift blood removal following stunning.

Equipment and Technology

The appropriate selection of equipment and technology is paramount for maintaining food safety standards during on-farm processing. Key technology and equipment include:

Mobile Slaughter Units (MSUs): They provide the capabilities of a standard slaughterhouse with the flexibility of location.

Sterilization Technology: Ensures all butchering tools are free from contaminants, reducing the risk of foodborne illnesses.

Animal Welfare and Ethical Standards

Adherence to animal welfare and ethical standards is non-negotiable. Oklahoma farmers involved in on-farm processing must ensure:

Humane Handling: All livestock must be treated humanely at all stages of the slaughter process.

Regulatory Compliance: Farmers must comply with federal and state regulations regarding the humane treatment of animals.

Environmental Management

Environmental management practices are critical to maintain sustainability and reduce the potential of environmental contamination:

Waste Disposal: Properly designed and managed systems are necessary for the treatment and disposal of wastewater and solid waste.

Air Management: Facilities must have measures in place to ensure air is clean and free from contamination, with an emphasis on proper airflow from clean to dirty areas to prevent contamination.

Marketing Strategies and Consumer Education

Focused marketing strategies and effective consumer education are critical for farmers and butchers in Oklahoma engaging in on-farm meat processing and direct sales. To thrive in this area, they must align their offerings with consumer demand, create a strong brand and position their products effectively, actively engage with their community, and build robust transparency to foster trust.

Understanding Consumer Demand

Farmers and butchers need to stay informed on what cuts and types of meats consumers are currently purchasing. Programs like the Farm-to-Table initiative have shown individual tastes can vary, with some consumers preferring grass-fed beef or heritage pork. Oklahoma producers should conduct market research to understand the preferences of various market segments, including local restaurants, hotels, institutions, and schools that may be part of the Hotel/Restaurant/Institutional (HRI) sector. Learning about customer preferences for meat processing — such as USDA-certified, grain-finished, or particular butchering techniques — can help target marketing efforts more effectively.

Branding and Positioning

Branding is crucial for differentiating farm-processed meat products from commercial ones. Oklahoma-based farmers need to create a distinctive brand that resonates with their consumers, whether that be for high-quality, locally processed meats or for products that meet specific ethical or food safety standards. Positioning such products involves storytelling about the origin, the quality of life of the livestock, and the care taken during the slaughtering and processing phases. This might be represented through logos, product labels, and consistent messaging across marketing materials.

Outreach and Engagement

Effective engagement with consumers and the HRI sector is achieved through consistent outreach, which can include farm visits, attendance at farmer's markets, or partnerships with local businesses. Educational materials that explain the benefits of farm-processed meats, such as fresher products and support for local agriculture, can be distributed during these interactions. Social media campaigns and email newsletters are also valuable tools for keeping the community informed about product offerings, processing methods, and availability.

Transparency and Trust-Building

To build trust with consumers and the HRI market, farmers must be transparent about their slaughtering and processing practices. Disclosing information such as food safety measures, animal welfare policies, and the details of the processing, which can include the level of inspection (federal USDA or state), reassures customers about the quality of the meat they purchase. Establishing clear communication channels for consumer inquiries and maintaining a presence at local events further enhances credibility and consumer confidence in the product's quality and safety.

Economic Aspects of Meat Processing

The economic landscape of meat processing involves various costs and profitability margins, influenced significantly by government subsidies and the prevailing market dynamics, which have notable implications for farmers, processors, and consumers.

Costs and Profitability

Costs associated with on-farm meat processing in Oklahoma include infrastructure investment, compliance with health regulations, and operational expenditures like labor, feed, and utilities. Profitability hinges on efficient production and marketing strategies to ensure that the price of meat covers these costs and yields a viable return. Meat processors often work closely with distributors and meat brokers to optimize their revenue streams.

Infrastructure: Building or upgrading facilities with slaughter and processing capabilities

Regulation: Costs to comply with USDA mandates and local health standards

Operational Expenses:

Labor: Skilled butchers and staff for operations

Feed: Quality feed for livestock prior to slaughter

Utilities: Water, electricity, and other utilities necessary for operation

Marketing: Developing relationships with buyers and advertising products

Government Subsidies and Support

The USDA has played a pivotal role in supporting the meat processing sector, especially noted during the response to COVID-19, with funds aimed at enhancing local processing capabilities. For example, using the American Rescue Plan, the USDA has invested significant amounts into expanding local and regional meat processing to aid farmers and ranchers in becoming more competitive and self-reliant.

Subsidies: Financial assistance for setting up or expanding processing plants

Grants: Research funding for innovation in meat processing and slaughter techniques

Support Programs: Assistance for farmers and processors affected by market disruptions due to COVID-19

Impact of Market Dynamics

Market dynamics have a substantial effect on meat processing from fluctuating consumer demand to international trade pressures. Factors such as global health events can disrupt the supply chain, leading to price volatility. Farmers and meat processors must continuously adapt to these changes to sustain their operations.

Consumer Demand: Variations in meat consumption patterns

Trade Pressures: Import and export regulations affecting meat prices

Supply Chain: The stability of the supply chain during disruptions such as pandemics

Future Trends and Innovations

In Oklahoma, the landscape of on-farm meat processing, butchering, and slaughter is poised to evolve significantly due to technological innovations, policy changes, and a growing consumer interest in sustainability.

Technological Advances

The advent of mobile slaughter units is transforming the way on-farm meat processing is conducted in Oklahoma. These units enable on-site slaughtering which can lead to fresher meat products and lower transportation costs. Advancements in meat science and processing technology are also helping butchers improve food safety and extend the shelf life of meat products, benefitting both consumers and processors.

Policy Changes and Industry Forecasts

State regulations and the Food Safety and Inspection Service (FSIS) requirements are forecasted to adapt to the changing meat industry landscape. Expectations are for more supportive policies toward small-scale operations, potentially including scaled regulations for mobile slaughter units which could increase their viability and ease burdens on farmers.

Sustainability and Organic Markets

Consumer demand for organic and sustainably-produced meat is growing in Oklahoma. Farmers are responding with a shift towards organic farming practices and on-farm processing, which align with state regulations. Mobile slaughter units may play a key role in this sphere, reducing the environmental footprint by minimizing animal transport and meeting consumer demands for locally sourced, sustainable meat.

Conclusion

On-farm meat processing in Oklahoma offers livestock owners an opportunity to directly market their products to consumers. Regulatory compliance is paramount, and producers must navigate a web of state and federal regulations to ensure food safety and quality. Oklahoma's guidelines dictate that animals must be slaughtered and processed into finished meat cuts in facilities that adhere to recognized inspection levels.

Facility investment is a significant aspect of on-farm processing. Producers must balance the initial capital investment with potential long-term gains offered by this direct marketing avenue. Despite the challenges, such as public perception and fluctuating market prices, successful operations enhance financial resiliency.

Food safety remains a critical concern. Producers must implement stringent processing standards to meet inspection requirements and safeguard consumer health. This involves choosing between custom exempt slaughter for private consumption or opting for state or federally inspected processing to sell to the public, including at farmers' markets or directly from the farm.

In summary, Oklahoma livestock owners who invest in on-farm processing and butchering must navigate a complex regulatory environment and public health responsibilities. Those who successfully manage these challenges are often rewarded with an alternative and potentially lucrative revenue stream, bolstering their position in a competitive market.

Key Considerations for On-Farm Processing in Oklahoma - Regulatory Compliance - Capital Investment - Public Perception - Market Price Variability - Ensuring Food Safety