On-Farm Meat Processing, Butchering and Slaughter in Ohio

A Comprehensive Guide

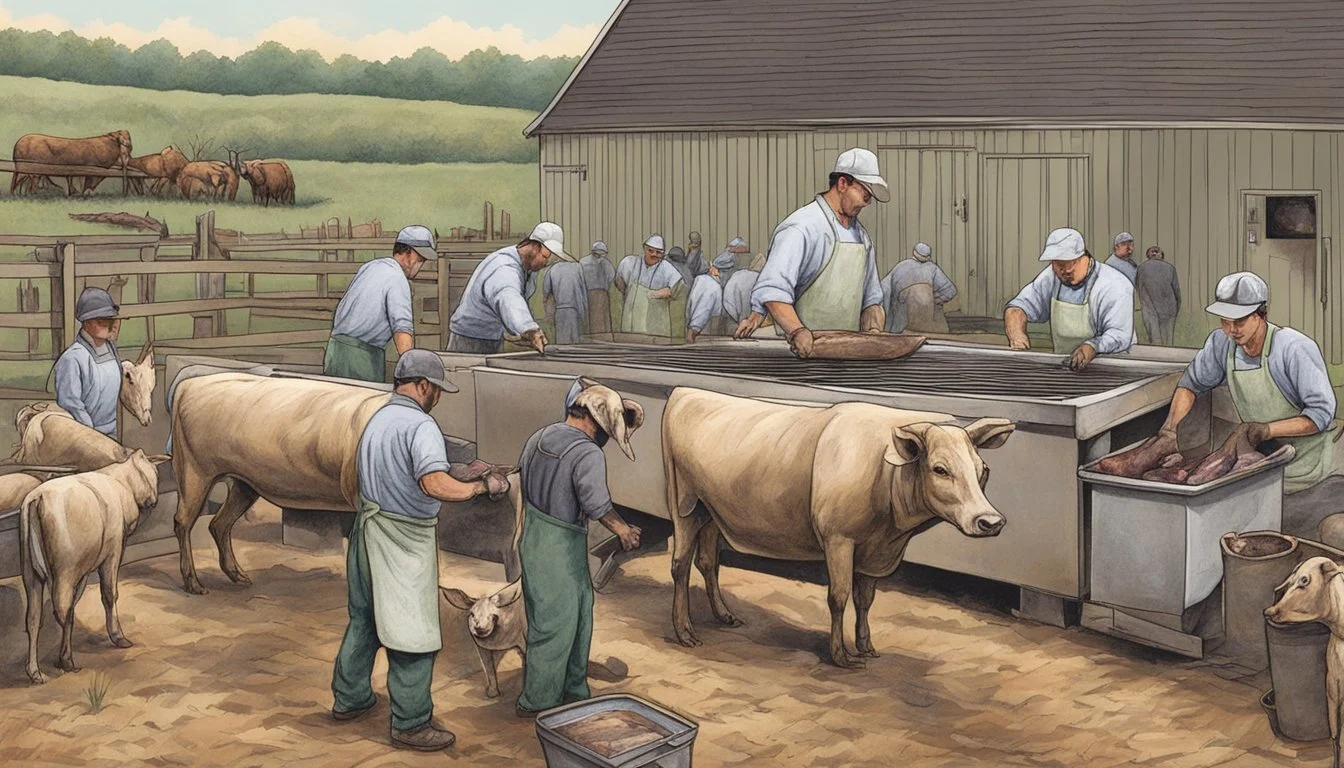

On-farm meat processing in Ohio is drawing considerable attention as a sustainable option for farmers to manage the butchering and slaughtering of livestock directly on their property. The practice offers producers a level of autonomy in managing their meat products from farm to table. In response to this trend, resources and guidance are being provided by agricultural experts, such as those at The Ohio State University College of Food, Agricultural, and Environmental Sciences (CFAES), to ensure that the process is carried out efficiently and in compliance with state regulations.

Navigating the complex landscape of regulations is essential for Ohio farmers who opt for on-farm butchering. State guidelines dictate that producers may butcher and sell their meat on their property without a license for specific small-scale operations, for example, handling fewer than 1,000 chickens or 250 turkeys. However, slaughtering animals owned by a second party necessitates a custom slaughter license through the Ohio Department of Agriculture's Division of Meat Inspection.

The emergence of mobile slaughter units is an innovative solution that complements on-farm meat processing, offering flexibility and addressing the need for proper facility inspection and waste handling which includes the by-products such as hide, offal, and wastewater. Despite the initial investment, mobile units provide a convenient option for farmers, ensuring that on-farm slaughtering adheres to strict sanitary and environmental standards. This adaptation signifies Ohio’s commitment to modernizing meat processing while supporting the agricultural community’s economic and logistical needs.

Understanding On-Farm Meat Processing in Ohio

On-farm meat processing in Ohio involves the slaughter and butchering of animals directly on the property where they were raised. This can provide a sense of self-sufficiency for farmers and an alternative route to meet their own family's needs in light of disruptions to larger meat processors.

Slaughter Considerations: On-farm slaughter in Ohio is subject to regulations meant to safeguard food safety. Farmers must adhere to these guidelines to ensure that the meat is safe for consumption.

Legal Framework: Personal-use exemption: Ohio law allows individuals to process their own livestock for personal consumption. The meat from such activities cannot be sold and is strictly for family or nonpaying guests. Violations, such as selling uninspected meat, are illegal.

Processing Dynamics: Small meat processors in the state have faced increased demand. With larger establishments experiencing disruptions like those during the COVID-19 pandemic, the role of on-farm processing has grown in significance. Ohio farmers are considering or actively engaging in this practice as a viable option for livestock processing.

Food Safety Protocols:

Compliance with state and federal regulations

Safe handling and sanitary procedures during processing

Farmers in Ohio must balance the desire to process meat on the farm with respecting laws that govern the slaughter and processing of meat and poultry. This ensures health and safety standards are not compromised.

Legalities and Regulations of Meat Processing

Meat processing in Ohio is subject to stringent regulatory standards to ensure food safety and public health. Compliance with both state and federal laws is mandatory for entities engaged in meat processing operations.

State and Federal Regulations

The United States Department of Agriculture (USDA) and the Ohio Department of Agriculture (ODA) jointly enforce regulations that oversee meat processing in Ohio. Federal laws, like those detailed in the Federal Meat Inspection Act (FMIA), are designed to maintain processing standards across the country. At the state level, processors must adhere to additional health and safety standards, often aligning with or exceeding federal requirements.

Ohio Department of Agriculture Compliance

The Ohio Department of Agriculture is the primary state regulatory body that ensures meat processors comply with health and sanitation standards. Legally, processors are inspected and assessed regularly to guarantee adherence to prescribed regulations. Those found in violation may face penalties, including fines or suspension of operations.

Licensing and Registration Requirements

To operate lawfully, meat processors in Ohio must obtain the appropriate licenses and registrations from both the ODA and local health departments. A processor with fewer than 25 full-time employees may qualify as a Cooperative Interstate Shipment (CIS) establishment, which still requires compliance with specific food safety and sanitation standards. Inspections are mandatory for both traditional and CIS establishments to maintain their registered status.

The Process of Slaughtering and Butchering

When slaughtering and butchering on a farm, the focus is on humane handling and efficient procedures from slaughter through to the final butchering of the animal. Ohio farms undertaking this task need to ensure they adhere to the necessary animal welfare protocols while utilizing appropriate techniques for both slaughtering and butchering.

Animal Welfare Considerations

Farmers are responsible for ensuring that the slaughtering process is conducted humanely. This involves several practices designed to minimize stress and pain for the animals:

Adequate training of personnel involved in the process

Proper handling to avoid undue stress

Employing methods of slaughter that cause rapid unconsciousness followed by death

Slaughter Procedures

On Ohio farms, slaughtering involves a series of steps that need to be carried out precisely:

Containment: Safe and secure handling of the animal leading up to slaughter.

Stunning: Use of methods such as captive bolt pistols to render the animal unconscious.

Exsanguination: Severing of major blood vessels to ensure humane death.

Farmers may also need to scald and dehair certain animals, such as pigs, to remove hair and prepare the carcass for butchering.

Butchering Techniques

After the slaughter, butchering is the next crucial phase. Ohio farmers typically:

Skin or dehair the carcass depending on the animal.

Eviscerate, which involves removing the internal organs carefully to avoid contamination.

Sectioning the carcass into primal cuts for easier handling and processing.

Butchering Stages:

Initial breakdown: Dividing the carcass into large sections.

Deboning: Removing bones while trying to maximize the meat yield.

Trimming: Cutting away excess fat and sinew to produce clean cuts of meat.

Mobile Slaughter Services

For farmers who do not have the facilities to perform on-farm slaughter, mobile slaughter services provide a flexible solution. They offer:

Convenience: Coming directly to the farm, reducing the need to transport livestock.

Compliance: Ensuring that the slaughter is carried out in accordance with state and federal regulations.

Expertise: Skilled professionals conduct the slaughter and initial butchering stages.

Mobile slaughter services facilitate the process for farmers aiming to maintain the welfare of their animals while producing meat locally and sustainably.

Health and Safety in Meat Processing

When processing meat on Ohio farms, operators must prioritize the health and safety of both the product and the workers. Preventing contamination and managing pathogens like E. coli O157, Salmonella, and Campylobacter are critical for maintaining food safety standards.

Managing Contamination Risks

Key steps to reduce contamination:

Sanitation protocols: Regular cleaning and sanitization of equipment prevent bacterial build-up.

Facility design: Implementing designs that separate clean and dirty areas to minimize cross-contamination.

Worker training: Ensuring that workers are trained in hygiene practices, such as proper handwashing, to maintain a safe processing environment.

Pathogen Prevention Strategies

Pathogens pose significant health threats in meat processing. Addressing them requires specific strategies:

Monitoring systems: Utilizing Hazard Analysis and Critical Control Points (HACCP) plans to identify and monitor critical points where contamination could occur.

Temperature control: Keeping meat at safe temperatures to inhibit bacterial growth.

Testing regimes: Regular testing for common pathogens to catch and address contamination early.

Market Dynamics and Economics

The economics of on-farm meat processing in Ohio reflects an intersection of fluctuating demand for specialized products and the financial realities of operating small-scale processing capabilities.

Demand for Local and Specialty Meats

The demand for local and specialty meats has seen a marked increase, particularly during the COVID-19 pandemic which underscored the value of short supply chains and community-based food systems. Ohio's consumers have demonstrated a sustained interest in products that are perceived as fresher, having a smaller carbon footprint, and supporting neighboring farmers. This pattern aligns with national trends where disruptions in conventional meat supply due to the pandemic led to a surge in demand for meats processed by small-scale local butchers and farms.

Financial Aspects of On-Farm Processing

On-farm processing involves significant financial considerations for Ohio farmers. While it can potentially lead to higher profit margins, it also requires substantial initial and ongoing investments in facilities, equipment, and adherence to regulatory standards.

Capital Costs

Slaughtering equipment

Refrigeration units

Processing space

Operating Expenses

Labor

Maintenance

Compliance with health and safety standards

Revenue Streams

Direct-to-consumer sales

Retail partnerships

Specialty service offerings

Small processors serving their communities had to adapt quickly during the pandemic, balancing the service to their neighbors with the economic strains caused by increased operational costs and the shifting landscape of meat retail. Despite these challenges, the coronavirus pandemic highlighted the resilience and essential status of local food systems, including on-farm meat processing.

Support and Resources for Meat Producers

In Ohio, meat producers have access to a variety of educational and technical resources designed to enhance their on-farm processing capabilities. These resources facilitate compliance with regulations, improve product quality, and support the growth of their businesses.

Educational Opportunities

Ohio State University Extension offers specialized training programs for meat producers. These are led by experts such as Dr. Lyda Garcia, an Assistant Professor of Meat Science, who imparts practical and scientific knowledge pertaining to meat processing. Additionally, Lynn Knipe, the Extension Processed Meats Specialist, is known for conducting valuable workshops and courses in meat science.

Workshops and Courses: Focused on topics like meat selection, butchering techniques, food safety, and regulatory compliance.

Webinars and Online Resources: Provide convenient access to current industry standards and emerging trends.

Extension Services and Technical Support

The U.S. Department of Agriculture (USDA) and the Ohio State University Extension office collaborate to offer extension services that are essential for meat producers looking to optimize their on-farm slaughter and butchering operations.

Technical Assistance: Producers can receive on-site consultations to enhance their facilities and processes.

Service Support: Information on grant opportunities, marketing advice, and best practices for meat processing is readily available.

These resources help maintain a well-informed producer community, capable of producing high-quality meat products while ensuring food safety and animal welfare.

Animal Husbandry and Breeding

In Ohio, effective animal husbandry practices are paramount for farm-based meat processing ventures. These practices ensure the health and quality of the livestock, whether it be cattle, swine, or poultry.

Health and Genetics of Livestock

An emphasis on the genetic health of livestock breeds forms the cornerstone of a robust animal husbandry program. Farmers must select breeds with traits that are favorable for the Ohio climate and farming practices. Cattle herds often include breeds known for their robust constitutions and high-quality beef production, while pork production might focus on swine breeds with efficient growth rates. Regular health check-ups, vaccinations, and proactive management of animal diseases are essential to maintain the wellbeing of livestock and ensure safe on-farm butchering.

Species-Specific Considerations

Each type of livestock requires tailored management practices for breeding and rearing:

Cattle: A focus on breed-specific nutritional requirements and calving practices ensure the production of healthy beef.

Swine: Detailed attention to breeding cycles and housing conditions is critical for high production standards in pork.

Poultry: Requires careful monitoring of flock health and is often bred more frequently, necessitating strict biosecurity measures.

In all cases, the health and genetics of the animals directly affect the quality and safety of the processed meat. Therefore, applying these species-specific strategies is critical for any operation, particularly for those intending to process meat on the farm.

Facility Requirements and Design

The design and construction of on-farm meat processing facilities in Ohio must meet stringent regulations to ensure safety and efficiency in the slaughtering and processing of livestock. These facilities are categorized into slaughter facilities, processing facilities, and mobile slaughter units, each with distinct requirements and design considerations.

Slaughter Facility Considerations

Slaughter facilities must prioritize the humane handling and slaughtering of animals, which includes features such as non-slip flooring and proper restraint systems. The design should accommodate the specific capacity planned for, being attentive to the number of animals processed per day. Ohio’s slaughter facilities operate under state and federal regulations, which dictate:

Structural design that allows for easy sanitation and maintenance.

Waste disposal systems that comply with environmental regulations.

Ventilation that prevents condensation and minimizes odor.

A separate space for non-slaughter activities to avoid contamination.

Processing Facility Essentials

Processing facilities, where meat is cut, trimmed, and packaged, necessitate a design that incorporates:

Temperature-controlled environments for different processing stages.

Equipment that is easily cleanable and appropriately sized for the expected volumes.

Storage areas for both raw and finished products, with clear separation to avoid cross-contamination.

Detailed Sanitation Standard Operating Procedures (SSOPs) and a Hazard Analysis and Critical Control Point (HACCP) plan.

Mobile Slaughter Units

Mobile slaughter units offer flexibility to farmers, particularly when processing young or smaller quantities of livestock. These units must:

Comply with the same health and safety regulations as permanent facilities.

Include features for slaughtering, processing, and refrigeration within the confined space of the trailer.

These mobile units are advantageous for small-scale producers and can help them scale their operations without committing to large, permanent facilities. They can also provide services to various farms by moving from one location to another, a subject often discussed during events like the Farm Science Review in Ohio.

By adhering to these specific design and facility requirements, on-farm meat processors in Ohio can ensure a functional, compliant operation that upholds industry standards for safety and quality.

Case Studies and Success Stories

In the landscape of Ohio's agricultural sector, on-farm meat processing, butchering, and slaughter have provided tangible benefits to local farmers. These case studies showcase how such operations have successfully integrated into the farming community.

Double Brook Farm in New Jersey offers a compelling story. Although outside Ohio, it demonstrates the feasibility of on-farm processing. Owners Jon and Robin McConaughy manage approximately 500 acres, navigating on-farm livestock processing's stringent challenges.

Entity Details Farmers Benefitted from direct sales, bolstering farm sustainability Beef Profitable due to reduced transportation and faster market access Elderly Benefits from fresher products and local support

Smucker’s Meats in Pennsylvania, also applicable to Ohio's context, has illustrated the demand for genuine, locally-sourced meat processing. Offering services to red meat producers, predominantly those raising beef, goats, and lamb, the family-owned operation is a testament to developing a profitable business model that aligns with sustainable practices.

The impact of the COVID-19 pandemic saw butchers and meat processors responding to an uptick in local demand. With supply chains disrupted, farmers turned to local processors to bridge the gap, ensuring a continual supply of beef, goat, and lamb meat to consumers, including populations such as the elderly who rely on local food sources.

In summary, these examples from nearby states are indicative of Ohio's potential success in on-farm meat processing. They represent a movement towards ownership and profitability in the local meat industry, ensuring farmers can respond accurately and efficiently to market demands.

Useful Links and Resources

When individuals or businesses in Ohio consider on-farm meat processing, accessing reliable resources is crucial for compliance with laws and ensuring safety and quality. Listed below are valuable links and resources that can provide assistance and insight into meat processing protocols within the state.

Ohio State University Resources:

The College of Food, Agricultural, and Environmental Sciences provides updated guidelines and information on on-farm butchering. Their resources can be accessed at meatsci.osu.edu.

Guidance on Legal Home Processing:

Legal aspects of meat processing at home are complex. Ohio State University's extension provides clear explanations of home processing laws at go.osu.edu/legalhomeprocessing.

On-Farm Meat Processing Guide:

For a step-by-step guide to on-farm meat processing, visit go.osu.edu/onfarmeatprocessing. This resource offers practical advice for those looking into harvesting meat for personal use.

State Agencies:

The Division of Meat Inspection plays a pivotal role in overseeing meat and poultry establishments to ensure safe, wholesome outcomes for consumers. For more information about state regulations and contacts, one can consult the official website or reach out to local county offices.

Federal Exemptions and Regulations:

Federal exemptions related to meat processing are important, especially for small operations. Refer to the relevant government websites or local authorities for information on these exemptions and how they apply in Ohio.