On-Farm Meat Processing, Butchering, and Slaughter in North Dakota

A Comprehensive Guide

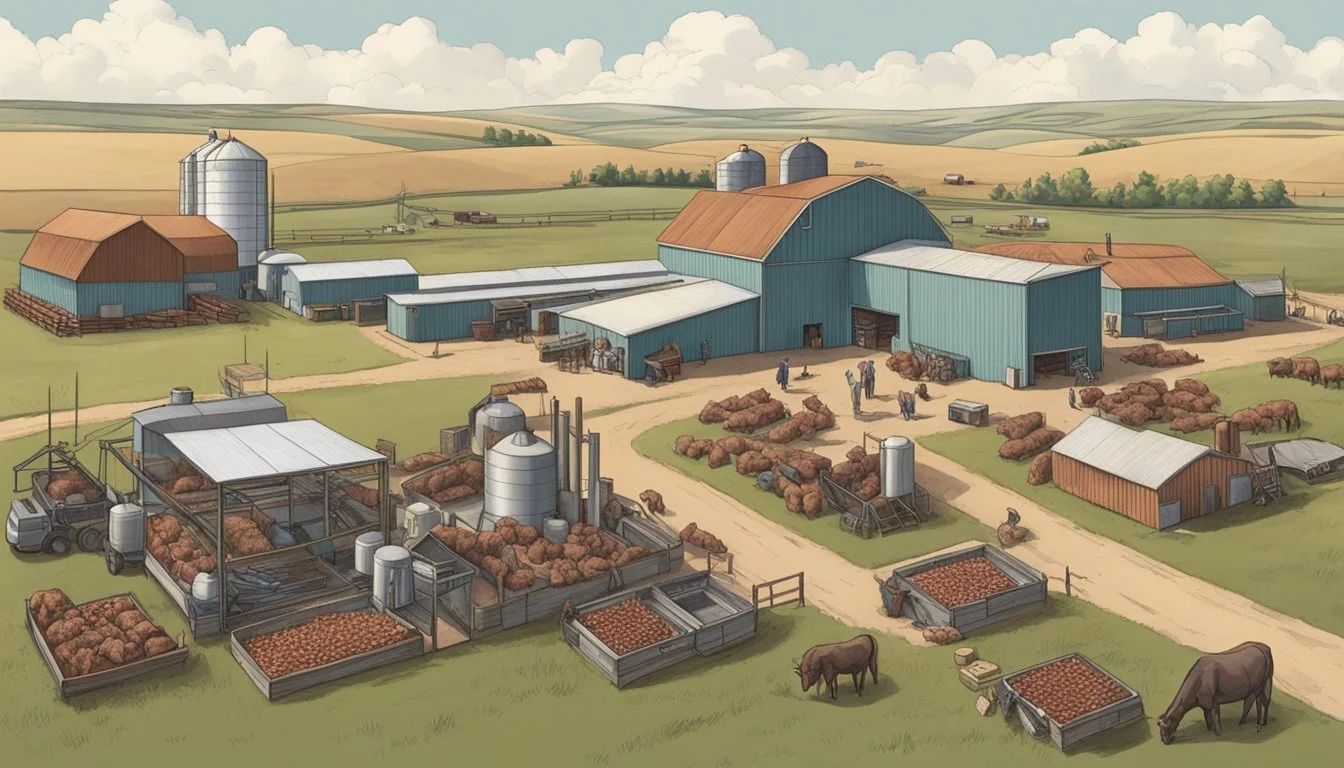

In North Dakota, the tradition of on-farm meat processing and butchering is more than a practice; it's a vital part of the community fabric. Amidst the wide-open plains, farmers and ranchers take immense pride in their ability to directly manage every stage of livestock rearing and processing. This hands-on approach ensures they can provide high-quality meats while sustaining the close-knit communities that dot the landscape. With the state's rich farming heritage, on-farm meat processing is not only a nod to self-reliance but also a strategic response to market demands and the desire for control over the quality and distribution of meat products.

The growth of local meat processing in North Dakota reflects a broader trend of shifting towards more localized, sustainable farming practices. State slaughter and meat processing services that operate under regulated inspection play a significant role in bolstering the state's agricultural economy. Farmers recognize the value of having the capability to process and market their livestock directly to the consumer, thereby reinforcing the farm-to-table movement. Moreover, meat processing facilities like Butcher's Edge in Edgeley further exemplify the effort of agriculturalists to address the processing needs of the community while maintaining a commitment to quality.

In response to challenges such as the COVID-19 pandemic and a growing focus on supply chain resilience, new meat processing plants have emerged as a solution for ranchers in North Dakota. These plants allow for the processing and slaughtering of livestock on-site, which aligns with the state's initiatives to support farmers and their livelihoods. By adapting to the changes within the agricultural sector, North Dakota is fostering an environment conducive to the growth of on-farm processing facilities, which ultimately contributes to the state's self-sufficiency and the stability of its farming communities.

Regulatory Landscape for On-Farm Processing

In North Dakota, on-farm meat processing is subject to specific regulatory requirements to ensure food safety and support fair competition within the meat supply chain. These regulations are designed to safeguard public health and provide clear guidelines for farmers and processors.

State Inspection and USDA Compliance

State-inspected facilities in North Dakota must adhere to standards that are "at least equal to" those imposed by the USDA federal inspection programs. This ensures that meat products processed on-farm can be sold legally within the state. USDA compliance is critical for farmers who wish to expand their market reach beyond state lines, as only USDA-inspected meats are allowed to be sold interstate.

USDA Federal Meat Inspection Act: This act provides the legal foundation for USDA inspection processes.

Equal-to Requirement: State programs must match federal standards to be recognized.

Legal Requirements for Slaughtering and Butchering

Farmers in North Dakota must follow the legal requirements for slaughtering and butchering animals on their farms. The Food Safety and Inspection Service (FSIS), under USDA, mandates regulations to ensure that all meat products are safe, wholesome, and correctly labeled.

Licensing: Operators need a license to slaughter or butcher animals.

Sanitation Standards: Must comply with FSIS regulations to prevent contamination.

Mobile Slaughtering Units and Regulations

Mobile slaughtering units (MSU) are an innovative approach to on-farm processing, increasing accessibility for farmers. The Ohio State University Extension and the Farm Science Review have discussed the potential benefits of MSUs. These units must comply with the same FSIS regulations as fixed facilities and are often a suitable option for farmers looking to process their meat within a controlled environment that comes to them.

Inspection Compliance: MSUs fall under the same stringent inspection requirements as stationary slaughterhouses.

FSIS Guidelines: They must follow federal guidelines for operation, which include facility design, waste disposal, and water supply standards.

By adhering to these regulations, on-farm processors contribute to a safer food supply and gain the opportunity to broaden their market presence.

Benefits of On-Farm Meat Processing

On-farm meat processing in North Dakota addresses critical aspects of the agricultural industry by bolstering local economies and enhancing product quality while prioritizing animal welfare.

Supporting Local Economies and Communities

On-farm meat processing provides a substantial boost to North Dakota's local economies. Farmers benefit from higher retention of revenue within the community as they process meat on their properties, reducing the need to rely on distant slaughterhouses. This localized approach also helps create jobs in rural areas and supports local businesses that may supply equipment or services to the farm.

Enhancing Meat Quality and Safety

When meat is processed on the farm, farmers have direct oversight of the entire procedure, which allows for a focus on meat science principles and adherence to food safety protocols. This hands-on approach often results in higher meat quality due to shorter transport times and fresher processing. Furthermore, the intimate scale of operations typically means that a more meticulous and personalized attention can be directed toward each animal, enhancing the safety and quality of the end product.

Reducing Stress in Animals

An on-farm slaughterhouse can significantly reduce stress in animals such as cattle, hogs, and sheep. The absence of long-distance transport to slaughter facilities means animals endure less handling and unfamiliar environments, two factors that can lead to stress. Lower stress levels in animals before slaughter are not only an ethical consideration linked to animal health but are also associated with improved meat quality.

On-Farm Butchering Techniques and Equipment

On-farm butchering requires meticulous technique and specialized equipment to ensure meat quality and safety. Adhering to best practices for each livestock type is essential for optimal results.

Butchering Best Practices for Various Livestock

Cattle: For beef, they should ensure that the animal is calm and stress-free prior to the butchering process. Once the cattle are humanely slaughtered, the carcass must be skinned, eviscerated, and split down the spine. Aging the beef is critical for flavor and tenderness.

Hogs: In butchering hogs, the proper scalding temperature is crucial for easy hair removal. Hogs are typically scalded at approximately 145°F after slaughter. After dehairing, they are eviscerated, and the carcass is split before the meat is cured or refrigerated.

Sheep: Sheep butchering involves shearing wool, humane slaughter, and immediately hanging the carcass to ensure proper bleeding and meat quality. The sheep carcass is then skinned, eviscerated, and cut according to the desired portions.

Poultry: For poultry, they should begin with humane slaughter followed by scalding to loosen feathers. The carcass is then plucked, eviscerated, and often chilled to reduce the risk of bacterial growth.

Selecting and Maintaining Butchering Equipment

Selecting the right equipment is pivotal for efficient on-farm butchering. They must invest in quality knives, scalders for hogs and poultry, pluckers for poultry, saws for splitting carcasses, and refrigeration units to store the meat post-butchery. Proper hygiene and regular maintenance of this equipment are imperative to prevent contamination and ensure longevity.

Knives: Must be made from high-grade stainless steel and kept razor-sharp for clean cuts, which aides in maintaining meat quality and reducing waste.

Scalders and Pluckers: Equipment must be regularly checked for the correct temperature and operational efficiency, especially for hogs and poultry.

Saws: Used for splitting carcasses, saws must be durable and appropriate for the size of the livestock being processed.

Refrigeration Units: Needed to keep meat at safe temperatures post-butchery and must be regularly serviced to meet food safety standards.

By following these specific techniques and maintaining the right equipment, farmers can ensure high-quality meat production from their livestock while complying with safety regulations.

Processing Facilities and Infrastructure

The facilities for on-farm meat processing in North Dakota are designed to support local agriculture, ensuring farmers have access to efficient and regulated meat processing services. The design and layout of such facilities, along with the implementation of rigorous sanitation protocols, play a pivotal role in maintaining meat safety and quality.

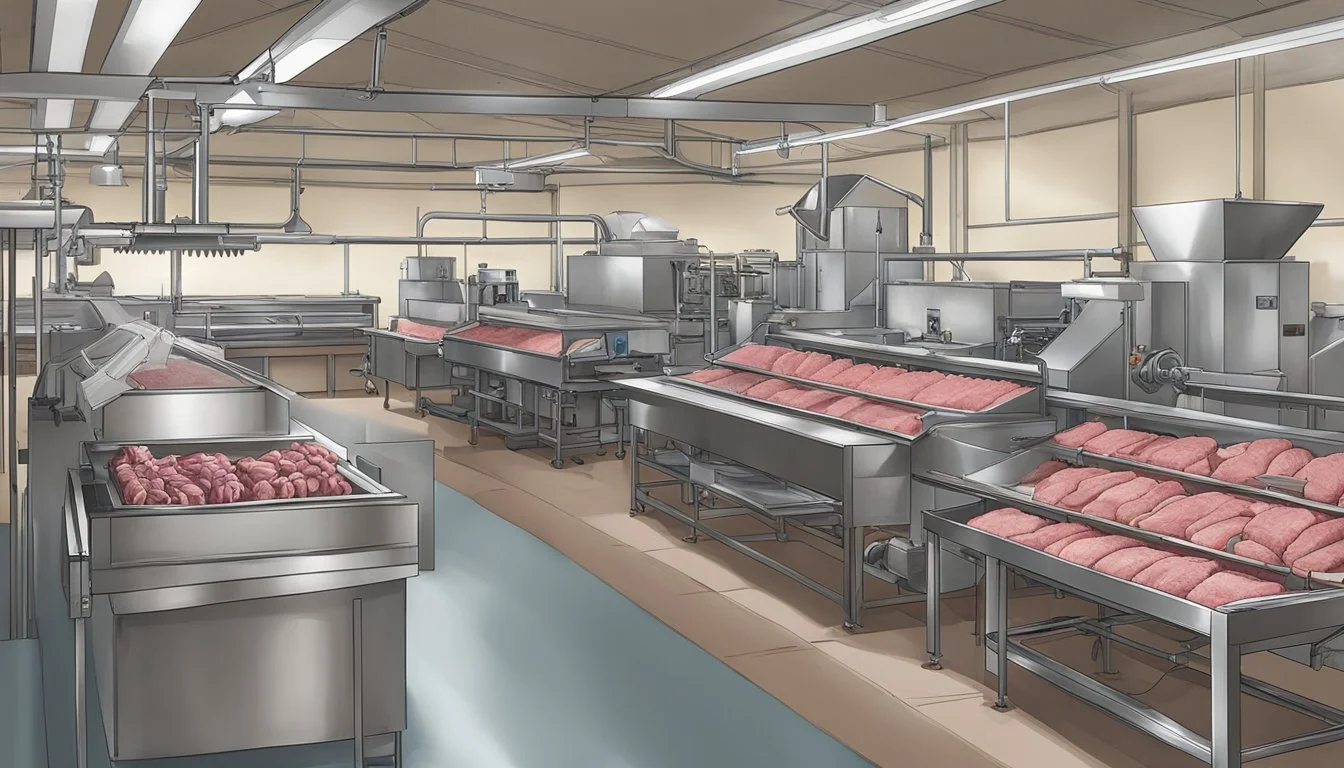

Design and Layout of Processing Units

Processing facilities in North Dakota adhere to specific standards to ensure the safe and efficient handling of meat products. Slaughter units and processing areas are structured to create a seamless flow from the point of receiving livestock to the final packaging of processed meat. The layout typically includes a reception area for livestock, a stunning area, bleeding and evisceration section, and a processing and packaging area. These facilities often include a trailer setup to allow flexibility in processing and easy transportation to different farms.

Farmers in the state can utilize these units to convert their livestock into market-ready products on their own farms. This reduces the need for long-distance transportation of animals and allows for fresher products. The layout is crafted to minimize cross-contamination risks and enhance worker safety.

Sanitation and Waste Management

Sanitation is a cornerstone of meat processing facilities to prevent contamination with pathogens such as E. coli O157, Salmonella, and Campylobacter. The processing areas are equipped with facilities for thorough cleaning and disinfection. This includes hot water, chemical sanitizers, and adequate drainage systems to handle waste.

Cleaning protocols are rigorously defined and include:

Pre-rinse to remove debris

Application of detergents

Post-rinse after chemical sanitizers

Regular deep cleans of equipment and surfaces

Waste management is critical to control odors and potential biohazard spread. Solid waste is often handled through rendering or composting, while liquid waste is managed via treatment systems that protect water quality. The design of waste management systems is integral to the facility, ensuring the environmental impact is minimized and complies with state and federal regulations.

Economic and Market Considerations

In North Dakota, on-farm meat processing has potential economic implications on local economies and the meat market, including influences on farmer’s incomes and job growth within the state.

Analyzing On-Farm Processing Profitability

On-farm meat processing can alter the economic landscape for farmers by providing a means to increase their income. By processing meat directly on the farm, they can bypass traditional meat processing bottlenecks, saving on transportation and handling costs. For example, the investment in on-farm facilities can offset the cost savings from using large-scale processors. However, farmers must consider the initial capital expenditures for equipment and facilities compliant with regulatory standards.

To determine profitability, farmers should compare the costs of:

Facility construction or modification

Equipment purchase or leasing

Obtaining necessary certifications and inspections

Labor, both skilled and unskilled

Marketing and distribution channels

Against the potential revenue increase from:

Selling meat products at a premium due to local and fresh appeals

Reducing losses from third-party processing fees

Lowering transportation costs

Marketing Meat Products to Consumers

When North Dakota farmers bring their products directly to markets, strategic marketing plays a crucial role in the success of on-farm processed meats. They should focus on:

Targeting Local Markets:

Capitalize on the growing demand for locally sourced meats.

Engage in community-supported agriculture (CSA) programs and farmers' markets.

Product Differentiation:

Emphasize quality, taste, and the story behind their product to stand out.

Use terms like "fresh," "locally raised," and "sustainably processed" to attract consumers.

Online Marketing:

Utilize websites, social media, and email campaigns to broaden their reach.

Offer insights into farm practices and behind-the-scenes views to build transparency and trust.

By considering these economic and market dynamics, on-farm meat processors in North Dakota can assess the viability of this venture and identify strategies for growth. This approach can also contribute to a more resilient supply chain, reduce meat processing bottlenecks, and create jobs, fostering overall growth in the state's meat market.

Emergency Preparedness and Biosecurity

Effective emergency preparedness and biosecurity are critical for mitigating risks associated with disease outbreaks and foodborne pathogens in on-farm meat processing operations in North Dakota. This ensures not only animal health and food safety but also the resilience of the farming sector to crises such as the COVID-19 pandemic.

Disease Outbreak and Foodborne Pathogen Management

On-farm meat processing facilities must adopt stringent measures to manage the risk of disease outbreaks and control foodborne pathogens such as E. coli O157, Salmonella, and Campylobacter. These measures include:

Regular Health Checks: Intensive surveillance and diagnostic testing to detect and respond to any signs of illness in livestock.

Sanitation Protocols: Thorough cleaning and disinfection routines to prevent the spread of pathogens during butchering and slaughtering processes.

Controlled Access: Restricted access to processing areas to prevent contamination and ensure biosecurity.

Crisis Management Strategies for Outbreaks

Strategies for handling crises like a disease outbreak are multi-faceted and require a coordinated approach involving all stakeholders:

Rapid Response Plans: Detailed and rehearsed action plans that can be swiftly implemented upon detection of pathogens or in the event of public health emergencies like the spread of COVID-19.

Collaboration: Coordination between farmers, health experts, and authorities to enhance resilience and protect public health.

Education and Training: Equipping farm and slaughterhouse employees with the knowledge and skills necessary to execute biosecurity measures effectively under crisis conditions.

Both sections underscore the importance of rigorously applied biosecurity measures and emergency preparedness to assure safety in the meat supply chain, shielding consumers and the industry from the dangers posed by widespread pathogens and crises.

Workforce Development and Training

For North Dakota's on-farm meat processing industry to thrive, highlighting an emphasis on robust workforce development and comprehensive training programs has become essential. These initiatives are key to ensuring a steady flow of proficient workers capable of safely fulfilling the increasing demands of meat processing jobs on farms.

Implementing Effective Employee Training Programs

In North Dakota, effective employee training programs are a cornerstone for building a skilled meat processing workforce. Farmers and meat processors are investing in hands-on training strategies that cover a broad spectrum of skills necessary for on-farm butchering and slaughter. Cultural techniques for handling livestock, understanding animal anatomy, and mastering precision cutting are among the vital job skills imparted.

Training Formats Include:

On-the-job training: Workers receive practical, task-oriented instruction.

Classroom-based education: This structured setting introduces theoretical aspects of meat processing.

Benefits for Workers:

Skill enhancement: Improved employability and job performance.

Professional growth: Opportunities for advancement within the farming and meat processing sectors.

Worker Safety and Occupational Health Standards

Adhering to worker safety and occupational health standards is critical for the wellbeing of individuals involved in the North Dakota meat processing industry. The state mandates strict protocols to mitigate workplace hazards inherent in meat processing jobs. These standards ensure that workers are protected from potential injuries and health risks, thereby fostering a safe and compliant farming environment.

Key Safety Measures include:

Personal protective equipment (PPE) usage

Regular training refreshers on safety protocols

Safety Training Focus:

Emergency response: Preparing workers for potential on-site accidents.

Equipment handling: Ensuring safe utilization of tools and machinery.

By maintaining diligent safety practices, farmers and meat processors contribute to the creation of sustainable jobs within a secure working environment, benefiting the entire agricultural community.

Future Perspectives in On-Farm Meat Processing

The landscape of on-farm meat processing in North Dakota is evolving, driven by innovations and genetic advancements that promise enhanced meat quality and more efficient livestock management for farmers.

Innovations in Livestock Handling and Butchering

State-of-the-art Technology: North Dakota's farmers are increasingly employing advanced technology in livestock handling and butchering. The introduction of mobile slaughtering units is set to transform the traditional processing model by providing on-site slaughter services, which can reduce stress for the animals and can lead to improvements in meat quality. This is particularly significant for cattle and hogs, the primary livestock in the state.

Automated Systems: New automated systems in butchering can deliver precision cuts that maximize yield while maintaining quality.

Training Programs: To support this growth, state programs aim to provide training for young farmers, ensuring they possess the knowledge necessary for these complex systems.

Potential for Genetic Selection and Breeding

Enhanced Meat Quality: The potential of genetic selection and breeding programs has become a cornerstone of on-farm meat processing. North Dakota's farming community is looking to capitalize on this by focusing on breeding cattle and hogs that possess traits for improved growth rates and meat quality.

Selective Breeding: By selectively breeding animals, farmers aim to produce livestock that is not only resilient to local climate extremes but also meets market demands for premium meat products.

Collaborative Projects: Collaborations between state agricultural departments and local farmers could potentially result in shared genetic pools that benefit the wider farming community's output.

Through these advancements, the state of North Dakota is positioning its farmers to meet the growing demands for high-quality meat products while also contributing to a sustainable and efficient agricultural sector.

Conclusion

In North Dakota, the embrace of on-farm meat processing reflects a commitment to bolstering the state's agricultural economy. Farmers and ranchers view this practice as a means to gain greater control over the quality of their livestock products. Through on-farm processing, they are able to provide locally-sourced meats, thus supporting the enhancement of community resilience and food sovereignty.

Meat processing on the farm poses its unique challenges, including navigating strict regulations and substantial capital investments. Despite these hurdles, the agility afforded by smaller scale operations allows for responsiveness to market demands and potential for increased financial stability.

Ranching communities within the state have displayed adaptability and innovation, factors crucial to sustaining the industry's momentum. Local meat processing is not only an assertion of this adaptability but also an investment in the state's agricultural viability.

North Dakota's agricultural landscape continues to be shaped by the endeavors of its farmers and their ability to streamline meat processing channels, with the ultimate aim of yielding high-quality products. This is aligned with the agricultural tenets of ecological stewardship, linking the health of livestock to the health of communities.