On-Farm Meat Processing, Butchering, and Slaughter in Mississippi

A Guide to Local Practices

In Mississippi, there is growing interest and activity in on-farm meat processing, which provides an alternative to the traditional meat supply chain. This approach allows local farmers to have greater control over the butchering and slaughtering of livestock, enabling them to cater to niche markets, maintain the quality of their products, and ensure humane treatment of animals. It addresses a significant bottleneck in the meat processing system where small to mid-sized farms often struggle with limited access to processing facilities, an issue that impacts the state's agricultural economy.

The state's focus on developing on-farm processing aligns with a nationwide initiative to support smaller, local meat processors. In doing so, it strives to enhance rural economies, support the local supply chain, and provide consumers with locally produced meat options. Mississippi farmers who engage in on-farm processing must navigate a range of challenges including capital investment, adherence to regulations, and managing public perception. Despite these obstacles, many are finding opportunities for growth and resilience in a fluctuating market.

On-farm processing in Mississippi is not just a response to economic and logistical challenges; it represents a shift towards a more sustainable food system. This system emphasizes traceability, reduced transportation costs, and a closer connection between consumers and the source of their food. While it holds promise, the practice of on-farm meat processing must be executed in compliance with USDA regulations to ensure food safety and public health, emphasizing the importance of access to appropriate resources and information for farmers interested in this processing model.

Mississippi Meat Processing Overview

Mississippi's meat processing industry plays a critical role in supporting local agriculture, ensuring food safety, and complying with both state and federal regulations. This section details how meat processing contributes to the state's economy, outlines the regulatory environment, and provides an overview of the meat species processed within Mississippi.

The Role of Meat Processing in Mississippi's Economy

Meat processing in Mississippi is a significant aspect of the state's agricultural sector, providing a vital link between farmers and the market. Processing facilities convert livestock into a variety of meat products suitable for consumption, thereby adding value to raw livestock and supporting the local economy. This industry not only aids in sustaining the livelihood of local farmers, but it also contributes to employment and economic growth within the state.

State and Federal Regulations in Meat Processing

Regulations governing meat processing in Mississippi are enforced to ensure food safety and public health. The Mississippi Department of Agriculture and Commerce (MDAC) works in cooperation with the USDA to oversee meat processing operations. The state adheres to laws such as the Meat, Meat-Food, and Poultry Regulation and Inspection Law of 1960 and the Mississippi Inspection Law of 1968, which were established to align with federal regulations. There are state-inspected facilities alongside those inspected by the USDA, allowing for a comprehensive regulatory framework that ensures processed meats meet stringent safety standards.

Overview of Meat Species and Products

In Mississippi, a range of meat species are processed, including cattle, pigs, sheep, goats, and poultry. Some species, particularly poultry, have certain exemptions allowing small-scale farmers to operate under less stringent regulations, such as the 20,000-bird exemption for on-farm poultry processing. However, meat from species that are slaughtered and processed under exemptions intended for personal use cannot be sold. The variety of meat products stemming from these species caters to consumer demands and preferences, with processed goods ranging from traditional cuts to specialty products.

On-Farm Processing Fundamentals

Farmers considering on-farm processing in Mississippi must navigate a series of critical steps, from facility setup and legal compliance to the design and equipment that will ensure food safety and operational efficiency.

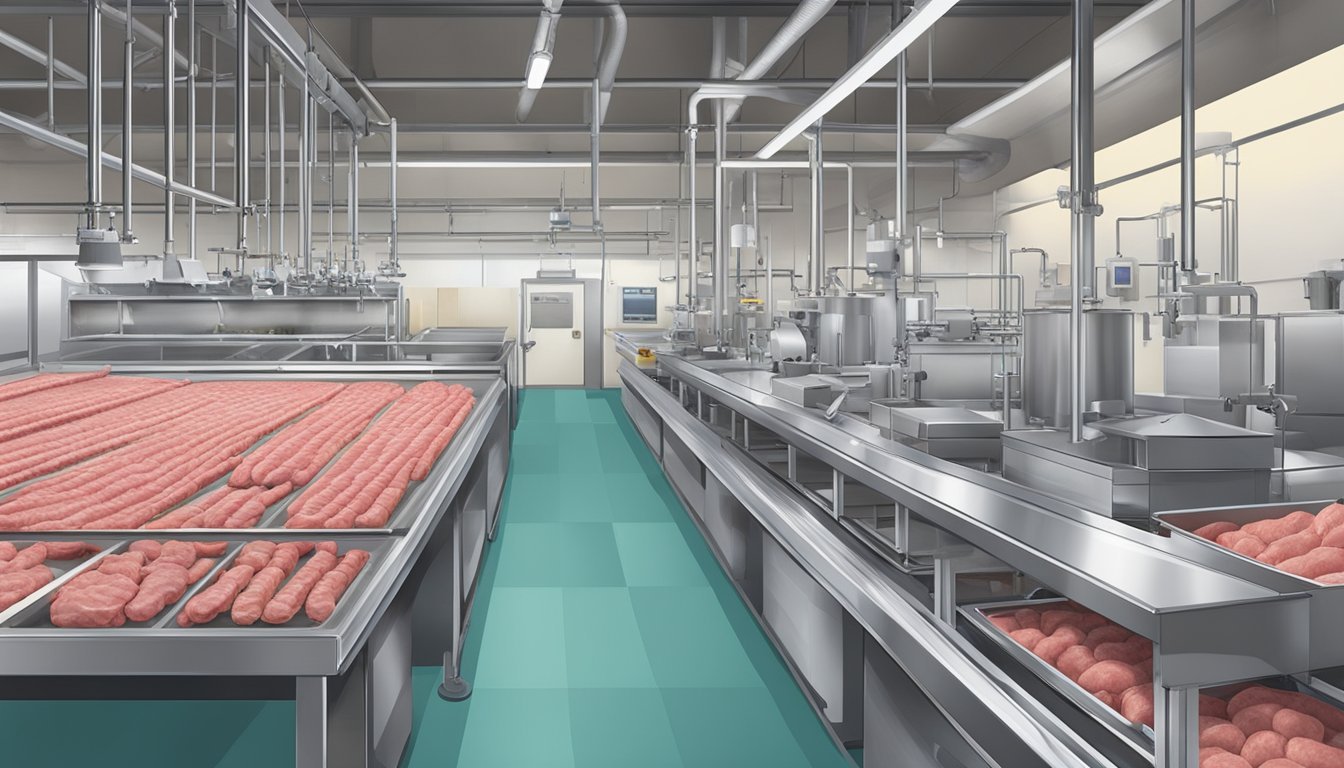

Setting Up On-Farm Processing Facilities

To begin on-farm processing, a farmer must construct a facility that complies with local and federal regulations. Space allocation will depend on the scale of operations and may include separate areas for slaughter, evisceration, and further processing. Facilities must be designed to avoid contamination and ensure the safety of both workers and the food produced.

Obtaining Licensing and Permits for Slaughter and Processing

Before any slaughter or processing begins, farmers must secure the necessary licenses and permits. This ensures adherence to food safety regulations and allows for the legal sale of meat products. In Mississippi, regulations will include state-specific health and environmental standards, as well as federal USDA guidelines if the meat is to be sold interstate.

Design and Equipment Considerations for Processing Facilities

Proper design and equipment are essential for maintaining food safety and product quality in on-farm processing. Key equipment choices include stunners for humane slaughter, scalding tanks for pig processing, and refrigeration units for meat storage. Stainless steel surfaces and tools are favored for ease of cleaning and sanitation. Each piece of equipment must meet the regulatory standards pertinent to on-farm processing operations.

Slaughter Operations

This section outlines the essential practices and requirements for effective slaughter operations in Mississippi. It provides information on humane slaughter methods, steps for processing both livestock and poultry, and the importance of waste management to comply with environmental standards.

Humane Slaughter Practices

In Mississippi, slaughter operations must adhere to strict guidelines to ensure the humane treatment of animals. This necessitates the use of practices that minimize pain and stress to the animals. Key elements include:

Proper restraint of animals to prevent injury

Use of approved stunning methods to render the animal unconscious before slaughter

Processing Livestock and Poultry

Processing of livestock and poultry involves several steps from slaughter to packaging, with food safety as a paramount concern. The process requires:

Inspection of animals before and after slaughter

Sanitary handling and processing to prevent contamination

Cutting and deboning in facilities that meet health codes

Proper storage at safe temperatures to maintain meat quality

Waste Management and Environmental Compliance

Efficient waste management systems are essential in slaughter operations to limit environmental impact and comply with regulatory standards. Operations must include:

An appropriate sewage treatment plan for wastewater

Solid waste disposal methods for non-edible byproducts

Continuous monitoring for compliance with state and federal regulations

Butchering Techniques

In Mississippi, on-farm meat processing requires farmers to employ skillful butchering techniques that cater to different types of livestock. These methods ensure the efficient conversion of animals into meat while adhering to safety standards and regulatory requirements.

Beef and Pork Butchering

For beef and pork, both of which are significant to Mississippi's agricultural output, the primary butchering technique involves several stages post-slaughter. Farmers begin with exsanguination, a process vital for meat quality and preservation. They then proceed to skin or scald and dehair the carcass, particularly for hogs, as part of the preparation for evisceration. Evisceration must be carefully conducted to avoid contamination, with organs either set aside for further processing or disposal according to safety guidelines.

Breaking the carcass down into smaller primal cuts follows, with a focus on preserving meat integrity and optimizing yield. Utilizing proper tools — such as saws for splitting and knives for trimming — is crucial. For pork, curing and smoking are additional steps that might be applied to produce traditional Mississippi delicacies like smoked ham or bacon.

Poultry and Small Livestock Butchering

Butchering poultry, such as chickens, and small livestock such as sheep and goats, requires a different set of techniques due to their size and anatomy. The process starts with slaughter, typically involving a swift cut to the throat for a quick bleed-out, ensuring humane treatment and meat quality. Scalding is then commonly done to facilitate feather or hair removal.

Evisceration in poultry and small livestock must be done with precision to avoid puncturing the internal organs, which can contaminate the meat. The carcasses are then often chilled to reduce the risk of bacterial growth before they are sectioned into parts or sold as whole animals, depending on market demand.

Age and Condition of Animals

The age and condition of the animal notably influence the choice of butchering techniques. Mature cattle and hogs tend to have tougher meat and more fat, requiring longer aging times to tenderize the meat. In contrast, younger animals, such as veal from calves or lamb from younger sheep, are usually tender and require less stringent aging.

Animal condition is equally crucial, as healthy animals provide high-quality meat. Farmers must be vigilant in the care and inspection of their livestock prior to slaughter to ensure that only those in optimal health are processed. This vigilance contributes directly to the safety and quality of the meat produced on the farm.

Mobile Slaughter Units

Mobile slaughter units have become a strategic solution to address the challenges of meat processing on farms. They offer flexibility, reduce animal stress by allowing slaughtering on-site, and cater to the need of small-scale farmers.

Benefits and Challenges of Mobile Slaughter

Benefits:

Reduced Stress for Livestock: Animals processed using mobile slaughter units experience less stress because they are not transported to distant facilities.

Flexibility and Convenience: Farmers can schedule slaughtering based on their own timeline and avoid the delays that can occur with stationary processing facilities.

Quality Control: On-farm slaughtering can potentially lead to better meat quality as animals are less stressed.

Challenges:

Regulatory Compliance: Operators must ensure that mobile units meet all state and federal inspection requirements.

Cost: While it reduces transportation costs, the initial investment and maintenance for a mobile slaughtering unit can be significant.

Capacity Limitations: They may have limited capacity compared to stationary facilities, often restricting the number of animals that can be processed at one time.

Setting Up a Mobile Slaughtering Unit

To set up a mobile slaughtering unit in Mississippi, farmers must take into account several specific considerations:

Compliance with Regulations: Ensure the unit complies with USDA regulations and the Food Safety and Inspection Service (FSIS) requirements.

Unit Specifications: A typical unit includes a 38-foot-long trailer for meat processing, with areas designated for each stage of slaughter.

Facility Features: Important features often include refrigeration, waste disposal systems, and equipment for various slaughtering processes.

Training and Operation: Proper training for those operating the unit is essential to maintain safety and regulatory standards.

These mobile units serve as a critical resource for local producers, providing a legal and practical alternative to transporting livestock to regional processors, which may not be easily accessible.

Direct Sales and Marketing

The success of on-farm meat processing in Mississippi hinges on effective direct sales and marketing strategies. By targeting local consumers, restaurants, and institutions, farmers can achieve better profit margins and foster community support.

Direct-to-Consumer Sales Strategies

Farmers in Mississippi can leverage several direct-to-consumer sales tactics to market their on-farm processed meats. Farmers' markets are a traditional venue where farmers can sell a variety of meat products directly to the public. They can also offer Community Supported Agriculture (CSA) shares, which often include meat along with other farm products. Additionally, online platforms extend the reach beyond local geography, enabling farmers to attract a wider consumer base. Crucial to these strategies is compliance with state and federal meat processing regulations, ensuring consumer confidence in the safety and quality of their products.

Farmers' Markets: a space to interact personally with consumers

CSA Shares: pre-sold packages including a variety of meat products

Online Sales: an extension of the market reach through digital platforms

Partnering with Local Restaurants and Institutions

Building relationships with local restaurants and institutions is paramount for farmers looking to enter commercial markets. Offering high-quality, locally sourced meats to restaurants helps in creating a niche market, appealing to consumers who value local farm-to-table initiatives. By forming partnerships, they can offer unique cuts and meats that are not readily available through large distributors. For institutional buyers like schools or hospitals, farmers must ensure consistent supply and meet specific product requirements, factoring in volume discounts and long-term agreements for a sustainable partnership.

Local Restaurants: a partnership opportunity for unique, locally sourced menu items

Institutions: potential for large volume sales through contracts requiring consistent supply and meeting precise product specifications

Food Safety and Quality Assurance

In Mississippi, food safety and quality assurance in on-farm meat processing are paramount to ensure the health and safety of consumers. Legislation and regulations set by both state and federal agencies guide the handling, storage, and inspection of meat products to mitigate risks associated with foodborne illnesses.

Handling and Storage of Meat Products

The handling and storage of meat products on Mississippi farms must adhere to strict guidelines to prevent contamination and spoilage. Temperature control is critical; meat should be stored at 40°F or below to inhibit bacterial growth. Cross-contamination is a significant concern, and it is imperative that raw meat is separated from other food products to prevent the spread of pathogens. Equipment and surfaces must be regularly sanitized, and meat handlers should be adequately trained in proper food safety practices.

State-Inspected versus USDA-Inspected Facilities

Facilities that process meat in Mississippi may be either state-inspected or USDA-inspected. State-inspected facilities must follow regulations that are at least equal to USDA standards to ensure meat products are safe for consumption. However, there is a fundamental difference: meat processed in state-inspected facilities is typically only approved for sale within the state, unless the plant is part of the Cooperative Interstate Shipment (CIS) program. In contrast, meat from USDA-inspected facilities is considered an approved source and can be sold across state lines, ensuring a broader market reach while maintaining rigorous food safety measures.

Legal and Financial Considerations

When establishing an on-farm meat processing operation in Mississippi, producers must navigate a complex landscape of legal requirements and financial considerations. Ensuring compliance with regulations and leveraging available funding opportunities are keys to a successful enterprise.

Insurance and Liability for On-Farm Processors

Insurance is critical for on-farm meat processors in Mississippi to protect against potential liabilities. They must hold comprehensive coverage that includes:

General liability insurance: To cover accidents that could occur on their property.

Product liability insurance: Specifically in case of contamination or illness caused by their meat products.

Additionally, processors must be aware of Mississippi's regulations pertaining to on-farm slaughter and processing to ensure that they are compliant with state and federal laws, which will in turn affect their liability.

Grants and Financial Assistance Programs

Grants and financial assistance are available for Mississippi’s niche meat processors to bolster their operations. They can explore programs offered by entities such as:

The U.S. Department of Agriculture (USDA): Grants may be available for meat and poultry processors looking to expand operations or transform the food supply chain.

Niche Meat Processor Assistance Network (NMPAN): A network offering support to small-scale processors including financial guidance.

Contact information for grants and assistance programs:

Agency Contact Details USDA Rural Development 1-800-670-6553 Available for queries on business and community programs. Niche Meat Processor Assistance Network Contact NMPAN Resources and network support for small-scale processors.

Producers should consult with legal experts to fully understand the implications of these legal and financial considerations for their specific operations.

Innovations and Trends in Meat Processing

As the meat processing industry in Mississippi adapts to changing demands and advances in technology, it encounters both opportunities and challenges. Two pivotal elements currently shaping this landscape include emerging technologies and the aftershock of the COVID-19 pandemic.

Emerging Technologies in Meat Processing

Innovative methods are revolutionizing how meat is processed on farms across Mississippi. Key developments include:

High-pressure processing: This technique extends the shelf life of meat products without the need for preservatives by using extreme pressure to eliminate pathogens.

Shockwave technology: By subjecting meat to high-energy pulses, this technology tenderizes the product and can enhance flavor.

Ultrasound processing: Utilized for meat tenderization and assessing the quality of the product, ultrasound is a non-invasive method gaining traction.

Electrical stimulation: Applied post-harvest, this method improves meat tenderization and quality.

These advancements aid local processors in enhancing food safety, improving product quality, and reducing environmental impact. They are increasingly being adopted to keep pace with both national standards and consumer expectations.

Impact of COVID-19 on Meat Processing Industry

The COVID-19 pandemic brought significant disruptions to meat processing industries, including in Mississippi. Processors faced several challenges including:

Worker safety: COVID-19 outbreaks in processing facilities highlighted the need for enhanced safety protocols to protect employees.

Supply chain interruptions: Movement restrictions and shifts in consumer behavior caused by the pandemic disrupted traditional supply chains, forcing processors to adapt rapidly to maintain operations.

Increased demand for local processing: As large-scale processors struggled with COVID-related shutdowns, there was a surge in interest in local, on-farm processing, which provided an opportunity for smaller processors to fill gaps in the market.

The pandemic underscored the importance of agility in the meat processing industry, with many processors in Mississippi investing in technologies that allow for safer, more efficient operations and a resilient supply chain.

Challenges Facing On-Farm Processing

On-farm meat processing in Mississippi faces significant obstacles, from the bottleneck in meat processing capacity to environmental and local community considerations. These challenges have tangible impacts on farmers, animals, and the marketplace.

Addressing the Meat Processing Bottleneck

The meat processing bottleneck refers to a lack of sufficient processing facilities relative to the number of animals ready for slaughter. Farmers often face lengthy wait times that can extend for months, delaying access to the marketplace and potentially causing financial strain. This bottleneck can lead to:

Overcrowding at farms as animals await slaughter, increasing the risk of disease and death

Increased stress for both livestock and farmers

Impediments to scaling operations to meet market demand

An insufficient number of USDA-inspected facilities exacerbates these issues, limiting farmers' options to sell their meat across state lines.

Environmental and Community Concerns

On-farm processing must address key environmental challenges, including waste management and the mitigation of odor. The presence of mud, manure, and other byproducts can create environmental concerns that need careful management to avoid contamination of water sources and the surrounding ecosystem. Communities situated near on-farm processing facilities may have apprehensions concerning:

Odor and noise that comes from the slaughtering and processing activities

Potential decreases in property values and quality of life

The management of waste products and byproducts, ensuring they do not pose a health or environmental risk

Farmers and processors must work conscientiously to address these valid community concerns while complying with stringent environmental regulations.

Case Studies and Examples

In the realm of on-farm meat processing and butchering, several states and cooperatives have pioneered successful approaches. Two such entities that stand as exemplars are Wisconsin and the Island Grown Farmers Cooperative, each providing unique insights into the niche meat processing landscape.

Wisconsin's Niche Meat Processor Model

In Wisconsin, the state's first mobile slaughtering unit exemplifies innovation in meat processing. Introduced by forward-thinking professionals in the meat industry, this 26-foot truck allows for the slaughtering of livestock directly on the farm, with the capacity to process animals to the point of hanging carcasses onto a rail in a cooler. This mobile unit is a direct response to farmers' needs for more accessible meat processing and evidences Wisconsin's commitment to developing niche meat processing capabilities.

Island Grown Farmers Cooperative's Success

The Island Grown Farmers Cooperative (IGFC), located in the Puget Sound region, provides an outstanding example of a community-based approach to meat processing. This cooperative operates under a USDA-inspected mobile slaughtering unit, allowing farmers to process their livestock on-site. They have effectively bridged the gap between local farmers and markets, emphasizing the collective power of small-scale operations to succeed in the niche meat processing industry.

The Niche Meat Processor Assistance Network has recognized models like IGFC's as pivotal for connecting farmers to the resources and networks necessary for sustainable meat production and processing. IGFC's model prioritizes promoting local products and supporting the growers within their community, creating a robust blueprint for success in the field.

Marketplaces and Consumer Demand

In Mississippi, consumer preferences and a rising interest in specialty meats significantly shape the marketplaces for on-farm meat processing. This shift in demand is transforming the local meat market, with consumers increasingly seeking out non-conventional options such as buffalo and elk, alongside the traditional red meat and poultry offerings.

Understanding Consumer Preferences

Consumers in Mississippi are becoming more discerning with regards to the source and quality of their meat. They are showing a preference for locally processed products, attributing value to transparency in production and slaughter processes. This interest extends to the desire for fresh, less processed chicken, moving beyond the typical grocery store offerings. As such, on-farm meat processing operations are not only responding to the demand for standard cuts but also for custom butchery that aligns with consumers’ ethical and quality standards.

The Demand for Specialty Meats

Within the marketplace, there is notable growth in the demand for specialty meats, such as buffalo and elk. These products cater to a niche yet growing consumer base that prioritizes health benefits and a leaner protein source. On-farm processors in Mississippi are taking note, accommodating these preferences by expanding their operations to include these specialty meats. With chicken processing already established, the move towards processing buffalo and elk represents an evolution of the meat market, with local producers and processors playing a pivotal role in meeting changing consumer demands.

Transparency and Trust

In Mississippi, on-farm meat processing is gaining ground as both farmers and consumers look closer at the source and handling of their meat. Transparency plays a pivotal role in building consumer trust, with an emphasis on each stage of the process from farm to table.

Building Consumer Trust Through Transparency

Mississippi farmers are opening their operations to scrutiny to establish confidence in their products. They engage in direct-to-consumer sales, which necessitates a clear communication of their methods. This openness allows for:

Farm Visits: Where consumers can see the conditions in which the animals are raised.

Processing Disclosure: Detailed information on how animals are processed on the farm.

These practices offer local consumers a way to verify the claims made about the meat they purchase, assuring them of the ethical and health standards adhered to by the state's farmers.

Tracing Meat from Farm to Table

Traceability is integral to a transparent meat production system, providing consumers with the assurance of safety and quality. Mississippi on-farm meat processors implement robust tracking systems to follow meat through each phase:

Identification: Each animal is tagged and recorded.

Slaughter Records: Comprehensive details about the slaughter process are maintained.

Processing Logs: Careful logging of butchering and packaging dates ensures freshness.

By tracing meat from farm to table, consumers can trust the direct-to-consumer pipeline to be free from contamination and mishandling, with a clear lineage back to the state's farms. Transparent practices help reinforce the trust between local producers and their customers, creating a solid foundation for the industry's growth within Mississippi.

Conclusion

On-farm meat processing in Mississippi represents an opportunity for local farmers and producers to enhance financial stability and gain control over the quality of meat products. Utilizing USDA-guided facilities and adhering to strict regulations, producers can mitigate challenges related to capital investment and public perception.

Effective on-farm processing requires:

Compliance with Regulations: Following local, state, and federal guidelines ensures safety and humane treatment throughout the processes of raising, slaughtering, and butchering animals.

Investment: Initial capital is necessary for setting up facilities that meet the required standards for meat processing.

Quality Control: By managing the processing on-site, farmers can directly impact meat quality, from selection through to the final product.

Education and Training: Operators must be well-versed in humane handling, food safety, and the legal frameworks governing meat processing.

The economic landscape is constantly changing, and Mississippi producers are adapting by considering these on-farm practices to create a more resilient agricultural community. Despite obstacles, the benefits of localized meat production have the potential to foster sustainability in the state's livestock sector.