On-Farm Meat Processing, Butchering, and Slaughter in Minnesota

A Guide to Local Practices

In Minnesota, the landscape of meat processing is evolving to accommodate the increasingly popular practice of on-farm slaughtering and butchering. The state hosts a variety of meat and poultry processing businesses, some of which are USDA-inspected plants essential for the broader commercial market, while others operate under custom exempt status. These custom exempt facilities are instrumental for small-scale farmers, allowing them to process meat for personal consumption, non-paying guests, and employees without the need for federal inspection, provided the meat is not sold.

The on-farm slaughter concept in Minnesota is driven by a push for local, sustainable food systems and a response to the bottleneck in meat processing capacity. This framework aligns well with consumer interest in locally sourced products and transparent farm-to-fork supply chains. Notably, the Minnesota Farmers Union is developing a mobile meat processing facility to further support this niche, providing a slaughter unit capable of traveling across the region to meet the processing needs at the site of various farms.

This shift toward local processing is underpinned by educational investments, such as meat cutting programs initiated by Central Lakes College and Ridgewater College. These programs aim to train a new generation in the trades of animal slaughter, butchery, and processing. Through such efforts, the state is working to ensure that the skills necessary to support on-farm meat processing are available, addressing workforce needs and bolstering the regional economy.

Legal Framework for On-Farm Meat Processing in Minnesota

In Minnesota, producers involved in on-farm meat processing must navigate a mix of state and federal regulations, which oversee everything from slaughtering to sale, and are designed to ensure food safety and animal health.

State Regulations and USDA Oversight

The Minnesota Department of Agriculture (MDA) regulates on-farm meat processing in conjunction with the USDA's Food Safety and Inspection Service (FSIS). Producers must ensure their operations comply with state regulations and undergo USDA oversight, which involves continuous inspection for facilities that slaughter and process meat for interstate commerce.

Licensing and Permits

To legally process meat on the farm, producers in Minnesota need to obtain the necessary licenses and permits. This includes registering their business with the state and potentially applying for exemptions that suit smaller operations, which is consistent with other states like Illinois and New Jersey.

Custom Exempt Processing Requirements

Custom exempt processing is an option for farmers who wish to process meat without continuous USDA inspection. In this scenario, the meat can only be returned to the owner of the animal for personal use and is not for sale. To engage in custom exempt processing, slaughterhouses must still comply with basic sanitation standards and are subject to periodic inspections.

Understanding the Grant of Inspection

For producers looking to sell meat, applying for a USDA Grant of Inspection is essential. This grant allows producers to operate as a USDA facility under continuous FSIS inspection, ensuring adherence to federal regulations. Facilities in Minnesota and states such as Wisconsin can apply for a grant through the FSIS.

Compliance with Federal and State Regulations

Producers must adhere to both federal and state regulations, which include Current Good Manufacturing Practices (CGMP) to minimize the risk of contamination during processing. Minnesota's own regulations also apply and may involve specific requirements for the handling, processing, and packaging of meat.

Interstate Regulations and Considerations

When meat products cross state lines, they must comply with federal regulations, a rule that applies equally to facilities in Minnesota and neighboring states. Interstate commerce requires adherence to USDA regulations and continuous FSIS inspection.

Bovine Spongiform Encephalopathy (BSE) Preventative Measures

Meat processors in Minnesota, as with processors in all states, must follow protocols to prevent the spread of Bovine Spongiform Encephalopathy (BSE), commonly known as mad cow disease. This includes removing specified risk materials from cattle during slaughter and processing.

Halal and Other Specialty Processing

Facilities that offer Halal and other specialty meat processing must meet standard federal and state regulations in addition to religious or cultural guidelines. Minnesota, recognizing diverse consumer preferences, accommodates such niche processing within its regulatory framework.

This overview highlights the meticulous legal structure governing on-farm meat processing in Minnesota, aimed at ensuring safe, high-quality meat products through rigorous and comprehensive regulatory compliance.

Infrastructure for On-Farm Meat Processing

On-farm meat processing in Minnesota requires meticulous attention to infrastructure, ensuring compliance with regulations and meeting the demands of both animals and processors.

Facility Requirements and Design

Farm-based slaughterhouses in Minnesota must conform to specific design parameters to operate legally. A USDA-inspected slaughterhouse typically includes a receival area, a stunning area, and separate zones for slaughtering and cutting. The facility design should facilitate efficient workflow and clean operations, often featuring non-porous surfaces, adequate drainage, and a rail system to move carcasses.

Equipment Needed for Efficient Processing

Essential equipment for on-farm meat processing includes but is not limited to:

Stunning devices

Knives and cutting implements

Saws for cutting through bone

Conveyors and rail systems

Wrapping and packaging stations

This equipment should be food-grade quality and designed for the rigors of meat processing.

Waste Management and Environmental Control

An efficient sewage treatment system is crucial for managing waste. Facilities must handle animal by-products responsibly, adhering to Minnesota's environmental control standards, which include solid waste treatment and liquid waste management, often requiring a sewage treatment plant or system.

Mobile Slaughterhouses and Units

Mobile slaughtering units provide flexibility, allowing farmers to process animals directly on the farm. These units are self-contained trailers equipped with essential processing tools and a waste containment system. They must still comply with state and federal regulations, similar to stationary facilities.

Additional Processing: Smoking and Wrapping

Secondary processing, such as smoking in a smokehouse and meat wrapping, can occur on-farm for added value. Smoking requires a dedicated smokehouse to impart flavor, and wrapping calls for clean, designated areas with equipment for airtight packaging of the product.

Operational Aspects of Meat Processing

Meat processing on farms in Minnesota encompasses a range of activities from slaughtering to carcass handling. Each step is critical and contributes to the final meat quality, which is crucial for both the producer and consumer.

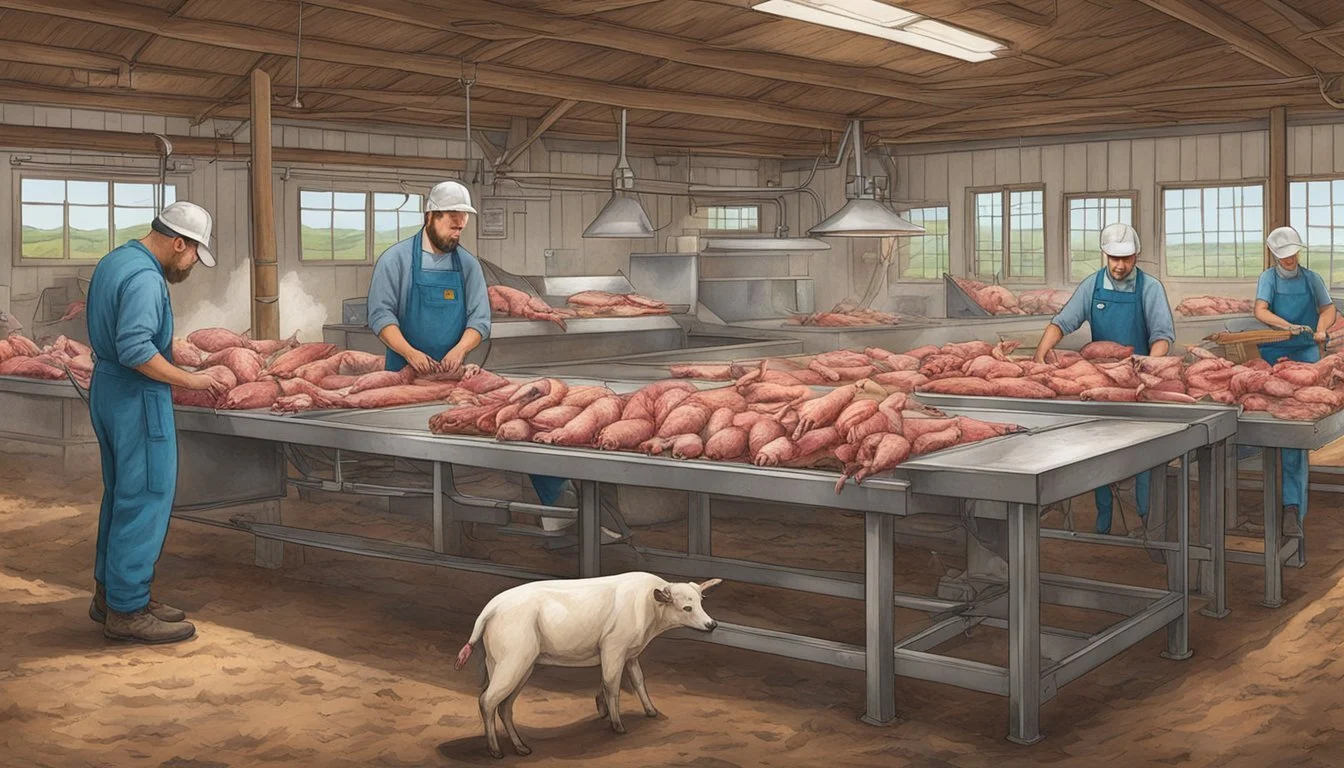

Slaughtering Techniques and Livestock Management

Slaughtering of livestock such as beef, hogs, sheep, buffalo, and elk on Minnesota farms must adhere to humane handling regulations to minimize stress for the animals. This includes the use of proper restraint techniques and effective stunning methods. Livestock management plays a pivotal role; it involves maintaining animal welfare throughout their life and during the slaughtering process to ensure high-quality meat for consumers and CSA (Community Supported Agriculture) members.

Post-Slaughter Processing and Carcass Handling

Immediately following slaughter, carcass handling is imperative. It begins with bleeding, followed by removing the skin, internal organs, and hooves. The carcass is then split along the rail, typically a stainless steel overhead system, to facilitate the chilling and processing stages. This step is crucial to prevent meat spoilage and ensure food safety.

Managing Processing Bottlenecks

The meat processing bottleneck in Minnesota has been a significant concern, exacerbated by events such as the COVID-19 pandemic. To address this, producers and owners are collaborating to enhance the resiliency of local meat processing facilities. Skilled labor shortages require strategic workforce development to maintain continuous and efficient operations.

Quality Control and Meat Preservation

Ensuring quality control during on-farm meat processing is paramount. Producers must monitor various aspects such as temperature control, sanitation, and storage conditions to prevent contamination and preserve meat freshness. Meat preservation methods, including curing, smoking, and freezing, are applied to extend shelf life and maintain the product's quality until it reaches the consumer.

Farm Meat Processing Economics

In Minnesota, on-farm meat processing presents distinctive economic considerations for farm owners. From initial costs to consumer demand, the financial aspects of processing meat on the farm are multifaceted.

Cost and Investment Analysis

Initial investment for establishing on-farm meat processing facilities can be substantial. For instance, constructing a facility may cost around $500,000, with annual operating expenses of approximately $125,000. In contrast, outsourcing slaughtering services can cost a farm about $350,000 annually. By processing on-site, a farm can potentially save $225,000 each year, thus recouping their initial outlay within a few years.

Pricing Strategies for Processed Meat

Farmers must develop pricing strategies that adequately cover their costs while remaining competitive in the meat market. They factor in the costs of slaughtering, butchering, packaging, storage, and compliance with health regulations. A careful balance is needed to ensure prices are attractive to consumers and profitable for the farm. This often results in a tiered pricing structure that varies for individual consumers, restaurants, and institutions, reflecting the value-added processing delivered.

Understanding Consumer Demand

Consumer demand drives the meat market, with a rising interest in locally sourced and processed meats. Farmers must understand their target consumers, whether they are individual households, restaurants, or other institutions, and adapt their processing and marketing strategies accordingly. Preferences for niche products like organically raised or grass-fed meats influence both the processing methods and the ultimate pricing of the final product.

Economic Impact of COVID-19 on Meat Processing

The COVID-19 pandemic has highlighted the vulnerabilities in meat supply chains, affecting meat processing at multiple levels. On-farm processors faced disruptions in logistics and fluctuating demand from meat markets, stores, and consumers. However, they've also experienced an increase in local consumer support driven by the desire for food security and supply chain transparency. The economic impact varies among farmers, influenced by how quickly they adapt to changing market conditions and consumer behaviors.

Best Practices in Animal Welfare and Ethics

In Minnesota, on-farm meat processing prioritizes humane handling and transparent operations to ensure both animal welfare and consumer trust. Practices adhere to rigorous standards that reflect ethical responsibilities of ranchers towards livestock and informed choices of consumers.

Stress-Free Slaughter on Farm Property

On-farm slaughter in Minnesota strives to minimize stress on animals by proceeding in surroundings familiar to the livestock. Ranchers employ methods to reduce anxiety such as maintaining quiet environments and handling animals gently. They follow specific protocols, including:

Pre-slaughter handling: Animals are kept in low-stress conditions, away from the sounds and sights of the slaughtering area.

Transportation: The need for long-distance transport is eliminated by slaughtering on the rancher’s property, thus avoiding additional stress.

Pasture-Raised and Ethical Meat Production

Pasture-raised meat production is a commitment to ethical farming where animals graze freely in their natural habitat. This method supports optimal animal welfare with benefits such as:

Natural Diet: Access to pasture ensures a diet that closely resembles what animals would consume in the wild.

Outdoor Environment: Animals benefit from sunlight and fresh air, conditions that contribute to healthier and less stressful lives.

Ranchers ensure livestock are provided appropriate shelter, especially during adverse weather conditions, like rain, to maintain comfort and prevent stress.

Transparency and Consumer Trust

Transparency is pivotal in fostering consumer trust. Minnesota ranchers keep consumers informed by:

Providing Details on Animal Care: Detailed accounts of how the animals are raised and processed are made available to consumers.

Open Communication: Consumers are encouraged to ask questions about the slaughtering process, and ranchers aim to provide clear, straightforward answers.

This open approach reassures consumers about the welfare standards and ethical considerations involved in on-farm meat processing.

Marketing and Sales of Processed Meat

When farmers in Minnesota process meat on their farm, they have multiple avenues to market and sell their products. These methods cater to different customer bases and have varied regulatory requirements.

Direct Selling to Consumers

Farmers who directly sell processed meats to consumers leverage the farm-to-table appeal. Direct sales can occur through on-farm stores, online outlets, or delivery. Minnesota regulations require that meats are processed at an inspected facility to ensure safety. Producers must be well-versed in marketing to effectively communicate the quality and origin of their meat products to the local consumer base.

Marketing to Restaurants and Institutions

Selling processed meats to restaurants and institutions calls for consistent product quality and reliable supply chains. Effective marketing strategies include establishing strong relationships with chefs and food service managers. In Minnesota, producers often emphasize the local aspect of their meats, focusing on the story behind the product which can entice restaurants to feature their meats as premium, locally-sourced options.

Farmers' Markets and Community Supported Agriculture

Farmers' markets provide a venue for producers to sell directly to consumers in a community setting. To partake in these, farmers must comply with local health department regulations relevant to meat sales. Community Supported Agriculture (CSA) involves consumers subscribing to receive regular shares of meat. Both methods require strategic marketing to maintain consumer interest and to educate them on the myriad benefits of supporting local agriculture and meat producers.

Food Safety and Public Health

Ensuring the safety and health of consumers is paramount in on-farm meat processing in Minnesota. This involves strict adherence to regulations and the application of meticulous safety measures throughout the butchering and slaughtering processes.

Continuous Inspection and USDA Compliance

On-farm meat processing facilities in Minnesota operate under the watchful eye of the USDA's Food Safety and Inspection Service (FSIS). Facilities must comply with the Federal Meat Inspection Act (FMIA) and the Poultry Products Inspection Act (PPIA), which mandate continuous inspection during slaughter and processing. USDA-inspected plants are subject to unannounced inspections, ensuring that safety standards are upheld at all times.

To maintain compliance:

Records must be kept accurately, tracking each stage of processing.

Facility designs should facilitate sanitary operations and ease of inspection.

Staff need adequate training on processes and regulations.

Pathogen Control and Meat Safety

The main goal within meat safety is the control and elimination of pathogens that could compromise consumer health. Farms and processing facilities must implement comprehensive strategies for pathogen control, often exceeding basic FSIS requirements.

Critical control methods include:

Temperature Regulation: Chilling and storing meat products at safe temperatures to inhibit bacterial growth.

Sanitation: Rigorous cleaning and disinfection of equipment and surfaces that come into contact with meat.

Testing: Regular microbiological tests on meat products to detect contaminants like E. coli, Salmonella, and Listeria.

By integrating these safety measures, on-farm meat processing can protect public health. This ensures that the consumer receives meat products that are not only nutritious and flavorful but also safe for consumption.

On-Farm Meat Processing Case Studies

This section showcases the evolution and benefits of on-farm meat processing through specific instances in Minnesota. It highlights the experiences of local ranchers and novel practices in butchering and processing directly on the farm.

Success Stories from Minnesota Ranchers

Local producers have begun to establish their own on-farm processing facilities, which have proven to be successful despite initial challenges. One notable example is a Minnesota-based farmer part of the Minnesota Farmers Union (MFU) initiative, who has successfully integrated a mobile meat processing unit that operates across Central Minnesota. This initiative has alleviated some of the strain on conventional processing systems.

Local Impact: By processing meat directly on the farm, these producers have shortened the supply chain, allowing for fresher products and a more resilient local economy.

Innovations in On-Farm Butchering and Processing

In Minnesota, the trend towards more localized butchering and processing has sparked innovation. The development of a mobile meat processing facility by the MFU is particularly groundbreaking.

Mobile Slaughter Facility: A state-of-the-art unit that travels across the region, addressing logistical challenges and providing on-site services to farms.

Butchering Efficiency: With on-farm facilities, butchering can be performed more efficiently, ensuring that the meat is processed quickly and maintains a high quality.

The ongoing efforts in Minnesota to develop on-farm processing solutions are creating more sustainable and self-sufficient agricultural communities.

Future of On-Farm Meat Processing

In Minnesota, the landscape of on-farm meat processing is evolving with technological innovations that aim to meet stringent state and local regulations while enhancing efficiency at farm-based processing facilities.

Technological Advancements and Automation

Farmers and meat processors in Minnesota are recognizing the value of integrating advanced technologies into their operations. Technological advancements are anticipated to play a pivotal role in how on-farm meat processing facilities operate, with automation being at the forefront of this transformation.

Automation offers several key benefits to on-farm meat processing:

Improved consistency in cuts of meat, which can enhance product quality.

Enhanced efficiency, reducing the time from slaughter to market.

Potential reduction in labor costs through automated systems.

Traceability from farm to table, providing clear records that can assist in meeting regulatory compliance.

However, these advancements must be navigated carefully to comply with Minnesota's regulations, which ensure food safety and animal welfare. Local state inspectors oversee these on-farm processing facilities to maintain standards in line with both state and federal requirements. The adoption of technology must therefore support these regulations, not circumvent them.

As on-farm processing facilities in Minnesota adapt, one can expect a deeper integration of technology that aligns with regulatory frameworks, ensuring that local meat processors offer safe, high-quality products while maintaining the viability and growth of the industry.