On-Farm Meat Processing, Butchering, and Slaughter in Missouri

A Comprehensive Guide

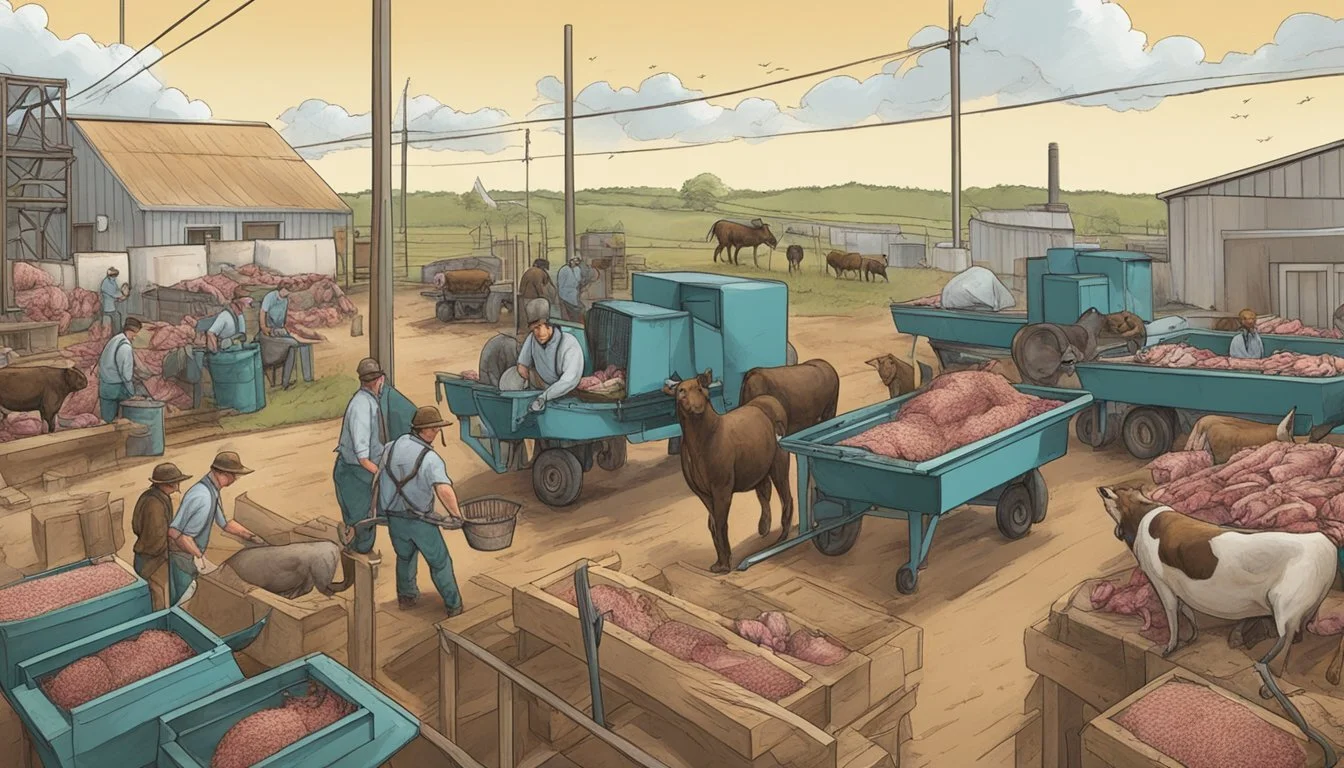

On-farm meat processing in Missouri is a vital part of the state's agricultural framework, providing residents with local options for obtaining meat directly from the source. This practice involves the slaughter, butchering, and processing of livestock on the very farms where the animals were raised. Missouri meat producers adhere to regulations set forth by the Missouri Department of Agriculture, ensuring that meat processing is performed in a manner that is safe, hygienic, and in compliance with state and federal standards. This not only supports the local economy but also offers traceability for consumers who value knowing the origin of their food.

The Missouri Meat and Poultry Inspection Program plays a crucial role in maintaining the quality and safety of meat processed within the state. Operated through the Missouri Department of Agriculture, the program provides inspection services that align with USDA requirements for operations that desire to sell meat. For those farms conducting on-farm slaughter, there are specific guidelines that must be followed to be deemed a custom exempt facility.

Custom exempt slaughter and processing denote that the meat provided is for personal use and not for sale to the general public. In these cases, the animals must be slaughtered and processed at a facility that meets the state requirements, but it doesn’t undergo continuous inspection. Such arrangements typically involve the animal's owner at the time of slaughter, and the meat is processed with the understanding that it won't enter the commercial marketplace. By offering an exemption, the state of Missouri facilitates a way for small-scale producers to provide meat for individuals while still upholding food safety standards.

State Regulations and Compliance

In Missouri, state-regulated on-farm meat processing facilities must conform to meticulous standards to ensure public health and safety. Adherence to the Missouri Meat and Poultry Inspection Program is mandatory, along with understanding the differences between state and federal inspections. Operators must also be aware of particular requirements for on-farm processing and adhere to COVID-19 protocols.

Missouri Meat and Poultry Inspection Program

The Missouri Department of Agriculture oversees the Missouri Meat and Poultry Inspection Program, which ensures that meat and poultry products are safe, wholesome, and correctly labeled. State-inspected establishments must comply with regulations that are at least equal to those imposed under federal inspection standards. The program mandates federal inspection and passing of meat products prior to handling by retail stores.

State Inspection vs. Federal Inspection

State inspection is administered by the Missouri Department of Agriculture and is required for meat and poultry sold within the state. The products from these establishments are deemed to be "state-inspected." Facilities that seek to operate under federal inspection are regulated by the USDA's Food Safety Inspection Service (FSIS), which allows interstate and international commerce of meat and poultry products. It is critical for facilities to determine their market reach to decide whether state or federal inspection meets their business needs.

Requirements for On-Farm Processing

Operators interested in on-farm slaughter and processing must adhere to specific requirements concerning health, sanitation, and facility standards to ensure safe handling of meat. Waste disposal measures must be taken seriously to protect the environment and adhere to food safety regulations. While small-scale poultry processors can operate under certain exemptions for sales to consumers and specific commercial entities, they must still comply with food safety and animal welfare regulations.

COVID-19 Protocols

During the COVID-19 pandemic, the Missouri Department of Agriculture and the USDA Food Safety Inspection Service implemented additional safety protocols. These incorporate measures such as social distancing, use of personal protective equipment (PPE), and increased sanitation processes to minimize the risk of virus transmission within processing facilities. Compliance with these protocols is crucial for maintaining operations and ensuring food safety during the pandemic.

The regulations in Missouri demand comprehensive adherence to legal and safety standards for on-farm meat processing. Facilities operating under state inspection ensure local products remain within the high expectations of food safety and quality while federal inspection opens the door to wider marketing opportunities. Keeping processing operations up to current standards and protocols ensures the continued safety and trust in Missouri's meat and poultry industry.

Infrastructure and Equipment

When establishing on-farm meat processing infrastructure in Missouri, operators must consider the setup of a permanent facility, options for mobile slaughter units, and adherence to sewage treatment and environmental standards. Each element is critical to ensure compliance, efficient operation, and sustainability.

Setting Up a Processing Facility

A processing facility in Missouri requires specific design and equipment to handle slaughter and butchering operations. Key components include:

Sturdy, non-porous surfaces for ease of cleaning and sanitation.

Adequate cold storage for carcass chilling and meat packaging.

Proper waste disposal systems aligned with environmental regulations.

A facility must pass the Missouri Meat and Poultry Inspection Program's standards, which align with federal guidelines, to be authorized to process and sell within the state.

Mobile Slaughter Units

Mobile slaughter units offer a flexible alternative to stationary facilities and are essential for farmers who may not have the capacity to process animals on site. These units should include:

USDA-approved equipment for slaughter, processing, and packaging.

Refrigeration units for carcass preservation post-slaughter.

Wastewater collection systems to avoid environmental contamination.

Mobile units also extend processing access to remote areas, broadening the market for local producers.

Sewage Treatment and Environmental Standards

Sewage treatment is imperative for all meat processing operations to protect water resources and comply with environmental standards. Facilities should have:

A well-designed sewage system that treats organic waste from slaughter and butchering processes.

Plans for regular monitoring and maintenance of the sewage system.

Appropriate permits from environmental agencies, ensuring the facility meets all state and federal requirements.

By adhering to these standards, operators not only protect the environment but also uphold public health safety.

Operational Practices

In Missouri, strict adherence to regulations and guidelines ensures that on-farm meat processing and butchering are carried out in a way that prioritizes animal welfare and food safety.

Humane Slaughtering Techniques

The state mandates that slaughtering animals must be done humanely, making the process as quick and painless as possible. Trained personnel use approved methods to render the animal unconscious before slaughter to prevent distress and pain, utilizing techniques that align with both state and federal standards.

Hazard Analysis Critical Control Points (HACCP)

HACCP is a systematic approach to food safety that is critical in the slaughtering and processing phases. Processors identify potential food safety hazards and implement stringent control measures at critical points during processing. The plan includes steps such as:

Monitoring: Checking temperatures and ensuring cleanliness at each step.

Documentation: Keeping records that verify the safety protocols in place.

Verification: Periodic testing to ensure the controls are effective.

Livestock Management and Welfare

Livestock welfare is paramount, with regulations requiring adequate housing, nutrition, and general care to maintain animal health before slaughter. Healthy animals are less prone to diseases, which can jeopardize food safety. Stress reduction techniques are also implemented, as they can significantly impact meat quality.

Processing and Butchering Techniques

In Missouri, meat processing and butchering techniques must comply with both state and federal guidelines. The butchering process includes:

Inspection: All animals are inspected pre- and post-slaughter to ensure they are free from diseases.

Separation: Meat is processed in clean environments with a clear separation from internal organs to prevent contamination.

Packaging: Meat is then packaged appropriately to prevent contamination and preserve freshness during storage and transport.

Economics and Market Opportunities

The economics of on-farm meat processing in Missouri present both opportunities and challenges. Local demand and marketing strategies play a critical role, while competition and pricing require careful consideration.

Understanding Local Demand

Local meat is increasingly valued by Missouri consumers for its freshness and traceability. Cattle producers must gauge customer interest and adjust production to meet the specific demands of their community. They can gather data through surveys or community events to better understand consumer preferences, especially concerning cuts of meat and processing practices.

Marketing and Selling Meat Products

Marketing efforts hinge on educating consumers about the benefits of locally sourced meat. Ranchers can use storytelling to connect with their audience, focusing on the humane treatment of animals and the environmental advantages of local ranching. Selling strategies might include:

Farmers Markets: Direct sales to consumers, offering opportunities for customer engagement.

Subscription Services: Regular deliveries that provide consistent revenue streams.

Online Promotion: Harnessing social media to reach a wider audience.

Competition and Pricing Strategies

Competition in Missouri's meat processing industry is influenced by larger meatpackers. However, small-scale processors can differentiate by emphasizing product quality over price. Pricing strategy for local meat should reflect:

Processing Costs: Calculating the expenses of slaughter and butchering for precise pricing.

Value Proposition: Conveying the superiority of local meat to justify potential price premiums.

Support for Small-scale Ranchers and Farmers

Missouri offers financial resources and technical assistance to help farm operations expand their meat processing capabilities. This includes grants aimed at transforming supply chains and creating better market opportunities. Ranchers should remain informed about:

State-Funded Programs: Accessing government-sponsored grants and loans.

Technical Assistance: Leveraging expert advice to optimize processes and reduce costs.

Small-scale farmers can capitalize on the rising consumer interest in local food systems by carefully managing economics and market potential for on-farm meat processing.

Safety and Quality Assurance

In Missouri, on-farm meat processing is governed by stringent regulations to ensure that the products reaching consumers meet the highest standards of food safety and quality. These regulations involve meticulous inspection procedures, advanced meat science practices for quality enhancement, and effective traceability systems to foster consumer trust.

Food Safety and Inspection

The Missouri Meat and Poultry Inspection Program (MMPIP), in conjunction with the U.S. Department of Agriculture (USDA) Food Safety Inspection Service (FSIS), plays a critical role in monitoring meat safety and inspection processes. All meat must be inspected and passed to be sold commercially, thus assuring that it is safe, wholesome, and properly labeled. Inspections are mandatory for any meat product intended for human consumption.

Inspection Entities: Missouri Department of Agriculture (MDA), Division of Animal Health, USDA FSIS.

Inspection Focus: Ensuring the safety, cleanliness, and correct labeling of meat and poultry.

Inspection Criteria: Includes examination of animals before and after slaughter, facility hygiene, and product handling.

Meat Science and Product Quality

Meat processors in Missouri utilize the principles of meat science to enhance product quality. By understanding the biochemical and physical factors that affect meat, they can guarantee that it meets high taste and texture standards.

Key Factors: Carcass composition, meat tenderness, flavor, and quality control measures.

Meat Processing: Techniques align with scientific research to maintain integrity and quality of meat products.

Quality Assurance Methods: Include aging, temperature control, and proper handling from slaughter to packaging.

Traceability and Consumer Trust

Traceability systems are in place to ensure that if any safety or quality issues arise, they can be traced back to their source swiftly. These systems are essential for maintaining consumer trust in Missouri's meat industry.

Traceability Mechanisms: Batch numbers, tracking of processing data, and clear labeling.

Consumer Assurance: Visibility of the product journey from farm to table reinforces consumer confidence.

Regulatory Compliance: Traceability is a key component of USDA regulations, helping to quickly isolate and address potential food safety issues.

Through adherence to food safety guidelines and leveraging meat science, Missouri's meat processors establish a reliable quality assurance foundation. With thorough inspections and robust traceability, consumer trust is bolstered.

Legal and Ethical Considerations

Missouri's on-farm meat processing, butchering, and slaughter are governed by both federal and state regulations aimed at ensuring food safety, animal welfare, and fair trade. Producers and processors must navigate a complex landscape of laws and ethical concerns.

Custom Exempt Facilities

Custom exempt facilities in Missouri operate under specific USDA regulations that allow for the slaughtering and processing of livestock for personal, non-retail use. These facilities must adhere to sanitary standards and occasional inspections, although they are not subject to the same continuous inspection requirements as federally inspected establishments. Farmers utilizing such facilities must understand that meat processed here cannot be sold to the general public and must be clearly marked as "Not for Sale".

Key entities involved: custom exempt facility, USDA, farmers, livestock

Regulations to comply with: USDA guidelines for sanitation and occasional inspections

Retail Store and Direct Sales Regulations

Retail stores and on-farm direct sales in Missouri fall under state and USDA oversight, where state regulations must be at least as stringent as federal ones. Meat sold directly to consumers from farms or at retail must be processed at a facility that has passed the necessary inspections, ensuring compliance with both food safety and animal health standards. Detailed record keeping and labeling requirements also apply to support traceability and inform consumers.

Core entities: retail store, state, USDA, farms

Regulatory focus: inspections, food safety, animal health, labeling

Animal Welfare and Ethical Slaughtering

Animal welfare is a critical aspect of on-farm slaughter in Missouri, with ethical considerations guiding many of the practices. Although the Humane Methods of Livestock Slaughter Act primarily targets slaughterhouses, farmers and custom exempt facilities are still expected to follow humane slaughtering practices to prevent unnecessary suffering of livestock. This includes the consideration of methods of slaughter and handling of animals prior to death.

Involved parties: farmers, custom exempt facilities, livestock

Ethical concerns: humane slaughtering methods, animal handling before slaughter

Future Perspectives

The future of on-farm meat processing in Missouri reflects a shift towards increased local control and innovation in response to challenges such as global pandemics. Producers are actively seeking sustainable solutions to meet the demands of the market and overcome the constraints faced by traditional meat processing systems.

Trends in On-Farm Meat Processing

Missouri is witnessing a growing interest among ranchers in on-farm meat processing as a way to bypass the often congested traditional meat supply chain. This trend accelerated because the COVID-19 pandemic exposed vulnerabilities in centralized processing facilities, leading to a surging consumer demand for locally processed meat. Operating small-scale slaughter and butchery facilities on the farm provides ranchers in Missouri—and similar economies like Colorado—a unique opportunity to control and customize their end product. This model holds potential for stronger ties between ranchers and communities, focusing on directly meeting consumer demands with an emphasis on quality and traceability.

Consumer Shift: Direct-to-consumer sales see an uptick as locality becomes a significant factor in purchasing decisions.

Rancher Response: Ranchers are adapting by investing in on-site processing to maintain a consistent supply stream and retain greater share of profits.

Innovations in Butchering and Slaughtering

Technological innovations are poised to modernize the butchering and slaughtering processes on farms across Missouri. With advancements such as mobile slaughtering units, the processor community is aiming to address the bottleneck issues formerly impeding small-scale operations. These units enable compliant and humane slaughtering with the added benefit of increasing processing capacity without substantial infrastructure overhead. Integration of smart technology in butchering practices enhances precision, reduces waste, and improves overall efficiency—opening a path to new standards in meat processing.

Mobile Units: Mobile slaughtering units are gaining traction due to their flexibility and reduced need for transport.

Smart Technology: Adoption of sophisticated tools and software for better tracking, inventory management, and meat processing accuracy.