On-Farm Meat Processing, Butchering and Slaughter in South Carolina

A Guide to Regulations and Best Practices

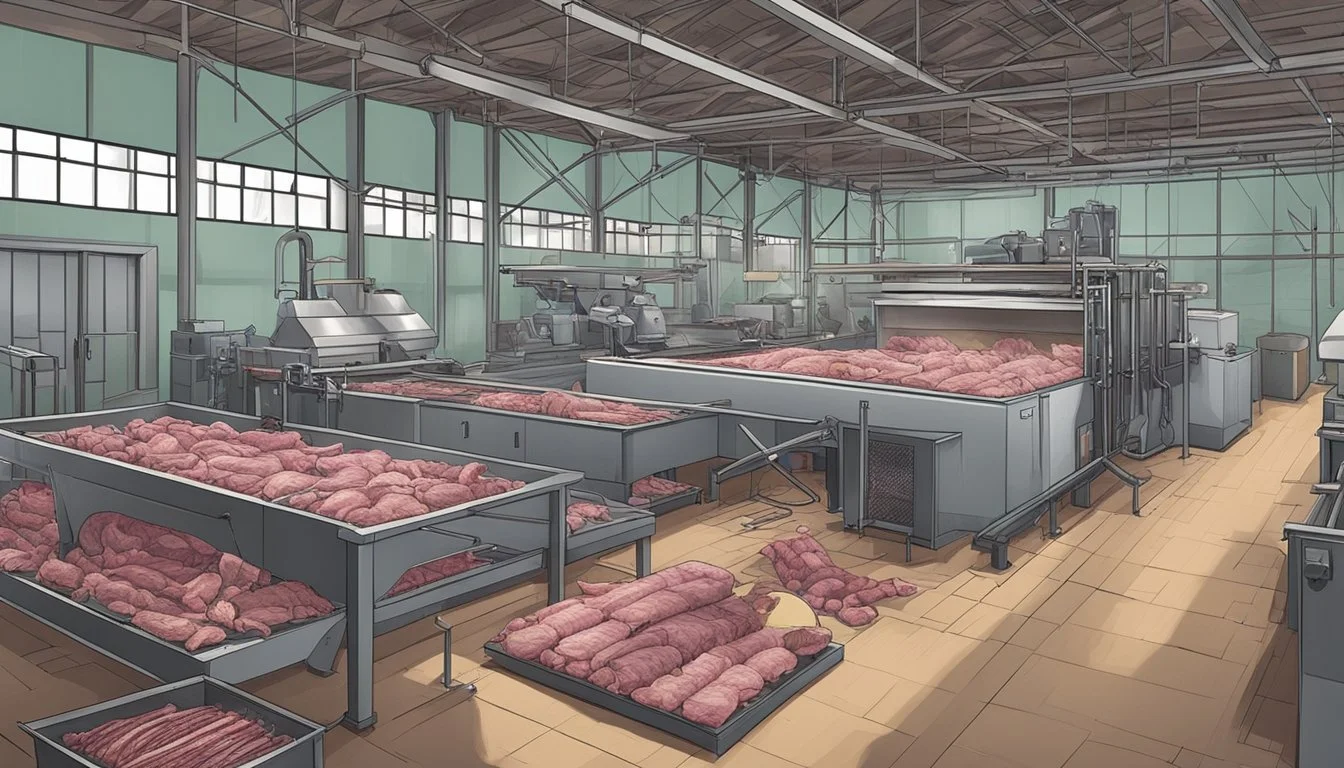

On-farm meat processing in South Carolina reflects a movement toward local food systems and self-sufficiency within the agricultural community. Producers are setting up facilities to process meat on their premises, navigating various challenges such as securing capital investment and adhering to a complex array of both federal and state regulations. However, many find success by adding value directly to their products, thus building financial resilience in a market where cattle and beef prices fluctuate significantly.

Butchering and slaughter methods on South Carolina farms must comply with stringent health and sanitation standards to ensure food safety and public health. These standards include waste disposal and specific building requirements tailored to on-farm meat processing operations. The state allows for a certain level of producer autonomy, enabling farmers to sell meat processed on-site directly to consumers, which encourages a direct farm-to-table supply chain.

South Carolina's interest in on-farm meat processing is not just about adherence to necessary legal frameworks; it is also an embrace of tradition and community. These on-farm processors often maintain a close relationship with their customers, gaining trust and support through transparency and the provision of locally sourced, fresh meat products. The increasing reservations for local beef and the ongoing operations of on-farm stores underscore the community's support for local agriculture and on-farm meat processing endeavors.

Understanding On-Farm Meat Processing

On-farm meat processing in South Carolina requires a clear understanding of the process through which meat goes from farm to table. Such processes involve slaughtering, butchering, and often packaging, retaining the freshness and quality of the meat. South Carolina farmers must adhere strictly to food safety regulations to ensure that the meat is safe for consumption.

The first step is slaughtering, where farmers must comply with animal welfare standards to ensure a humane end for livestock. They must be well-versed in ethical practices and humane handling to not compromise the well-being of the animals.

Meat quality is paramount and is greatly influenced by the process it undergoes after slaughter. Effective on-farm processing methods help maintain the integrity of the meat's texture, taste, and nutritional value.

Food safety is another critical component; farmers must establish a sanitary environment to prevent contamination. This includes the proper disposal of waste and the thorough cleaning of equipment.

Direct-to-consumer sales have motivated farmers to invest in on-farm processing. This approach allows them to control every aspect of production, ensuring a high-quality product while fostering a connection with consumers who value local, high-quality meat.

Here is a brief outline of on-farm meat processing:

Slaughtering: Ensuring ethical and humane practices.

Butchering: Skillfully breaking down carcasses.

Preservation: Applying techniques to retain freshness.

Packaging: Preparing meat for sale while maintaining safety.

Regulatory Compliance: Following local and federal guidelines for food safety and animal welfare.

Direct Sales: Engaging with consumers for a farm-to-table experience.

These procedures enable South Carolina farmers to provide a product that meets high standards of quality and safety, directly connecting with their community.

Regulatory Framework in South Carolina

In South Carolina, on-farm meat processing is subject to a structured regulatory framework, ensuring food safety and compliance with both state and federal laws. This framework is critical for producers who aim to process and sell meat within the state.

State Regulations and Compliance

The regulatory environment at the state level is maintained by the South Carolina Department of Agriculture (SCDA) and the State Livestock-Poultry Health Commission. Specific regulations guiding on-farm meat processing are outlined in SC Code of Laws Title 47, where definitions, responsibilities, and the requirement for a state-approved facility for processing are detailed. Entities must adhere to regulations such as:

27-1022: State Poultry Inspection Regulation

27-1023: State Meat Inspection Regulation

This includes the mandate that meat products must be processed in a facility that has been preapproved, as listed under 27-1029, and the products should be properly labeled to assure consumers of their safety. Producers are also required to obtain relevant permits before engaging in the marketing and sale of meat products in intrastate commerce.

USDA Standards and Certification

For those intending to operate beyond South Carolina's borders, compliance with the United States Department of Agriculture (USDA) standards is necessary. The USDA ensures that meat processing facilities meet stringent federal requirements for safety and sanitation. The process entails:

Obtaining USDA certification for the facility, which qualifies it as a USDA facility.

Following USDA's regulations, which include facility design, processing procedures, and ongoing compliance checks.

These federal regulations are in place to ensure that meat products are consistently safe for consumption, wholesome, and correctly labeled. Facilities operating under USDA certification can engage in interstate commerce, thus reaching a wider market.

By complying with both state and federal regulations, meat processors in South Carolina can operate effectively within the established legal parameters conducive to public health and business growth.

Setting Up On-Farm Processing Units

Setting up on-farm processing units in South Carolina involves stringent infrastructure requirements and often the implementation of mobile processing units to ensure adherence to regulations and to enhance efficiency.

Infrastructure Requirements

The establishment of on-farm processing units requires farmers to construct suitable infrastructure that adheres to state and federal guidelines for meat processing. A typical on-farm slaughter facility must have:

Adequate space for holding pens for the livestock awaiting processing.

A slaughter floor, which should be designed for efficient workflow and easy cleaning.

Cooling facilities to store meat at safe temperatures post-slaughter.

Equipment such as stunners, dehiders, and saws, which must meet safety and quality standards.

These facilities must ensure hygienic processing, proper waste disposal, and prevent contamination. The design should allow for adequate inspection, which is a cornerstone for gaining certification and maintaining the trust of consumers and regulators.

Mobile Processing Units

Mobile processing units or mobile slaughter units offer an alternative for farmers who seek more flexibility and lower initial investments. These units are trailers equipped with essential processing equipment that can be transported directly to the farm site. Mobile slaughtering units from providers such as Cornerstone Farm Ventures can be a practical solution, especially for farmers operating in remote areas.

Key features of mobile slaughter units include:

Processing Area:

Knives, hooks, and other butchering tools

Spaces for evisceration and other processing tasks

Cooling Area:

Refrigeration systems to chill the meat post-processing

USDA Compliance:

Built to meet USDA's Food Safety and Inspection Service (FSIS) standards for safety and hygiene

Farmers using mobile processing units need to schedule operations, ensure the availability of an inspector if selling meat, and maintain the equipment. The flexibility and reduced need for capital infrastructure make mobile units a viable choice for local meat production.

Livestock Management for Slaughtering

When managing livestock for slaughter in South Carolina, farmers prioritize animal welfare and stress reduction, as both factors significantly affect meat quality. For various livestock raised for meat, including cattle, hogs, poultry, sheep, buffalo, and elk, specific management practices help ensure a humane process.

Cattle and Hogs: They require careful handling to avoid stress. Farmers use techniques like low-stress herding and provide familiar environments. Properly designed holding pens and walkways help facilitate the movement of animals to the slaughtering area.

Poultry: Due to their flocking nature, poultry should be kept in groups to reduce anxiety. Controlled lighting helps to keep them calm before processing.

Sheep: Similarly to cattle, sheep respond well to gentle handling and minimal noise. Keeping sheep in visual contact with each other reduces panic during herding.

Buffalo and Elk: These animals, less commonly farmed, are often raised on larger pastures. They need acclimatization to handling facilities well before slaughter to minimize stress.

Farmers monitor each species closely for signs of distress, employing practices that align with guidelines for humane handling and slaughter. They follow regulations that dictate how livestock must be processed, ensuring food safety and quality:

Entity Consideration for Slaughter Livestock Ensure gentle handling and reduced crowding Animal Welfare Monitor for stress; use humane processing methods Slaughter Area Design for smooth and calm movement of animals

In conclusion, South Carolina farmers are attuned to the needs of their livestock, and they apply meticulous care during the slaughtering process. The well-being of animals is paramount, and it is reflected in the quality of the meat produced through on-farm processing.

Environmental and Community Considerations

In South Carolina, on-farm meat processing poses specific concerns for the environment and the relationships with local communities. These concerns are primarily centered around the impact of such activities on neighbors, potential liabilities, and environmental sustainability involving elements like grass and corn.

Local Neighbors and Community Relations

Liability and Neighbor Relations: On-farm meat processing can affect local neighbors through noise, odor, and increased traffic. South Carolina farms must adhere to regulations designed to minimize disruptions and maintain good community relations. Transparency with neighbors about operations, along with addressing any concerns swiftly, helps in reducing tension and avoiding legal liabilities.

Community Involvement: Farmers should communicate with their neighbors and consider their input, which helps in fostering a community-centric approach to agricultural practices.

Environmental Impact and Sustainability

Resource Use: Meat processing is resource-intensive, utilizing significant quantities of water and energy, particularly in the cultivation of feed crops such as grass and corn. Efficient resource management is crucial to reduce the environmental footprint.

Waste Management:

Water Contamination: Facilities must manage waste carefully to prevent runoff that could lead to water pollution affecting local ecosystems and water supplies.

Sustainability Practices: Implementing sustainable practices, such as proper waste disposal and potentially using waste as fertilizer, can mitigate negative environmental impacts. This includes managing blood, oil, grease, and other byproducts in compliance with environmental standards.

Adopting these considerations into on-farm meat processing activities in South Carolina can lead to more ethically and environmentally responsible practices, benefitting both the community and the natural surroundings.

Economic Aspects of On-Farm Processing

On-farm meat processing in South Carolina involves significant economic dimensions, impacting both local farmers and the wider market. Cost management and strategic market engagement are pivotal for maximizing profitability in this sector.

Costs and Investments

The initiation of on-farm processing requires a substantial capital outlay. Key investments include facilities that meet USDA standards, processing equipment, and workforce training. For a typical setup, farmers might face costs such as:

Facility construction or modification: Costs vary depending on size and specifications.

Equipment procurement: This includes slaughter and butchering equipment, which can range from basic tools to more advanced machinery.

Regulatory compliance: Ensuring adherence to health, safety, and environmental regulations entails both initial and ongoing expenses.

Personnel: Training existing staff or hiring skilled butchers and processors can result in a significant investment in human resources.

Revenue and Market Opportunities

On-farm meat processing can open various revenue streams. Income is primarily derived from the sale of processed meats, which can vary based on market demand and pricing strategies. Farmers can take advantage of different market opportunities such as:

Direct-to-consumer sales: Selling meat directly to consumers can fetch higher prices and foster consumer loyalty.

Local meat markets: Supplying to local butcher shops and farmers' markets may increase a farm's visibility and customer base.

Niche markets: Targeting consumers interested in organic, free-range, or locally-sourced meats can provide premium pricing opportunities.

Developing effective marketing and distribution strategies is crucial for capturing additional market share and increasing the farm's processing income.

Challenges and Bottlenecks

In South Carolina, on-farm meat processing faces distinct challenges, marked by capacity constraints and complex supply chain issues. These bottlenecks have been further strained by the COVID-19 pandemic.

Processing Capacity Challenges

On-farm meat processors in South Carolina confront a significant shortage in capacity. Capacity constraints are manifested in the form of limited availability of USDA-certified processing facilities, which is necessary for meat to be sold commercially. This bottleneck has been exacerbated by the COVID-19 pandemic, which led to an increase in demand for local meat processing as large facilities faced disruptions. Small-scale producers often experience delays, which in turn affects their ability to deliver meat to markets in a timely fashion.

Supply Chain and Distribution Hurdles

The supply chain for on-farm meat processing is multifaceted, with issues spanning from procurement of animals to the distribution of finished products. The COVID-19 pandemic highlighted the vulnerability of these supply chains; disruptions in transportation and labor shortages have led to further complications. Producers and processors need to navigate these hurdles to maintain a steady flow of goods, which is vital for the viability of local meat markets and the satisfaction of consumer demand.

Quality and Safety in Meat Processing

In South Carolina, meat processing facilities prioritize meat quality and food safety to meet consumer expectations for fresh and safe products. Ensuring meat quality involves careful handling of animals from farm to slaughter. Factors such as stress and diet can significantly impact the end product, thus on-farm practices are tightly regulated.

Food safety is paramount, and facilities must adhere to strict hygiene and sanitation standards to prevent contamination. They implement Hazard Analysis and Critical Control Points (HACCP) plans to identify and manage potential hazards in the meat processing chain.

Antibiotics usage in livestock is monitored to prevent antibiotic resistance. South Carolina's producers are moving towards raising animals with minimal antibiotic inputs, aligning with consumer demands for meat products from animals raised without unnecessary medications.

Table 1: Quality Control Measures

Measure Description Ante-mortem Inspection Animals are inspected for signs of disease before slaughter. Temperature Control Meat is kept at safe temperatures to prevent bacterial growth. Hygiene Protocols Facilities and equipment are sanitized regularly. Traceability Meat products are traceable back to their source.

Facilities strive to maintain the integrity of the meat during processing and butchering, as freshness is a crucial aspect of quality. They are equipped to process meat quickly and efficiently, reducing the time from slaughter to packaging, which helps in preserving the meat's freshness.

In summary, South Carolina's on-farm meat processing standards reflect a knowledgeable commitment to providing high-quality and safe meat products, with considerations for minimizing the usage of antibiotics and maintaining the freshness of the meat produce. These efforts ensure that the state's meat processing industry can provide consumers with products that are both high in quality and safe for consumption.

Agriculture Diversity and Specialty Processing

South Carolina's agricultural sector extends beyond traditional farming, encompassing a range of diverse and specialty meat processing practices. These include the processing of small-scale and specialty livestock as well as the innovative developments within the aquaculture and alternative meats industries.

Small-Scale and Specialty Livestock

Small-scale livestock and specialty meat operations in South Carolina appeal to niche markets seeking local, often artisanal, meat products. Unlike larger commercial processing, these facilities often focus on quality and specific consumer preferences. Producers here have adapted to market demands by providing a variety of meats from species that are less commonly processed at industrial scales.

Species Commonly Raised:

Heritage breed pigs

Free-range chickens

Processing Characteristics:

Limited processing volume

High-quality, custom butchering

Focus on humane handling and ethical practices

These smaller operations directly support the local economy and are integral in maintaining the breadth of the country's agricultural diversity. Localized meat processing also serves as a template for other US states, such as Kentucky and Wisconsin, which have recognized the value in supporting small-scale agricultural ventures.

Aquaculture and Alternative Meats

Aquaculture in South Carolina has seen growth in response to the increased demand for seafood and sustainable fish farming practices. This sector offers an alternative to wild-caught species, contributing to food security and lessening the environmental impact on natural fish populations.

Aquaculture Practices Include:

Raising fish in controlled freshwater and saltwater environments

Utilizing renewable practices to ensure long-term production sustainability

Species Focused On Include:

Catfish

Trout

Shellfish

South Carolina's approach to aquaculture has mirrored trends in other parts of the US, where there is a growing emphasis on decreasing the reliance on foreign seafood imports and bolstering domestic production. This trend is not exclusive to the country; international markets are also exploring aquaculture as a viable means of meeting global seafood demand.

Through both small-scale livestock processing and the developing aquaculture sector, South Carolina exemplifies the synergy between traditional agricultural methods and modern, sustainable practices—continuously driving the state toward innovative food production solutions.

Consumer Education and Outreach

In South Carolina, the education of consumers on on-farm meat processing plays a crucial role in shaping the market. A well-informed public can make educated choices, increasing demand for locally processed meats. Awareness programs illuminate the process of local meat production and contribute to transparency, fostering trust between consumers and farmers.

Educational Workshops & Events

Seminars: Regular seminars on the benefits of local meat processing.

Farm Visits: Scheduled visits for consumers to see the operations firsthand.

Cooking Classes: Utilize locally processed meats to educate on culinary techniques.

Awareness Campaigns

Social Media Initiatives: Targeted campaigns that highlight the impacts of local processing.

Brochures and Flyers: Distributed at farmers markets to promote the benefits of supporting local processors.

Building Consumer Demand

Quality Emphasis: Educating on the superior taste and nutritional benefits of locally processed meats.

Environmental Impact: Outreach on reduced carbon footprint due to shorter transportation routes.

The educational component ensures consumers understand the stringent regulations that govern local meat processing, dispelling misconceptions and highlighting safety. Workshops led by industry experts encourage dialogue, ensuring questions can be comfortably addressed. Consumer outreach in South Carolina takes a multi-faceted approach, representing a committed drive towards a sustainable, transparent, and health-conscious meat supply.

Future of On-Farm Processing in South Carolina

South Carolina is poised for growth in on-farm meat processing, propelled by innovative advancements and evolving legislative frameworks.

Innovations in Meat Science and Technology

The meat processing sector in South Carolina is undergoing a significant transformation, thanks to cutting-edge advancements in meat science and technology. These innovations are tailored to enhance product quality, safety, and efficiency. There is a focus on automated processing equipment, which promises to improve butchering precision and reduce labor costs. Additionally, food science plays a pivotal role in extending product shelf-life and safety protocols with new preservation techniques derived from rigorous research.

Legislation and Policy Evolution

Policies and legislation in South Carolina are continually adapting to better support on-farm processing. Recent cooperative movements by cattle farmers indicate a push towards greater local processing capacities. These alterations in the policy landscape reinforce the sector and offer new opportunities for farmers and processors alike. Lawmakers are increasingly inclined to update regulations to facilitate local meat processing initiatives, thereby fostering a more resilient and sustainable local food system.

Changes in policy are expected to address concerns like capital investment requirements and stringent regulations, which previously impeded the growth and establishment of local meat processing facilities. This legislative evolution not only benefits current producers but also attracts new entrants to the market, bolstering the overall sector's future.