On-Farm Meat Processing, Butchering, and Slaughter in South Dakota

An Overview of Local Practices

As the agricultural landscape adapts to changing market dynamics, South Dakota has seen a noteworthy shift in its meat industry with a growing interest in on-farm meat processing, butchering, and slaughter. A testament to this transformation is the emergence of establishments like The Meathouse, a family-owned, federally-inspected processing shop in Andover. Such facilities are not only a reflection of the state's enterprising spirit but also a response to the increasing demand for local meat processing options that can offer producers more control over their products and potentially increase their financial resilience.

While the concept of on-farm processing in South Dakota presents several advantages, it also comes with its unique set of challenges. Producers who embark on this route must navigate the complexities of capital investment and stringent regulations to maintain USDA certification. Despite these hurdles, the state's agriculture sector recognizes the long-term benefits, including reduced transportation costs, the ability to directly market their meats, and the appeal to consumers looking for locally-sourced products. These factors are driving more producers to explore and ultimately establish on-farm slaughter and processing services.

The movement towards localized meat processing in South Dakota is also influenced by market volatilities, like the fluctuating prices of cattle and beef. New ventures in the state, such as the proposed construction of the nation's largest beef plant, indicate a significant investment in the local meat processing infrastructure. In this push for self-sufficiency, South Dakota stands at the forefront, redefining the boundaries between traditional agriculture and innovative agribusiness models.

Understanding On-Farm Meat Processing

On-farm meat processing in South Dakota entails converting livestock into marketable meat products directly at the farm of origin. This section explores the essential aspects of this practice, including scientific, economic, and regulatory dimensions.

Key Concepts in Meat Science

In meat science, understanding muscle biology and the factors affecting meat quality is crucial. On-farm meat processing requires knowledge of animal husbandry, slaughter techniques, and carcass handling to maintain integrity and quality. Aging, pH levels, and temperature control are pivotal in ensuring the final product is safe and of high quality.

Benefits of On-Farm Processing

Farmers in South Dakota who engage in on-farm processing often experience direct economic gains and increased control over their product. This vertical integration allows them to:

Bypass traditional supply chains, reducing the meat processing bottleneck.

Cater to local markets seeking transparency and traceability.

Capitalize on the niche for locally-produced and potentially organic meats.

Challenges and Bottlenecks

Despite the benefits, farmers face obstacles such as:

Substantial capital investment and ongoing costs.

Navigating complex zoning and food safety regulations.

Limited processing capacity, contributing to the meat processing bottleneck.

Food Safety and Regulations

Food safety is paramount. On-farm processors must adhere to both state and federal laws, which may include:

Inspections by the USDA or state authorities.

Compliance with the Hazard Analysis Critical Control Point (HACCP) systems.

These regulations ensure that on-farm processed meats meet the same safety standards as those processed in larger facilities.

Regulatory Landscape

The complex regulatory landscape of on-farm meat processing in South Dakota is defined by interplay between state-specific mandates and federal oversight. Navigating these regulations is crucial for compliance and successful operation.

State Specific Regulations

In South Dakota, the State Animal Industry Board is the primary regulatory agency overseeing the slaughter and processing of meat. Businesses interested in these operations must adhere to the state's health, sanitization, and facility standards incorporating:

Building requirements specific to meat processing

Waste disposal protocols ensuring environmental safety

Sanitation practices to avoid the contamination of meat products

Entities engaging in meat processing are also subject to state liability laws which address the consequences of failing to follow the mandated standards.

Federal Oversight and Compliance

At the federal level, the U.S. Department of Agriculture's Food Safety and Inspection Service (USDA FSIS) holds the authority over meat processing facilities, ensuring they meet the safety and quality standards set out in the Federal Meat Inspection Act.

Compliance with federal regulations includes:

Facility inspections: Periodic reviews to certify that operations maintain federal standards

Product inspections: Assessment of meat quality to prevent distribution of contaminated meat

Businesses must navigate both federal and state regulations cohesively, as adherence to one does not absolve liability from the other. Ensuring compliance on both fronts is integral to operating within the legal frameworks and maintaining public health standards.

Animal Welfare and Stress Management

In South Dakota, on-farm meat processing accentuates the need for stringent animal welfare practices and effective stress management to ensure the quality of meat from livestock such as beef, sheep, swine, buffalo, elk, and cattle.

Handling Livestock

In South Dakota's farming landscape, the handling of livestock is paramount for animal welfare and the quality of meat from animals including beef cattle, sheep, buffalo, and elk. Proper handling practices are a cornerstone of stress management, thereby contributing to better meat quality post-processing. Handlers are trained to guide and move animals in a calm and non-threatening manner. Design features such as non-slip surfaces and curved chutes are implemented in handling areas to promote a stress-free environment for bulls, steers, and other animals.

Stress Reduction Techniques

The application of stress reduction techniques is recognized as an essential component of the slaughtering process for animals in South Dakota. The following measures are often implemented:

Resting Periods: Livestock such as swine and cattle are given time to rest upon arrival at the processing facility before the butchering process begins.

Environmental Controls: Maintaining an environment with appropriate lighting, temperature control, and noise reduction is essential in minimizing stress for animals such as sheep and elk.

Humane Slaughter Methods: Swift and humane slaughtering techniques ensure that stress for animals like buffalo and beef cattle is kept to an absolute minimum.

Through these practices and a commitment to continuous improvement, South Dakota aims to uphold animal welfare standards while securing meat quality in its on-farm meat processing operations.

Slaughter Process and Techniques

In South Dakota, the art of meat processing on farms integrates tradition with strict adherence to humane and sanitary standards. Attention to detail during the slaughter and processing stages ensures both the welfare of livestock and a high-quality end product.

Slaughtering Livestock

In on-farm slaughter units, the process starts with the proper restraint of livestock to minimize stress and avoid injury. Stunning is the first critical step to render the animal insensible to pain, a procedure done to respect humane slaughter methods. Methods of stunning typically include captive bolt pistols, electric shock, or controlled atmosphere systems that induce unconsciousness swiftly and effectively. After stunning, the animal's throat is cut (exsanguination) to allow the blood to drain, a necessary step for both meat quality and compliance with sanitary regulations.

Animals handled and slaughtered on the farm must be dealt with efficiently to ensure regulatory compliance and maintain integrity of the carcass. Facilities in South Dakota that conduct on-farm slaughter must follow both state and federal guidelines, which set forth standards for humane handling and safety.

Carcass Processing

Once slaughtered, the carcass undergoes further processing which includes skinning, evisceration, and splitting. Skinning involves the careful removal of the hide, taking care not to contaminate the meat. During evisceration, internal organs are removed, a critical step where precision is paramount to avoid contamination of the carcass with intestinal contents. Afterwards, the carcass is often split down the middle to form two sides, which are then chilled to prevent spoilage and bacterial growth.

Butchering, the process of breaking down the carcass into retail cuts, occurs after the carcass has been adequately chilled. On-farm butchering allows farmers to directly market their meats, adding value and offering consumers farm-to-table transparency. Each step is meticulously carried out to ensure the meat is of the highest quality and safe for consumption. Slaughter techniques and carcass processing on South Dakota farms are crafted to uphold quality while honoring the age-old traditions of livestock farming.

The Role of Mobile Slaughtering

Mobile slaughtering units offer an on-farm processing solution that bridges the gap between farmers and the market. In South Dakota, these units are integral for meat producers seeking efficient and humane slaughtering processes right on their property.

Advantages of Mobile Units

Customized Services: Mobile slaughtering allows farmers in South Dakota to schedule on-site butchering, reducing animal stress and transportation costs. This adaptability also extends to meet specific market demands.

Regulatory Compliance: Many mobile units are built to comply with federal and state regulations, ensuring the meat is safe and can be sold across state lines.

Freshness and Quality: Slaughtering animals on the farm can maintain freshness and reduce the potential for quality degradation associated with long-distance transport.

Support for Local Economies: By servicing small to mid-sized farms, mobile slaughter units contribute to the local food movement and help sustain the agricultural economy.

Setup and Operation

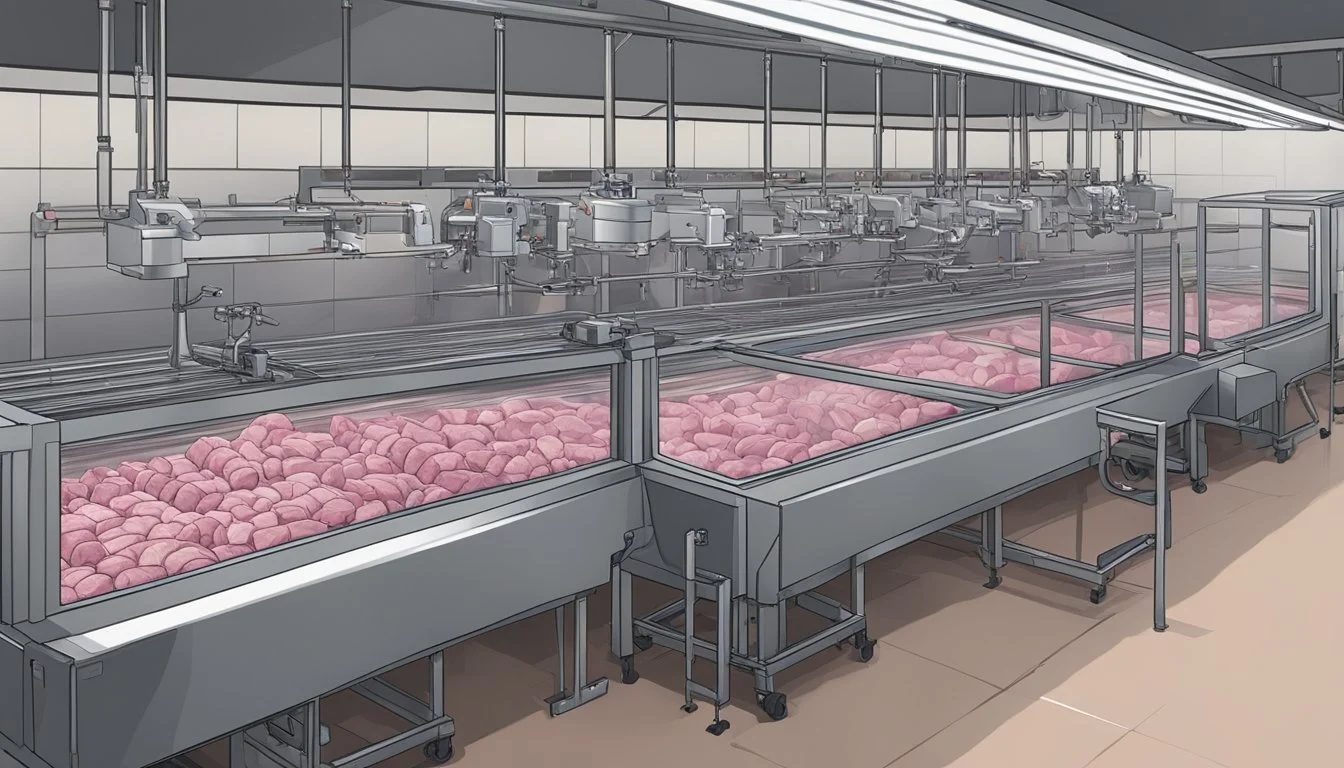

Equipment and Design: Typically housed in a trailer, the design includes areas for slaughtering, processing, and refrigeration. Units are equipped with tools and facilities comparable to stationary slaughterhouses, scaled for mobility and smaller operations.

Process Flow: The operation of a mobile slaughtering unit in South Dakota follows a sequence of steps from stunning to processing, often carried out by a skilled team adhering to the same health and safety standards as fixed-location plants.

Step in Process Description Arrival and Setup The unit arrives at the farm and is set up for operation. Slaughtering Animals are humanely slaughtered and prepared. Processing The meat is processed, packaged, and made ready for sale or transport. Sanitation The unit is thoroughly cleaned to maintain a hygienic processing environment.

Mobile slaughter units in South Dakota serve as a flexible and practical option for farmers who may not have access to traditional processing facilities or aim to market their products locally, ensuring quality and efficiency in the farm-to-table supply chain.

Packaging and Distribution

In South Dakota, on-farm meat processing involves meticulous packaging and strategic distribution to ensure meat quality and market demands are met. Each step, from cut and wrap to labeling, is crucial for maintaining product integrity, while distribution requires a seamless network for timely delivery.

Cut, Wrap, and Labeling Procedures

Once the butchering and slaughtering processes are complete, the meat is carefully transitioned into the phase of cut, wrap, and labeling. On-farm processors in South Dakota follow stringent guidelines to ensure that:

Cut: The meat is sectioned into retail cuts, paying close attention to the preservation of meat quality and the fulfillment of market preferences.

Wrap: Each piece is wrapped using materials that meet safety standards, typically employing vacuum sealing for extended freshness.

Labeling: The final products are labeled according to the USDA regulations, with clear records documenting the cut, weight, and date of packaging.

Labels include critical information such as the origin, processing dates, ingredients, and any allergen warnings.

Distribution Channels

Distribution channels are pivotal to getting South Dakota’s processed meat from the farm to the table. They consist of:

Local Meat Markets: On-farm processed meats are often sold directly to consumers through farmers' markets or on-site farm stores, which keep short supply chains and emphasize freshness.

Direct Sales: Farms may also establish relationships with restaurants and local groceries, supplying them with farm-processed meats and maintaining detailed sales records for traceability.

Statewide Distribution Networks: For larger-scale operations, meats are transported through a network of refrigerated vehicles, ensuring that products arrive at various outlets in a saleable condition, thus maximizing reach and revenue for the farms.

Both cut and wrap services and distribution contribute significantly to the agricultural economy of South Dakota, with on-farm processed meat gaining popularity for its quality and local appeal.

Best Practices for On-Farm Meat Processing

On-farm meat processing in South Dakota requires adherence to both federal and state regulations to ensure food safety, animal welfare, and environmental sustainability. Operators should start by confirming that their facilities meet the guidelines set by the USDA or state inspection programs.

Site Preparation: The processing site should be clean, well-lit, and equipped with potable water. Proper disposal systems for waste and by-products must be in place to prevent contamination and odor issues that can affect neighbors.

Handling Live Animals: Handlers should be trained in humane animal handling practices. This includes minimizing stress for the animals during transport and leading up to slaughter, as this can affect meat quality. Animals should have access to fresh water and, when necessary, feed, up until processing.

Compliance Area Key Considerations Transportation Stress-free, safe for animals Holding Pens Clean, with access to water Slaughter Humane methods, quick and efficient

Slaughter Techniques: Use approved methods that result in immediate unconsciousness and swift death. Equipment must be well-maintained and appropriate for the size and species of the live animal.

Sanitation: All processing areas must be kept clean. Surfaces in contact with meat need regular disinfection. Handlers should wear protective clothing and be trained in sanitation protocols.

Record-Keeping: Maintain detailed records of processing activities for traceability. All procedures should be documented, including animal source, date of processing, and steps taken during butchering.

Farmers must ensure that they engage with their community, respecting the rights and preferences of their neighbors while maintaining an open channel of communication about their on-farm processing activities.

Economic and Market Considerations

In South Dakota, the economic landscape for on-farm meat processing is notably shaped by recent federal funding and a concentrated market structure. The infusion of funds seeks to enhance capacity and foster competition within the meat market, particularly in response to challenges exacerbated by the COVID-19 pandemic.

Local Markets and Demand

The demand for locally processed meat in South Dakota has shown resilience and growth, bolstered by consumers' increasing preference for locally sourced products. This demand signals a significant opportunity for small to mid-sized processors in the region. Data demonstrates that the American Rescue Plan Act of 2021 allocated substantial funds, with South Dakota receiving approximately $27 million to support local meat processing facilities. This financial aid aims to not only meet growing local demand but also to strengthen the state's meat supply chain.

Federal Funding: $32 million allocated to South Dakota processors since COVID-19.

Local Consumer Preference: Increased interest in locally sourced meat.

Overcoming Market Barriers

Confronting market barriers remains crucial for new and existing meat processors in South Dakota. Market concentration poses a formidable challenge, as noted by the rising CR4 rates—an indicator of market concentration—in the beef and pork sectors nationally. For instance, the CR4 for beef witnessed an upsurge from 25 percent in 1977 to 85 percent in 2018, which indicates that a few companies hold a disproportionate share of the market. This concentration can stifle competition and present entry barriers for smaller processors. The federal grants and funding aim to dilute this concentration by enabling smaller entities to scale operations and enhance competitiveness.

Market Concentration (CR4 Rates):

Beef: Increased from 25% (1977) to 85% (2018).

Pork: Increased from 33% (1976) to 70% (2018).

Federal Initiatives: Directed to expand small and mid-sized processors' capabilities.

Case Studies and Comparative Analysis

This section delves into the specifics of on-farm meat processing within South Dakota and provides a comparative understanding through insights gained from Wisconsin and other states.

On-Farm Processing in South Dakota

In South Dakota, on-farm meat processing has been an essential aspect of the agricultural industry, adapting to local demand and regulatory frameworks. Farmers' Markets and Co-ops in South Dakota have shown an increasing trend in offering locally sourced meat, bolstering the need for on-farm processing. The state has implemented programs like the South Dakota Meat Inspection Program, which mirrors federal inspection requirements and allows state-inspected meats to be sold within the state. Entities in South Dakota adhere strictly to these regulations to ensure food safety and public health.

Challenges:

Regulatory compliance

Access to capital

Workforce training

Rewards:

Local market expansion

Control over product quality

Increased farm revenue

Insights from Wisconsin and Other States

Wisconsin, with a rich dairy and livestock tradition, offers a comparative case for on-farm processing. Here, small to mid-scale meat processors** lean on the technical support provided by the Wisconsin Department of Agriculture, Trade and Consumer Protection**. This department assists businesses in navigating federal and state regulations, quality assurance, and offers grant programs like the Meat Processor Grant, which facilitate development and growth.

The University of Wisconsin-Extension Service plays a vital role in providing education on best practices in meat processing, which could be instrumental for South Dakota as it continues to develop this sector. Lessons from Wisconsin underscore the importance of strong support systems and share vital insights including:

Innovative Practices:

Mobile slaughter units

Diversification into value-added products

Business Strategies:

Development of niche markets

Stronger focus on local consumer demand

Examining practices from other states demonstrates that successful on-farm processing is reliant on a confluence of regulatory compliance, community engagement, and continuous learning. These factors contribute to the resilience and self-sufficiency of the local food systems.

Future Trends and Innovations

In South Dakota, the meat processing industry is poised for evolution, with several adverse bottlenecks prompting innovation.

Streamlined Processing: Small-scale, on-farm processing plants may emerge as a trend to combat the meat processing bottleneck. These modular facilities are designed for efficiency and can be scaled to match demand, increasing the state's meat processing capacity.

Automation and Robotics: The integration of automation technology in processing plants is a key innovation. Automation can expedite butchering and slaughter processes, enhancing precision and safety while addressing labor shortages.

Mobile Slaughter Units (MSUs):

Flexibility: MSUs can travel directly to farms, reducing stress on animals and potentially improving meat quality.

Regulatory Compliance: These units are expected to adhere to USDA regulations, ensuring meat safety and quality.

Sustainability Practices:

Adoption of waste-reducing equipment

Implementation of energy-efficient systems

Technology in Traceability:

RFID tagging for real-time tracking

Blockchain for transparent supply chains

Overall, technological advancements and a focus on sustainability are setting the pace for the future of on-farm meat processing in South Dakota, with innovations expected to improve efficiency, ensure compliance, and meet consumer demands for transparency and quality.