On-Farm Meat Processing, Butchering and Slaughter in Hawaii

Navigating Regulations and Best Practices

On-farm meat processing in Hawaii reflects the state's commitment to bolstering local agriculture and enhancing food security. Amid the global disruptions caused by the COVID-19 pandemic, the significance of local meat supply chains became particularly evident. Hawaii, with its unique geographical challenges, has seen a renewed interest in on-farm meat processing as a way to ensure the availability of fresh, local meats. This method of processing also meets specific state regulations designed to maintain the quality and safety of locally processed products.

With limited access to large-scale slaughterhouses, Hawaiian ranchers and small-scale livestock farmers have recognized the value of on-farm meat processing. Such facilities enable producers to exert more control over the humane handling and butchering of their animals. In compliance with state regulations, these on-farm processors sometimes utilize mobile slaughtering units that allow for efficient and regulated processing right on the farm. The meat is either marked for custom consumption by the owner or subjected to state inspection for sale.

Through Hawaii's adaptation to on-farm processing, the state's agricultural sector is working to improve its self-sufficiency. By embracing state-inspected and mobile units for meat processing, Hawaii's livestock industry aims to increase the availability of local meats while adhering to necessary health and safety standards. This approach supports the islands' food sustainability goals and offers a case study for other states considering the implementation of more localized meat processing solutions.

Historical Context and Modern Relevance

In Hawaii, the trajectory of meat processing on farms reflects broader shifts in food systems and has seen renewed interest in light of recent global challenges. Key historical developments and the impact of a modern crisis have shaped the present scope of on-farm processing in the region.

Evolution of On-Farm Processing in Hawaii

On-farm meat processing in Hawaii initially mirrored traditional practices, with small-scale operations handling the slaughter and butchering of animals locally. With no significant land-based predators, traditional Hawaiian meat processing could take advantage of open grazing. However, as U.S. influence grew, mainland practices were adopted, leading to the establishment of centralized meat processing facilities. This shift marginalized local slaughterhouses, moving towards a system that mirrored the mainland's industrial scale of meat production and processing bottlenecks.

Despite these changes, small, local slaughterhouses continued to operate, preserving the knowledge and skills of on-farm processing. The local knowledge of meat processing has been essential in maintaining a part of Hawaii's agricultural independence, allowing farmers to provide locally processed meats to their communities.

COVID-19 and Renewed Interest

The advent of the COVID-19 pandemic led to a nationwide meat processing bottleneck, with many larger facilities temporarily closing due to health concerns. This disruption highlighted the vulnerabilities in the meat supply chain and led to a surge in demand for smaller-scale, local meat processing options.

Increased Demand: Consumers and producers in Hawaii have shown increased interest in on-farm processing to ensure a consistent supply of meat.

Regulatory Environment: The pandemic has prompted discussions on revising regulations to better support local and on-farm processing.

Local Slaughterhouses' Role: They became critical in meeting community needs, providing an essential service at a time when the traditional meat supply was under stress.

This period has underscored the relevance of on-farm processing as both a contingency plan and a sustainable model, aligning with the growing consumer preference for locally sourced foods and transparency in the food supply chain.

Regulatory Framework

In Hawaii, the on-farm meat processing industry operates within a complex structure of various regulations ranging from state guidelines to federal oversight. Adherence to these regulations ensures food safety, animal welfare, and community harmony.

State Guidelines and Compliance

Hawaii's State Department of Health enforces food safety standards that local meat processors must follow to ensure public health. These state-specific regulations are compatible with federal laws but can include additional requirements pertinent to Hawaii's unique environment. Processors must obtain state licenses and may be subject to regular inspections to maintain operational compliance.

USDA Regulations and Inspections

The United States Department of Agriculture (USDA) oversees meat processing at a national level. The USDA's Food Safety and Inspection Service (FSIS) is the primary agency responsible for ensuring that meat products are safely and humanely handled. Federal law requires that meat intended for commerce must be processed in a USDA-inspected facility or under a state system that has standards equivalent to those of the USDA.

USDA Inspection Presence: Mandatory at slaughtering and processing plants.

Guidelines Enforced: Sanitation, humane handling, product labeling.

USDA-certified establishments are subject to unexpected inspections and must comply with USDA regulations to remain operational.

Local Bylaws and Neighbor Relations

Local bylaws serve as additional regulatory layers concerning on-farm meat processing. These bylaws can dictate operational details, such as waste disposal and noise levels, which may affect neighbor relations. Meat processors in Hawaii must also consider the proximity of their operation to residential areas and engage with the community to mitigate any potential disturbances.

Waste Management: Must adhere to local environmental protection bylaws.

Noise Control: Operations must consider local noise ordinances.

Fostering good relations with neighbors is essential, as community members can raise concerns with local agencies, potentially triggering investigations or sanctions against non-compliant activities.

On-Farm Meat Processing Operations

On-farm meat processing in Hawaii is gaining traction as a means to enhance the sustainability and self-sufficiency of local agriculture. These operations allow farmers to maximize control over their products from pasture to plate.

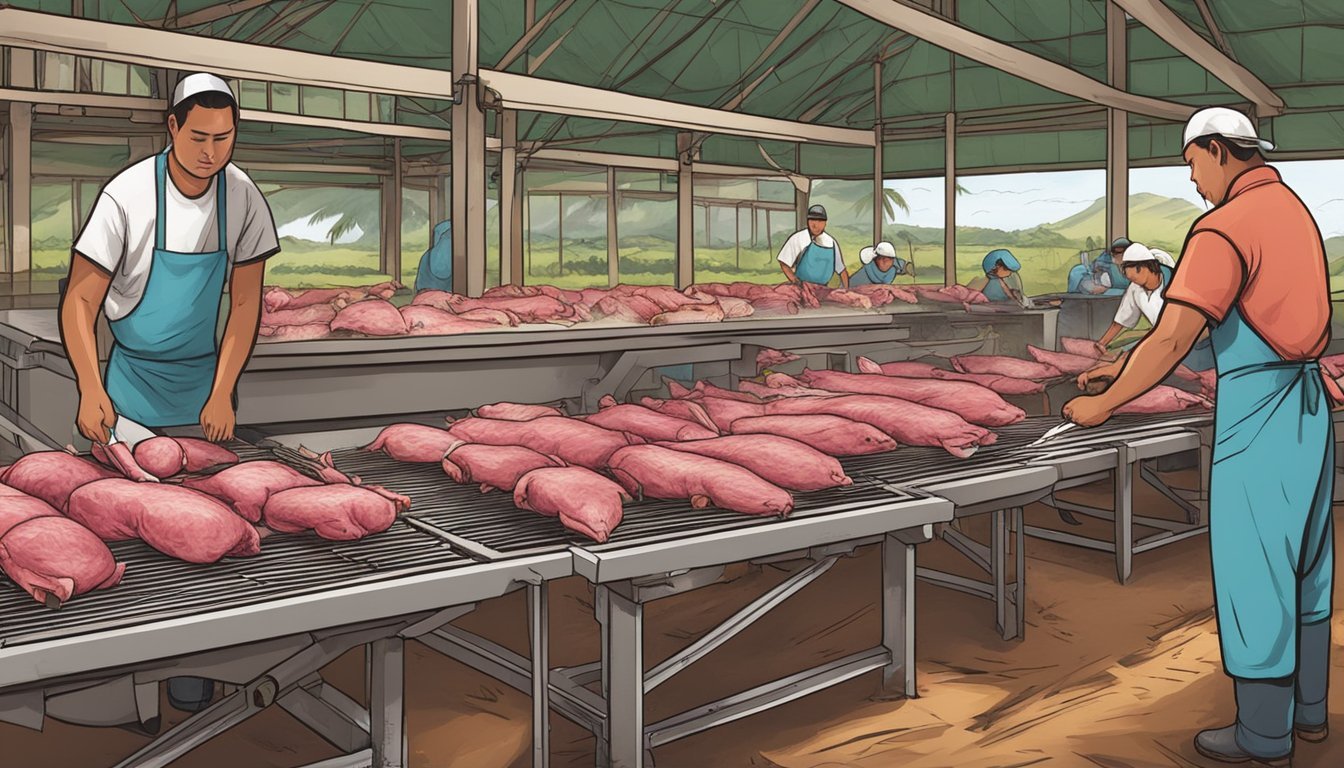

Setting Up an On-Farm Processing Facility

When a farmer in Hawaii decides to establish an on-farm processing facility, they engage in a process that requires careful planning and adherence to regulatory standards. Construction of the facility entails meeting USDA inspection requirements to ensure food safety. The typical facility is equipped with essential processing tools such as cutting tables, refrigeration units, and packaging equipment. On-farm facilities enable farmers to process meat products on-site, reducing the need for transportation and potentially lowering costs.

Mobile Slaughter Units

Mobile Slaughter Units (MSUs) serve as an innovative solution for farmers seeking USDA-inspected slaughter services. These units travel directly to farms, offering a range of butchering services that comply with federal regulations. MSUs provide many benefits, including:

Reduced transportation costs: By bringing processing services to the farm, livestock do not need to be transported long distances.

Stress minimization for animals: Shorter travel distances can lead to a reduction in animal stress, which is often associated with improved meat quality.

Flexibility: Farmers with smaller herds or those who operate on non-contiguous lands find MSUs especially useful.

Waste Management and Environmental Concerns

Effective waste management practices are crucial for on-farm processing operations to minimize their environmental impact. Farmers must incorporate strategies for dealing with by-products and waste materials, which can include:

Solid waste: Offal and other solid by-products need to be dealt with in a sanitary manner, either through composting or rendering.

Wastewater: Facilities must have proper sewage treatment systems to handle the blood and other fluids generated during processing. This often involves installing systems to treat and repurpose wastewater safely, in compliance with environmental regulations.

Proactive environmental management is pivotal, demonstrating a farm's commitment to sustainability and regulatory compliance.

Animal Husbandry and Welfare

Animal husbandry and welfare in Hawai‘i’s meat processing industry focus on ensuring responsible livestock raising practices, minimizing stress during slaughter, and selecting robust genetics for superior meat quality.

Livestock Raising Practices

In Hawaii, livestock raising practices prioritize the care and management of animals throughout their lives. Beef cattle, hogs, and other livestock are typically given environments that allow for natural behaviors, which is critical for maintaining their physical and psychological well-being. These practices are evident in the smaller, family-run farms that often dominate the islands' agricultural landscape, where animals tend to have more space and personalized care compared to larger, mainland operations.

Stress Reduction in Slaughter Methods

Reducing stress is a key component of humane slaughter methods within the Hawaiian meat processing sector. Lowering animals' stress levels not only aligns with ethical standards but also affects meat quality post-slaughter. Techniques employed may include:

Design of Facilities: Calm, quiet environments that reduce startling stimuli.

Handling: Gentle and patient handling by trained professionals.

Slaughter Method: Quick and efficient methods to minimize fear and pain.

These measures collectively ensure compliance with animal welfare standards while maintaining the integrity and quality of the meat.

Genetic Selection for Meat Quality

Genetic selection plays a significant role in meat production in Hawaii. By choosing breeds and individual animals with traits conducive to high-quality meat production, farmers can influence the tenderness, marbling, and overall taste of the meat. While beef is often the focus of genetic selection due to the high value placed on premium beef cuts, similar principles apply to hog production. Selective breeding programs are meticulously managed to combine ethical animal treatment with the desired meat quality outcomes.

The Butchering Process

The butchering process on a farm involves specific techniques to transform animal carcasses into consumable meat cuts. It requires strict adherence to safety and quality standards, from the initial breakdown of the carcass to the final packaging.

From Carcass to Cut

Once the animal is humanely slaughtered and the carcass is cleaned, it is broken down into its primary cuts through a process known as butchering. Expert butchers on Hawaii farms take great care to follow anatomical guidelines to separate beef into large sections like chuck, rib, loin, and round. Each section is then further processed into steaks, roasts, and other marketable cuts.

Primary beef cuts:

Chuck: Shoulder region; yields roasts and steaks.

Rib: Upper back; produces ribeye steaks (What wine goes well with ribeye steak?) and prime rib.

Loin: Lower back; known for tenderloin and sirloin cuts.

Round: Hindquarters; source of rump roasts and round steaks.

Aging and Hanging Techniques

Aging is a critical step for enhancing meat flavor and tenderness. On Hawaiian farms, carcasses are typically aged using two methods: wet and dry aging.

Wet Aging: Involves vacuum-sealing meat cuts and refrigerating them. This method is more rapid and less costly than dry aging.

Dry Aging: Carcasses or large cuts of meat are hung in a controlled environment for several weeks. The process allows natural enzymes to break down muscle tissue, resulting in a concentrated flavor.

Packaging and Labelling Standards

Upon reaching the desired age, the meat is processed into final cuts, packaged, and labeled in compliance with USDA regulations. Packaging often involves vacuum-sealing to preserve freshness, while labeling must include information like slaughter and packing dates, weight, and cut type.

Label information requirements:

Slaughter date: The exact date on which the animal was processed.

Packing date: The date when the meat was packaged.

Weight: The actual weight of the meat product.

Cut type: A clear description of the kind of cut enclosed.

Farmers ensure that all processes, from butchering to packaging, are carried out with the utmost care for quality and safety, resulting in premium products for consumers.

Business and Financial Considerations

In Hawaii, the viability of on-farm meat processing hinges on a clear understanding of the processing bottleneck, thorough cost-profit analysis, and labor cost management—each a critical factor in achieving sustainable operations.

Understanding the Processing Bottleneck

The processing bottleneck occurs when demand for processing outstrips the capacity of meat processing facilities. In Hawaii, due to the limited number of USDA-inspected facilities, on-farm processors often face significant delays. This leads to longer holding periods for livestock, which, in turn, can result in increased feed costs and delayed revenue. The ability to process meat on-farm can be key to mitigating this bottleneck by providing farmers with more control over their supply chain timelines.

Cost Analysis and Profitability

When considering on-farm meat processing in Hawaii, producers must conduct a comprehensive cost analysis to determine potential profitability. Here are key financial factors to assess:

Capital investment: Costs of setting up facilities, including expenses for equipment and meeting regulatory compliance standards.

Operational costs: Ongoing expenses like utilities, sanitation, and maintenance.

Market prices: The price points at which meat can be sold warrant careful attention, as they directly affect profit margins.

To help visualize, a basic cost-profit table might look as follows:

Cost Type Estimated Cost (USD) Initial Setup (One-time) 100,000+ Equipment Maintenance 2,000+ Utilities (Monthly) 500+ Inspection and Compliance 1,000+ Labor (Monthly) 4,000+ Total Estimated Cost - Expected Monthly Revenue - Estimated Profit Margin -

Profitability also depends on efficient scale operations and niche marketing, both crucial in Hawaii's unique economy.

Labor Costs and Scaling Operations

Labor is one of the primary costs for on-farm processing operations. Hiring skilled butchers and processors is essential, and in Hawaii's tight labor market, this can command higher wages. Understanding the relationship between labor input and output volume is key to scaling operations effectively.

For small operations, labor costs might represent a more significant percentage of total costs compared to larger operations that benefit from economies of scale. Assessing whether to increase scale should be driven by a careful analysis of labor costs versus increased throughput and potential market expansion.

Optimal Scaling Example:

Small-scale operation, labor vs. output (monthly):

Labor costs: 4,000 USD

Meat processed: 1,000 lbs

Labor cost per pound: 4 USD

Scaled-up operation, labor vs. output (monthly):

Labor costs: 12,000 USD

Meat processed: 4,000 lbs

Labor cost per pound: 3 USD

By scaling up, the operation can potentially reduce labor costs per pound of meat processed, assuming that the increase in volume does not lead to inefficiencies or additional bottlenecks.

Quality and Safety of Meat Products

When it comes to on-farm meat processing in Hawaii, maintaining the highest standards of quality and safety is paramount. The focus is on implementing rigorous processing plant hygiene protocols, meticulous carcass handling, and quality control measures, coupled with comprehensive record-keeping for traceability.

Processing Plant Hygiene

In Hawaii, slaughter units must adhere to strict hygiene practices to prevent contamination and ensure the safety of meat products. Surfaces and equipment used for meat processing, especially for cut and wrap services, are required to be sanitized regularly. It is essential to:

Use antibacterial agents suitable for food processing areas.

Ensure regular staff training on hygiene and safety standards.

Monitor hygiene practices through routine inspections.

Carcass Handling and Quality Control

Meat quality begins with proper carcass handling. From the slaughter to the cut and wrap phase, attention to detail is critical. This includes:

Monitoring carcass temperature to reduce microbial proliferation.

Inspecting meat for defects or signs of disease.

Implementing a "from farm to table" approach to trace each product back to its source.

Record-Keeping and Traceability

Accurate records are vital for traceability and ensuring the safety and quality of meat products. Records must include details of:

Each animal slaughtered: date, time, and method.

Processing details: temperatures, handling procedures, and packaging.

Distribution: tracking the meat from the slaughter unit to the consumer.

By maintaining rigorous standards in these areas, the meat processing industry in Hawaii can assure customers of the integrity and safety of their meat products.

Community and Market Engagement

Engagement with local stakeholders is crucial in the evolution of Hawaii's on-farm meat processing sector. Effective collaboration and clear communication channels are key to nurturing a sustainable local meat economy.

Building Relationships with Local Farmers and Ranchers

Forging strong relationships between local meat processors and Hawaii's farmers and ranchers is essential. They collaborate closely to ensure the livestock is raised in compliance with welfare standards, and processing aligns with demand. Partnerships are strategically developed through regular meetings, farm visits, and shared initiatives, enhancing trust and facilitating the exchange of best practices.

Marketing Pasture-Raised Meat

Pasture-raised meat is a product of robust marketing strategies deployed by the local meat processors. They employ various tools such as:

Direct marketing: Selling directly to consumers through farmers' markets or subscriptions.

Retail partnerships: Aligning with local stores that prioritize local, pasture-raised products.

Educational campaigns: Highlighting benefits of pasture-raised meat, including taste and nutritional value.

Processors and ranchers target niche markets that appreciate the quality of pasture-raised meat, while also exploring broader market segments.

Consumer Education and Transparency

Educating consumers is a top priority for Hawaii's meat processing stakeholders. They aim to provide clarity on the origins of meat and the benefits of supporting local production. To achieve this, they:

Offer farm tours and processing demonstrations to foster consumer trust.

Provide clear labeling on products, indicating the local provenance.

Share stories of local ranchers and farmers through media, highlighting their dedication to raising high-quality livestock.

By increasing transparency, consumers become more informed and likely to support the local meat market.

Technology and Innovation in Meat Processing

The landscape of meat processing in Hawaii is seeing significant technological strides in equipment and facility design. These improvements aim to enhance efficiency, product quality, and address on-farm slaughtering needs.

Advancements in Slaughtering Equipment

Mobile Slaughtering Units (MSUs): These are becoming pivotal for small-scale farmers in more remote areas of Hawaii. MSUs bring the capability directly to the farm, reducing stress for the animals and lowering transportation costs. Featuring state-of-the-art slaughter equipment, such as stunners and automated bleeding lines, these units are designed for quick deployment and compliance with regulatory standards, thus supporting humane and efficient practices.

High-Precision Tools: Modern slaughtering equipment also now incorporates high-precision tools. These include laser-guided cutting instruments and advanced monitoring systems, which ensure precision in butchering while maintaining safety for workers.

Processing Plant Design Innovations

Modular Design: Processing plant design has embraced modularity, facilitating customizable and scalable solutions that can adapt to the varying demands of meat processing needs in Hawaii. This also allows for rapid expansion or reconfiguration with minimal downtime.

Sustainability Focus: Efficiency in design extends to water and energy use, with innovative plants incorporating green technologies like solar power and wastewater treatment systems. This push towards sustainability is especially crucial in the context of Hawaii's unique environmental considerations.

Ergonomic and Safe Environments: Ergonomics is a focal point in contemporary processing plant layouts. Enhanced lighting, ventilation, and temperature controls ensure a safer and more comfortable work environment, which in turn can improve productivity and employee well-being.

By embracing these technologies and innovative designs, meat processing in Hawaii is positioned to grow sustainably while supporting local agriculture and providing high-quality products to consumers.