On-Farm Meat Processing, Butchering, and Slaughter in Indiana

A Comprehensive Guide

On-farm meat processing in Indiana has emerged as a vital part of the state's agricultural landscape, offering livestock producers the ability to process meat locally. This practice is not just a means of turning animals into market-ready products but also allows farmers to maintain control over the quality and safety of the meat. With a focus on food safety, these local processing operations adhere to stringent regulations to ensure the health of consumers and integrity of the product.

In Indiana, the trend towards local processing has been supported by various surveys and studies, including one conducted with 80 livestock producers across the state to gauge their experiences with slaughter and butchering services. A significant number of these farmers rely on meat sales as their main source of income. Thus, the efficiency and availability of on-farm processing facilities directly impact their livelihoods and the local economy.

Slaughter and butchering within the farm premises present the farmers with both challenges and rewards. Navigating through the complexities of capital investment, navigating regulatory frameworks, and addressing public perception are part of establishing a USDA-compliant on-farm processing facility. Yet, the growing support for these independently operated units reflects a movement towards sustainable agriculture and the strengthening of local food systems in Indiana.

Basics of On-Farm Meat Processing

On-farm meat processing in Indiana involves the slaughtering and butchering of livestock, including beef, pork, lamb, and poultry, by farmers. This section offers a concise overview of the fundamentals of on-farm meat processing, emphasizing its impact on meat quality.

Understanding Slaughter and Processing

Slaughter refers to the humane killing of livestock for food. Indiana farmers who engage in on-farm slaughter must comply with both federal and state regulations to ensure food safety and animal welfare. The primary steps in the slaughter process include stunning, exsanguination (bleeding out), and evisceration (removal of internal organs).

Stunning: Involves rendering the animal unconscious before exsanguination to minimize pain.

Exsanguination: The animal’s major blood vessels are severed to cause death through blood loss.

Evisceration: Removal of the animal's internal organs immediately after death, a critical step for preventing contamination.

Processing, on the other hand, involves converting the slaughtered animal into market-ready meat products. This includes skinning or defeathering, cooling, cutting, and packaging. The quality of meat processing directly impacts the end product's taste, tenderness, and shelf-life. Farmers who process meat onsite provide a clear chain of custody for their meat, assuring consumers of the meat's origins and treatment.

Overview of Livestock Types

Livestock types commonly processed on Indiana farms include:

Beef (cows): Known for a range of cuts, beef requires aging for enhanced tenderness.

Poultry (chickens, turkeys): Generally processed whole but can be segmented into breasts, thighs, wings, and other cuts.

Pork (pigs): Offers a variety of products from bacon to ham and needs careful handling due to its fat content.

Lamb (sheep): Less commonly processed but valued for its distinctive flavor and various cuts like chops and roasts.

Table of Key Livestock and Associated Meat Qualities:

Livestock Type Primary Meat Products Considerations for Processing Beef (Cow) Steaks, roasts, ground beef Aging for tenderness, stringent cut specifications Poultry Whole birds, breasts, wings Quick processing post-slaughter to prevent spoilage Pork (Pigs) Bacon, ham, pork chops (What wine goes well with pork chops?) Fat preservation, smoke curing as an option Lamb (Sheep) Chops, roasts, ground lamb Less processing volume, unique market demand

Farmers are responsible for ensuring that the processing methods for each livestock type align with best practices for meat quality and safety. The goal is to produce high-quality meat that meets or surpasses consumer expectations and complies with health and safety standards.

Regulatory Compliance and Food Safety

In Indiana, on-farm meat processing and butchering must adhere to stringent safety regulations to ensure the well-being of consumers. Meeting these obligations involves understanding and complying with USDA oversight and implementing robust food safety protocols.

USDA Regulations and Inspections

United States Department of Agriculture (USDA) regulations mandate that meat processing, especially slaughter, is subject to federal inspection. Specifically, the Food Safety and Inspection Service (FSIS) enforces these requirements, assuring that processors maintain high standards for safety and wholesomeness. Processors in Indiana that sell meats across state lines are obliged to undergo this federal inspection. However, those selling within state borders may be subject to a State Meat and Poultry Inspection (MPI) program, provided it satisfies federal standards as stipulated by 21 U.S.C. 661.

To be compliant, on-farm processors must ensure that:

Every carcass is inspected by a qualified inspector.

Food safety standards set by FSIS are strictly followed.

The processor's compliance with these standards is regularly verified through inspections.

Food Safety Measures

Food safety is a fundamental concern for producers and growers (processors) to protect consumers. It encompasses several measures that processors implement to mitigate hazards and prevent contamination.

These measures include:

Proper sanitation of tools and facilities.

Implementation of Hazard Analysis and Critical Control Points (HACCP) plans.

Regular employee training on best practices in handling and processing meat.

Additionally, processors should maintain accurate records as required by the FSIS to document compliance and facilitate traceability should a food safety issue arise. The overarching goal is to ensure that meat products are not only safe and wholesome, but also correctly labeled and packaged.

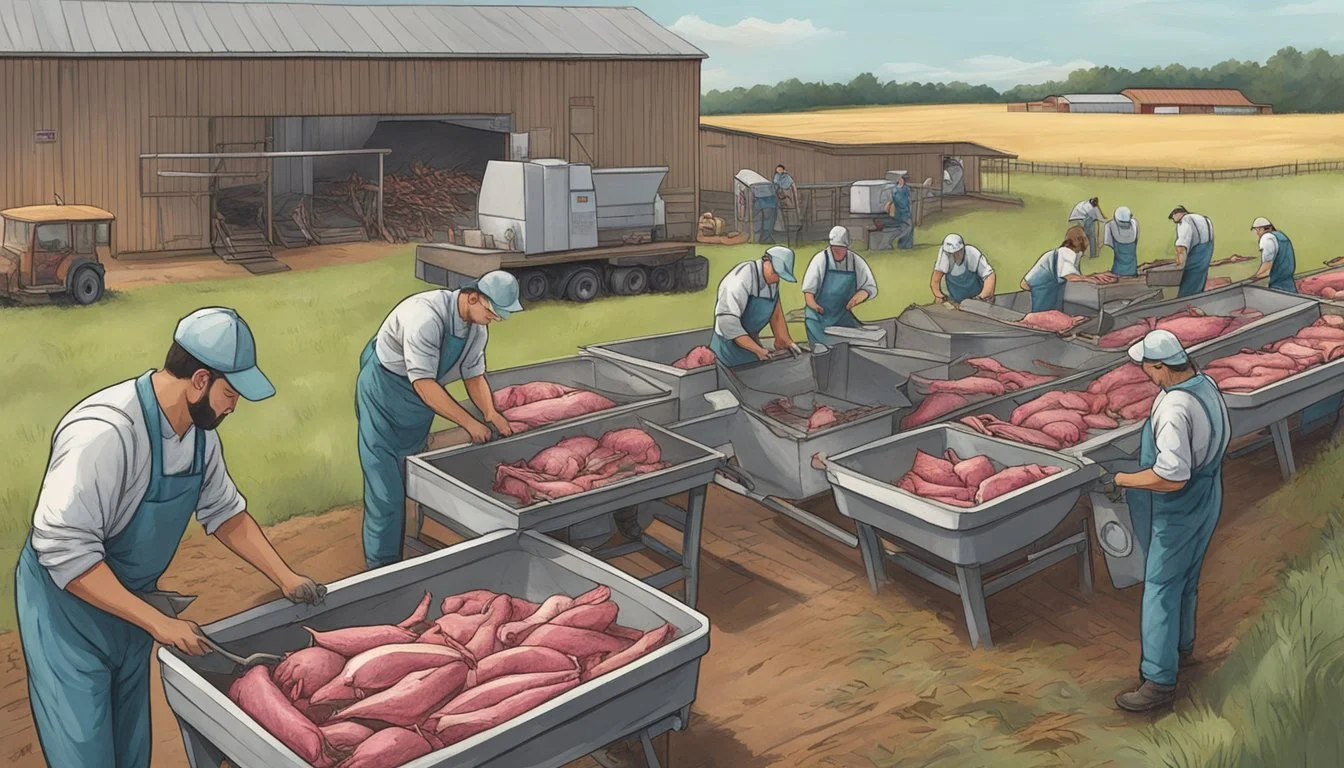

On-Farm Meat Processing Infrastructure

Increasing capacity and optimizing processing infrastructure are vital for on-farm meat processing in Indiana. These farms are enhancing their business models by investing in facilities and mobile units that align with regulatory standards and meet rising demand.

Building or Upgrading Facilities

Farm operators in Indiana are recognizing the importance of developing or improving their on-farm meat processing facilities. The statewide initiative to bolster the local meat processing capacity has led to Indiana's Department of Agriculture awarding $4 million to assist in enhancing existing infrastructures. Upgrades to processing facilities ensure:

Compliance with USDA regulations

Increased slaughtering throughput

Enhanced safety and quality control

Facilities focus on incorporating new technologies and equipment which directly impact their processing abilities and allow for a more predictable and resilient business operation.

Mobile Slaughter Units

Mobile slaughter units (MSUs) are gaining popularity among Indiana's farmers, providing a versatile approach to meat processing. MSUs are designed to:

Navigate to different farm locations

Offer on-site slaughtering services

Reduce transportation stress on animals

Expand access to processing resources for small to mid-size farm businesses

This flexibility is crucial in addressing the fluctuating demands of the market, ensuring the farm businesses can adapt quickly without the need for substantial infrastructure investments. Mobile units are essential in creating a distributed network of processing capacity that supports local agricultural economies.

Animal Welfare and Meat Quality

The relationship between animal welfare and the quality of meat obtained through on-farm processing is a crucial aspect of Indiana's meat industry. Ensuring humane handling and slaughtering practices are adhered to not only reflects ethical standards but also significantly impacts the final meat product.

Humane Handling and Slaughter

In Indiana, regulations on humane handling and slaughter are designed to mitigate stress on animals during the farming and slaughtering process. Stress directly affects meat quality, making it essential for slaughterhouses to follow strict guidelines on humane treatment. This includes proper diet, grazing practices, and a finishing period that contributes to both the well-being of livestock and the quality of the meat. Slaughter processes must minimize pain and distress to animals, with proper handling from farm to slaughter being paramount.

Factors Affecting Meat Quality

Meat quality can be influenced by a variety of factors spanning the lifetime of the animal. These range from diet and grazing practices to the method and efficiency of the slaughtering process. Meat quality is also affected by:

Finishing: Feeding strategies during the last phase of growth can alter fat composition and meat tenderness.

Stress: Pre-slaughter stress may lead to poor meat quality, including issues like pale, soft, and exudative (PSE) meat in pigs.

Handling: Livestock undergoing rough handling can experience stress that degrades meat quality.

Striving for excellence in animal welfare and proper handling techniques is not just an ethical imperative; it is closely linked to the production of high-quality meat in Indiana's on-farm processing industry.

The Business of Meat Processing on the Farm

The demand for locally sourced meat has highlighted the significance of on-farm meat processing in Indiana. Farmers seek efficient methods to deliver their products directly to consumers, while ensuring adherence to regulations and quality standards.

Strategies for Small Farmers

Small farmers in Indiana have identified collaboration as a key strategy to navigate the challenges of meat processing. A case in point is the partnership between Nightfall Farm and Plumer & Bowers Farmstead, which engaged with Indiana University researchers to assess the impact of processing experiences on farm businesses. These farmers often form cooperatives and associations to share resources such as equipment and knowledge, thus providing a combined front to tackle the costs and complexities of slaughtering and processing. For example, through cooperative efforts, small-scale meat processors have pooled investments to enhance their processing capabilities, creating better economies of scale.

Furthermore, state initiatives like the Indiana Meat Processing Expansion & Development Grant Program have granted financial support to local processors. Funds from this program have been allocated to offset the pandemic's impact and improve infrastructure, which is crucial for small farmers who rely on these processors for their farm-to-table enterprises.

Exploring Direct-to-Consumer Sales

Direct-to-consumer sales provide an attractive alternative for farmers and ranchers aiming to maximize their profit margins and build relationships with their customer base. Local small-scale processors play a pivotal role in enabling direct sales through a range of services, from slaughtering to packaging and labeling. This not only brings farmers closer to consumers but also promotes transparency and trust in the supply chain.

The recent USDA funding initiatives underscore the importance of expanding processing capacity. A significant investment has been documented to bolster operations and revolutionize the agricultural markets, which subsequently benefits both producers and consumers by potentially offering competitive pricing and higher quality meat options, like poultry and beef, from their local processors. Moving towards a direct-to-consumer model also means that farmers must keenly understand market demands and regulations to maintain a viable business.

Marketing and Distribution

As the demand for local meat in Indiana continues to grow, farmers are leveraging innovative marketing and distribution strategies. These strategies directly connect them with local consumer markets and establish enduring partnerships with restaurants and institutions.

Local Consumer Markets

Farmers in Indiana have tapped into the rising consumer interest in locally sourced meat. They are effectively adopting direct-to-consumer models, such as Community Supported Agriculture (CSA), farmers' markets, and on-farm retail stores. This approach not only fosters consumer trust through transparency but also ensures that the economic benefits remain within the local community. Farmers also maintain an online presence, offering websites and social media platforms for consumers to purchase meat directly, facilitating a deeper connection between the producer and the consumer.

Connecting with Restaurants and Institutions

Partnerships with restaurants and institutions, such as schools and hospitals, have become integral for local meat distribution. Indiana farmers work to form relationships with chefs and procurement officers, focusing on the quality and sustainability of their meat products. By distributing their products to local restaurants, which often showcase regional flavors, farmers secure consistent and reliable markets for their meat. Additionally, institutions have started to source meat locally to meet the demands for healthier and more sustainable menu options. Such partnerships not only support local economies but also help in educating consumers about the benefits of choosing local meat.

Packaging, Labeling, and Branding

In Indiana, on-farm meat processing is viewed as both a craft and a science, necessitating meticulous attention to packaging and labeling domains. These facets are vital not just for preserving meat quality but also for upholding consumer trust through transparency.

Packaging for Preservation

Proper packaging is crucial in preserving the quality and safety of meat products from on-farm processing. In Indiana's context, farms employing meat processing technologies often use vacuum sealing or modified atmosphere packaging to optimize the shelf life of meats. This form of packaging ensures that local meat retains its freshness from the farm to the kitchen.

Vacuum sealing: Removes air from the package, inhibiting bacterial growth.

Modified atmosphere packaging: Replaces the oxygen inside the packaging with gases like nitrogen or carbon dioxide to slow down spoilage.

Meat packaged in such ways helps maintain its integrity, taste, and nutritional value, which is particularly important when transported to different markets or directly to the consumer.

Labeling for Transparency

Labeling is more than just a regulatory requirement; it is a commitment to transparency. Indiana's on-farm meat processors adhere to the Federal Food Labeling Requirements as they help consumers make informed choices. The key labeling elements include:

Product Name: The type of meat or poultry product.

Net Weight: The weight of the meat product.

Ingredient Statement: If the product contains more than one ingredient.

Inspection Legend: Evidence of inspection by the relevant regulatory body.

Handling Instructions: How to safely store and prepare the meat.

These elements ensure that consumers are well-informed about the meat they purchase, supporting their ability to select local, high-quality products with confidence. Transparent labeling tells the story of the product, from the farm's commitment to quality to the meticulous care in processing and handling, instilling greater confidence in local food systems.

Industry Challenges and Trends

The on-farm meat processing industry in Indiana faces significant obstacles, including the impact of the COVID-19 pandemic and ongoing supply chain limitations, which have tested the resilience of both producers and the food system at large.

Coping with COVID-19's Impact

The COVID-19 pandemic has exerted unprecedented stress on Indiana's on-farm meat processing operations. Producers have had to navigate health and safety concerns for workers, leading to labor shortages and subsequent production delays. The pandemic has also affected consumer behavior, with a marked increase in demand for locally sourced meat, placing further strain on processing capacity.

Supply Chain and Capacity Issues

Supply chain disruptions have been a hallmark challenge for the industry, exacerbated by the pandemic's effects on transportation and logistics. Indiana's on-farm processors must contend with limited access to essential inputs, from packaging materials to processing equipment. A key issue is the processing capacity, as many farms lack the infrastructure to scale up operations, limiting their ability to meet growing consumer demand for local meat products. This deficiency hinders their capacity to support a robust, secure food system.

Support and Resources for Processors

In Indiana, meat processors are supported through various avenues that bolster their operational capabilities and contribute to a robust food supply chain. These include financial assistance programs and educational resources designed to enhance efficiency and compliance with regulations.

Grants and Funding Opportunities

Department of Agriculture Grants: The U.S. Department of Agriculture (USDA) offers funding for meat and poultry processors aiming to expand their operations. Processors can access these grants to improve their facilities, incorporate new technologies, and meet market demands more effectively. In August of 2023, for instance, USDA introduced additional grants to assist processors in transforming the food supply chain and creating better markets for producers.

State-Level Support: The Indiana State Department of Agriculture has shown its dedication to local meat processors by awarding significant funding through initiatives like the Indiana Meat Processing Expansion & Development Grant Program. This program provided $4 million to 41 meat processing businesses in the state, aimed at mitigating the challenges posed by the coronavirus pandemic.

Educational Programs and Outreach

USDA Educational Outreach: USDA Rural Development not only provides financial support but also engages in educational outreach. It delivers resources and programs to help processors understand industry best practices, regulatory compliance, and ways to enhance their competitive edge in the market.

Local Training Programs: Processors can benefit from local and state educational programs that offer training in business management, food safety, and processing techniques. These programs are vital in ensuring that meat processors are well-prepared to meet both consumer demand and regulatory requirements effectively and safely.

Through these concerted efforts of funding opportunities and educational programs, meat processors in Indiana are equipped with the resources they need to thrive in a competitive industry.