On-Farm Meat Processing, Butchering, and Slaughter in Iowa

Navigating Regulations and Best Practices

On-farm meat processing in Iowa reflects a growing interest among small-scale farmers wanting to take greater control of their products from pasture to plate. With increasing consumer demand for locally sourced meats and transparent production practices, these farms often seek ways to process their livestock on-site. This model allows farmers to bypass traditional meat processing bottlenecks and respond more agilely to market demands. The on-farm approach, while offering a more direct route from farm to consumer, does come with its fair share of operational challenges and regulatory requirements, especially concerning meat safety and inspection standards.

The state of Iowa has acknowledged these challenges and is proactively addressing the surge in calls for small-scale processing support. Through the Iowa Department of Agriculture and Land Stewardship’s Meat and Poultry Inspection Bureau, the state provides oversight and guidance for meat processing within its jurisdiction. This not only ensures that safety standards are met but also has the potential to aid in diminishing the processing bottleneck by allowing for more authorized facilities to operate in accordance with regulations.

As demand for on-farm processed meat continues to grow, so does the exploration of innovative solutions such as mobile slaughtering units, which offer the potential to streamline the meat processing pipeline. Although facing their own set of logistical hurdles and scalability questions, these mobile units represent a forward-thinking approach to meeting the needs of Iowa farmers and consumers alike, contributing to the state's evolving agricultural landscape.

Overview of On-farm Meat Processing

On-farm meat processing in Iowa has a rich history and continues to evolve, with local slaughterhouses playing a crucial role in the state's agricultural landscape. It offers numerous benefits for both producers and consumers.

History of On-farm Slaughter in Iowa

Iowa's history of on-farm slaughter dates back to the state's early settlements where local farmers practiced this method as a means to sustain their households and communities. Over time, regulations and modernization have shaped its current framework, ensuring safety and quality in the meat processing industry.

Current State of On-farm Meat Processing

Today, on-farm meat processing in Iowa operates within a regulatory environment aimed at maintaining safety standards while supporting local agriculture. Producers find value in on-site processing to circumvent the challenges posed by large-scale facilities, such as availability and scheduling conflicts, which in turn ensures a more stable income stream.

The Role of Local On-farm Slaughterhouses

Local on-farm slaughterhouses in Iowa serve as a critical link between producers and consumers. They provide services tailored to the needs of the state's farmers while adhering to the USDA guidelines, ensuring the meat is processed in a controlled and sanctioned manner.

Benefits of On-farm Processing For Producers and Consumers

For producers, on-farm processing implies greater control over their products, resulting in fresher and potentially higher quality meats. For consumers, it offers the possibility of purchasing meats that are transparently sourced and processed, often leading to a product that aligns with their values concerning animal welfare and sustainability.

Regulatory Landscape

In Iowa, on-farm meat processing and slaughter are governed by a complex web of regulations to ensure consumer safety while balancing the needs of the agricultural community. These regulations are administered by both state and federal agencies, each playing a critical role in the oversight of animal slaughter and meat processing operations.

State Regulations and Compliance

The Iowa Department of Agriculture and Land Stewardship (IDALS) enforces state regulations which are designed to work in tandem with federal mandates. These rules apply to a variety of livestock, including cattle, sheep, swine, goats, and domestic poultry. Meat and Poultry Inspection Bureau is the specific body tasked with ensuring compliance within the state. State-certified establishments must undergo regular inspections to maintain their operational status.

Key state regulation entities and contacts:

Organization: Meat and Poultry Inspection Bureau

Phone: (515) 281-3338

Fax: (515) 281-4819

Food Safety Considerations

Under both federal and state regulation, there is a strong emphasis on food safety. This encompasses thorough inspections of animals pre- and post-slaughter, handling of meat products, and the processing facilities themselves. In Iowa, the adaptation of the Federal Meat Inspection Act guides the safety protocols that local slaughterhouses and processors must follow. These standards are implemented to eliminate the risk of foodborne illnesses and ensure that products are safe for consumer markets.

Impact of Regulations on Small Farmers

Regulatory compliance can present challenges to small-scale farmers and processors. However, federal initiatives have been introduced to support these businesses. For example, USDA Rural Development grants aim to expand operations and create better markets for producers, indirectly influencing state-level activities. Additionally, federal exemptions, such as the producer/grower exemptions under certain thresholds, allow for sales in intrastate commerce which can include direct-to-consumer sales, hotels, restaurants, and institutions.

Notable exemptions affecting small farmers:

Producer/Grower 1,000 Bird Exemption: This allows sales to certain entities within the state.

Producer/Grower 20,000 Bird Exemption: Includes additional sales opportunities.

Regulations frame the operational landscape for Iowa's meat processing and butchery businesses, ensuring food safety while also acknowledging the economic impact on small farmers.

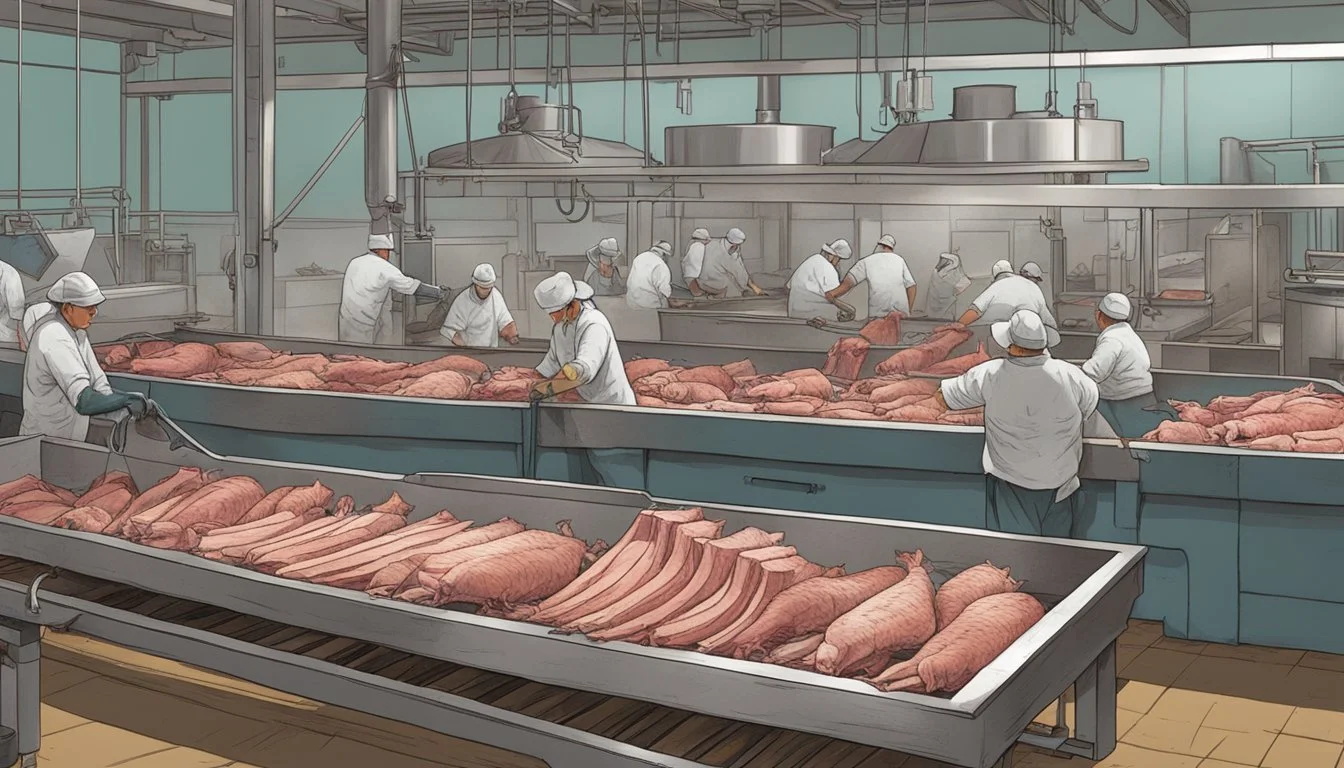

Meat Processing Infrastructure

Iowa's meat processing infrastructure is adapting to meet the needs of its livestock producers through innovative solutions such as mobile slaughter units, the establishment of stationary on-farm slaughterhouses, and the embrace of new technological advances.

Mobile Slaughter Units

Mobile slaughter units (MSUs) address the bottleneck issue in meat processing by providing on-site slaughtering services capable of handling 25-30 beef and 30-40 hogs per week. These units are typically housed in large vehicles, such as 26-foot box trucks, and can operate as "custom" processors for meat intended solely for the animal's owner or as "state-inspected" facilities, where meat can be sold under state oversight.

Stationary On-farm Slaughterhouses

Stationary on-farm slaughterhouses in Iowa offer increased control to livestock producers over the processing phase. By operating their own facilities, farmers can ensure adherence to safety regulations and quality standards. These installations vary in scale but are essential in creating a more resilient and self-reliant local food system.

Equipment and Technological Advances

The equipment used in meat processing in Iowa has seen significant technological advances, enhancing both capacity and efficiency. This includes:

Automated cutting lines, which improve precision and reduce labor needs.

Advanced refrigeration systems, ensuring meat is preserved at optimal temperatures for safety and quality.

Integrated software solutions, which manage inventory, track processing stages, and ensure compliance with regulatory requirements.

Such technologies not only streamline processing operations but also bolster food safety and traceability within Iowa's meat processing sector.

Animal Husbandry and Welfare

In Iowa's on-farm meat processing, the focus is on aligning animal welfare practices with the rigorous demands of production. This includes managing stress in livestock during slaughter and adhering to pasture-raised, grass-fed approaches to improve well-being.

Stress Management in Livestock Slaughter

In Iowa's animal husbandry, minimizing stress during slaughter is a pivotal aspect of welfare. Stress in animals can have a direct impact on meat quality, manifesting in issues like Pale, Soft, and Exudative (PSE) meat. To address this, Iowa meat producers implement practices like:

Handling Techniques: Use of low-stress herding and handling techniques to move animals calmly.

Facility Design: Slaughter facilities designed to reduce noise and visual distractions that can cause stress.

Training: Workers trained in humane slaughter methods, ensuring a quick and stress-free death.

Key Measures:

Factor Implementation Handling Gentle, minimal physical contact Transportation Short, well-planned journeys Pre-slaughter Adequate rest and food access

Pasture-Raised and Grass-Fed Approaches

Pasture-raised approaches reflect a commitment to animal well-being and eco-friendly practices. Livestock are given access to natural pastures, where they can graze on grass, which is beneficial for their digestion and overall health. Key points about pasture-raised and grass-fed production in Iowa include:

Lower Stress: Livestock experience lower levels of stress in pasture settings, contributing to better physical and psychological health.

Improved Quality: Pasture-raised meat is said to have greater nutritional value, including higher levels of omega-3 fatty acids and vitamins.

Grass-Fed Standards:

Access to Pasture: ensuring livestock spend the majority of their life on true pasture.

Grass Diet: a diet consisting of sustainably managed grass and forage from weaning onwards.

Health Benefits: producing meat with potentially higher beneficial nutrients levels.

Operational Challenges and Solutions

In Iowa's burgeoning farm-to-table landscape, operators face distinct challenges in meat processing and slaughter which necessitate innovative solutions.

Managing Meat Processing Bottlenecks

Meat Processing Bottleneck: Bottlenecks often occur at the slaughter phase due to facility shortages, affecting the overall supply chain. Operators are exploring mobile slaughtering units capable of processing 25-30 beef and 30-40 hogs per week to alleviate these bottlenecks. Mobile units provide flexibility, allowing processing to meet the variable demand more effectively.

Addressing Skilled Labor Shortages

Skilled Labor Shortage: The meat processing industry consistently grapples with the dearth of skilled labor, exacerbated by high turnover rates and labor-intensive work. Strategies implemented by Iowa facilities include:

Partnering with educational institutions such as Iowa State University to provide HACCP certification and additional lab work.

Development of course modules like Basic and Advanced Meat Processing, aiding in workforce upskilling.

Sustainable Waste Management

Sewage Treatment and Waste: Sustainable management of waste materials, particularly sewage treatment, is critical in meat processing. Facilities are investing in advanced waste management systems that not only comply with stringent regulations but also aim to recycle and repurpose waste into value-added products, reducing the environmental impact of processing activities.

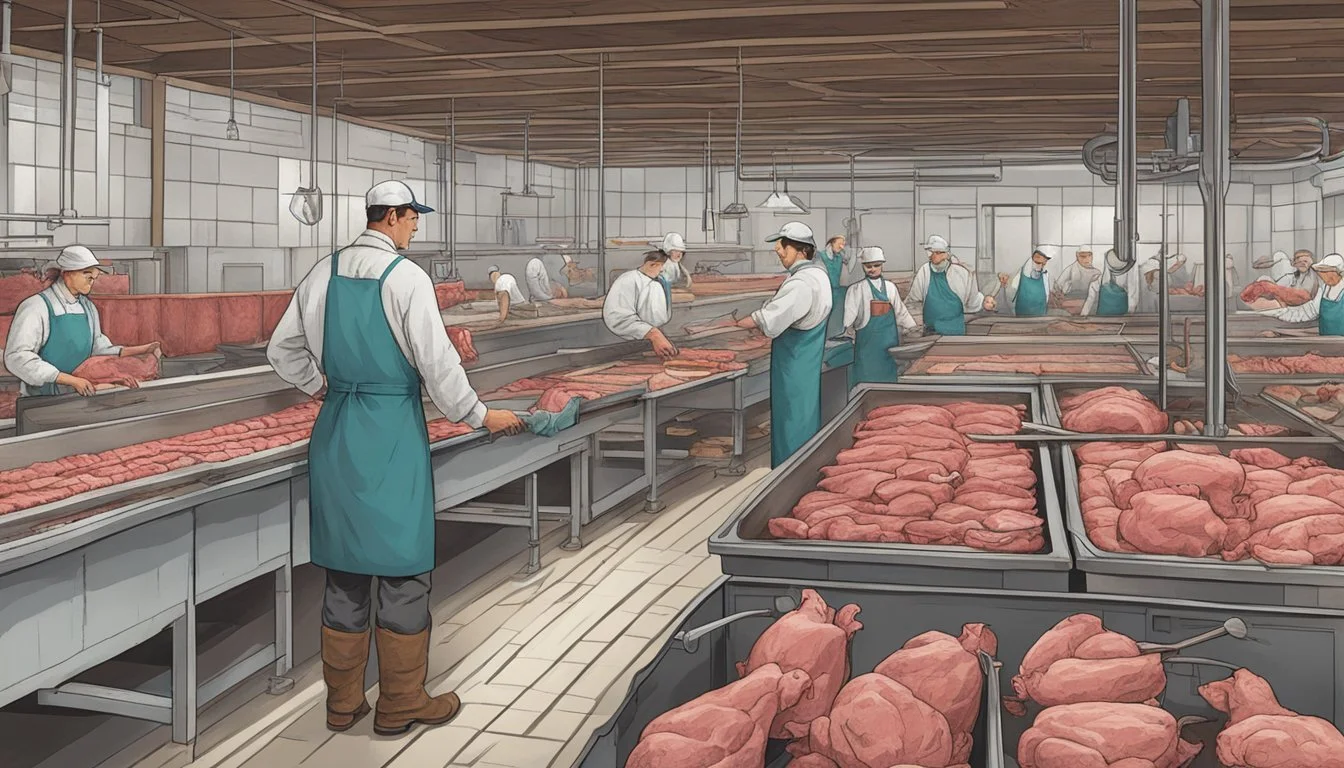

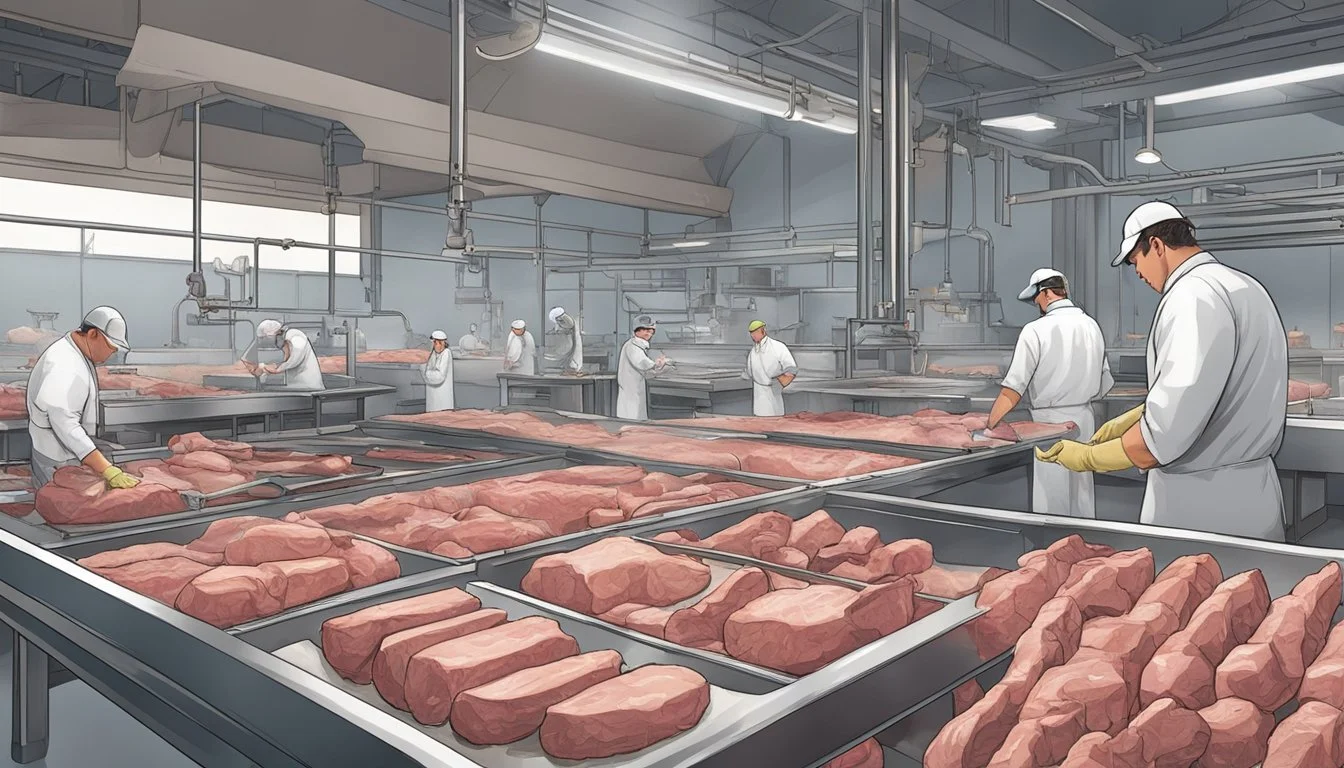

Quality Control and Meat Science

The quality of meat from on-farm butchering and slaughter in Iowa is paramount. This section addresses how meat quality is assessed and the importance of proper carcass handling during the processing phase to ensure high-quality end products.

Understanding Meat Quality Factors

Meat quality is influenced by a combination of factors starting from the farm to the processing facility. On-farm practices, including feed quality, stress management, and genetic selection, significantly impact the intrinsic qualities of the meat: tenderness, flavor, and juiciness. In Iowa, rigorously maintaining animal health and diet is central to achieving superior meat quality.

Carcass attributes also determine meat quality. They assess the appearance, texture, and color of the meat. The cut and wrap process must carefully consider these attributes as they directly affect the consumer's perception and market value.

Carcass Handling and Processing Techniques

Proper carcass handling is crucial for preserving meat quality. Post-slaughter, the carcass should be promptly and adequately cooled to reduce microbial growth and ensure a stable meat quality. Iowa's meat processors use refrigeration techniques that follow stringent guidelines to achieve this.

Processing techniques are scientific in nature and are designed to maximize meat quality and shelf-life. The methodology of segmenting carcasses into cuts must be meticulously carried out to avoid contamination and ensure uniformity. The role of meat science in this phase is instrumental, as experts employ systematic methods to analyze and enhance meat properties throughout the cut and wrap process.

By remaining vigilant on these protocols, meat producers in Iowa endeavor to ensure that the end product meets consumer expectations and safety standards.

Market Dynamics and Consumer Demand

In Iowa, the market for on-farm meat processing is significantly influenced by consumer preference for local products and the intricacies of distribution networks.

Exploring the Demand for Local Meat

The demand for local meat in Iowa has been on an upward trajectory, fueled by consumers' increasing interest in the provenance and quality of their food. They seek transparency in meat production and prioritize supporting the local economy. Local meat is synonymous with freshness and a reduced environmental impact due to shorter transportation distances. This burgeoning demand presents an opportunity for local farmers and butchers to develop niche markets and cater to consumers who are willing to pay a premium for these perceived benefits.

Marketing and Distribution Strategies

Effective marketing and distribution are crucial for on-farm meat processors to capitalize on the growing demand for local meat. Farmers and meat processors in Iowa employ several strategies to reach their consumer base:

Direct Sales: Selling meat directly to consumers through farmers' markets, community-supported agriculture (CSA), or on-farm stores.

Online Marketing: Utilizing social media and farm websites to engage with consumers, share the story of their farm, and market their meat products.

Local meat processors have to navigate a complex network of regulations and logistical challenges to distribute their products efficiently. Despite these hurdles, a well-developed distribution strategy can expand their reach to a variety of local and regional markets, thereby ensuring that they meet consumer demand effectively.

Species-Specific Considerations

Each species has its own set of requirements for processing, which are governed by their biological characteristics and the regulations in place. Here are essential considerations for various animal groups.

Beef and Cattle Processing

Beef cattle require large facilities with equipment capable of handling animals that often weigh over 1,000 pounds. In Iowa, humane handling and slaughter methods are paramount to ensure not only ethical treatment but also meat quality. Stress before and during slaughter can adversely affect the beef, leading to tougher meat. Equipment for beef processing typically includes a stun box, hoist, dehiding tools, and refrigeration units large enough for carcass chilling.

Poultry Slaughter Procedures

Poultry, consisting mostly of chickens, turkeys, and ducks, requires different handling due to their size and physiology. After immobilization, usually by electric stunning, a precise cut is made to the throat for bleeding out. Proper scalding and plucking are critical to ensure the removal of feathers while maintaining skin integrity. Small-scale processors in Iowa must also be aware of the Exemptions for Poultry Slaughter under federal law, which may apply to them.

Swine, Sheep, and Goat Processing

Swine, sheep, and goats, smaller than cattle but larger than poultry, entail their own set of processing considerations. They need facilities designed for medium-sized animals. Stunning methods often include electric prods or captive bolt pistols. Especially for swine, Iowa’s processors focus on proper scalding and dehairing to ensure a quality product. Traceability is important in sheep and goat processing to ensure the origin and quality of the meat.

Processing Game Animals (Deer, Elk, Bison)

Processing game animals such as deer, elk, and bison (What wine goes well with bison?) involves navigating additional regulations, as these meats are often processed during hunting season and under field conditions. Facilities must ensure that contamination risks are minimized, and meat is rapidly chilled to prevent spoilage. Specialized equipment like skinning gambrels and large cutting tables is crucial for handling the size and weight of these animals.

Conclusion

In Iowa, the intersection of on-farm meat processing and state regulations reflects a balance between entrepreneurial spirit and ensuring food safety. Producers embracing on-farm processing have confronted challenges head-on, adhering to regulations that safeguard public health while fostering robust local food systems.

Regulatory Landscape: The state mandates compliance with strict safety standards, which, although demanding, have not deterred the growth of on-farm processing. Facilities must navigate these requirements, which serve to maintain consumer trust in the safety and quality of local meats.

Benefits for Livestock Producers: By processing on-farm, Iowa's livestock producers can add value to their products, exercise greater control over meat quality, and potentially achieve a closer connection with consumers who value transparency in food production.

Economic Implications: While initial capital investment can be significant, the potential economic benefits of on-farm meat processing are worth noting. These ventures can lead to financial stability for farmers, especially in times of market volatility.

Environmental Consideration: Producers operating on-farm processing facilities often integrate sustainable practices, mindful of their environmental footprint and the stewardship of the land.

It is evident that on-farm meat processing in Iowa represents a vital component of the state’s agricultural identity. Through compliance with regulations, a focus on maintaining high standards of animal welfare, and an understanding of the market dynamics, these facilities play a pivotal role in the continuance of Iowa's rich farming heritage.