On-Farm Meat Processing, Butchering, and Slaughter in Wisconsin

Navigating Regulations and Best Practices

In Wisconsin, evolving consumer demands and a growing interest in locally sourced meat are driving a resurgence in on-farm meat processing. This trend is a response to processing bottlenecks that have become increasingly evident, where traditional meat processing facilities are overwhelmed, causing delays for farmers and consumers alike. On-farm processing offers farmers the flexibility to butcher their livestock on their premises, catering to direct-to-consumer sales and promoting a closer connection between farmers, their livestock, and the end consumers.

Mobile slaughtering units have emerged as a strategic solution to these processing challenges in the state. A particularly innovative approach has been witnessed with the introduction of Wisconsin's first USDA-inspected mobile slaughter facility. By bringing processing capabilities directly to the farm, these units allow for on-the-spot butchering, reducing the need for farmers to transport livestock to distant facilities and enabling a more efficient farm-to-table supply chain.

Such initiatives not only alleviate the strain on the state's meat processing infrastructure but also align with the growing consumer trend toward transparency and sustainability in the food system. The adaptability and lower overhead costs associated with mobile and on-farm slaughter may potentially reinvigorate the local meat industry in Wisconsin, granting farmers more control over their products and margins.

The State of On-Farm Meat Processing in Wisconsin

Wisconsin's on-farm meat processing sector, an integral component of the state's agriculture, faces challenges. Regulatory frameworks aim to maintain meat quality and food safety, while local farmers depend on these systems to sustain operations and meet consumer demand.

Overview of Local Meat Processing

In recent years, the demand for local meat processing in Wisconsin has surged, boosting engagement in on-farm meat processing activities. A handful of innovators in the meat business have launched Wisconsin's first mobile slaughtering unit, addressing the need for accessible meat processing services at the farm level. This approach simplifies the transportation of livestock and serves small to medium-sized farms that contribute to the local meat market.

Regulations Governing On-Farm Processing

Regulatory oversight in Wisconsin is rigorous, aiming to uphold the highest standards of meat quality and food safety. Any on-farm meat processing facility, whether fixed or mobile, must comply with rules set forth by the USDA and state authorities. These include:

Antemortem inspections: Livestock are examined before death to exclude any diseases or health conditions.

Postmortem inspections: Carcasses and animal parts are thoroughly inspected after death.

Drug residue compliance: Farms must ensure that carcasses are free of illegal drug residues, such as antibiotics.

State meat inspectors, trained in federal and state regulations, are responsible for overseeing these procedures to ensure adherence to the strict guidelines.

Importance of Meat Processing to Wisconsin Farmers

For many Wisconsin farmers, including dairy farm operators, on-farm meat processing offers important value-added opportunities. The ability to process livestock on-site or through mobile units is particularly significant amidst an increasingly congested meat processing system. This self-reliance not only aids in managing the supply chain but also in maintaining control over meat quality, directly affecting the livelihoods of farmers and the strength of the state's agricultural economy.

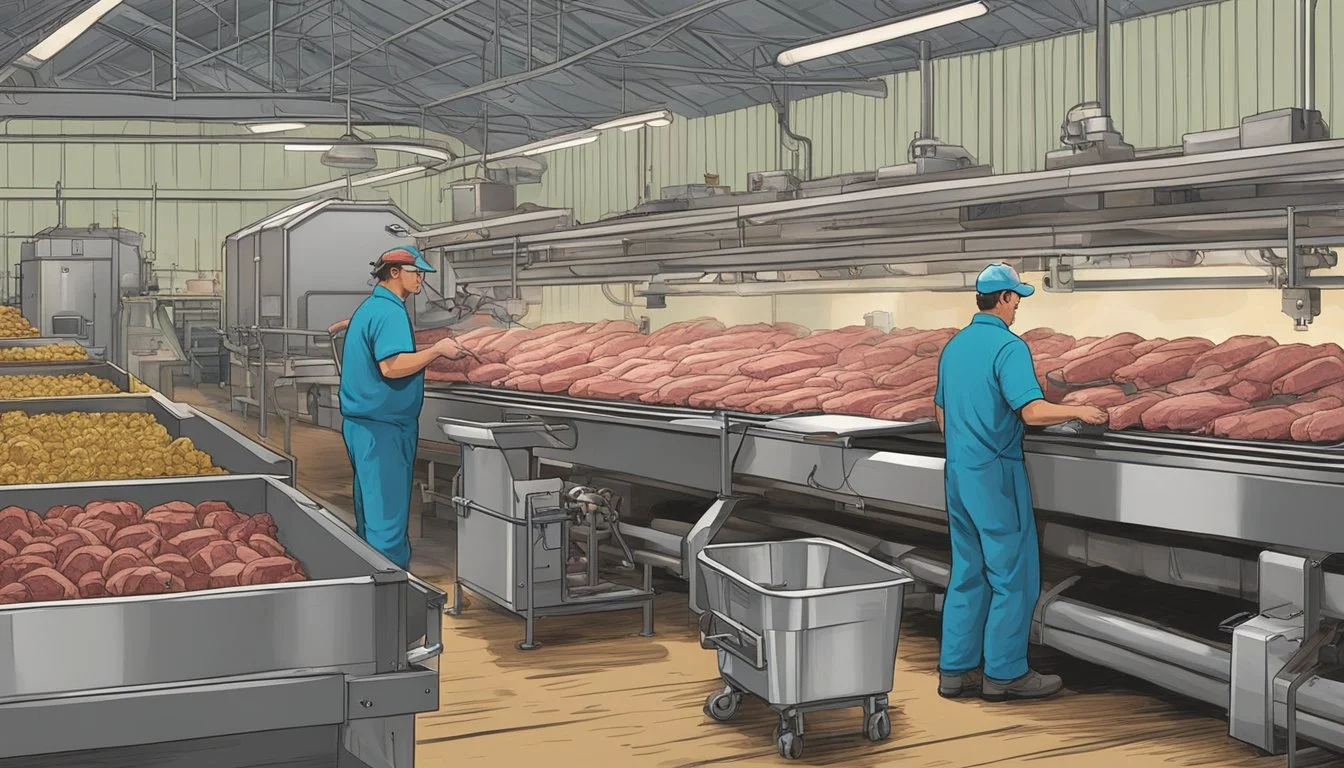

Butchering and Slaughtering Practices

Wisconsin's approach to meat processing leverages meticulous butchering techniques and humane slaughtering practices to ensure high-quality meat. Local farmers and producers focus on both animal welfare and end-product excellence.

Butchering Techniques for Quality Meat

Butchering involves more than mere dismantling of livestock; it's an art that impacts meat quality significantly. Wisconsin butchers apply specific cutting techniques to enhance the meat's tenderness and flavor. For beef and sheep, precise cuts along the muscle grain are crucial. Poultry producers also stress the importance of proper processing conditions to maintain meat integrity.

Cattle: Emphasis is given to aging the meat, which can lead to dramatically improved taste and texture.

Hogs: Butchers often cure the pork for additional flavor.

Sheep: Special care is taken to avoid damaging the meat during shearing and butchering.

Incorporating genetic selection, farmers raise livestock bred for specific meat qualities, allowing butchers to work with superior raw materials.

Slaughtering Livestock on Wisconsin Farms

On Wisconsin farms, slaughtering is carried out with the utmost regard for animal welfare, as stress can adversely affect meat quality. The process is typically conducted in a calm environment to ensure that livestock remains tranquil, particularly when handling cattle, sheep, and hogs.

Mobile Slaughtering Units: These facilities travel to farms, allowing animals to be processed in a familiar setting.

On-Farm Facilities: Some farms have their own setups, ensuring they can manage the slaughtering phase directly and maintain full control over the process.

By managing stress levels and using humane slaughtering techniques, Wisconsin farmers are able to produce high-quality, stress-free meat products.

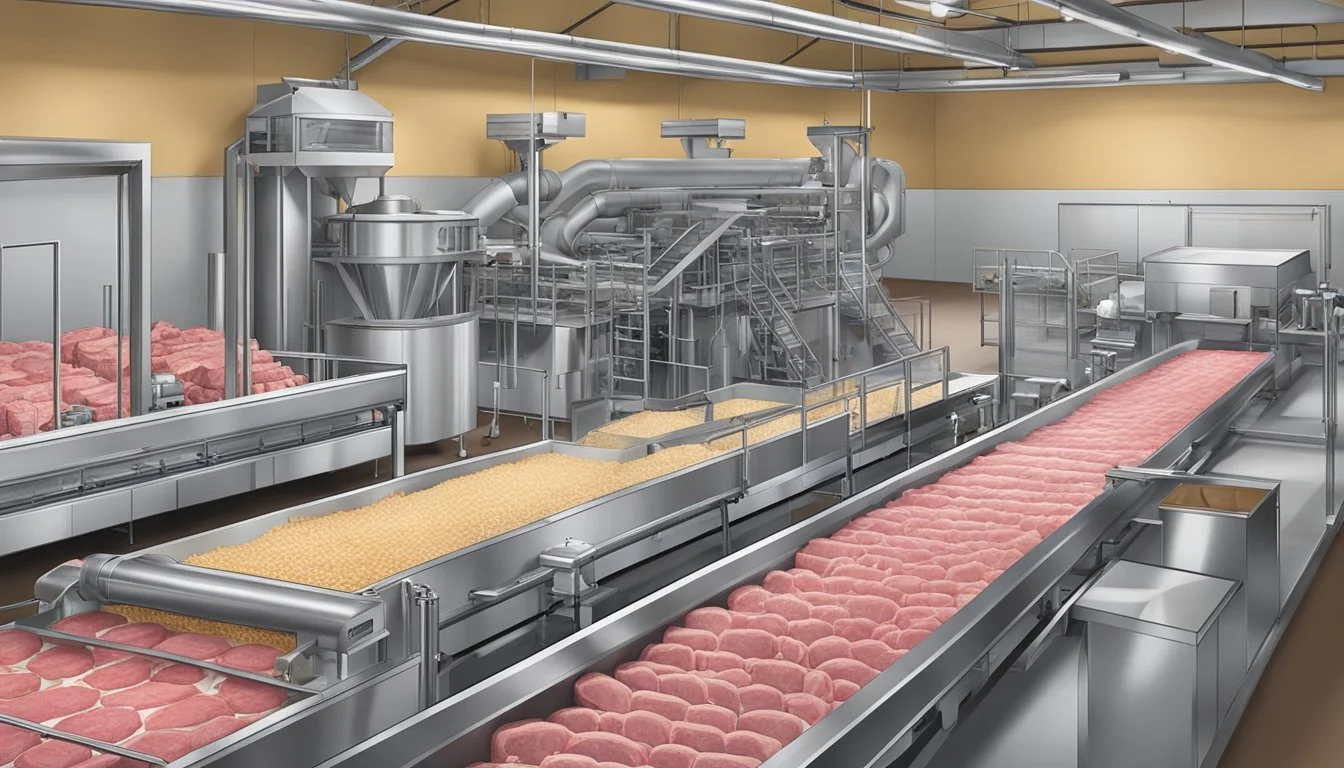

Mobile Slaughtering Units

In Wisconsin, farmers are utilizing mobile slaughtering units as an innovative approach to address meat processing bottlenecks, providing on-farm slaughter services that improve efficiency within the livestock industry.

Benefits of Mobile Slaughtering

Convenience: Farmers can have their livestock processed on-site, reducing the stress on animals caused by transportation and minimizing the risk of meat contamination.

Direct-to-Consumer Sales: These units allow farmers to streamline the process from pasture to plate, enhancing their ability to sell meat directly to consumers.

Regulatory Compliance: Mobile units are designed to meet state requirements. For instance, Natural Harvest’s mobile slaughtering unit in Wisconsin is equipped with essential tools and complies with state regulations.

Community Support: They offer a solution to the local meat processing backlog by increasing slaughter capacity, benefiting both farmers and consumers in the community.

Operation and Management of Mobile Units

Unit Composition: A typical mobile slaughter unit is housed in a large trailer, such as a 38-foot gooseneck, with necessary facilities like a generator, hot water heater, water pump, electric panels, cooler, winch, and rail system.

Slaughter Process: The mobile unit includes a designated slaughter area and an inspection table, ensuring that the slaughtering process is carried out in a clean and professional manner.

Health Inspection: Regular inspections by entities such as the Wisconsin Department of Agriculture, Trade and Consumer Protection ensure that mobile units maintain high standards of hygiene and safety.

Service Provision: Companies like Natural Harvest offer these services across the state, with their units fully operational and traveling to area farms, thus supporting on-farm butchering needs.

Local Farming Community and Economy

In Wisconsin, on-farm meat processing has emerged as a solution to the state's bottlenecked meat processing system. This local initiative offers a beacon of resiliency for farmers and the state's agricultural economy.

Impact on Local Farmers and Neighbors

On-farm meat processing allows farmers in Wisconsin greater control over the meat production process. Direct-to-consumer sales have become more feasible, creating stronger community ties between local farmers and their neighbors. These neighbors, as consumers, enjoy fresher products and contribute to sustaining smaller-scale farming operations. Such initiatives can relieve pressure on traditional processing facilities and streamline the path from farm to table, ensuring a steadier flow of products.

Contributions to Wisconsin's Agricultural Economy

Wisconsin's move toward on-farm processing represents a strategic investment in its agricultural sector. This shift is not only about sustaining farm operations; it's about invigorating the local economy. By keeping the processing local, farms contribute to job creation within the community and help circulate money within the local economy. For the state, these efforts enhance the overall stability and resilience of Wisconsin's agricultural sector, helping it to remain competitive and versatile in meeting demands.

Addressing Processing Bottlenecks

In the state of Wisconsin, farmers have confronted significant meat processing bottlenecks, prompting innovative solutions to streamline on-farm butchering and slaughter, particularly during the rise in demand caused by events like the COVID-19 pandemic.

Challenges Faced by Wisconsin Farmers

Farmers in Wisconsin have historically been reliant on a limited number of meat processing facilities. The capacity of these facilities often falls short of demand, particularly as disruptions like COVID-19 put additional stress on the food supply chain. Prem Meats, a company based in Spring Green, understands that such bottlenecks can delay the transition from farm to market, impacting both farmer revenues and consumer access to local meat products. Mitigating liability issues associated with on-farm processing and navigating the complex web of regulations also present significant hurdles for farmers looking to process meat on their own properties.

Options for Expanding Processing Capacity

To enhance processing capacity, some innovative solutions have emerged in Wisconsin. Mobile slaughtering units, for example, provide farmers with the flexibility to process livestock directly on the farm, reducing transportation costs and streamlining the supply chain. Wisconsin's first mobile slaughtering unit, which comes to farms and processes livestock to the point of hanging the carcass on a rail in a cooler, is an example of how local businesses are attempting to close the gap. These units are subject to USDA inspection and certification, ensuring that they meet the necessary safety standards.

Farmers have also looked into forming cooperatives to address the meat processing bottleneck. By pooling resources, they can invest in shared processing facilities that increase overall capacity, mitigate individual risks, and maintain compliance with regulations. Collaborative efforts also benefit small-scale operations that may not have the bandwidth to support their own processing infrastructures.

In summary, to directly address the meat processing constraints in Wisconsin, farmers and businesses are working together to develop localized and cooperative processing solutions. These measures aim to make meat processing more accessible, efficient, and tailored to the needs of the local agriculture community.

Case Studies and Real-World Examples

In Wisconsin, on-farm meat processing presents unique success stories and innovations in the face of industry-wide challenges. This section examines specific cases that illustrate the effective strategies and methods used by local farms and businesses to overcome processing bottlenecks and meet the demand for meat products.

Prem Meats: A Wisconsin Success Story

Prem Meats has established itself as a critical player in Wisconsin's meat processing landscape. Their approach to farm-to-table production has allowed them to cater to the needs of both the local community and the broader market. By maintaining control over the entire process, from butchering to retail, Prem Meats ensures a quality product that reflects the care and expertise of Marty Prem and his team.

Services provided: Custom processing of beef, pork, and other meats

Addressed challenges: Local supply chain efficiency, quality control

Community impact: Strengthened local farms by enabling them to process and sell their livestock directly to consumers and retailers

Natural Harvest, LLC and On-Farm Innovation

Natural Harvest, LLC takes on-farm processing a step further with innovative practices that emphasize sustainability and animal welfare. They prioritize a model that reduces transportation stress on livestock, thus maintaining the integrity and quality of the meat.

Innovation focus: On-farm harvesting units, reducing liability and stress on animals

Production impact: Increased capacity for handling livestock with a commitment to ethical production practices, and innovative processing solutions that potentially inspire others in the country to follow suit

By embracing change and prioritizing both efficiency and quality, these case studies demonstrate the possibilities and benefits of local meat processing solutions in Wisconsin's agricultural sector.

Legal Considerations and Liability

When operating or using meat processing facilities in Wisconsin, one must navigate a complex set of regulations to stay within legal bounds. Proper adherence to inspection protocols and understanding the landscape of liability are crucial for both farmer and processor.

State-Inspected vs. USDA-Inspected Facilities

State-inspected facilities in Wisconsin are subject to the Wisconsin Meat Establishment Inspection Program, which maintains standards comparable to the United States Department of Agriculture (USDA). However, meat products processed in state-inspected plants may only be sold within the state. In contrast, facilities inspected by the USDA under the Federal Meat Inspection Act can sell meat across state lines, adhering to rigorous food safety protocols.

State-Inspected: Can sell processed meat only within Wisconsin.

USDA-Inspected: Can sell processed meat interstate.

Understanding Liability for Farmers and Processors

Liability for farmers and processors centers around compliance with health and safety standards. Processors may be liable if they fail to maintain sanitary conditions or if their actions result in the contamination of meat products. Farmers engaging in natural harvest methods or on-farm butchering must be aware that without proper inspection, meat from such animals cannot be sold and is strictly for personal consumption.

Farmers: Must use inspected facilities for meat intended for sale; on-farm slaughtered meat is for personal consumption only.

Processors: Held to rigorous safety standards; non-compliance can lead to legal repercussions.

Meat processing and slaughtering carry inherent risks, and Wisconsin laws aim to mitigate these through stringent regulations. It is imperative for all parties involved to understand their responsibilities within the country's legal framework to ensure food safety and reduce liability.

Future Trends in Meat Processing

The landscape of meat processing in Wisconsin is evolving with a focus on technology and sustainability. These advances cater to both increasing demand and regulatory frameworks intent on maintaining safety and efficiency within the industry.

Technological Advancements in Slaughtering

Mobile Slaughtering Units: In Wisconsin, mobile slaughtering units have emerged as a solution to the processing bottleneck, enabling smaller scale farmers to process livestock on-site. These units are equipped with essential features such as a rail system for hanging carcasses and hot water supply, necessary for proper sanitary practices. State regulations oversee their operation to ensure compliance with food safety standards.

Automation and Data Analysis: Technological integration into the processing sector is becoming more prevalent. The introduction of automated cutting lines and data analysis software helps in streamlining operations and minimizing human error. These innovations contribute to enhancing the speed and precision of the processing task.

Sustainable Practices and Genetic Selection

Environmental Stewardship: Meat processing entities in the state are increasingly adopting sustainable practices. This includes waste reduction strategies and the implementation of renewable energy sources such as solar or biogas to power facilities. Reducing environmental footprints has become a priority alongside the efficiency of operations.

Genetic Selection: Sustainable meat production is further supported by advances in genetic selection. Livestock producers are concentrating on breeding animals with traits that enhance growth efficiency and meat quality. This not only improves the end product but also aligns with the consumers’ demand for more ethically produced meat.

These trends indicate significant progress in the meat processing industry, reflecting adaptability and a progressive mindset among Wisconsin's producers and processors.