On-Farm Meat Processing, Butchering, and Slaughter in West Virginia

A Comprehensive Guide

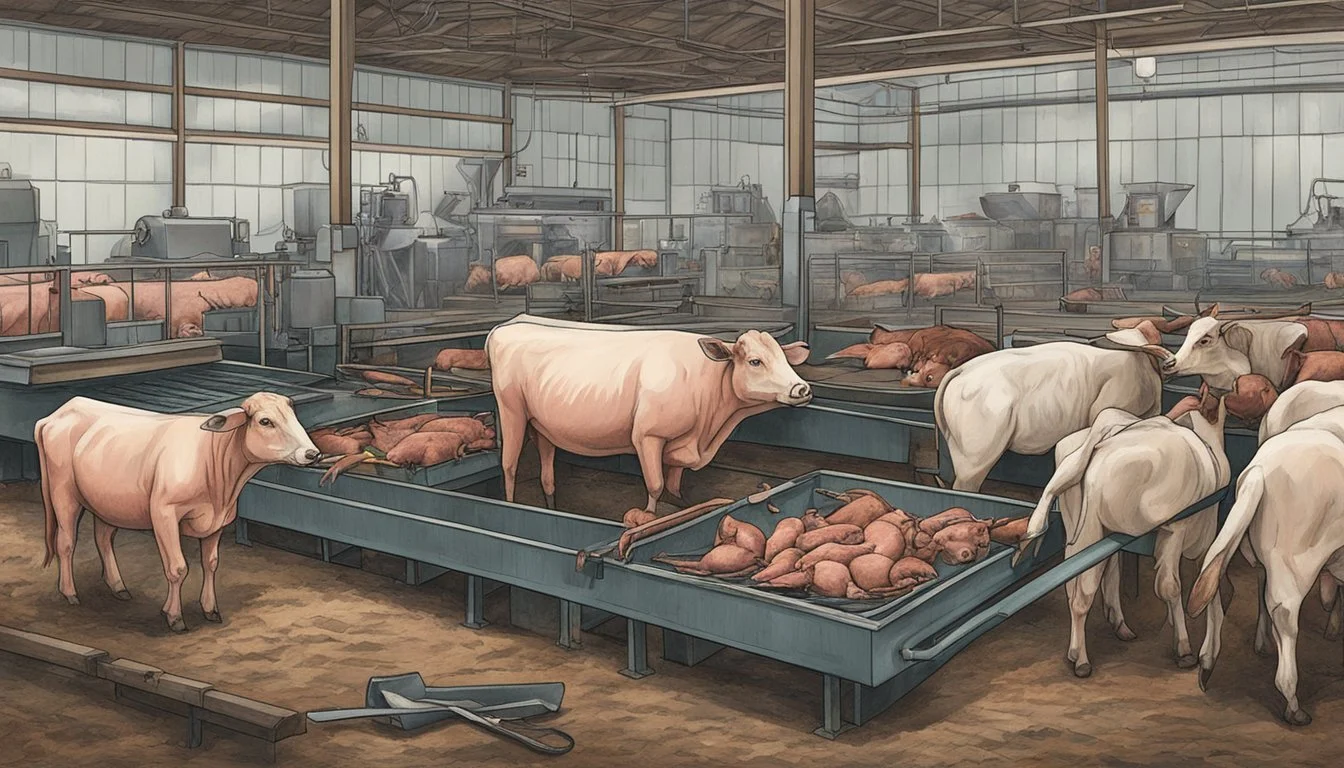

On-farm meat processing, butchering, and slaughter practices are pivotal aspects of the agricultural industry in West Virginia. These operations are integral for local farmers, offering a means to bring their livestock to market and provide consumers with fresh, locally-sourced meats. West Virginia has establishments like Lost River Butcher Block, where one can purchase quality cuts of meat as well as obtain custom meat processing to get the precise cuts desired. The state's commitment to agricultural practices is evident in the presence of full-service USDA inspected facilities such as Appalachian Abattoir, which is notable for being the first of its kind to offer both USDA inspection and grading in West Virginia.

The emergence of mobile meat processing units has introduced a new dimension of convenience and animal welfare, by allowing the processing facilities to come directly to the farm. These custom-exempt mobile processing units serve remote locations in West Virginia, among other states, thus facilitating a stress-free and humane experience for the animals. They prioritize animal welfare, environmental stewardship, and fair dealings with clientele, aligning with contemporary expectations of ethical practices in meat production.

Regulatory oversight ensures the hygiene and safety of meat products processed in the state. The West Virginia Department of Agriculture outlines the various licenses and registrations required for businesses or individuals involved in the meat and poultry supply chain. This system guarantees that all entities, from commercial slaughterhouses to meat distributors, operate within established food safety standards, thereby maintaining the integrity of West Virginia's meat processing industry.

Regulatory Landscape for Meat Processing in West Virginia

In West Virginia, meat processing is strictly regulated to ensure the safety and quality of products for consumers. The state operates under robust systems to oversee operations, including both state and federal levels of inspection.

State vs. Federal Inspection

State-inspected facilities in West Virginia are subject to the regulations enforced by the West Virginia Department of Agriculture (WVDA). These state regulations are designed to be "at least equal to" those enforced by the United States Department of Agriculture (USDA). Meat and poultry products can be sold within the state when processed under state inspection. State-inspected facilities are mandated to follow stringent guidelines that focus on food safety and sanitation to prevent foodborne illnesses.

On the other hand, facilities that opt for federal inspection by the USDA are able to sell their meat across state lines. USDA-inspected plants adhere to the Federal Meat Inspection Act and the Poultry Products Inspection Act, which are comprehensive in addressing safety concerns. These regulations ensure that products meet national standards for safety, wholesomeness, and labelling.

Mobile Slaughter Compliance

Mobile slaughter units provide a flexible option for farmers who wish to process their meat on-site. They must comply with both state and federal regulations, which include the proper handling of livestock and carcasses to prevent contamination and ensuring that all waste by-products are disposed of in accordance with environmental regulations. The state of West Virginia encourages the use of mobile slaughter facilities by offering resources for compliance. Mobile units are required to possess the necessary licenses and must follow strict protocols outlined by the WVDA for safe and sanitary operations, similar to permanent facilities.

The WVDA Meat and Poultry Inspection Division monitors meat processing and distribution facilities, ensuring that the consumers receive safe, wholesome, and unadulterated products. This division frequently inspects meat processing facilities for compliance with health and sanitation standards, as well as the structural suitability of the facilities for hygienic meat processing and storage.

Compliance with these regulations is critical for meat processors in West Virginia, as it not only ensures the safety of the products but also supports consumer confidence in domestically produced meats.

The Economic Impact of Local Meat Processing

The economic viability of local meat processing in West Virginia hinges on the careful consideration of the costs associated with on-farm processing and the identification of market opportunities and challenges that farmers face.

Cost Analysis of On-Farm Processing

Investment in Equipment: Farmers incur significant upfront costs for purchasing equipment essential for on-farm processing, such as slaughtering tools, cooling units, and packaging machinery. An example breakdown might include $5,000 for a basic slaughtering kit, $2,000-$10,000 for a walk-in cooler, and additional costs for sanitation and waste disposal systems.

Operational Costs: On-going expenses involve labor, which can vary widely based on the scale of operations, utility costs for running the processing equipment, and expenses for maintaining compliance with safety regulations.

Breakeven Analysis: Farmers must calculate the number of livestock units required to process to cover their costs and identify the price point that makes their business sustainable in the long term. This involves balancing the costs of feed, livestock care, processing, and marketing to ensure profitability.

Market Opportunities and Challenges

Access to Local Markets: Farmers can capitalize on the growing consumer demand for locally-sourced meats. Direct-to-consumer sales offer a premium price point, while local restaurants and farmers' markets present additional avenues for revenue.

Regulatory Requirements: They must navigate federal, state, and local regulations, which can be complex and costly. Compliance with the USDA or state inspection standards ensures product safety but also adds to the cost of processing meat on-farm.

Competition and Pricing: The meat market is competitive, with large-scale operations benefiting from economies of scale. Local farmers must find the right balance between competitive pricing and the higher costs of smaller-scale operations to maintain a share in the marketplace.

Supply and Demand Dynamics: They need to understand the local demand for various types of meat and adjust production accordingly. Overproduction can lead to surplus and waste, while underproduction may miss potential sales and reduce financial performance.

Infrastructure Requirements for On-Farm Processing

On-farm meat processing in West Virginia requires appropriate infrastructure to maintain compliance with regulations and ensure food safety, whether through mobile or stationary setups. Both mobile slaughtering units and stationary facilities have specific equipment and facility requirements that must be met.

Mobile Slaughtering Units

Mobile slaughtering units are an adaptable option for on-farm processing, designed to be transported to different locations. In West Virginia, these units must comply with federal and state meat processing regulations to operate legally. Infrastructure-wise, a typical mobile slaughter unit is a self-contained trailer that includes:

Slaughtering Area: Equipped with hoists, and restraining equipment.

Processing Area: Contains stainless steel tables, cutting instruments, and packaging supplies.

Waste Disposal System: Must be designed to handle by-products and waste material responsibly.

Refrigeration: Adequate cooling systems to store meat at required temperatures.

Hot Water Supply: Critical for sanitation, a mobile unit must have on-demand access to hot water for cleaning equipment and facilities.

These trailers have to be properly designed to handle the entire slaughtering process including bleeding, skinning, evisceration, and carcass splitting. Meeting USDA requirements for on-site inspections is mandatory for these units to operate.

Stationary Facilities and Equipment

Stationary on-farm meat processing plants in West Virginia are fixed facilities where meat is processed in a single location. Key infrastructure and equipment components include:

Slaughtering Hall: This area should feature non-porous, easy-to-clean surfaces, with proper ventilation and drainage.

Cooling and Freezing Equipment: Walk-in refrigerators and freezers to store carcasses during processing and prior to sale or further processing.

Processing Equipment: Saw, knives, grinders, and other cutting equipment necessary for butchering.

Packaging Area: With vacuum packers and other packaging tools for preparing meat for sale.

Inspection Office: For use by federal or state inspectors as required.

Water Supply: Hot and cold water sources are vital for cleaning and sanitation purposes.

Waste Treatment: Proper disposal systems or arrangements to handle solid and liquid waste in accordance with environmental standards.

It's necessary for stationary facilities to ensure that their infrastructure supports the humane handling of animals, proper meat processing, and adherence to food safety standards.

Animal Welfare and Stress Management

In West Virginia, on-farm meat processing requires strict adherence to animal welfare and stress management to ensure both ethical treatment of livestock and the production of high-quality meat.

Best Practices for Humane Slaughter

Effective practices for humane slaughter prioritize the minimization of pain and stress for animals. West Virginia's regulations underscore rapid stunning methods that render the animal unconscious instantly, without causing undue distress. Proper training for handlers in low-stress handling techniques is also vital. These practices include:

Pre-slaughter handling: Animals should be moved calmly and without force. Handlers must use gentle guidance and avoid loud noises to prevent panic and stress.

Stunning procedures: Facilities must be equipped with appropriate stunning devices that are regularly inspected and maintained. Each animal must be checked post-stunning to ensure it is unconscious.

Adhering to these standards is imperative to maintain both animal welfare and compliance with local legislation.

Stress Impact on Meat Quality

Stress has a direct correlation to meat quality, with stressed animals producing meat that can be tougher and have a shorter shelf life. Stress in animals can lead to conditions like pale, soft, and exudative (PSE) meat, characterized by a pale color and reduced water-holding capacity, or dark, firm, and dry (DFD) meat, which is darker and drier than normal. Strategies for stress reduction include:

Transport: Livestock should be transported safely with adequate space to avoid physical stress and injury.

Holding pens: Holding areas should provide sufficient space and access to water to reduce stress before slaughtering.

Slaughter timing: Efficient scheduling is critical to prevent prolonged waiting times, which can escalate stress levels.

By managing stress effectively, the meat processing industry can significantly enhance meat quality and support animal welfare.

On-Farm Slaughter and Butchering Techniques

In West Virginia, on-farm meat processing represents a blend of time-honored traditions and modern innovations, each adhering to stringent standards to ensure quality and safety in meat science.

Traditional Butchering Methods

Traditional butchering starts with the humane slaughter of the animal, typically employing methods that farmers have used for generations. The process involves:

Stunning: Ensuring that the animal is rendered insensible to pain before slaughter.

Exsanguination: The precise cutting of blood vessels, commonly known as bleeding out, to ensure the animal's blood is drained.

Once the animal is slaughtered, butchering commences in methodical steps:

Skinning: Careful removal of the hide without contaminating the carcass.

Evisceration: Removal of internal organs, sorted for either consumption or disposal.

Carcass Splitting: Using tools such as a meat saw, the carcass is divided, typically down the spine.

Farmers exercise a deep understanding of meat processing, breaking down the carcass into primal cuts and eventually into retail cuts, all while maintaining the integrity and cleanliness of the meat.

Innovative Approaches to Meat Processing

With advancements in meat science and technology, farmers in West Virginia are increasingly adopting innovative approaches:

Mobile Slaughter Units: These facilities bring USDA-compliant processing directly to the farm, reducing stress on animals and enabling efficient processing.

On-Site Cooling Facilities: Immediate post-slaughter chilling is vital to prevent spoilage and maintain meat quality. On-farm cooling facilities are integral in controlling the temperature from the moment of harvest.

Farmers frequently update their processing techniques to enhance product quality and safety while also adhering to regulatory standards that govern on-farm slaughter and butchering. These methods ensure a natural harvest, respecting the animal and providing high-quality meat.

Food Safety and Public Health Considerations

Ensuring the safety of meat processed on farms in West Virginia involves stringent attention to preventing contamination and the presence of dedicated oversight. These practices are vital to safeguard public health.

Preventing Contamination and Illness

On-farm meat processing requires strict protocols to prevent bacterial contamination and subsequent illness. These protocols include:

Cleanliness: Workers must frequently wash their hands and keep all surfaces clean to inhibit the spread of bacteria.

Separation: Raw meat should be kept separate from other foods to avoid cross-contamination.

Cooking: Meat must reach the safe minimum internal temperature of 165 °F to ensure it's free from harmful pathogens.

Chilling: Promptly chilling meat after butchering and during storage minimizes bacterial growth.

Producers should implement a farm-to-table approach, controlling food safety at each production stage to minimize risks.

Inspectors and Oversight

The U.S. Department of Agriculture's (USDA) Food Safety and Inspection Service (FSIS) plays a critical role in overseeing meat slaughter and processing:

Inspections: FSIS inspectors are responsible for the enforcement of the Federal Meat Inspection Act and other pertinent regulations to ensure meat is safe for consumption.

Guidance: FSIS provides guidelines for producers to manage risks associated with Escherichia coli 0157 and other contaminants.

Without this oversight, the risk of foodborne illness escalates, highlighting the importance of inspector presence in farm meat processing operations.

The Role of On-Farm Processing in Local Communities

On-farm processing facilities play a crucial role in bolstering the autonomy of local food systems and empowering West Virginia’s agricultural sectors.

Supporting Local Farmers and Ranchers

On-farm processing supports local farmers and ranchers by enabling them to maintain control over the entire lifecycle of their products—from raising livestock to processing and selling the meat. This localized approach to slaughter and butchering allows them to:

Increase Profit Margins: By processing on-site, farmers can reduce transportation costs and fees paid to third-party processors.

Enhance Product Quality: Farmers are directly involved in the processing, ensuring high-quality standards and humane practices.

These advantages help fortify the economic resilience of West Virginia’s smaller-scale farmers in a fluctuating market, thereby reinforcing the agricultural backbone of both the community and the country.

Educational Outreach and Community Engagement

On-farm slaughter facilities can serve as pivotal community resources for educational outreach and engagement. These farms provide a transparent view of their operations which:

Fosters Knowledge Sharing: Neighbors and consumers can learn about humane livestock practices and the butchering process, cultivating a knowledgeable community.

Strengthens Community Ties: Engaging local communities through farm visits, workshops, and partnerships with local schools and institutions, on-farm processors solidify the relationships between producers and consumers.

This empowerment through education helps to build trust and understanding between the agricultural and non-farming residents of West Virginia.

Environmental Considerations of On-Farm Processing

On-farm meat processing in West Virginia carries significant environmental implications, particularly concerning the reduction of carbon emissions and the implementation of sustainable farming practices.

Reducing Carbon Footprint through Local Processing

Local processing of meat on farms in West Virginia has the potential to lower overall carbon emissions. By decreasing the distance animals travel from farm to processing, on-farm slaughter can significantly cut transportation-related emissions. Transportation is a key factor in the agricultural sector's carbon footprint, and by limiting this travel, farmers can contribute to a more environmentally friendly meat production process. This local processing approach supports the idea of sustainability by reducing fuel consumption and exhaust fumes associated with long-distance travel.

Sustainable Farm Practices and Animal Rearing

Farms engaged in on-farm processing often adopt more sustainable farm practices across the board, including animal rearing. Utilizing grass-fed systems, for instance, is a method that can enhance soil health and biodiversity, contributing to a more sustainable ecosystem. Grass-feeding livestock, as opposed to relying on feed sourced from monocultures, can also reduce the environmental impact of meat production.

Sustainable genetic selection further plays a role in environmental stewardship. Farmers can opt for breeds that are well-adapted to local conditions, which may require fewer resources and have a lower overall environmental impact compared to breeds that aren't as well-suited to the local climate and forage. Through careful management and choice of breeds, farmers are able to promote a more sustainable cycle of meat production that is better for the environment.

Case Studies and Best Practice Examples

This section focuses on two case studies that exemplify successful on-farm meat processing operations. It offers insight into the operational models and contributions these entities make to the industry.

Island Grown Farmers Cooperative in Washington

The Island Grown Farmers Cooperative (IGFC) provides an illustrative example of a farmer-driven solution to meat processing challenges. Farmers in Washington State established IGFC to address the scarcity of local meat processing facilities. The cooperative model has been imperative in streamlining the process from farm to market, ensuring that members have access to USDA-inspected processing services. This initiative has strengthened the local meat supply chain and serves as a credible model for small-scale producers in West Virginia looking to develop on-farm or community-supported processing facilities.

Niche Meat Processor Assistance Networks

The Niche Meat Processor Assistance Network (NMPAN) is a national network that supports processors and producers who contribute to local and regional meat production. Case studies from NMPAN demonstrate actionable strategies for establishing and maintaining economically viable niche meat processing operations. A prime example provided is the NMPAN's comprehensive guide on best practices for small processors, which includes topics such as facility design, regulatory compliance, and business planning. Their resources are tailored to assist new and existing processors to overcome the hurdles of niche meat processing while adhering to safety and quality standards.

Looking to the Future of On-Farm Processing

The future of on-farm processing in West Virginia is set to embrace technological innovations and policy reforms that aim to address current meat processing bottlenecks and aim for a more self-sufficient agricultural sector.

Technological Innovation in Meat Processing

Technological advances are key to enhancing on-farm meat processing capabilities. Mobile slaughter units stand out as a promising solution, offering farmers the flexibility to process livestock directly on the farm, reducing transportation stress for animals and potentially trimming the costs linked to centralized slaughtering facilities. These units could incorporate smart technology to streamline operations and ensure compliance with health regulations.

The integration of data analytics into on-farm processing could also lead to more efficient supply chain management. Detailed tracking of meat products from farm to table not only boosts consumer confidence but also enhances the ability of farmers to manage inventory and predict market trends.

Policy Implications and Potential Reforms

Legislation and policy play significant roles in shaping the trajectory of on-farm processing. Recent moves by the US Department of Agriculture (USDA) indicate an increased willingness to support the industry. Initiatives that provide funding for meat and poultry processors to expand operations and increase competition are already underway. Farmers in West Virginia may benefit from these programs by securing grants designed to enhance local meat processing infrastructure.

Policy reforms could further serve to reduce barriers for small-scale producers. A potential shift towards more tailored regulations that recognize the unique needs of on-farm processing operations may emerge. This would involve balancing food safety with the reality of small-scale operations, enabling them to compete more effectively in the marketplace.