On-Farm Meat Processing, Butchering, and Slaughter in Washington

Regulatory Insights and Best Practices

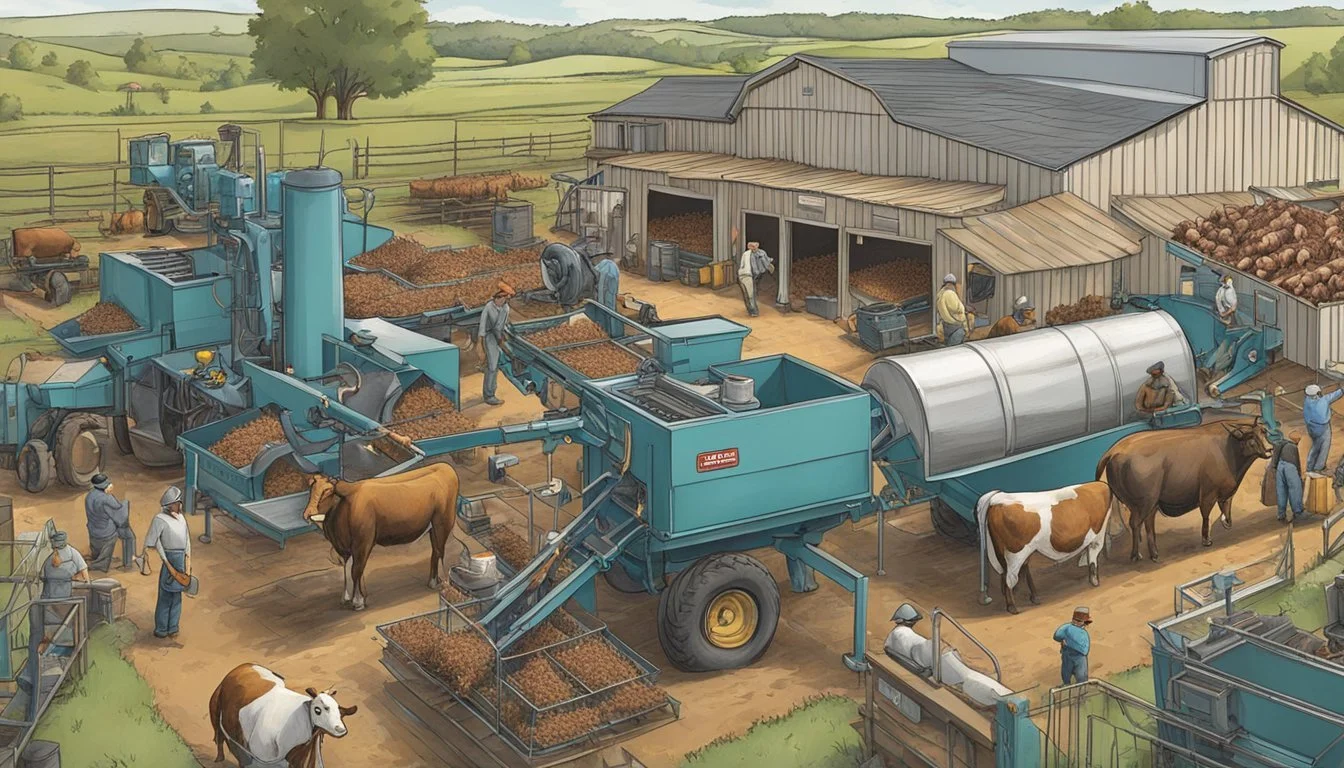

On-farm meat processing in Washington State offers a unique connection between livestock producers and the local community, fostering a farm-to-table approach. By allowing the slaughtering and butchering to occur on the premises where animals are raised, this practice provides farmers with greater control over the entire process from raising livestock to selling meat products. It ensures that the meat is freshly processed, adhering to personalized standards of quality and animal welfare.

Washington State supports this localized approach to meat production through various licensed facilities and services, including custom slaughter establishments. In accordance with state regulations, these facilities handle the slaughter of meat food animals exclusively for the owner's personal, household, guest, and employee use. Moreover, they play a crucial role in maintaining the state’s agricultural heritage and in offering consumers transparency regarding the origins and handling of their meat.

Mobile slaughter units are a key component in Washington's on-farm processing sector. By traveling directly to farms, these units provide a service that reduces animal stress, as they are processed in their familiar environments. The services typically extend beyond slaughter, including custom cutting and wrapping, ensuring that the meat is conveniently prepared for consumption or sale aligned with customer specifications.

Overview of On-Farm Meat Processing in Washington

In Washington, on-farm meat processing is a critical component of the state’s agricultural framework, closely tied to its history and local economy.

Historical Context and Recent Trends

Washington State has a storied history with regard to on-farm meat processing, where farms historically butchered their livestock to meet local demand. With the advent of large-scale industrial processing facilities, traditional on-farm processing saw a decline. However, recent trends point toward a resurgence in this practice due to the increasing demand for local, sustainably sourced meats. Farms are responding by developing on-site slaughtering and butchering capabilities to serve a market that values transparency and local provenance.

Significance for Local Agriculture and Economy

On-farm meat processing is significant for Washington's agriculture, providing local farmers with the autonomy to directly supply consumers and contributing positively to the state’s economy. Local butchering and slaughtering enable small-scale livestock operations, including beef, hog, poultry, and sheep ranches, to thrive by reducing reliance on centralized processing plants. As a result, on-farm meat processing bolsters the resilience of Washington's farming communities, sustains local economies, and meets consumer demand for farm-to-table meat options.

Regulatory Environment and Compliance

The regulatory landscape for on-farm meat processing in Washington is guided by a complex interplay of state and federal rules that require strict compliance to ensure food safety and maintain public trust.

State and Federal Regulations

In Washington, local slaughterhouses and processing facilities engaged in on-farm meat processing must navigate both state and federal regulations. The state provides its own set of guidelines that operate alongside national mandates. The Federal Meat Inspection Act sets the baseline, requiring that all meat processing facilities adhere to stringent standards. On the local level, Washington's own requirements may mirror or sometimes even exceed federal regulations, especially when it comes to the handling and processing of organic meats.

Federal rules mandate that any facility engaged in interstate commerce must have continuous USDA inspection. This ensures a consistent approach to food safety across all states. For facilities operating within state boundaries and executing a smaller scale of processing, state-level inspections are conducted, which must also align with federal standards, although they may differ in some procedural aspects.

USDA Inspection and Certification

It is the responsibility of the USDA's Food Safety and Inspection Service (FSIS) to inspect and certify meat processing and slaughtering facilities. Without this certification, the facility cannot legally operate. USDA inspectors are tasked with overseeing the entire process within slaughterhouses and processing facilities, ensuring that each stage of meat processing adheres to the prescribed food safety protocols:

Ante-mortem inspections are conducted before slaughter.

Post-mortem inspections follow immediately after slaughter.

Processing procedures are examined to ensure they comply with health and sanitary regulations.

Facilities exempt from continuous inspection, specifically those described as "custom exempt," are for personal use by the owner, their household, guests, or employees and are not for sale to the public. This exemption does not exempt operators from maintaining safe practices but does allow for less frequent USDA inspection.

Every meat processing and slaughtering facility in Washington is required to have a plan for sanitary operation, including facilities certified to process organic meats. These plants must also comply with additional organic certification regulations, which include the avoidance of synthetic chemicals and adherence to animal welfare standards.

Setting Up an On-Farm Processing Facility

Setting up an on-farm processing facility in Washington requires meticulous planning and a clear understanding of both the physical infrastructure and financial investment necessary to ensure compliance and efficiency in meat processing operations.

Infrastructure Requirements

In Washington, a farmer interested in on-farm processing must consider the essential infrastructure for slaughtering and butchering animals. At a minimum, they need a processing unit with stainless steel equipment to meet sanitary standards. Adequate slaughter facilities, a refrigeration system, waste disposal mechanisms, and a clean water supply are also critical. The stationary facility or Mobile Poultry Processing Unit (MPPU) should be designed for easy cleaning and disinfection, with smooth, impervious surfaces.

Sanitary Requirements:

Stainless steel equipment for contact surfaces

Smooth and cleanable walls and floors

Proper drainage systems

Processing Area:

Adequate space for slaughtering, eviscerating, and packaging

Separate zones for different stages to prevent cross-contamination

Utilities:

Constant supply of potable water

Reliable electricity for refrigeration and equipment

Waste disposal systems in compliance with environmental regulations

Investment and Costs

Investors must account for the capital necessary to establish and maintain a facility that adheres to regulatory standards for an on-farm processing unit. The upfront costs include construction, procurement of equipment, and obtaining required certifications. The ongoing expenses will encompass labor, utilities, maintenance, and possible upgrades. Farmers typically face the following expenditures:

Initial Costs:

Construction or modification of facilities: $20,000 - $100,000+

Processing equipment and tools

Operational Costs:

Staff salaries: highly dependent on size and scale of operations

Utilities (water, electricity, refrigeration, etc.)

Maintenance and sanitation supplies

Operational Challenges

The operation of an on-farm processing facility involves navigating various challenges such as regulatory compliance, workforce training, and efficient process management. Farmers must develop a Hazard Analysis Critical Control Point (HACCP) plan and pass inspections. They must also overcome hurdles such as finding skilled labor and managing the variability in demand and supply. Here are some challenges operators may face:

Regulatory Compliance:

Meeting federal and state meat processing regulations

Obtaining and maintaining a Conditional Grant of Inspection

Validating HACCP plans within strict timeframes

Labor:

Recruiting qualified and reliable personnel

Training staff to adhere to safety and quality standards

Market Dynamics:

Managing fluctuations in livestock supply and market demand

Establishing consistent revenue streams through direct sales or contracts

Mobile Slaughter and Processing Solutions

Mobile slaughter and processing units are emerging as a versatile and efficient means of meeting the needs of small and mid-sized livestock producers in Washington. These units streamline the transition from pasture to plate.

Advantages of Mobile Units

Mobile slaughter units (MSUs) present numerous benefits. They eliminate the need for live animals to travel long distances to processing facilities, which can reduce stress for the animals and potentially improve meat quality. MSUs also provide producers with the ability to process their livestock directly on the farm, ensuring greater control over the quality and safety of the meat. These units support the local food movement and enable producers to sell meat within local and interstate markets while staying compliant with regulations.

Flexibility: They can travel to different farms or serve regional producers at central collection sites.

Convenience: Farmers can schedule processing on an as-needed basis.

Regulatory Compliance: Units are designed to be compliant with USDA and FSIS standards.

Mobile Slaughter Unit Operations

Mobile slaughtering operations must adhere to strict protocols to ensure safety and compliance. A mobile slaughterhouse typically encompasses a 38-foot-long self-contained trailer equipped with the necessary tools and facilities for humane slaughter and butchering. Operations within the unit include stunning, bleeding, skinning, evisceration, and cooling.

Setup:

Trailers are typically outfitted with refrigeration.

Units may include a rear entry door and ramp step for livestock loading and a side door for meat unloading.

Processing:

The internal layout is optimized for workflow efficiency.

Equipment follows sanitary standards for processing.

Mobile processing units (MPUs) have specialized staff trained in humane handling and butchering techniques, ensuring the process upholds animal welfare and meat quality standards. Proper waste disposal methods are also integral to MPU operations, safeguarding environmental health.

Animal Welfare and Ethical Considerations

When processing meat on farms, ensuring animal welfare and adhering to ethical standards are of paramount importance. The procedures should address both humane slaughtering practices and the benefits of pasture-raised meat to align with both animal welfare concerns and consumer expectations.

Humane Slaughtering Practices

Washington requires humane slaughtering methods to ensure livestock are treated with compassion and respect. This involves minimizing stress for animals throughout the process, from handling to the actual slaughter. Using well-maintained equipment and following meat science guidelines help ensure animals are unconscious before slaughtering, thus preventing unnecessary pain or distress. Key practices include:

Proper training for slaughterhouse staff on humane handling.

Adherence to the American Veterinary Medical Association guidelines for humane killing.

Regular inspection and upkeep of stunning devices to ensure efficacy.

Pasture-Raised Meat Benefits

Pasture-raised meat is increasingly sought after for its ethical and ecological advantages. Animals raised on pasture often have higher levels of welfare due to increased mobility, more natural diets, and reduced stress from overcrowding. Specific benefits include:

Improved animal health and wellbeing, leading to better quality meat.

Environmental benefits such as reduced methane emissions and enhanced soil quality.

These ethical considerations keep consumer trust and respect at the forefront, reflecting an understanding that the quality of life for livestock is intertwined with the quality of the meat produced.

Waste Management and Environmental Impact

Effective waste management and mitigation of environmental impact are critical aspects of on-farm meat processing, butchering, and slaughter in Washington. Technologies and processes for slaughter waste handling and carbon footprint reduction are essential for sustainable agriculture.

Slaughter Waste Handling

In Washington, on-farm meat processing generates various types of waste including blood, organ content, and non-edible parts such as bones, tendons, and hides. Techniques for managing this waste include:

Sewage treatment: Proper treatment of liquid waste is necessary to prevent contamination of water systems.

Solid waste management: Composting and rendering are practices used to handle solid waste sustainably.

This proper handling of waste helps in reducing the risk of soil and water pollution and the spread of diseases.

Carbon Footprint Reduction

The meat processing industry is associated with a significant carbon footprint. On-farm processors in Washington can implement strategies to reduce these emissions:

Renewable energy: Use of solar or wind power for operations.

Efficient transportation: Local slaughtering reduces the need for long-distance transport of live animals and meat products.

By focusing on these measures, the industry aims to lower its overall impact on the environment and contribute to a more sustainable food system.

Economic Viability and Market Trends

The economic viability of on-farm meat processing hinges on small farmer adaptability and market responsiveness. This section dissects the challenges and opportunities in scaling for small-scale operations and how they navigate market fluctuations.

Scaling for Small Farmers

Small farmers are finding increasing opportunities to tap into the growing demand for local meats. Post COVID-19, consumers have shown a desire to support local economies and source food with transparency, creating a niche market. However, small farmers must consider the economics of on-farm processing. It requires significant upfront investment in facilities, equipment, and compliance with regulatory standards, which could be prohibitive. Yet, the revenue generated from direct sales to consumers and restaurants can be substantial, offering higher profit margins compared to wholesale.

Investment Costs: High initial infrastructure and licensing costs.

Revenue Streams: Direct to consumer and local restaurants, with potential for premium pricing.

Regulatory Compliance: A barrier that requires careful planning and financial forecasting.

Navigating Market Fluctuations

Market fluctuations present both a challenge and an opportunity for those involved in on-farm meat processing. During the pandemic, the meat processing bottleneck highlighted vulnerabilities in the supply chain, but also showcased the resilience of local processors. Small farmers must be adept at responding to these changes by diversifying their market outlets and maintaining a steady supply to meet restaurant and consumer demands. They also need to build resilience against market shocks, which may require maintaining a flexible business model that can cater to both retail and wholesale markets if necessary.

Demand Variability: Shifts in consumer behavior can affect demand, requiring agility in business strategy.

Supply Chain Stresses: Small processors must be prepared to handle disruptions in input supplies or changes in meat market dynamics.

Business Agility: A key to weathering market fluctuations and sustaining profitability.

Collaborative Efforts and Community Support

The landscape of on-farm meat processing in Washington is significantly shaped by collective initiatives and the robust support framework provided by the community. These collaborative models enhance the processing capacity and strive to meet local demands effectively.

Co-Op Models for Processing

In Washington, cooperative models have emerged as a substantial force in bolstering on-farm meat processing capabilities. These co-ops typically involve a group of producers pooling resources to establish facilities that would otherwise be cost-prohibitive for individual farmers. Cooperative ventures afford member producers better control over the slaughtering process, ensure adherence to quality standards, and improve the economic viability of small-scale operations.

Key Components of Co-Op Models:

Shared investment and ownership

Collective decision-making

Streamlined processing aligned with local needs

Cost efficiency through shared expenses

Producer/Grower Partnerships

Direct partnerships between producers and growers reflect a proactive approach to meat processing in the community. By working together, they are able to maintain a consistent and quality supply of meat to local markets. Such partnerships often involve agreements that secure a steady volume of livestock for processing, potentially stabilizing prices and ensuring a fair distribution of profits throughout the supply chain.

Elements of Successful Partnerships:

Long-term contractual agreements

Transparency in operations and pricing

Mutual support in times of market fluctuations

Collaborative marketing efforts to promote local meat

Both models emphasize the importance of community support and the role it plays in sustaining operations. The synergy between producers, growers, and the community fosters a resilient local food system that can adapt to challenges and seize opportunities in the market.

Education and Training in Meat Processing

The meat processing industry in Washington requires skilled butchers and ongoing research and innovation to sustain high-quality production. Education and training programs are critical in equipping individuals with the necessary skills and knowledge to meet the demands of the sector.

Skill Development for Butchers

In Washington, butchering is a skilled trade that necessitates comprehensive training in areas such as meat cutting, safety regulations, and proper handling techniques. Educational institutions offer programs that combine classroom instruction with hands-on training to hone the precision and expertise required by butchers. These programs often cover topics like:

Fundamental butchering techniques: Students are taught precise cutting skills, including how to properly break down carcasses into retail and wholesale cuts.

Food safety and sanitation: Training includes the development and implementation of Sanitation Standard Operating Procedures (SSOPs) and ensures strict adherence to food safety regulations.

Meat Processing Research and Innovation

Advancements in meat science play a pivotal role in Washington's agricultural education and the growth of the meat processing industry. Research institutions and universities collaborate with meat processing facilities to drive innovation in areas such as:

Product development: New meat products are developed, considering consumer preferences and market trends.

Process improvement: Current processing techniques are evaluated and improved upon, often using Hazard Analysis and Critical Control Point (HACCP) systems to enhance food safety and quality.

Meat science researchers also work alongside educational entities to provide up-to-date training materials for those entering or currently in the meat processing workforce, continuously elevating industry standards.

Case Studies and Success Stories

Case studies in Washington showcase the triumphs of local ranchers and highlight innovative approaches within small-scale meat processing operations.

Local Ranch Successes

Heritage Meats, located in Rochester, Washington, exemplifies the success of tailored meat processing services. They operate a USDA-inspected facility that stands out to both independent farmer-marketers and retail butcher shops for its comprehensive fee-for-service processing of all red meat species. Their operation also includes a custom-exempt side for those requiring freezer-beef services, demonstrating a successful business model that caters to a range of customer needs in the local meat processing industry.

Innovative Small-Scale Operations

Small USDA-inspected facilities demonstrate innovation by addressing unique market needs. Smucker's Meats, though not in Washington, serves as a guiding example with its facility in Mount Joy, Pennsylvania. They manage a spectrum of services including slaughter, fabrication, and vacuum-packaging of products like beef, bison, and pork. Their model extends to offer case-ready retail cuts, available both fresh and frozen, and customized with client labels. This case study highlights the potential for small-scale operations to adapt and thrive by creating a diverse array of value-added products.

Future Prospects and Opportunities

The landscape of on-farm meat processing in Washington is poised for significant growth, harnessing technological innovations and an evolving market towards specialized consumer demands.

Technological Advancements

State-of-the-art technologies are enhancing on-farm meat processing by improving efficiency and product quality. Automation and data analytics are at the forefront, optimizing processes from slaughtering to packaging. Investments in research and development are paving the way for advanced machinery that can increase throughput while maintaining, or even improving, adherence to safety regulations. These advancements present an opportunity for processors to reduce labor costs and minimize the risk of contamination.

Automation: Smart machinery for slaughtering, cutting, and packaging

Data Analytics: Systems to track quality control and logistics

Expanding to Niche Markets

Washington's meat processors are well-positioned to explore niche markets where consumers seek out specialty products such as grass-fed, organic, or locally raised meats. The USDA's recent funding programs signal ample opportunities for processors to cater to these segments, allowing for diversification and growth. There is also potential for processors to provide transparent sourcing, which is increasingly valued by consumers attentive to the origins and conditions of their food.

Specialty Products: Listings of in-demand meat types (e.g., organic, grass-fed)

Market Expansion: Strategies to reach new consumer bases, such as local farmers markets and co-ops

The expansion into these markets is not only a growth opportunity but also a chance for processors to contribute to a more resilient and sustainable food supply chain in line with consumer expectations and environmental considerations.

Appendix: Additional Resources

Governmental Resources

Washington State Department of Agriculture (WSDA)

Website: agr.wa.gov

Resources: Guides for custom slaughter and processing, licensing information, and applicable regulations.

Grant Programs

USDA Meat and Poultry Processing Expansion Program

Eligibility: Projects for construction and equipment purchase.

Grant Range: $250,000 to $10 million.

Educational Materials

A Beginner's Guide to Raising Animals for Meat by WSDA

Format: PDF guide.

Contents: Overview of meat processing in the U.S., step-by-step guidance, and regulatory compliance.

Legislation

Federal Meat Inspection Act

Scope: Processing cattle, sheep, swine, goats, and voluntary exotic animal processing.

Regional Grants and Awards

Washington State Department Specific Awards

"Small projects" grants: Ranges from $20,000 to $150,000.

"Large projects" support: For significant capacity expansions.

Note: For the most current and comprehensive information, individuals and businesses should directly refer to the WSDA website or contact the USDA. Ensuring adherence to regulations and successful application for grants requires thorough review of the available resources.

Conclusion

On-farm meat processing in Washington presents a viable pathway to reinforce the economic stability of local agriculture by enabling producers to manage their meat products from pasture to plate. Washington state adheres to the Federal Meat Inspection Act, ensuring that meat processing meets stringent safety standards, whether involving conventional livestock or, on request, exotic animals.

Benefits Include:

Enhanced Control: Producers maintain quality throughout the process.

Local Economy Support: Small-scale operations stimulate regional industry.

Consumer Trust: Shorter supply chains build consumer confidence in product origins.

Challenges Noted:

Capital Investment: Significant upfront costs can be prohibitive.

Public Perception: Necessary to balance operational transparency with community relations.

Regulatory Navigation: Compliance with federal and state regulations requires diligence.

Farmers and ranchers in Washington aiming to implement on-farm processing must weigh these factors carefully. While opportunities for increased revenue and market differentiation exist, they come alongside responsibilities to adhere to regulations and address the concerns of the surrounding community.

In the context of meat quality, both on-farm and processing factors are crucial; therefore, continuous improvement in practices is essential for maintaining high standards. With a mindful approach, on-farm meat processing can contribute substantially to local agriculture economies and provide a foundation for sustainable meat provisioning.