On-Farm Meat Processing, Butchering, and Slaughter in Virginia

Regulations and Best Practices

On-farm meat processing in Virginia is a critical component of the state's agricultural industry, ensuring that meat products are safe, wholesome, and accurately labeled. With an infrastructure supported by both the U.S. Department of Agriculture and the Virginia Department of Agriculture and Consumer Services, local farmers and producers have the capability to process meat and poultry on their premises. Adherence to high standards of meat processing is pivotal for maintaining public health and consumer trust.

The butchering and slaughter of livestock on farms throughout Virginia are activities that are deeply rooted in both tradition and necessity. Small-scale producers often opt for on-farm processing to maintain control over the entire supply chain, from raising the animals to the final meat product. This approach allows for a more personal touch in meat production and can lead directly to a closer connection with local consumers who value understanding where their food originates.

In addition to the practices of on-farm meat processing, Virginia offers resources for producers to learn and adhere to regulations for meat and poultry products. The state's guidelines ensure that only meat and poultry products that have undergone proper inspection are sold to consumers. Such regulatory measures are significant not only for consumer protection but also for the reputation and sustainability of the meat industry within the state.

Overview of On-Farm Meat Processing

On-farm meat processing in Virginia involves farmers managing the slaughtering and butchering of livestock directly on their property, offering a level of control and self-sufficiency in meat production.

Historical Context

On-farm meat processing has roots in Virginia's agricultural traditions, where farmers historically managed all aspects of livestock production from rearing to processing. This practice allowed for a complete farm-to-table approach. Over time, increasing regulations and the growth of large-scale meat processors shifted the industry towards centralized processing facilities. Despite this, a number of farms continued to maintain traditional practices, keeping the skills and knowledge of on-farm processing alive.

Current Trends and Statistics

Presently, there is a resurgence of interest in on-farm meat processing in Virginia. This is due in part to the desire for more locally sourced and controlled meat products. Small processors are becoming more prevalent as they serve a community that appreciates the transparency and traceability of their meat. Farmers are seeking to process livestock on their premises due to various reasons, including processing bottlenecks at larger facilities and a growing consumer market for artisanal meats.

The state has seen an increase in facilities that provide services such as mobile slaughtering units geared toward small-scale farmers. These mobile units help farmers comply with regulations while providing flexibility. They focus on either "custom" processing, where meat is returned to the owner and not sold, or "state-inspected" processing, which allows the meat to be sold commercially after inspection.

Meat science plays a significant role in ensuring that on-farm processing meets quality and safety standards. With universities such as Virginia Tech offering programs in meat science, farmers can stay informed about best practices and advancements in the field.

Legal Framework and Regulations

The legal framework and regulations governing on-farm meat processing, butchering, and slaughter in Virginia involve federal and state statutes as well as guidelines set forth by the USDA to ensure food safety and compliance with various health and sanitation requirements.

Federal Laws

At the federal level, the Federal Meat Inspection Act (21 USC 601 et seq) dictates stringent laws regulating meat processing. It mandates inspections and sets out standards to prevent adulterated or misbranded meat and meat products from being sold. Implementing regulations are laid out in Title 9 of the Code of Federal Regulations (9 CFR 300 et seq). These laws require USDA-inspected slaughter facilities, ensuring that meat processing is conducted in a manner that prioritizes public health and safety.

Virginia State Regulations

In the Commonwealth of Virginia, the meat and poultry processing industry must adhere not only to federal requirements but also to state-specific regulations. The Virginia Department of Agriculture and Consumer Services (VDACS) enforces these regulations, which cover aspects such as facility sanitation, waste disposal, and licensing requirements for on-farm processing.

State regulations may vary, and they often elaborate on the federal requirements to take into account local needs and considerations. For instance, Virginia offers resources and forms helping businesses comprehend and comply with these detailed local standards.

USDA Guidelines

The USDA Food Safety & Inspection Service (FSIS) provides oversight and guidance for the meat and poultry industries. It publishes directives, notices, and policy decisions, which collectively contribute to carrying out its mission to protect public health.

Establishment Design and Construction: USDA provides a guidebook that outlines the essential design and construction standards for facilities to ensure food safety.

Exemption Guidance: There is specific guidance for determining whether a poultry operation is exempt from certain inspections.

Product Inspection: A directory outlining meat, poultry, and egg product inspection protocols further supplements these guidelines, making sure the meat and poultry slaughter processes follow recognized standards.

Through these combined federal and state regulations, along with USDA guidelines, the meat processing industry is closely regulated to protect consumers and ensure the integrity of the food supply chain.

Animal Welfare and Human Safety

In Virginia's on-farm meat processing landscape, the assurance of animal welfare aligns closely with human safety. Practices are designed to minimize stress and avoid injury, contributing to better outcomes for both livestock and handlers.

Humane Slaughter Practices

Humane slaughter laws mandate that livestock should be rendered insensitive to pain before butchering. It is crucial for animals to be slaughtered in a way that causes the least distress and pain. There are various methods approved for this process, such as captive bolt stunning to ensure immediate unconsciousness.

Key factors include:

Proper use of technology and techniques

Continuous monitoring and training of personnel to ensure compliance and swift, humane action

Elderly and Young Livestock

Special considerations for elderly and young livestock impact both animal welfare and safety during slaughter:

Elderly Livestock:

They might be more susceptible to stress and injury.

Handlers adjust procedures to account for potential frailty and reduced mobility.

Young Livestock:

They require careful handling to prevent distress or injury.

Modified equipment and facilities ensure their safety and humane treatment.

Farmer and Processor Safety

For the safety of farmers and processors, adherence to stringent guidelines is required:

Proper equipment and training reduce the risk of accidents.

Protocols for illness and injury are established to avoid any potential for transmission between livestock and humans.

Working environments are structured to limit stress and physical strain on the workers, reducing the risk of occupational hazards.

Health Risks and Disease Prevention

In Virginia, on-farm meat processing possesses inherent health risks primarily due to the possibility of pathogenic contamination. Effective disease prevention methods are crucial to safeguard both workers and consumers from illnesses.

Pathogen Risks

On-farm meat processing in Virginia heightens the risk of exposure to several pathogens, notably E. coli O157, Salmonella, and Campylobacter. These bacteria can cause serious gastrointestinal illnesses and are most commonly associated with meat products. The processes of slaughtering and butchering are potential stages where these pathogens can be introduced if the animals carry these bacteria in their gastrointestinal tract. It's imperative for workers to recognize the signs of illness in live animals, as this is a primary defense against pathogens entering the meat supply.

Contamination Prevention Methods

To prevent contamination during on-farm meat processing, stringent methods must be employed, including:

Sanitation Protocols: Regular cleaning and disinfection of equipment and surfaces where meat is processed to eliminate any pathogens present.

Personal Hygiene: Workers must adhere to high standards of personal hygiene, including proper handwashing and the use of protective gear such as gloves and aprons.

Temperature Control: Meat should be maintained at proper temperatures during processing and storage to inhibit bacterial growth.

Cross-contamination Avoidance: Tools and surfaces must be designated for specific tasks to prevent cross-contamination between raw and processed meat.

These preventive measures are vital to ensuring the health and safety of consumers and must be diligently applied by all workers involved in the meat processing chain.

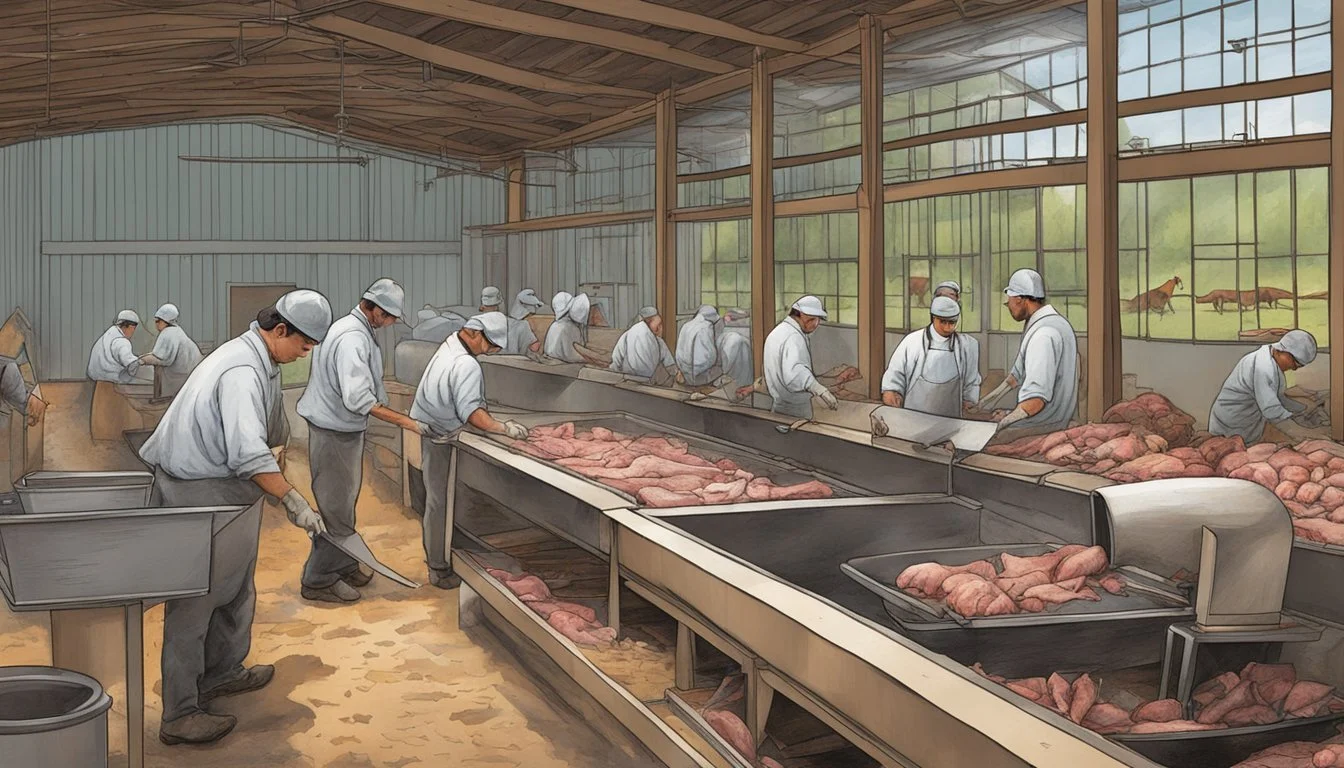

Processing Techniques and Equipment

Efficient on-farm meat processing in Virginia hinges upon the application of the correct slaughter methods, utilization of precise butchering tools, and the implementation of effective waste management practices. These components are critical in ensuring the transition from live animals to packaged meat products that are safe, high in quality, and ready for the market.

Slaughter Methods

The slaughter of animals must be performed humanely and in accordance with Virginia's regulations. Scalding is a common technique used primarily for hogs where they are submerged in hot water to loosen hair and prepare for dehairing. This is critical in the production of products such as ham, where a clean and precise cut is necessary. The right equipment, including stunners and restraining equipment, ensures the process is as stress-free as possible for the animal.

Butchering Tools

After slaughtering, the butchering stage involves various specialized tools tailored for each task. Key equipment includes:

Breaking saws or cleavers for cutting through bone and carcass

Boning knives for trimming and preparing the meat

Meat hooks and gambrels for hanging and handling the carcass during processing

The condition and sharpness of these tools directly affect the efficiency of the process and the quality of the final product.

Waste Management

Effective waste management systems are imperative to both environmental stewardship and food safety. Facilities must have in place methods for handling blood, bone, fat, and other byproducts to prevent contamination. Packaging materials must be suitable for meat products, preserving their freshness and preventing exposure to contaminants. Practices such as rendering and composting can be utilized to manage organic waste, turning what would be refuse into useful byproducts.

By maintaining high standards throughout these stages, Virginia's meat producers can assure quality and compliance within their meat processing operations.

Mobile Slaughter and Processing

Mobile slaughter and processing units have emerged as a vital solution to alleviate the bottleneck issues faced by meat producers, particularly in the wake of increased demand and processing challenges heightened by events such as the COVID-19 pandemic.

Mobile Slaughter Units

Mobile Slaughter Units (MSUs) are equipped to handle the on-farm slaughtering process, thereby eliminating the need to transport livestock over long distances. In Virginia, such units offer services that cover the slaughtering of small ruminants like sheep and goats. These MSUs are designed to optimize animal welfare by reducing stress associated with transportation and unfamiliar environments, which can also impact meat quality.

Capacity: A typical MSU can accommodate various livestock quantities. For example, a unit might hold up to 20 hogs or 26 sheep at a time.

Functionality: These units are a part of a larger system intended to streamline the farm-to-table process, bring processing tools directly to the farm's doorstep, and support small to mid-sized farms.

States Utilizing MSUs: Colorado and Virginia are among the states that have adopted the use of MSUs to support local meat processors during times of increased demand.

Regulatory Compliance for Mobile Units

Regulatory compliance is crucial for mobile slaughter units to ensure food safety and public health. They operate under the oversight of the United States Department of Agriculture (USDA) or state inspection programs that adhere to similar standards.

USDA Inspection: MSUs must pass USDA inspection in order to legally process meat for public consumption. This involves adhering to stringent sanitation and process control standards, similar to fixed slaughterhouse facilities.

State-Specific Regulations: Each state may have additional requirements; for instance, Virginia has its own set of regulations for the operation of MSUs which must be followed in tandem with federal guidelines.

COVID-19 Considerations: In response to the pandemic, there has been an increase in scrutiny and adaptation of MSUs to ensure worker safety and maintain the integrity of the food supply chain.

Companies involved in the manufacture and operation of these mobile units are essential players in this niche market, ensuring that processors, farmers, and ultimately consumers can rely on a system that is safe, efficient, and compliant with all regulatory standards.

Economic Aspects and Business Planning

The success of on-farm meat processing in Virginia hinges on thorough economic analysis and strategic business planning. This includes careful consideration of direct costs and potential market opportunities for products such as beef, poultry, and value-added meat items.

Cost Analysis

For small farmers considering the venture into on-farm meat processing, cost analysis is critical. Initial setup costs for a meat processing facility, especially those looking to be USDA-inspected and to comply with Virginia's state regulations, can be substantial.

Infrastructure: Upfront costs include construction or renovation of a processing facility to meet regulatory standards and to handle the expected volume of cattle or poultry.

Equipment: Specialized butchering and processing equipment represent a significant investment.

Operational Costs: Ongoing expenses such as labor, utilities, maintenance, and sanitation must be factored in.

Certification and Inspection: Compliance with federal and state regulations incurs costs for permits, licenses, and regular inspections.

Profitability in meat processing also requires control of the above expenses while scaling up operations in a manageable manner.

Market Opportunity Exploration

To maximize economic efficiency, there is an emphasis on identifying market opportunities. Small farmers and processors can benefit from trends such as direct-to-consumer sales and the establishment of retail stores associated with the processing facilities.

Direct-to-Consumer Sales: Offering products directly to consumers can increase margins by skipping intermediaries. This requires strong marketing strategies and may involve online sales, community-supported agriculture (CSA), or farmers markets.

Local and Niche Markets: Focusing on local or niche markets allows small operations to tap into consumer demand for locally sourced and specialty products.

Retail Store Setup: Creating a retail space either on-farm or through partnerships can provide an accessible point for consumers to purchase the meat, which can increase local visibility and sales.

The selection of product types, through an understanding of market demand, whether it be premium beef cuts, whole chickens, or a variety of meats, influences the business's profit potential. Virginia farmers have the opportunity to capitalize on a growing consumer interest in provenance and quality of locally raised meats, making a well-planned business essential to thriving in the agricultural economy.

Community Impact and Considerations

The implementation of on-farm meat processing in Virginia is not just a logistical change; it affects the fabric of community interactions and economic health. The dialog on on-farm slaughter must consider the implications for neighbor relations and the potential economic benefits to the local economy.

Neighbor Relations

On-farm meat processing facilities should maintain open communication with neighbors to foster positive relationships. These facilities, while crucial for food production, can be sources of concern for neighboring residents due to potential noises, odors, and increased traffic. To mitigate these potential disturbances, processors may employ strategies such as strategic placement of processing facilities away from property lines, sound dampening measures, and clearly defined operational hours.

Proactive engagement with the community, such as planning meetings or informational sessions, is essential. This can ensure that neighbors are well informed about the nature of the operations and how they will be managed to minimize any negative impacts. Additionally, facilities might explore community benefits they can offer, such as job creation or educational opportunities.

Local Economy Benefits

A strong local meat processing sector supports the local economy by providing jobs and keeping more of the food dollar in the community. It serves both the producers through cost reduction in transportation and the consumers by potentially reducing the end price of meat products. Investment in local meat processing can catalyze other economic activities, such as secondary processing facilities and further development in the agriculture services sector.

Meat processing facilities done right can lead to a diversified food supply and facilitate greater access to markets for farmers. The recent interest and funding through grants such as those from the U.S. Department of Agriculture (USDA) suggest a growing recognition of the economic potential that these facilities can provide. Local governments often view the development of on-farm butchering and slaughtering capabilities as positive economic development that supports regional producers, creating a robust system that can support rural economic growth.

Processing Exemptions and Small Scale Operations

In Virginia, small scale meat processors can benefit from specific USDA exemptions, which can streamline their operations. These exemptions are crucial for the functioning and prosperity of small-scale entities within the meat processing industry.

Processing Exemptions

Exemptions from the USDA’s inspection requirements are available for small-scale poultry producers under certain conditions. For instance, those who process fewer than 1,000 birds per year may be eligible for exemption from continuous inspection. These producers must still adhere to sanitary and labeling guidelines, but the exemption allows for processing without the presence of an inspector. This exemption aims not to lower safety standards but to accommodate the scale of operation, making processing more accessible and less burdensome.

Specifically in Virginia, producers can use the on-farm processing exemption if they meet the USDA's criteria, suggesting a distinct opportunity for small-scale processors to operate within a more flexible framework.

Networking with Small Processors

Small processors benefit significantly from networking, as it can lead to shared best practices, resources, and marketing strategies. This collaboration can also facilitate a greater understanding of the regulatory environment. In Virginia, there are resources available which small meat processors may access, such as educational seminars, funding assistance programs, and cooperative initiatives focused on rural development. Interaction between small-scale processors can lead to synergies that enhance their economic resilience and their ability to meet local food demands.

Furthermore, organizations may provide platforms for processors to connect, exchange information on obtaining grants or exemptions, and navigate the inspection process more efficiently. This support is vital to the success of small processors who may not have the same resources as larger companies.

Education and Resources

Virginia's agricultural sector offers various opportunities for individuals interested in on-farm meat processing, butchering, and slaughter. Key to this sector's success are comprehensive training programs along with accessible online resources and extension services.

Training Programs and Workshops

Virginia Cooperative Extension and other local entities offer workshops aimed at educating producers and processors in meat-cutting and processing skills. For example, Virginia State University has launched a program aimed at training individuals in the art of meat cutting to address the industry's shortage of skilled workers. This hands-on training could increase the state's slaughter capacity. Furthermore, Ohio State University Extension provides resources such as fact sheets and virtual information sessions aimed at educating individuals on the essentials of meat processing on farms. Dr. Lyda Garcia, an assistant professor at Ohio State University, has been actively involved in creating educational materials and providing workshops such as those conducted during the Farm Science Review.

Key Resources:

Fact Sheets: go.osu.edu/onfarmeatprocessing, go.osu.edu/legalhomeprocessing

Educational Workshop: Farm Science Review

Online Resources and Extension Services

Online resources are crucial for the dissemination of information and best practices related to on-farm meat processing. Extension services offer a host of virtual tools and materials. Ohio State University Extension, led by experts like Dr. Lynn Knipe, Associate Professor, provides valuable guidance via their website, including legal aspects of home processing and best practices. The online resources also include detailed information on regulations and compliance to aid small-scale meat processors in their operations.

Notable Online Tools:

Legal Aspects: go.osu.edu/legalhomeprocessing

Best Practices: go.osu.edu/onfarmeatprocessing

These educational programs and online materials support the needs of Virginia's farming community by offering essential knowledge and training, ensuring the state's meat products are safe, properly labeled, and produced in line with industry standards.

Case Studies and Innovative Practices

This section examines practical examples and recent advancements within on-farm meat processing, drawing insights from specific case studies and the implementation of emerging technologies.

Case Studies from Other States

In Odessa, Washington, the Livestock Producers Cooperative Association (LPCA) operates as a multi-species, cooperatively-owned meat processing plant. They provide valuable insights into cooperative models, which can be beneficial when considering scalability and sustainability in Virginia.

Another noteworthy example comes from Ohio State University's study, emphasizing the importance of understanding both national and regional industry challenges before enhancing local meat processing capabilities. While it does not offer a direct case study, the focus on stakeholder awareness is imperative when considering the development of processing facilities in Virginia.

Emerging Technologies in Processing

The use of mobile slaughter units is an emerging trend designed to increase processing capacity without the need for permanent facilities. States like Oregon and Wisconsin have been pioneering in this regard, allowing small farmers to process meat on-site under USDA inspection guidelines, thus addressing a key hurdle in local meat production.

Processing Facility Technologies:

Automated Systems: Improved efficiency and precision in meat cutting and packaging.

Sanitation Innovations: New procedures and equipment to enhance food safety.

The integration of these technologies can significantly enhance an operation's productivity and adhere to stringent safety standards. Implementing such innovations within Virginia's infrastructure could position the state as a leader in sustainable and efficient meat processing practices.

Environmental Considerations

When discussing on-farm meat processing, butchering, and slaughter in Virginia, it is crucial to analyze the environmental footprint, particularly the impact on land and water resources, and the adoption of sustainable practices.

Impact on Land and Water Resources

On-farm meat processing in Virginia affects the environment, specifically land and water resources. These processes require substantial amounts of water for operations such as cleaning and cooling and generate waste that can pollute water bodies if not managed correctly. Land resources are impacted by the need for space to raise livestock and grow feed, as well as the potential for overgrazing and erosion.

Water Usage: Slaughterhouses consume significant quantities of water, potentially leading to freshwater scarcity.

Waste Management: Improper disposal of byproducts can contaminate groundwater and soil, posing risks to ecosystems and human health.

Sustainable Practices

Farmers and processors in Virginia can mitigate environmental impacts by employing more sustainable practices. By implementing waste reduction techniques, water recycling, and energy-efficient systems, the meat processing industry can reduce its environmental footprint.

Waste Reduction: Practices like rendering and composting can transform waste into useful products, decreasing environmental pollution.

Resource Management: Efficient resource use, such as rainwater harvesting and precision feeding, conserves water and land, leading to lower resource depletion.

The incorporation of these practices ensures that meat processing is conducted with a heightened awareness of its ecological implications.

Consumer Education and Marketing

Consumer awareness and informed choices are integral to the success of on-farm meat processing in Virginia. Producers must focus on educating consumers about meat quality, while employing strategic marketing to promote their products effectively.

Educating Consumers on Meat Quality

Consumers often seek clarity on the quality and sourcing of their meat products. In Virginia, on-farm processors facilitate this by providing detailed information about how their animals are raised, the specifics of their diet, and the humane handling practices prior to slaughter. They may also help customers understand grading systems and the benefits of locally processed meats, such as freshness and supporting the local economy.

Marketing Strategies for On-Farm Processed Meat

Successful marketing strategies for on-farm processed meat include direct pre-sales to consumers, which can ensure sales before processing begins. This method provides transparency and builds trust, as consumers know exactly where their meat is coming from. Marketing efforts may also include:

Local Branding: Highlighting "Virginia-grown" to appeal to state pride and the local food movement.

Educational Programming: Incorporating butcher demonstrations or farm visits to engage customers and create memorable experiences.

Labeling and Packaging: Ensuring that all packaging is professionally labeled with clear, straightforward information about the meat inside, whether it's fresh or frozen, and includes any certifications or special qualities (grass-fed, organic, etc.).

These focused efforts in consumer education and strategic marketing can set Virginia's on-farm meat processors apart in a competitive market and foster a loyal consumer base invested in high-quality, locally-sourced meat products.

Impact of COVID-19 on On-Farm Processing

The coronavirus pandemic significantly disrupted on-farm meat processing activities in Virginia, altering consumer behavior and prompting adaptation strategies among farmers.

Changes in Consumer Behavior

During the COVID-19 pandemic, Virginia witnessed a shift in consumer behavior towards local meat sourcing. Food supply chain interruptions led shoppers to look beyond traditional grocery stores, fueling a rise in direct farm purchases. On-farm meat processors experienced an increased demand, as consumers sought transparency and a reduced number of touchpoints in their food procurement.

Adaptation Strategies for Farmers

Virginia's farmers responded to the challenges posed by COVID-19 with innovative measures to sustain on-farm processing. They implemented enhanced biosecurity protocols to protect both their workers and customers. Farmers also expanded their cold storage capacity and optimized appointment systems for slaughtering services to cope with the heightened demand.

Adaptation Strategies:

Biosecurity enhancements: Implementing social distancing, use of personal protective equipment (PPE), and sanitation protocols.

Infrastructure adjustments: Increasing cold storage facilities and streamlining processing schedules.

Online platforms: Utilizing online ordering systems to manage direct sales and maintain supply chain stability.

These changes aimed not just at addressing the immediate impacts of the pandemic but also at future-proofing their businesses against similar disruptions.

Breeds and Genetic Selection for Processing

In Virginia's on-farm meat processing sector, breeds are carefully chosen and genetic traits meticulously selected to optimize product quality and processing efficiency. This strategic approach plays a vital role in the state's cattle and poultry production as well as in alternative livestock such as bison (What wine goes well with bison?) and deer.

Cattle and Poultry Breeds

Virginia's farmers typically raise Angus, Hereford, and Charolais cattle, known for their meat quality and processing attributes. Black Angus cattle, in particular, are prized for their marbling and tenderness, which contribute to higher quality beef. Dairy breeds like the Holstein are also common, where their milk production is primary but beef can be a secondary product.

Broilers are the predominant poultry breed in Virginia, selected for their rapid growth and feed efficiency. Genetic selection has enabled these birds to reach market weight quickly and with notable uniformity, an asset in processing.

Genetic Factors in Meat Processing

Cattle genetic factors influence meat quality characteristics such as marbling, tenderness, and flavor. Specific genes are targeted in breeding programs to propagate desirable traits. Bulls with high-quality genetic markers can command higher prices, reflecting the value attached to their breed-improving potential.

In poultry, genetic selection emphasizes feed conversion ratios and growth rates, significantly impacting profitability in processing. It is not uncommon for genetic selection to also focus on traits that reduce the susceptibility of flocks to common diseases.

Virginia's engagement with alternative breeds such as pigs, bison, deer, and elk also hinges on genetic traits favorable to meat quality and processing efficiency. For instance, bison are selected for their lean meat, which is growing in popularity among health-conscious consumers. Genetic selection within deer and elk populations is often towards optimizing meat yield and ensuring robust health under farm conditions.