Predicting Spoilage Without Opening the Package Advances in Non-Invasive Food Monitoring

Predicting food spoilage without opening the package is now possible thanks to innovative technologies that detect freshness through smart sensors and non-intrusive methods. Devices can monitor changes in volatile compounds or use smart packaging to signal when food is no longer safe, helping reduce uncertainty and waste.

Recent advancements allow consumers and producers to assess whether food is fresh or spoiled by using apps, hand-held scanners, or sensor-equipped packaging—all without breaking the seal. These approaches use data from chemical indicators, light sensors, and even smartphone cameras to provide accurate freshness information.

As households and food companies alike look for solutions to minimize waste and avoid unnecessary losses, these non-invasive methods make it easier and safer to determine shelf life and food quality throughout the supply chain.

Understanding Food Spoilage

Food spoilage is largely driven by microorganisms, with bacterial contamination being a key contributor to unsafe and wasted foods. Recognizing how and why spoilage occurs, as well as identifying its specific signs, supports safer choices and reduces unnecessary food waste.

Microbial Growth and Its Impact

Microbial growth occurs when bacteria, yeasts, or molds multiply on or within food products. The rate and extent of microbial growth depend on factors such as temperature, moisture, oxygen availability, pH level, and the type of food.

Certain bacteria, including E. coli, Salmonella, and Listeria monocytogenes, are particularly known for contaminating foods and compromising safety. These pathogens can cause illness even before food looks or smells spoiled.

Microbial activity leads to changes in texture, odor, flavor, and color. Spoilage organisms break down nutrients, producing gases or toxins. The following table outlines key influences on microbial growth:

Factor Effect on Microbial Growth Temperature Warmth accelerates growth Moisture High water content increases risk pH Low acidity supports growth Oxygen Aerobic microbes thrive Food composition Nutrient-rich foods spoil faster

Common Causes of Bacterial Contamination

Bacterial contamination often results from improper food handling, cross-contamination, or inadequate storage. Raw meats, unwashed produce, and ready-to-eat foods are frequent sources of dangerous bacteria.

E. coli can be introduced through undercooked beef or contaminated water. Listeria is known to contaminate dairy, deli meats, and soft cheeses, while Salmonella is common in eggs, poultry, and some vegetables.

Contamination is also linked to poor hygiene, unclean surfaces, and breaches in packaging integrity. Storage at improper temperatures can allow bacteria to multiply quickly, even if the food appears unchanged.

Signs and Indicators of Spoilage

Spoilage can present with a range of visible and sensory cues. Common indicators include:

Change in color (e.g., grayish meats, dull produce)

Unpleasant odor (sour, rotten, or sulfur-like smells)

Altered texture (slimy, mushy, or sticky surfaces)

Gas production (swollen or puffed packaging)

Visible mold (green, black, or white patches)

Not all spoiled foods produce clear warning signs. Some dangerous bacteria, like Listeria, do not always alter the appearance or smell of food, making microbial detection challenging without appropriate technology. Careful attention to storage instructions and use-by dates remains essential.

The Importance of Predicting Spoilage

Predicting spoilage without opening the package enables consumers and businesses to minimize unnecessary waste, adhere to regulations, and maintain quality standards. It provides practical benefits at each stage of the supply chain and supports informed decision-making.

Reducing Food Waste

Food waste significantly impacts both the environment and the economy. Accurately forecasting spoilage helps prevent the disposal of products that are still safe and edible. With advanced techniques such as smart packaging and AI-enabled freshness detection, stakeholders can make more precise judgments about shelf life.

Shorter and more accurate predictions allow retailers to optimize stock rotation and sales strategies. This reduces the volume of discarded food, which supports sustainability goals and helps control operational costs. The consumer also benefits by being able to use products before they truly expire, further lowering household waste.

By enabling data-driven decisions, spoilage prediction supports more responsible resource use throughout the food supply chain.

Enhancing Food Safety

Early detection of spoilage risks helps protect public health. Predictive microbiology allows for the assessment of spoilage and pathogen growth, giving producers and regulators critical information to act before contamination reaches consumers.

Effective prediction methods reduce the likelihood of distributing unsafe food. By using cumulative probability models and sensor technologies, companies can take action if risk thresholds are met. This approach not only protects end users but also ensures compliance with food safety standards.

Timely interventions minimize the spread of foodborne illnesses and prevent costly recalls or liability issues.

Ensuring Product Integrity

Maintaining product quality from packaging to consumption is vital for brand reputation and consumer trust. Predictive spoilage techniques provide a scientific basis for shelf-life estimations and reduce the reliance on conservative expiration dates.

Manufacturers can use predictive models to set accurate use-by dates, improving traceability and accountability in the event of a safety concern. This supports industry efforts to align with legal requirements and best practices for integrity and transparency.

Preserving product integrity helps companies maintain customer satisfaction, reduce waste caused by premature disposal, and ensure that only high-quality goods reach store shelves.

How Food Spoilage Is Traditionally Detected

Ensuring food quality and safety has depended on a range of practical, observable techniques. The most common approaches rely on either date labeling or direct examination to assess whether food is still consumable.

Expiration Dates and Shelf Life

Manufacturers assign expiration dates and best-before labels to packages based on shelf life data. Shelf life refers to how long a food product maintains acceptable taste, texture, safety, and nutritional value under specific storage conditions.

These dates are determined using microbiological counts, chemical stability, and sensory evaluation over time. For example, standardized sampling methods monitor the growth of spoilage organisms until a sample is considered unacceptable (often exceeding 10^7 CFU per gram for many foods).

Consumers and retailers depend on these visible dates for decision-making. However, this method cannot account for temperature abuse, package damage, or unexpected changes in storage conditions after packaging. This makes expiration dates a helpful but sometimes imprecise guide for true food quality.

Physical Inspection Methods

Physical inspection methods involve examining the food or its packaging for visible and sensory signs of spoilage. Key indicators include changes in color, texture, and odor. For many products, especially fresh produce and meats, visible mold, off-smells, or a slimy surface immediately flag potential spoilage.

Inspectors or consumers may also check for swelling in sealed packages, which can indicate gas production by spoilage microorganisms. Tactile cues, such as stickiness or a change in firmness, can also signal degradation.

These detection methods are direct but not always reliable for all types of foods. Some spoilage processes occur without noticeable external changes, which means issues may be missed until food is consumed. Despite these limits, physical checks remain a widespread tool for identifying compromised food quality before consumption.

Advancements in Spoilage Prediction Technologies

Emerging technologies are transforming how food spoilage is detected and prevented. These advancements leverage sensors, data analysis, and packaging innovation to provide real-time insights without opening the product.

Sensors and IoT Integration

Advanced sensors, such as gas sensors and electronic noses, now enable detection of spoilage markers like volatile organic compounds and gases associated with bacterial activity. These devices monitor food quality through packaging by measuring indicators—such as carbon dioxide, ammonia, and hydrogen sulfide—without the need for human inspection.

Internet of Things (IoT) technology plays a key role by connecting sensors to cloud-based systems, allowing remote, continuous monitoring and automated data collection. This integration supports real-time alerts if spoilage is detected, reducing waste and preventing unsafe consumption.

Table: Common Spoilage Markers Detected by Sensors

Marker Indicates CO2 Microbial growth NH3 (Ammonia) Protein degradation H2S (Hydrogen Sulfide) Bacterial activity

Machine Learning And Artificial Intelligence

Machine learning (ML) and artificial intelligence (AI) enhance spoilage prediction by analyzing large datasets from sensor data, chemical profiles, and historical trends. These models can identify subtle patterns linking specific marker changes to product shelf-life and safety risks.

AI systems can learn from sensory and chemical measurements, continually improving their accuracy over time. Applications include automatic quality grading, dynamic shelf-life prediction, and early detection of unusual spoilage events across various food products.

List: Key Benefits of AI in Spoilage Detection

Early, automated warning before spoilage is visible

Improved accuracy versus manual inspection

Adaptive models that learn from new data

Role of Innovation in Packaging

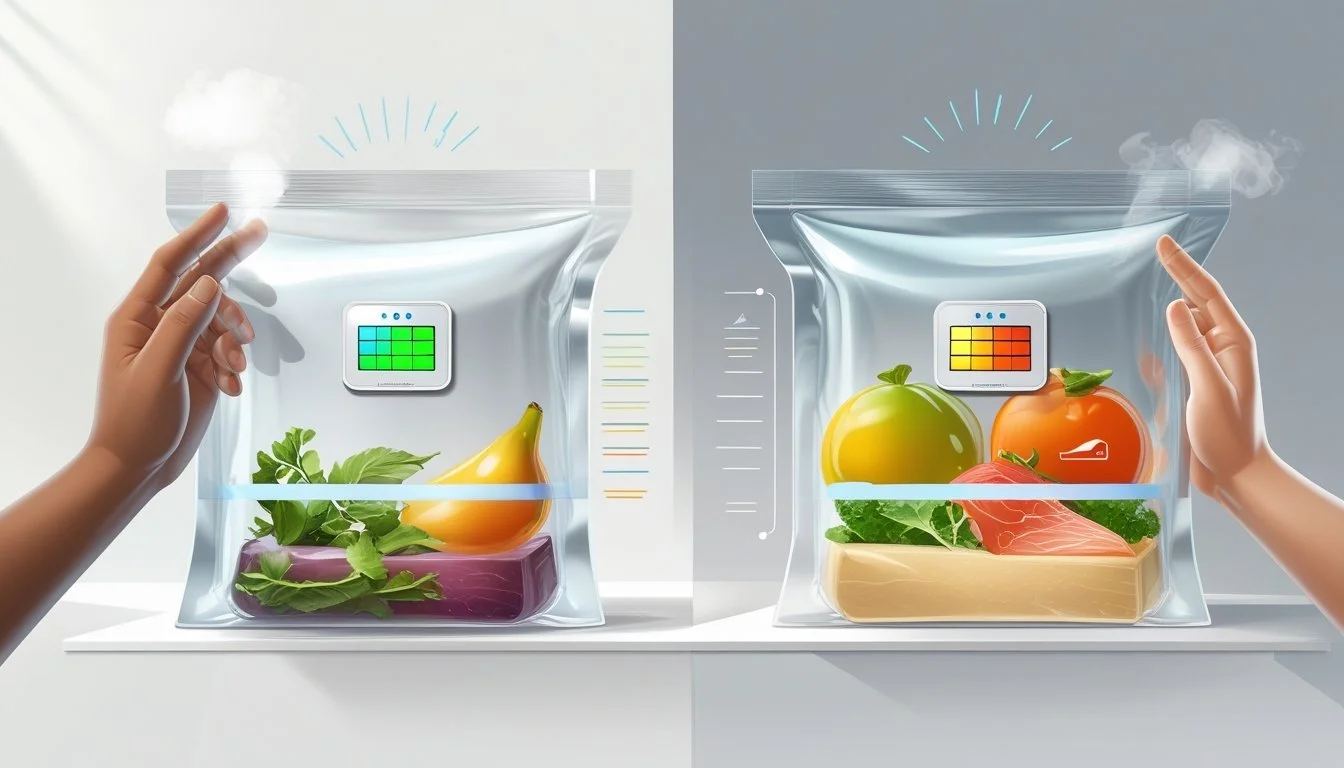

Innovative food packaging extends spoilage prediction capabilities by embedding smart sensors and communication devices directly into packaging materials. These intelligent packages can track internal environments, alert users to temperature abuse, and indicate product freshness on labels or through digital platforms.

New materials and printing technologies allow for embedding thin-film sensors and RFID tags that transmit data externally, supporting traceability and inventory management. Some solutions also use color-changing labels to provide a visual indication of spoilage status, making the information accessible to consumers and retailers.

Such advancements help maintain food safety, reduce unnecessary waste, and support accurate inventory turnover in supply chains.

Implementing Non-Invasive Detection in the Supply Chain

Non-invasive detection methods are transforming how perishable goods are monitored throughout the supply chain. These technologies help maintain freshness and reduce waste by offering real-time data without opening packaging or disrupting the product’s environment.

Monitoring Perishable Goods with Technology

Non-invasive sensors, such as gas sensors, acoustic devices, and mm-wave systems, allow continuous monitoring of internal conditions of packaged goods. For example, IoT-based sensors can detect gases released during spoilage or measure subtle physical changes without damaging the packaging.

Smart sensors provide real-time alerts when spoilage indicators cross critical thresholds. This enables distributors to act promptly, minimizing the risk of spoiled goods reaching consumers. Advanced systems can be integrated with data analytics platforms, making it possible to analyze patterns and predict spoilage events.

Some systems use a combination of sensor inputs, including temperature, humidity, and VOC (volatile organic compound) levels. This multi-factor approach gives a more accurate picture of a product’s condition, compared to single-metric monitoring. Data collected from these sensors is securely transmitted to cloud-based dashboards, ensuring compliance and traceability.

Ensuring Freshness from Production to Consumer

Maintaining freshness across the supply chain requires automation and transparency at every stage. Technologies such as blockchain can be integrated with sensor data to create a traceable record of each product’s journey, ensuring data integrity from production to retail shelves.

AI-driven platforms interpret sensor data and identify shipments at risk, helping logistics teams prioritize their response. This minimizes product recalls and reduces food waste. Retailers can also use this information to manage shelf life more efficiently.

A typical flow involves the following steps:

Stage Technology Used Key Benefit Production IoT sensors, analytics Early issue detection Transportation Cloud dashboards, GPS Real-time updates Retail Blockchain, AI Improved allocation

By combining technology at each link of the chain, stakeholders ensure perishable goods remain fresh and safe until they reach the end consumer.

Challenges and Future Directions

Implementing technologies for predicting spoilage without opening the package raises unique regulatory, safety, and practical considerations. Effective solutions must align with industry standards and address risks related to bacterial contamination that may escape detection.

Balancing Compliance and Technology Adoption

Food packaging innovations, such as smart indicators and AI-enabled sensors, must align with food safety regulations established by authorities like the FDA and EFSA. Compliance requirements may differ across regions, increasing the complexity for manufacturers operating internationally.

Adopting new technology involves navigating data security, labeling standards, and consumer transparency. Companies must validate that sensor-readouts and digital apps provide consistent and legally defensible results about product safety.

A comparison of smart packaging enforcement by region:

Region Regulatory Body Key Focus US FDA Food contact safety EU EFSA Material toxicology Asia National regs Local standards vary

Integration with legacy logistics systems and ensuring the interoperability of smart packaging with supply chain platforms also pose challenges. Updates to regulatory frameworks may be needed to fully approve emerging predictive technologies for spoilage.

Addressing Bacterial Risks in Emerging Solutions

Detection methods that do not directly touch the food may miss certain forms of bacterial contamination, such as pathogens hidden by packaging layers or environmental contamination not detected by external indicators. This limits the ability of non-invasive tools to guarantee food safety.

Some AI-based systems analyze images or volatile compounds, but may be less sensitive to low bacterial loads or non-uniform spoilage. It is crucial for these solutions to integrate with established microbiological safety protocols, such as periodic swab testing and validated shelf-life studies.

Key bacterial risks to monitor include:

Salmonella

Listeria monocytogenes

Escherichia coli

Continued research will focus on calibrating technology to reduce the risk of false negatives, and on ensuring that digital spoilage signals are interpretable by both regulators and consumers. Future solutions may combine sensor data with real-time analytics to improve detection of bacterial threats inside sealed packaging.