Ethylene Gas and Premature Ripening

Causes, Effects, and Prevention Tips

Ethylene gas plays a central role in triggering and accelerating the ripening of many fruits and vegetables. Elevated ethylene levels can cause produce to ripen—and spoil—much faster than intended, leading to significant losses during storage and transport. Knowing how ethylene affects ripening is essential for growers, distributors, and consumers who are interested in extending the shelf life of fresh produce.

Ethylene is released naturally by several fruits, such as bananas, apples, and tomatoes, especially as they mature. In environments where different kinds of produce are stored together, ethylene from one fruit can easily initiate ripening in others, sometimes causing premature softening, color change, or decay.

Understanding ethylene’s effect on produce allows people in the supply chain to make informed decisions about storage, handling, and the use of ethylene control technologies. This knowledge can help maintain quality and minimize waste, making the entire process more efficient from farm to table.

Understanding Ethylene Gas

Ethylene is a simple hydrocarbon gas that serves as a key regulator in plant growth and fruit ripening. Its effects are seen throughout the plant kingdom, particularly in the transformation and development of fruits.

Ethylene as a Plant Hormone

Ethylene is classified as a plant hormone, functioning as a signaling molecule within plant tissues.

It is unique because, unlike most hormones that are transported in solution, ethylene diffuses as a gas. Due to this property, ethylene can quickly move between plant cells and even between different plants in close proximity.

Its most notable impact is on fruit ripening, where it triggers a series of biochemical reactions that soften tissues and develop flavors. Ethylene also influences leaf abscission, flower wilting, and response to stress, but its central role in fruit maturation is economically significant.

Natural Ethylene Production in Plants

All higher plants naturally produce ethylene throughout their life cycle. The amount produced varies with species, plant part, and developmental stage.

Climacteric fruits such as bananas, apples, and avocados generate large bursts of ethylene during maturation. This rapid production accelerates ripening and can lead to premature spoilage if not managed.

Vegetables and flowers also produce ethylene, although often at lower levels. The presence of external sources of ethylene, such as ripening fruit nearby, can induce or speed up ethylene production in adjacent produce.

Ethylene Biosynthesis Pathways

Ethylene biosynthesis in plants is a well-characterized enzymatic process. It begins with the amino acid methionine, which is converted into S-adenosylmethionine (SAM).

The process continues when ACC synthase converts SAM to 1-aminocyclopropane-1-carboxylic acid (ACC). Then, ACC oxidase catalyzes the final step, converting ACC to ethylene gas.

Key Steps in Ethylene Biosynthesis:

Step Enzyme Intermediate/Product 1 None Methionine 2 — S-adenosylmethionine (SAM) 3 ACC synthase ACC 4 ACC oxidase Ethylene gas

The regulation of ACC synthase and ACC oxidase activity directly influences ethylene production rates, which is crucial in controlling ripening and senescence in plants.

Ethylene Gas and Fruit Ripening

Ethylene is a plant hormone that acts as a key regulator in the ripening process of many fruits. It triggers a range of physiological and biochemical changes that affect the texture, color, and taste of fruit as it matures.

Function of Ethylene in Fruit Ripening

Ethylene is a simple hydrocarbon gas, but it plays a central role in fruit development. When produced by fruits, especially at the onset of ripening, ethylene initiates a cascade of genetic and metabolic events.

This hormone stimulates the activity of specific enzymes that soften fruit tissue, convert starches to sugars, and enhance aromatic compounds. Ethylene also leads to increased respiration rates known as the climacteric rise in certain fruits, which speeds up internal changes.

Fruits react to ethylene at various stages, with increased sensitivity as they mature. Commercial facilities may carefully monitor and control ethylene exposure to influence the timing and uniformity of ripening.

Climacteric and Non-Climacteric Fruits

Fruits are often grouped based on their response to ethylene and the associated rise in respiration. Climacteric fruits—such as bananas, apples, tomatoes, and peaches—produce a burst of ethylene and show a significant increase in respiration during ripening.

They can be harvested when mature but unripe and will continue to ripen off the plant in response to ethylene. Non-climacteric fruits—like grapes, citrus, and strawberries—do not show such increases and are less responsive to external ethylene.

These fruits must ripen on the plant because they do not have the same internal system for continued ripening after harvest. Sensitivity to ethylene distinguishes these two categories and determines postharvest handling steps.

Colour Development and Sensory Changes

Ethylene triggers enzyme activity that leads to the breakdown of chlorophyll and synthesis of pigments such as carotenoids and anthocyanins. This process causes green fruits to turn yellow, orange, or red, signaling ripeness.

Besides impacting color, ethylene also affects the synthesis of sugars and acids. These biochemical changes improve the sweetness and flavor profile of fruits while reducing their firmness.

A summary table:

Change Biochemical Role Result Chlorophyll loss Enzyme activation Color development Starch to sugar Amylase stimulation Increased sweetness Cell wall breakdown Pectinase, cellulase Softening Acid modification Organic acid metabolism Improved flavor

Fruits that respond strongly to ethylene develop attractive colors, aromas, and tenderness, making them palatable and market-ready.

Premature Ripening and Spoilage Induced by Ethylene

Ethylene gas is a key factor in the timing of fruit ripening and can strongly affect shelf life and spoilage rates. When ethylene concentrations rise during storage or transport, produce can deteriorate rapidly, leading to significant post-harvest losses and food waste.

Mechanisms of Premature Ripening

Ethylene is a natural plant hormone involved in the ripening process. When fruits are exposed to elevated ethylene levels, the hormone binds to specific receptors in plant cells. This interaction initiates a cascade of enzymes that break down cell walls, convert starches into sugars, and degrade chlorophyll.

These biochemical changes are essential for ripening, but early or excessive ethylene exposure accelerates them prematurely. As a result, fruits may soften, develop full color, and produce characteristic aromas before they are ready for market or consumption. This process is not limited to climacteric fruits like bananas and tomatoes; non-climacteric produce can also experience changes that reduce their market value.

Transport and storage environments with poor ventilation can cause localized hotspots of ethylene, making careful monitoring of gas concentrations critical. Mixing ethylene-producing and ethylene-sensitive products in the same storage space increases the risk of unwanted ripening.

Premature Spoilage and Loss of Shelf Life

Premature spoilage occurs when fruits and vegetables overripen quickly after being harvested, leaving less time for distribution and sale. High ethylene concentrations are strongly linked to this shortened shelf life.

Signs of spoilage include excessive softening, color loss, water loss, and the development of unpleasant odors or flavors. Overripe produce becomes more susceptible to physical damage and microbial growth, which further contributes to food loss.

Producers often rely on ethylene management strategies, such as ethylene scavengers and temperature control, to reduce premature spoilage. Proper handling from harvest through distribution is essential to maintain quality and minimize waste. Limiting ethylene exposure can add days or even weeks to the commercial shelf life of certain perishable commodities.

Regulation of Ethylene Synthesis and Action

Ethylene production in plants is tightly regulated at both the biosynthesis and signaling levels, ensuring precise control over processes like fruit ripening and senescence. Specific proteins and genetic regulators are responsible for detecting ethylene and mediating its effects throughout the plant.

Ethylene Receptors and Signal Transduction

Plants possess multiple ethylene receptors, primarily located on the endoplasmic reticulum membrane. These receptors, such as ETR1 and ERS1 in Arabidopsis, bind ethylene gas and initiate a signaling cascade that alters gene expression.

Ethylene binding inactivates the receptors’ kinase activity, which in turn leads to the activation of downstream signaling proteins like CTR1, a Raf-like kinase. When CTR1 activity is inhibited, further downstream effectors (such as EIN2) become activated, propagating the signal to the nucleus.

The signaling cascade modulates the expression of ethylene-responsive genes, changing cell behavior. Key outcomes include regulation of fruit ripening, leaf abscission, and stress responses. Multiple receptor types allow fine-tuned responsiveness to changing ethylene levels.

Table: Major Ethylene Receptors in Arabidopsis

Receptor Location Function ETR1 Endoplasmic Reticulum Ethylene perception ERS1 Endoplasmic Reticulum Signal modulation

Role of ein3 and arabidopsis in Ethylene Research

The EIN3 protein is a critical transcription factor in the ethylene signaling pathway. In Arabidopsis, loss-of-function ein3 mutants fail to respond to ethylene, demonstrating its essential role. EIN3 directly activates the transcription of a set of ethylene-responsive genes upon signal reception.

Arabidopsis thaliana serves as the main model organism for studying ethylene signaling. Its well-characterized genetics and the availability of multiple mutants, including etr1, ctr1, and ein3, have contributed to mapping the ethylene pathway in detail.

EIN3 stability is tightly controlled, as the protein is rapidly degraded in the absence of ethylene. Upon ethylene exposure, EIN3 accumulates and orchestrates downstream transcriptional changes. Studies in Arabidopsis continue to inform research on ethylene function across diverse plant species.

Factors Affecting Ethylene-Induced Ripening

Ethylene gas plays a central role in the ripening of many fruits, but its effects are shaped by several critical factors. Temperature, humidity, and overall storage conditions determine the rate and uniformity of ethylene-induced ripening.

Impact of Temperature and Humidity

Temperature strongly influences how quickly fruits respond to ethylene. Higher temperatures generally accelerate the ripening process, while lower temperatures slow it down. For example, bananas ripen rapidly at temperatures above 20°C but will ripen much more slowly if kept below 15°C.

Humidity also has a direct impact. High humidity levels help maintain fruit firmness by reducing moisture loss, whereas low humidity can cause shriveling and texture changes. Keeping relative humidity around 85–95% is common in storage rooms to minimize desiccation.

Proper control of both temperature and humidity is essential in post-harvest handling to avoid uneven ripening and spoilage.

Effects of Environmental Conditions

Closed storage environments trap ethylene and allow its concentration to rise, which can cause faster and more uniform ripening across fruit batches. In contrast, open or ventilated spaces dilute ethylene, leading to slower and uneven ripening.

Other environmental factors, such as light exposure and air circulation, also contribute to the ripening process. In controlled storage, minimizing exposure to external pollutants and maintaining clean air further helps in managing the action of ethylene gas.

The use of chemical agents or ethylene-releasing systems in post-harvest facilities can be optimized by closely monitoring these environmental parameters, leading to improved fruit quality and lower spoilage rates.

Respiration and Senescence in Premature Ripening

Premature ripening of fruit is closely tied to shifts in respiration activity and the onset of senescence. Ethylene gas plays a critical role in accelerating both these physiological processes, affecting the quality and shelf life of produce.

Respiration Rate Changes

When fruit is exposed to ethylene, a marked increase in respiration rate often occurs. This surge, known as the "climacteric rise," leads to faster metabolic activity and the rapid breakdown of storage compounds like starches into sugars.

Key features of respiration rate changes in premature ripening:

Increase in CO₂ production: Ripening fruit can show a spike in carbon dioxide output as metabolic reactions intensify.

Early onset: In ethylene-sensitive (climacteric) fruits, these changes happen soon after ethylene exposure, even at lower concentrations.

Table – Comparison of Respiration Patterns

Fruit Type Normal Ripening Premature (Ethylene-Induced) Ripening Banana Steady rise Rapid, early spike Tomato Gradual peak Early high peak

This accelerated respiration can result in quicker softening and a shortened postharvest life due to faster resource consumption inside the fruit.

Advancement of Senescence

Senescence refers to the aging and eventual deterioration of fruit tissue. Ethylene hastens this process by altering gene expression related to cell breakdown, pigment changes, and membrane stability.

Visible signs of early senescence include loss of firmness, color changes, and the development of off-flavors. Cell walls degrade more quickly, and water loss is often more pronounced, resulting in shriveled or unappealing produce.

Premature senescence not only affects the outward appearance but also makes fruit more vulnerable to microbial infection and spoilage. This rapid aging limits distribution and marketing options for affected crops, increasing the risk of postharvest loss.

Detection and Measurement of Ethylene Gas

Accurate detection and measurement of ethylene gas are critical for managing ripening and reducing food spoilage. The most widely adopted techniques involve both direct and indirect methods, with gas chromatography and real-time monitoring playing central roles in quality control.

Gas Chromatography for Ethylene Detection

Gas chromatography (GC) is one of the most established techniques for ethylene gas analysis. It separates and quantifies volatile compounds in gas samples by passing them through a column and measuring detector responses. In ethylene detection, GC systems often include components such as pre-concentrators, SnO₂ detectors, and mass flow controllers.

This method allows for high sensitivity, with detection limits reaching as low as 15 parts per billion (ppb) under optimized conditions. GC’s precision is ideal for research, post-harvest monitoring, and storage facilities needing reliable results. However, the setup can be complex, requiring calibration, sample preparation, and technical expertise.

A typical workflow includes collecting gas from around produce, injecting it into the GC system, and analyzing the output. Results are quantitatively displayed, enabling the identification of trends and potential issues with premature ripening.

Monitoring Ethylene Concentrations

Continuous or periodic monitoring of ethylene concentrations is vital for industries handling perishable produce. Concentrations below 1 part per million (ppm) can already influence ripening rates for many fruits and vegetables. Real-time monitoring systems, such as photoacoustic or sensor-based devices, provide ongoing feedback to operators.

Modern ethylene sensors offer linear responses across a wide range, typically from 0.5 to 50 ppm. Devices used in storage facilities are often designed for robustness, showing negligible performance loss over several days of operation. Data from these monitors are used to fine-tune ventilation and storage practices.

Table: Ethylene Gas Concentration Ranges and Their Effects

Concentration (ppm) Effect on Produce <1 Initiates ripening 1–10 Accelerated ripening >10 Possible spoilage, decay

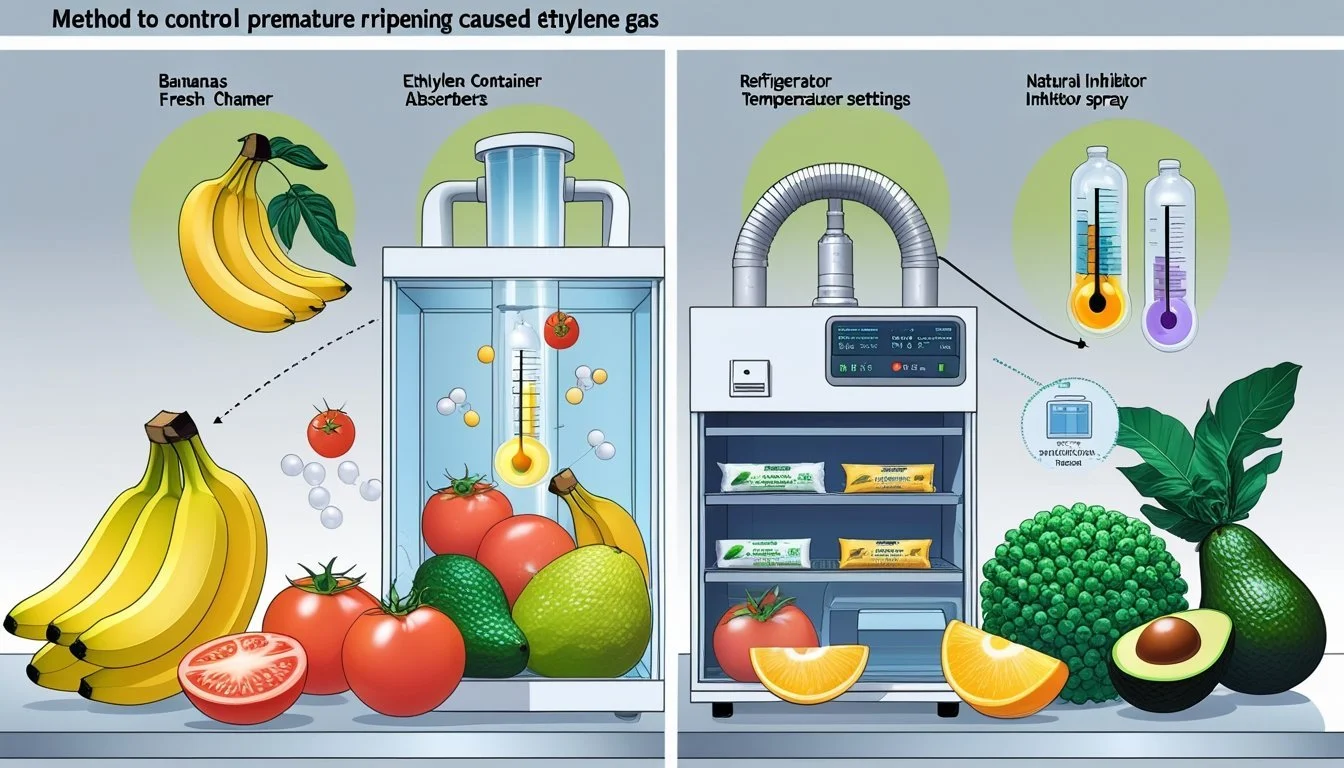

Methods to Control Premature Ripening

Managing ethylene gas levels is essential to slow down fruit and vegetable ripening during storage and transport. A combination of ethylene removal technologies and proper cooling methods reduces spoilage and maintains produce quality.

Technologies for Ethylene Removal

Several technologies are used in storage rooms and containers to reduce ethylene concentrations and delay ripening:

Ethylene scrubbers use chemical agents such as potassium permanganate to oxidize and remove ethylene from the air. These scrubbers are often placed in storage rooms or packaging units to keep ethylene-sensitive produce from ripening prematurely.

Ozone generators offer a different approach by producing ozone gas, which reacts with and breaks down ethylene molecules. Ozone must be carefully controlled, as excessive ozone can damage produce or create safety concerns.

Some facilities use activated carbon or other filtration media to absorb ethylene. These systems are installed in ventilation systems and require periodic replacement or reactivation to remain effective.

Ethylene removal methods are chosen based on facility size, produce type, and cost considerations. Regular monitoring of ethylene concentration is important to ensure that these systems are working as intended.

Cold Storage and Refrigerated Containers

Maintaining produce at low temperatures is one of the most effective ways to reduce ethylene production and slow ripening. Cold storage rooms and refrigerated containers are standard for extending shelf life during transport and storage.

Temperature settings are adjusted based on the needs of different fruits and vegetables. Many cold storage facilities also use controlled atmosphere practices, which may involve reducing oxygen levels and increasing carbon dioxide to further slow respiration and ethylene synthesis.

Proper airflow and humidity control are important to prevent condensation, reduce the risk of mold, and evenly distribute cold air. Some modern storage units combine refrigeration with ethylene removal technologies for enhanced protection against early ripening.

Routine equipment checks and temperature monitoring are essential to ensure that storage conditions remain consistent and that produce quality is preserved throughout the supply chain.

Additional Effects of Ethylene on Plant Biology

Ethylene gas influences many aspects of plant function beyond ripening. It affects how plants grow, form structures, and interact with their environment, while also playing a role in how seeds sprout and utilize nutrients.

Ethylene’s Role in Plant Growth and Development

Ethylene regulates key growth processes in plants, including stem elongation, root development, and leaf movement. During germination, it can promote the formation of adventitious roots and root hairs, crucial for water and nutrient uptake.

Fruit ripening is a widely recognized effect, but ethylene also contributes to leaf abscission and flower opening. It can trigger senescence, leading to programmed leaf and flower death, which is important for nutrient recycling.

Ethylene also modulates growth responses to environmental stress. For instance, during flooding, it helps plants adjust by promoting growth changes like leaf epinasty (downward bending) to avoid submersion.

Key ethylene-regulated growth processes:

Fruit ripening and flower opening

Leaf abscission and senescence

Root and shoot architecture changes

Influence on Seed Germination and Nutrients

Ethylene can break seed dormancy, allowing seeds to germinate when conditions are right. It works by stimulating physiological changes that prepare the seedling for growth, such as enhancing cell expansion and enzyme activity.

The hormone also influences nutrient mobilization within seeds. By triggering enzymes that release stored nutrients, ethylene makes essential compounds available for the developing seedling.

Ethylene’s control over root hair formation aids in nutrient absorption from soil. This results in more efficient uptake of minerals like nitrogen and phosphorus, critical for early plant development.

Highlighted roles in germination and nutrient use:

Breaking dormancy and triggering sprouting

Activating nutrient-releasing enzymes in seeds

Promoting root hair development for mineral absorption