How Smart Labels Detect Food Degradation and Ensure Freshness

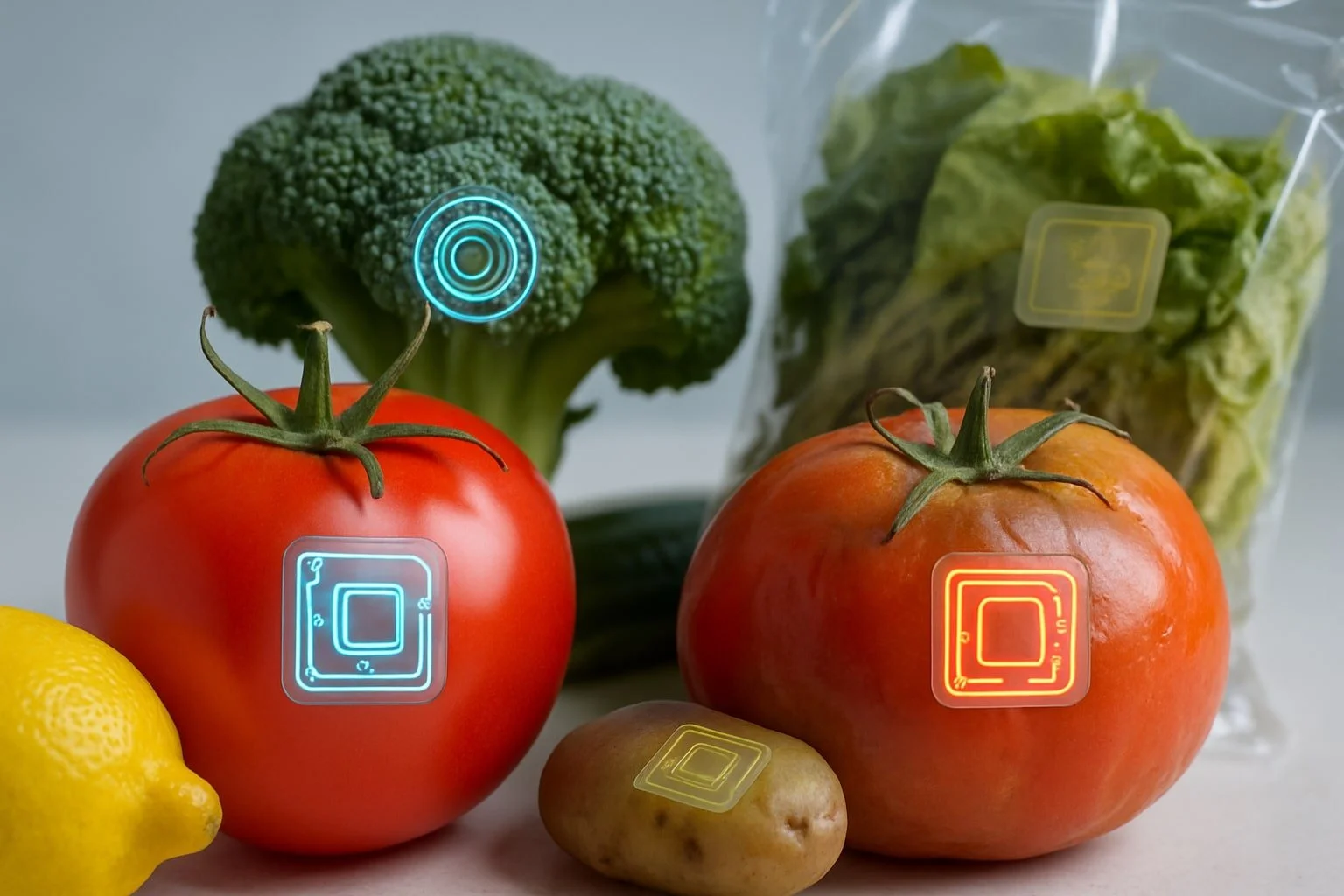

Smart labels are changing the way the food industry monitors product freshness and safety. Using sensors and indicators built into food packaging, these labels provide real-time information about food degradation that consumers and suppliers can easily understand. Smart labels detect changes such as gas emissions or pH shifts caused by microbial or chemical breakdown, giving a clear cue—often through a visible color change—when food quality begins to decline.

These innovative labels use technologies like printed sensors and flexible circuits, making them suitable for perishable products. By responding to gases or other byproducts released during spoilage, smart labels deliver a simple yet effective freshness indicator. This helps prevent food waste and ensures that consumers can quickly assess the safety of what they are about to eat.

Interest in smart packaging has grown rapidly, as both retailers and consumers seek trustworthy ways to monitor shelf life. With easy-to-read signals on the packaging itself, smart labels bring valuable transparency and convenience to the modern food industry.

Principles Of Smart Label Technology

Smart labels use embedded sensors and intelligent materials to monitor specific indicators of food degradation, like temperature, freshness, and gas levels. Their design and material composition play a central role in how they function and what type of information they provide.

How Smart Labels Work

Smart labels are integrated into packaging to track chemical or physical changes associated with food spoilage. They operate by detecting triggers such as changes in temperature, pH, oxygen, or carbon dioxide levels within the food environment.

Most smart labels visually communicate information through color changes, digital readouts, or scannable QR codes. Visual cues, such as a shift in color, give quick feedback to consumers and retailers about the product’s condition.

Some advanced labels employ biosensors that react with specific degradation products or microbial activity. These biosensors convert biological reactions into measurable signals. This enables real-time, non-destructive monitoring of food safety and quality without opening the package.

Types Of Smart Labels

There are two primary types: indicator labels and sensor labels. Indicator labels typically use color-changing agents that respond to freshness or temperature thresholds. For example, time-temperature indicators (TTIs) reveal if food has been kept within a safe temperature range.

Sensor labels go a step further, using electronic or chemical sensors to detect gases or spoilage markers. These can include oxygen, carbon dioxide, or compounds produced during food degradation. Biosensor-based labels specifically detect biological changes, such as enzyme activity or the presence of pathogens.

Below is a simple outline of main types:

Type Main Function Example Use Indicator Labels Visual indicator of freshness or temperature Meat, dairy Sensor Labels Detect specific gases or spoilage compounds Packaged produce Biosensor Labels Sense microbial activity or proteins Seafood, ready meals

Components And Materials

Smart labels are constructed from a combination of sensors, intelligent materials, and biopolymers. The sensing elements may incorporate chemical reagents, colorants, or microelectronic circuits. These components respond to changes in food quality by emitting signals or changing appearance.

Many smart labels use biopolymers as substrates due to their flexibility, non-toxicity, and compatibility with food contact requirements. Common materials include cellulose, chitosan, and other biodegradable polymers.

Supporting components like adhesives and protective films help preserve the accuracy and stability of the label during storage and handling. The selection of materials is critical to ensuring the label’s sensitivity and safety for food applications.

Detection Mechanisms For Food Degradation

Smart labels use a variety of detection methods to identify food spoilage. These mechanisms target chemical, biological, and physical changes that signify degradation, helping consumers and suppliers maintain food quality and safety.

Chemical Detection Methods

Chemical detection methods often involve chemical sensors that react to gases and compounds produced during food spoilage. These sensors are specifically designed to quantify indicators such as ammonia (NH₃), trimethylamine (TMA), and biogenic amines, which commonly arise from protein degradation.

Smart labels utilizing chemical agents may change color or display digital readings when exposed to target chemicals. For example, a colorimetric sensor might shift from green to blue in the presence of increasing volatile amines. The detection process is typically direct and rapid.

The table below shows common chemical indicators detected by sensor smart labels:

Indicator Relevance to Spoilage Ammonia (NH₃) Protein decomposition TMA Seafood spoilage Ethanol Fermentation and yeast activity Biogenic amines General protein spoilage

These chemical sensors are crucial for spoilage detection in meats, seafood, and dairy products.

Biological Detection Methods

Biosensors on smart labels are engineered to detect the presence of microbial agents that cause foodborne illness or spoilage. These biosensors incorporate biological recognition elements, such as enzymes, antibodies, or nucleic acids, to bind specifically to microbial contamination.

Detection can involve identifying enzymes produced by bacteria, antigen–antibody interactions, or even genetic material from microorganisms. When these agents are present, the biosensor generates a measurable signal, often visible as a color change or electronic output.

Biosensor-based detection is particularly valuable in monitoring milk, cheeses, and fresh produce, where microbial growth is a major concern. They enable prompt action before visible spoilage appears, thus supporting food safety.

Physical Detection Methods

Physical detection methods rely on measuring changes in the physical properties of food or packaging, such as temperature, humidity, or gas permeability. Sensor smart labels may monitor for package swelling, compromised seals, or deviations in storage conditions linked to spoilage risk.

Common physical sensors include RFID tags that track temperature history or humidity-sensitive films that change texture or color. These labels can record cumulative exposure to conditions that favor microbial contamination or chemical reactions, offering an indirect warning system.

Physical methods serve as an added layer, supporting chemical and biological detection by indicating potential breaks in the cold chain or other mishandling that could accelerate food degradation.

Sensors And Indicators In Smart Labels

Smart labels use specialized sensors and indicators to monitor key factors that affect food quality. They are designed to give real-time visual or digital feedback on changes that signal degradation.

Colorimetric Sensing

Colorimetric sensing in smart labels relies on color change to report food freshness and quality. These labels often use natural pigments, such as anthocyanins, or synthetic chemical agents that react to spoilage byproducts.

For example, a color-sensitive smart label may shift from green to yellow as volatile gases increase, signaling microbial activity. The response is typically visual, making it clear for consumers and supply chain managers.

Colorimetric indicators are valued for their simplicity and low cost. Their performance depends on how sensitive the chemicals or pigments are to the target substances, such as ammonia or hydrogen sulfide from spoiled proteins.

Most color-sensitive labels are printable and flexible, allowing easy integration with various packaging formats. They offer a direct way to observe food degradation without any special equipment.

pH Monitoring And Sensors

pH sensors in smart labels detect changes in acidity, which often signals spoilage. As foods begin to degrade, pH levels shift due to the formation of organic acids or bases from microbial and chemical reactions.

These labels include pH-sensitive indicators that respond to these shifts, often via visible color change. Natural pigments, like anthocyanins, are commonly used because they change color across different pH levels.

Such sensors are especially useful for products like meat, fish, and dairy, where spoilage is closely associated with pH fluctuations. The ability to monitor pH in real-time offers both manufacturers and consumers better information about the remaining shelf life and possible safety risks.

Their effectiveness is influenced by the stability of the indicator and the compatibility with the packaged food.

Temperature-Sensitive Smart Labels

Temperature-sensitive smart labels track the thermal history of food products by reacting to cumulative temperature exposure. Many use time-temperature indicators (TTIs) that change color depending on how long and how intensely the product has been exposed to non-ideal temperatures.

These indicators often contain chemical agents or polymeric materials that undergo a predictable and irreversible color shift. Some labels also use embedded electronics for more precise readings, though most remain visual and passive for cost and simplicity.

Temperature monitoring is vital because many pathogens and spoiling processes are temperature-dependent. These labels help identify if products have been kept outside safe storage conditions.

Integration with existing packaging is typically straightforward, and manufacturers can select labels that match the needs of specific products. The response of these labels is permanent, providing a clear record for stakeholders throughout the supply chain.

Smart Labels In Active And Intelligent Packaging

Smart labels are essential tools in advancing food packaging. They help maintain food safety, monitor product conditions, and extend shelf life using specialized materials and technologies.

Active Packaging Technologies

Active food packaging includes materials that interact with food or the surrounding environment to preserve quality and safety. Common features of active packaging are oxygen scavengers, moisture absorbers, and carbon dioxide emitters.

Antioxidant and antimicrobial agents are often embedded in packaging materials to reduce spoilage and inhibit microbial growth. Ethylene scavengers in fruit packaging slow down ripening and prevent premature spoilage.

Smart labels in active packaging may change color or display signals when exposed to specific conditions, such as increased temperature or oxygen levels. These indicators help detect early food degradation by providing real-time visual cues to both retailers and consumers.

Intelligent Food Packaging Systems

Intelligent food packaging uses smart labels and sensors to monitor, record, and communicate the actual status of food products. These systems provide dynamic feedback about freshness, temperature history, and possible contamination.

Key features of intelligent food packaging:

Time-temperature indicators (TTIs): Visual cues that show if a product experienced unsafe heat.

Gas indicators: Detect changes in gases like oxygen or carbon dioxide inside packaging.

RFID tags and barcodes: Store and transmit data about storage conditions and product origin.

For example, a QR code may link to real-time data about a product’s journey, while biosensors can detect spoilage bacteria. This enables smarter inventory decisions and gives consumers accurate, actionable information.

Edible Films And Biopolymer Use

Edible films and biopolymers serve as both protective and intelligent packaging materials. They are derived from natural sources such as proteins, polysaccharides, and lipids.

These films can be infused with antimicrobial properties or antioxidants, helping extend shelf life while remaining safe for consumption. Some edible films are designed to carry intelligent indicators, such as pH-sensitive dyes, which signal spoilage by changing color in response to chemical changes in the food.

Biopolymer-based smart packaging reduces reliance on traditional plastics. In addition to reinforcing food safety and sustainability, they can provide real-time visual feedback that assists in quick assessment of product freshness.

Key Food Degradation Indicators Detected

Smart labels monitor several measurable changes linked to food spoilage and safety. These technologies rely on physical, chemical, and biological indicators that are known markers of product degradation or contamination.

Microbial Growth And Contamination

Microbial growth is a leading cause of food spoilage and can signal the presence of harmful pathogens, such as Salmonella, Escherichia coli, and Listeria monocytogenes. Smart labels often detect degradation by responding to by-products generated by these organisms.

Sensors can identify rapid microbial proliferation by measuring shifts in pH or the presence of organic acids. Some labels use color-changing dyes that react to microbial metabolic activity. Visual signals provide a simple method for consumers and suppliers to assess potential contamination without relying on laboratory tools.

Biological indicators embedded in packaging are especially important for perishable goods like meat and dairy where pathogenic bacteria pose serious health risks. This early detection capability aims to prevent illness from spoiled or contaminated foods.

Gas Concentration Changes

Smart labels are frequently designed to monitor changes in gas concentrations inside food packaging. Shifts in key gases like carbon dioxide (CO₂), oxygen (O₂), and ethylene serve as vital freshness indicators.

For example, increased CO₂ concentration can signal active microbial metabolism and ongoing spoilage. Low O₂ levels may indicate package leakage or the start of anaerobic microbial activity. Ethylene content, particularly important in fruit and vegetable packaging, accelerates ripening and can hasten the onset of spoilage if levels are too high.

Gas sensor integration enables real-time monitoring, helping to maintain safe storage environments and alerting stakeholders to possible degradation events.

Chemical Degradation

Chemical changes are a hallmark of food spoilage and degradation. Smart labels use indicators that detect alterations in chemical composition, such as shifts in pH, accumulation of organic acids, and the presence of specific spoilage molecules.

Common approaches include colorimetric strips capable of registering even slight pH changes resulting from microbial fermentation or natural aging processes. Some smart labels monitor oxidized compounds or lipid degradation products in high-fat foods.

These chemical indicators give insight into both the age and quality of consumables, supporting informed decisions around shelf life and safe consumption.

Protein And Amines Monitoring

Protein degradation produces biogenic amines, such as putrescine and cadaverine, which serve as direct markers of spoilage in protein-rich foods. Smart labels are now equipped to detect elevated amine concentration through sensitive chemical or sensor-based reactions.

Amine detection is particularly useful in meat, fish, and cheese products where protein breakdown drives food spoilage. Some labels utilize indicator compounds that change color in the presence of amines, allowing for rapid and easy assessment of freshness.

By tracking both overall protein degradation and amine levels, smart labels help minimize the risk of consuming unsafe foods and reduce unnecessary waste. These tools enhance food safety through continuous, real-time surveillance of product quality.

Applications Of Smart Labels In Food Sectors

Smart labels are increasingly used throughout the food industry to monitor freshness, reduce food waste, and provide actionable information on product quality. Their integration allows for real-time assessment based on measurable indicators such as temperature, humidity, and gas emissions.

Meat And Seafood Quality Management

Smart labels are commonly applied to meat and seafood packaging to help maintain optimal food quality. They monitor environmental conditions like temperature and pH, which are key indicators of spoilage.

Sensors within these labels can detect shifts that occur as meat and seafood degrade. By tracking these parameters, processors and retailers can quickly identify when products are nearing the end of their shelf life.

This approach reduces the risk of selling unsafe or poor-quality meat and helps maintain transparent supply chains. Customers benefit from clearer insights into freshness, supporting informed purchasing decisions.

Dairy Product Freshness Control

Dairy products are highly perishable and sensitive to temperature variations. Smart labels enable real-time freshness monitoring by tracking temperature abuse or deviations from ideal storage conditions.

Some labels are equipped with time-temperature indicators that reflect cumulative exposure to unsuitable conditions. If a dairy product sits too long outside cold storage, the label will signal potential degradation, helping prevent the sale of spoiled items.

Retailers and suppliers use this information to improve their inventory management practices. It minimizes waste and protects consumers from the health risks associated with spoiled dairy.

Fruit And Vegetable Inspection

Fresh fruit and vegetables can lose quality quickly due to fluctuations in temperature and humidity. Smart labels help by regularly assessing environmental conditions throughout the supply chain.

These labels may include color-changing indicators to visualize freshness for handlers and consumers. Tracking gas emissions, such as ethylene, is also possible, which is important for early detection of ripening or spoilage.

Such applications streamline the distribution process by signaling when produce needs to be moved, sold, or discarded. This level of inspection improves shelf life and reduces losses for producers and retailers.

Industrial Baking And Other Sectors

In industrial baking, smart labels are used to ensure baked goods maintain their desired freshness and quality after production. These products are susceptible to moisture changes and staling if not stored properly.

Labels in this sector can measure humidity and temperature inside packaging. By tracking these parameters, bakeries and distributors can quickly detect deviations that impact product quality.

Other sectors, such as ready-to-eat meals and packaged salads, use smart labels to monitor for spoilage and maintain food safety standards. This provides assurance to both retailers and consumers regarding the quality of these products.

Role Of Smart Labels In Food Safety And Quality Control

Smart labels are transforming how food producers and retailers monitor quality, enhance traceability, and meet safety standards. These labels provide real-time indicators and data that allow for immediate action to reduce risks and ensure consumer trust.

Preventing Foodborne Illnesses

Smart labels play a significant role in minimizing foodborne illness by monitoring environmental factors and spoilage indicators. Using embedded sensors, these labels can detect changes in temperature, humidity, or gas concentrations such as oxygen and carbon dioxide.

If food is exposed to unsafe temperatures during storage or transport, the label can change color or send a digital alert, signaling potential growth of harmful pathogens. This immediate visibility enables workers to remove or address compromised products before they reach consumers.

By tracking freshness and identifying breaches in the cold chain, smart labels help lower the likelihood of bacterial contamination, such as Salmonella or Listeria. They provide direct quality monitoring at every stage of the supply chain.

Allergen And Contaminant Detection

Certain smart labels can detect the presence of specific allergens or contaminants in packaged foods. These labels use biosensors that recognize target molecules, such as peanut proteins or pesticide residues, and trigger visual or electronic alerts.

Example: A smart label embedded with an antibody-based sensor can detect trace amounts of gluten, instantly warning individuals with celiac disease.

This technology increases product transparency and helps prevent accidental allergen exposure, a leading cause of food recalls. By alerting consumers and workers to unintended ingredients or chemical contamination, smart labels aid in managing risks and reducing the incidence of allergen-related emergencies.

Regulatory Compliance

Regulatory agencies require strict monitoring of food safety and traceability. Smart labels help companies comply with these regulations by recording and transmitting critical data—such as time-temperature history, batch information, and handling conditions—through RFID or QR codes.

Digital documentation provided by smart labels streamlines quality control processes and audit trails. For example, blockchain-enabled smart labels create tamper-proof records for inspectors and regulatory authorities.

This improves supply chain transparency and makes it easier to identify the source of contamination in recall situations. By supporting accurate recordkeeping and validation, smart labels align with evolving food safety laws and standards worldwide.

Improving Food Preservation And Reducing Waste

Smart labels play a direct role in maintaining food quality and minimizing unnecessary discard by providing timely, accurate information on product freshness. These technologies support more precise decisions throughout the supply chain and at the consumer level.

Shelf Life Extension

Smart labels help extend the effective shelf life of products by monitoring real-time indicators of spoilage. Unlike fixed expiration dates, these labels track factors such as pH, bacterial growth, and biogenic amines. This information allows manufacturers and retailers to adjust storage or display based on actual conditions.

The dynamic data generated by smart labels means food is only removed from sale when it truly degrades. Some systems use visual cues like color changes, simplifying the process for staff and consumers. By identifying and responding to specific spoilage markers, overall shelf life management becomes more accurate and less wasteful.

Key monitored indicators:

Indicator What It Reveals pH Levels Acidic changes from spoilage Bacteria Growth Microbial contamination Biogenic Amines Protein breakdown

Reduction Of Food Waste

Smart labels help address the issue of premature food disposal. By continually updating food status, these technologies provide a more precise assessment of freshness than printed dates.

Retail staff and consumers are less likely to discard safely edible products. As a result, businesses can sell items closer to actual spoilage, reducing losses and keeping edible food out of landfills. In some cases, retailers use the updated information from smart labels to discount products nearing the end of their shelf life, improving inventory turnover.

These methods help minimize food waste at multiple points, from warehouses to households. Efficient labeling directly translates to better use of natural and financial resources.

Cold Chain Logistics

Cold chain logistics rely heavily on temperature stability to preserve food safety. Smart labels integrate temperature sensors and spoilage indicators to ensure products stay within safe ranges during transport and storage.

If any temperature abuse occurs—such as during loading, unloading, or transit—the smart label responds by registering changes in spoilage indicators. This allows immediate intervention, such as removing compromised items before reaching consumers.

Key benefits:

Greater transparency throughout the cold chain

Faster detection of handling issues

Increased confidence for all stakeholders

Immediate feedback from smart labels reduces risks related to fluctuating temperatures and supports robust cold chain management.

Innovations In Smart Labelling And Packaging Technology

Recent advancements in food packaging are reshaping how products are monitored for quality and safety. Technologies such as nanomaterials, integrated electronics, and traceability systems are increasingly used in commercial smart labels and sensors.

Advances In Nanomaterials

Nanomaterials are improving the sensitivity and functionality of smart labels. By using nanoparticles, such as silver, gold, or carbon-based nanomaterials, smart labels can detect chemical changes resulting from food spoilage.

These materials enable the detection of gases like ammonia or sulfur compounds, which are early indicators of protein degradation in meat or fish. Some labels use color-changing nanomaterial films that visually signal contamination or unsuitable storage conditions.

Key benefits of nanomaterials in smart labels:

Enhanced sensitivity to trace compounds

Faster response times for degradation detection

Ability to be incorporated into thin, flexible packaging layers

This technology reduces the need for additional plastics or bulky sensors while providing reliable food status indicators at a glance.

Integration With Electronic Technology

The integration of microwire, RFID (Radio Frequency Identification), and NFC (Near Field Communication) technology has enabled real-time monitoring through electronic smart labels. These electronic components can record time, temperature, and humidity data directly from the package, transmitting information to mobile devices or cloud systems.

Many labels now include printed circuits using conductive inks, allowing cost-effective sensor arrays within standard packaging materials. Some systems are paired with mobile apps, providing alerts related to expiry dates or when certain safety thresholds are exceeded.

Examples of electronic features in smart labels:

RFID tags for batch tracking and recall readiness

Digital expiry labels with interactive displays

Wireless temperature and humidity sensors embedded within the packaging

This integration promotes proactive food safety management and reduces food waste by delivering accurate product status information.

Intelligent Systems For Traceability

Traceability systems combine unique identifiers, such as QR codes or blockchain tags, with smart labelling to offer end-to-end tracking throughout the food supply chain. By scanning labels, manufacturers, retailers, and consumers can access detailed data about a product’s origin, handling conditions, and shelf life.

These systems can capture and store events including production date, storage temperature, and distribution routes. Some platforms use blockchain to ensure that traceability data is tamper-resistant.

Core features of intelligent traceability systems:

Comprehensive data access for every step in the supply chain

Fast, targeted recalls if contamination is detected

Transparency that supports regulatory compliance and consumer trust

With the support of smart sensors recording environmental parameters, traceability becomes both more accurate and accessible, transforming how the freshness and safety of food are managed.

Challenges And Future Directions

The development and adoption of smart labels for food degradation detection face clear technical, market, and regulatory obstacles. Technical reliability, standardization, commercialization, and consumer trust are central to the advancement of these technologies.

Standardization And Quality Assurance

A major challenge is the lack of unified protocols and standards for smart label sensors. Different manufacturers use varied detection methods and indicator substances, making results inconsistent across products. This hinders accurate comparison and widespread adoption.

Reliable quality control procedures are essential for these labels, especially for food safety applications. Ensuring consistent sensor performance, such as reproducibility and sensitivity in detecting freshness indicators (like pH shifts or microbial metabolites), is a persistent issue. Regulatory oversight is still catching up, with limited harmonization on safety, labeling, and testing requirements internationally.

Efforts are underway to develop universal assessment criteria and certification processes. Standardized calibration methods, validated reference materials, and clear performance benchmarks can help align industry practices. This will improve trust among producers, retailers, and regulatory bodies.

Commercialising Smart Labels

Bringing smart label technologies to market requires overcoming several business and technical hurdles. Scaling up production must address the cost of advanced materials, like biosensors and nanomaterials, which currently keep prices high. Manufacturing at scale also requires reliable integration with packaging lines without slowing processes.

List of core commercial challenges:

Maintaining low-cost production while ensuring high-quality sensor output

Achieving sensor stability across diverse food types and storage conditions

Navigating complex regulatory landscapes in different countries

Manufacturers must balance cost, accuracy, and durability to make these labels commercially viable. Partnerships with major food brands and packaging companies can help drive adoption, but require proof of consistent performance and measurable value in reducing food waste or fraud.

Consumer Acceptance And Market Trends

Consumer trust is vital for the success of smart labels. People want clear, easily interpreted information about food quality and safety. However, awareness of smart label technologies remains limited, and some consumers express skepticism about sensor reliability or new labeling systems.

For market growth, it is essential to focus on easy-to-understand visual cues and unambiguous instructions. Retailers and brands are beginning to pilot QR codes and digital expiry systems, helping educate users and drive acceptance. Transparent communication about how labels work, data privacy, and real-world benefits is critical to increase consumer confidence.

Market trends suggest growing demand for freshness and sustainability information. Smart labels must adapt to shifting consumer preferences, including more informative and interactive solutions that align with concerns over food waste and transparency.