On-Farm Meat Processing, Butchering and Slaughter in Arkansas

A Guide to Local Practices

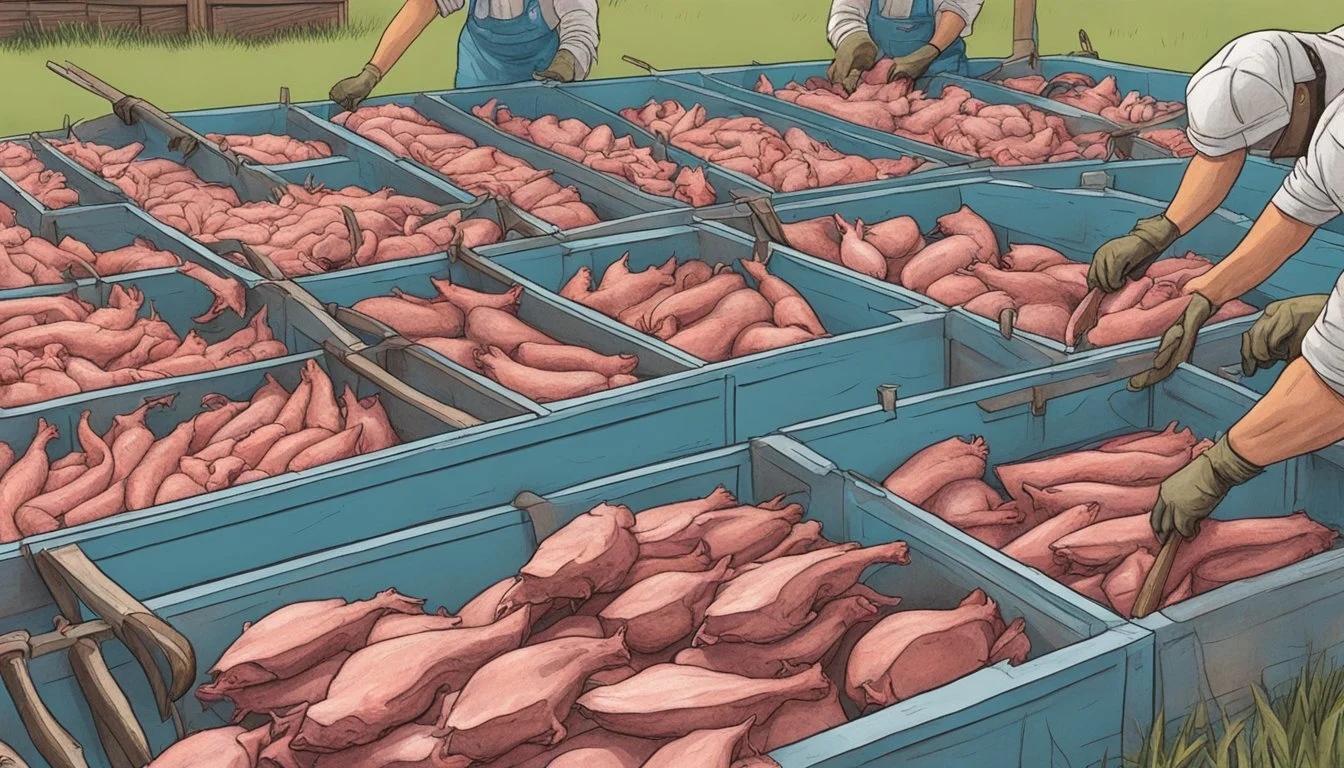

On-farm meat processing in Arkansas marks a significant development in the agricultural sector, responding to a growing need for local food systems and sustainable farming practices. As such operations flourish, they serve not only to bolster the local economy but also to ensure that humane and ethical standards of animal slaughter and butchering are upheld. Arkansas farmers, by adopting on-farm processing, are revitalizing an industry that allows for closer control over the meat production process, aligning with consumer demands for traceability and quality.

Such on-farm facilities range from mobile slaughtering units to permanent onsite processing establishments, offering versatile options that cater to different scales of operation. They present unique opportunities and challenges, involving stringent regulatory compliance to ensure food safety and quality. For many farmers in Arkansas, the move towards on-farm processing, while labor-intensive, has been a strategic decision to capture more value, create jobs, and support the supply chain directly within their communities.

The Cypress Valley Meat Company is an example of how attention to detail in meat processing and commitment to worker investment can be successfully achieved in Arkansas. Concurrent initiatives by the USDA to provide more grants to meat and poultry processors exemplify federal support to expand and transform the industry, facilitating these businesses to thrive. Despite the complexities involved, Arkansas's on-farm meat processing embodies an integral shift in meat production that speaks to a future of greater resilience and self-reliance in agriculture.

Framework of On-Farm Meat Processing

The framework of on-farm meat processing in Arkansas is shaped by a network of regulations and practices that ensure food safety, animal welfare, and sustainable industry development. This framework guides producers through meticulous processes to maintain a viable and responsible meat supply chain.

Licensing and Regulations

In Arkansas, on-farm meat processors must adhere to state and federal regulations. The USDA Food Safety and Inspection Service (FSIS) oversees licensing requirements to ensure that facilities comply with standards resembling those of commercial slaughterhouses. Meanwhile, state-specific licenses and exemptions, depending on the scale and distribution, can be acquired through the Arkansas Department of Health.

Animal Health and Welfare

It is mandatory for livestock to be handled humanely and slaughtered with minimal distress. State regulations incorporate animal welfare guidelines that align with federal recommendations. Producers must be trained in humane handling and slaughtering techniques to promote animal welfare.

Food Safety Standards

Preventing foodborne illnesses is a priority with strict sanitation protocols in place to combat pathogens such as E. coli O157, Salmonella, and Campylobacter. On-farm meat processors must implement Hazard Analysis Critical Control Point (HACCP) plans to systematically manage food safety risks.

State-Specific Guidance and Resources

Resources for Arkansas producers are available through extensive extension services which offer guidance documents and workshops (refer to links such as go.osu.edu/onfarmeatprocessing). These cover local regulations, licensing procedures, as well as best slaughtering and butchering practices.

Outbreak Response and Management

During health crises, such as the COVID-19 pandemic, Arkansas’s on-farm meat processors are equipped with response plans. This reduces disease transmission risks and addresses potential processing bottlenecks that affect food supply.

Economic Impact and Market Dynamics

Small-scale, local processes like on-farm slaughter can influence the meat market's economic landscape. They provide resilience against market volatility by maintaining local meat supply chains and can improve financial returns for producers.

Environment and Sustainability Practices

On-farm processors are also responsible for environmentally sustainable practices, including waste management. Proper sewage treatment and disposal methods are integral to maintaining ecosystem health.

Education and Extension Services

Educational programs and Extension services, such as those provided by the University of Arkansas Division of Agriculture, play a crucial role in training for best practices in meat processing and butchering.

Industry Examples Outside Arkansas

Looking beyond Arkansas, states like California, Colorado, and Washington State showcase diverse models of on-farm processing facilities from mobile slaughtering units to permanent on-site facilities.

The Role of Technological Innovation

Technology plays a vital role in enhancing food safety, traceability, and efficient operation within on-farm meat processing. It streamlines processes, contributing to the scalability and sustainability of local meat production.

Case Studies and Best Practices

Examples of successful on-farm meat processing operations can provide valuable insights. Best practices identified through analysis help shape effective business models and safety protocols for new and existing facilities.

Section

The intricacies of on-farm meat processing in Arkansas encompass a wide array of considerations, from legal compliance to ethical practices, and span to various operational and business aspects. This section aims to provide specific insights into each critical element that stakeholders involved in on-farm meat processing should be aware of.

Legality and Compliance

In Arkansas, meat processing is subject to state and federal laws to ensure safety and quality. Farmers and ranchers must operate within these boundaries, which includes obtaining necessary permits and passing inspections. Custom exempt processing facilities are permitted to operate under certain conditions, primarily servicing livestock owners exclusively for personal consumption without the meat entering commerce.

Ethical Considerations

When slaughtering animals, it is paramount to do so humanely. Standards for ethical treatment require minimizing stress and pain to the animal, which in turn can affect meat quality. Proper training in humane handling and butchering techniques is important for all individuals involved.

Business Models and Operational Setup

On-farm processing ventures may vary in scale, from small processors serving local communities to larger operations. Producers must carefully design their business model, considering aspects such as supply chain logistics, cost-management, and market demands for various species like cattle, sheep, goats, and swine.

Species-Specific Processing Information

The butchering and processing of livestock are subject to species-specific guidelines. For example, processing cattle for beef requires different facilities and equipment compared to processing sheep or goats.

Supply Chain and Logistics

The supply chain for on-farm meat processing involves coordination from slaughter through cut and wrap to distribution. Reliable logistics ensure the meat reaches consumers promptly while maintaining quality and freshness.

Butchering Techniques and Meat Handling

Effective butchering techniques are critical for optimizing meat yield and maintaining hygiene. Meat handlers must also understand safe practices to prevent cross-contamination and spoilage, ensuring consumer safety.

Consumer Education and Public Relations

Educating consumers about the source and processing of their meat can foster trust and transparency. Arkansas producers and processors often engage with the local community to highlight the benefits of local, fresh meat from well-managed facilities.

Risk Management

Operators must have plans to mitigate risks associated with on-farm processing, such as financial losses, carelessness in processing, or disease outbreaks. Insurance and continual training can be part of effective risk management.

Health and Disease Control

Regular monitoring for animal health and potential pathogens is crucial. Livestock meat inspectors work to assure that health standards are met to prevent disease transmission from animals to humans.

On-Farm Processing Roles and Employment

On-farm meat processing provides various employment opportunities. Roles can range from slaughtering and butchering to administrative tasks within the processing facility, all of which require specific training and adherence to regulatory standards.

Conclusion

On-farm meat processing in Arkansas presents a blend of challenges and rewards. Facilities incur significant initial costs, estimated at roughly $500,000, alongside annual operational expenses near $125,000. Despite these figures, producers can realize savings when compared to outsourcing slaughter, which may cost about $350,000 a year, thus providing a financial incentive to adopt on-farm processing.

The benefits extend to animal welfare and meat quality. On-farm slaughtering minimizes animal stress attributed to transportation and unfamiliar environments, which is favorable for both the animals and the end product. Enhanced welfare practices align with consumer preferences for ethically sourced meat, potentially granting market advantages to local producers.

Moreover, the educational component cannot be overlooked. Training programs, such as those offered by expert institutions, enrich industry professionals with comprehensive skills ranging from harvest to butchering, ensuring a knowledgeable workforce.

In summary, while on-farm slaughterhouse utilization represents a significant investment, it carries potential for cost savings, improved animal welfare, superior meat quality, and an educated workforce—all of which are valuable to the Arkansas meat industry.