How to Build a Biogas Digester

A Guide for Converting Manure into Renewable Energy on Homesteads

Biogas digesters present a sustainable solution for homesteaders looking to reduce their carbon footprint and harness renewable energy. These systems convert organic waste, such as manure, into biogas, a mixture mainly composed of methane and carbon dioxide. The process not only diminishes greenhouse gas emissions by capturing methane— a potent climate-warming gas — but also provides a clean energy source that can be used for cooking, heating, or even generating electricity. As more individuals seek ways to decarbonize and live sustainably, the implementation of biogas digesters becomes increasingly relevant.

Building a biogas digester on a homestead involves creating an anaerobic environment where microorganisms can break down manure in the absence of oxygen. This design encourages the natural decomposition process, allowing the biogas to be safely collected and stored. By converting biowaste to biogas, homesteaders take an active role in the movement towards sustainable living, simultaneously managing waste and producing energy in an environmentally-friendly manner.

Adopting such practices contributes to a cleaner future and advocates for the responsible use of resources. The application of anaerobic digestion technology aligns with numerous U.N. Sustainable Development Goals and supports global efforts in combating climate change. For homesteaders, the benefits are twofold: they achieve self-sufficiency in energy production and take part in the larger context of global sustainability and renewable energy utilization.

Understanding Biogas

Biogas production through anaerobic digestion is a practical way to turn organic waste into renewable energy. This section breaks down the basics of biogas and its advantages as a sustainable energy source.

Fundamentals of Biogas

Biogas is a mix of gases produced by the breakdown of organic material in the absence of oxygen, a process known as anaerobic digestion. The primary components of biogas are methane (CH₄) and carbon dioxide (CO₂), with methane being the main ingredient for energy production. During digestion, microorganisms decompose organic matter, such as manure, producing biogas as a byproduct.

The typical steps involved in biogas production are:

Collection of organic waste

Anaerobic digestion of the material

Upgrading the produced biogas to enhance its methane concentration.

Benefits of Biogas as Renewable Energy

Biogas offers numerous benefits as a source of renewable energy. Primarily, it helps in the reduction of greenhouse gas emissions by capturing methane, a potent greenhouse gas, and converting it into a usable form of energy. Furthermore, it provides a reliable supply of energy that can replace fossil fuels in many applications. Upgraded biogas is often referred to as renewable natural gas, which can be used similarly to conventional natural gas for heating, electricity, and fuel for vehicles. Utilizing biogas systems transforms waste management issues into energy solutions.

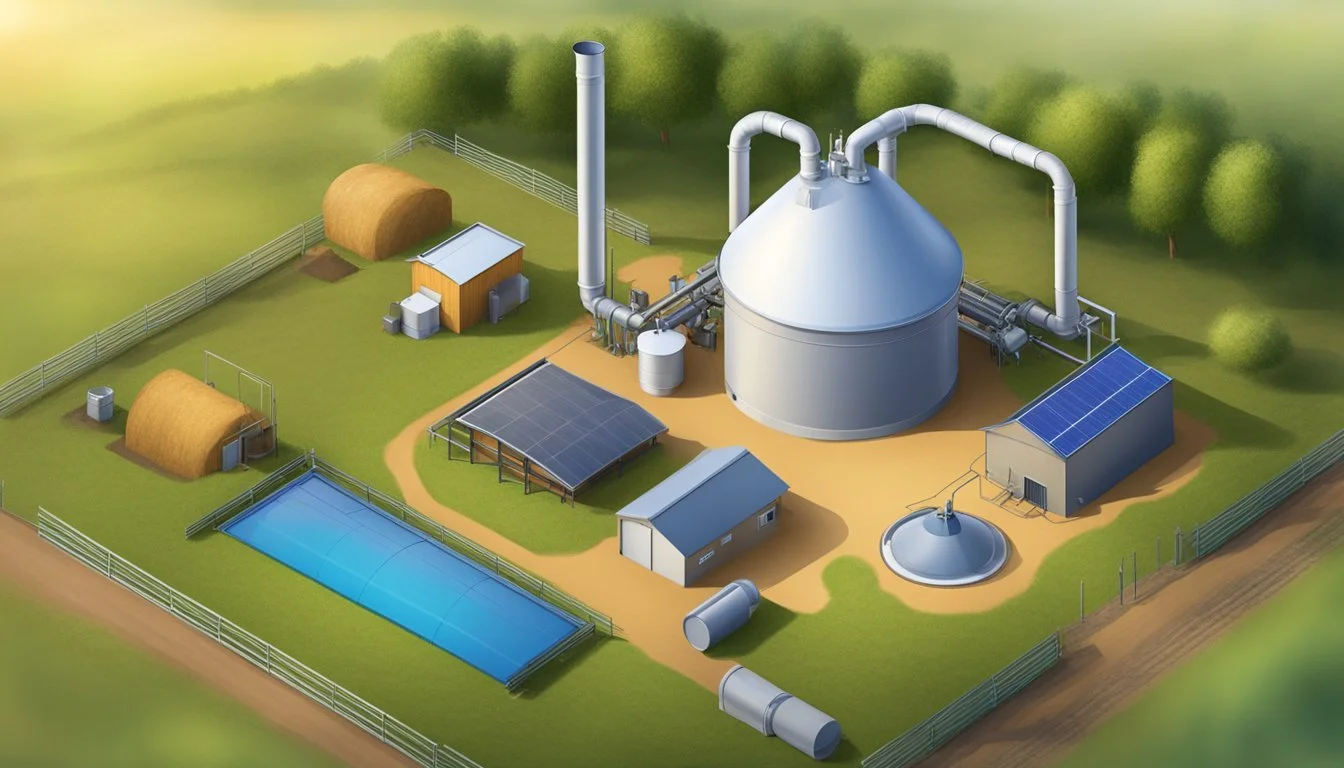

Components of a Biogas Digester

Building a biogas digester involves understanding its key parts and the role they play in the conversion of organic material into renewable energy.

Anaerobic Digesters Overview

Anaerobic digesters are crucial for biogas production. They provide an environment where bacteria can thrive and break down organic material without the presence of oxygen. There are two critical factors within an anaerobic digester that must be monitored:

pH Level: A stable pH level is crucial for maintaining bacterial health and activity. The optimal pH range for a biogas digester is neutral to slightly alkaline, approximately from 6.5 to 8.5.

Temperature: Bacteria in the digester are sensitive to temperature fluctuations. Digesters should maintain a temperature between 30-38°C (mesophilic range) or between 50-57°C (thermophilic range) for optimal biogas production.

Key Elements of a Methane Digester

The methane digester, as a type of anaerobic digester, includes several key elements that work together to facilitate the conversion of organic waste into methane-rich biogas:

Insulation: Efficient insulation is essential to maintain a consistent internal temperature conducive to bacterial metabolism and activity.

Retention Time: This refers to the time the organic material is held within the digester. Proper retention times, typically between 15 to 30 days, ensure that material is fully digested and maximum biogas is produced.

Bacteria: Specialized anaerobic bacteria are the workforce of the digester, breaking down organic matter. They require a balanced environment to efficiently produce methane.

By attentive management of these components, a methane digester can convert manure and other organic wastes into a valuable source of renewable energy for a homestead.

Preparation and Feedstock Management

Successful biogas production begins with thorough preparation and strategic feedstock management. The choice of materials and their blend directly impact the efficiency and output of the digester.

Feedstock Types and Characteristics

Manure: A primary feedstock for biogas production, especially cow manure, is rich in organic matter conducive to methane generation. Slurry, a semi-liquid mixture, often from cattle and pigs, is particularly effective due to its high biodegradability and ease of handling within a digester.

Cow Manure: Contains approximately 45-65% methane potential.

Slurry: Can be pumped, facilitating easier handling and transfer into the digester.

Non-manure Organic Materials: Including food waste or food scraps can enhance the blend but must be managed carefully to avoid process imbalance.

Food Waste: Adds necessary nutrients and accelerates the digestion process.

Grass Clippings: A source of fibrous organic material; should be used in moderation.

Optimizing the Digester Recipe

Creating the optimal mix, or recipe, for a biogas digester involves balancing the carbon to nitrogen ratio (C), moisture content, and ensuring consistent particle size for even digestion.

Balancing C Ratio: For effective microbial activity, maintain a C ratio between 20:1 and 30:1.

Animal Manure: Already has a near-optimal C ratio for digestion.

Food Scraps: May need to be offset with carbon-rich materials such as straw to maintain balance.

Moisture Content: Too much or too little moisture can hinder digestion, maintain moisture levels at around 70-90% for efficient operation.

Feedstock Pre-treatment: Chop or shred feedstock to increase the surface area for microbes to work on.

Mixing: Consistent mixing avoids forming layers within the digester, allowing for uniform gas production.

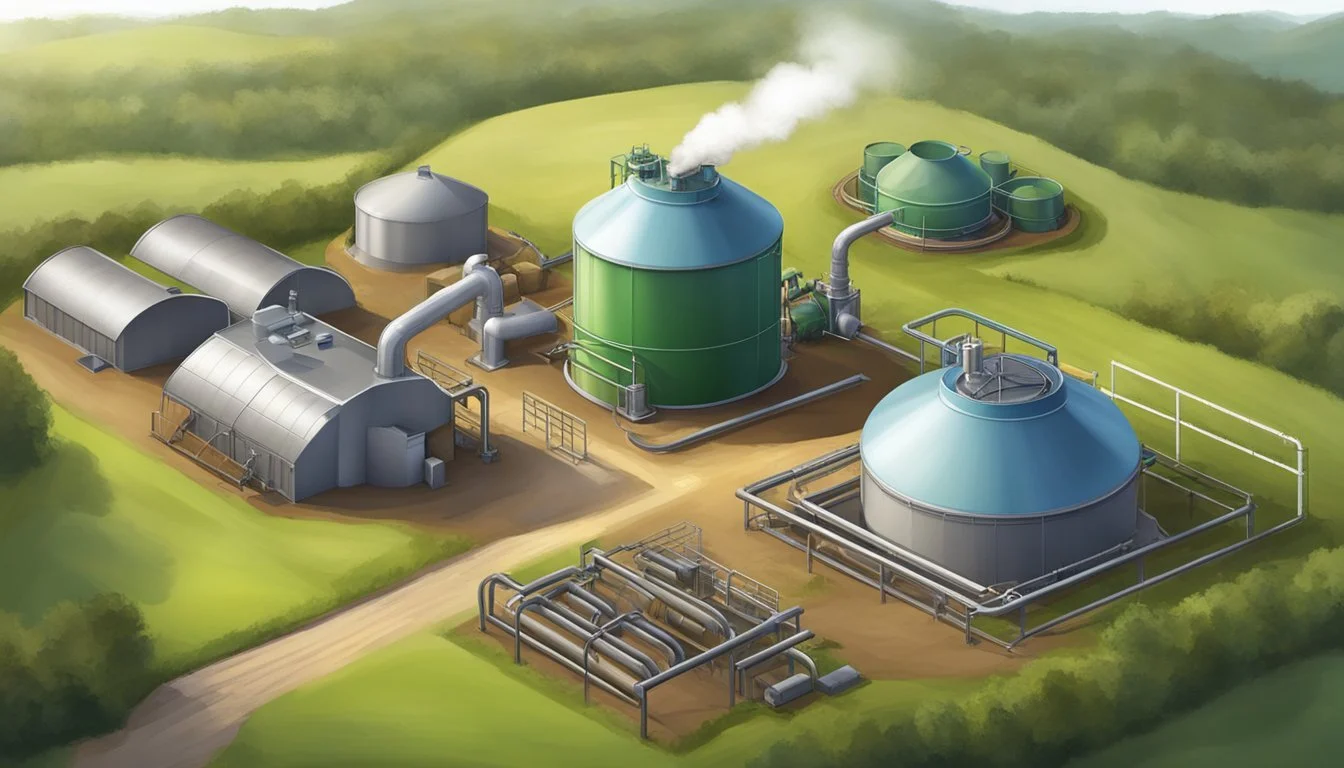

Biogas Digester Construction

When building a biogas digester, one must carefully consider location and follow a structured construction process. Proper design, selection of materials, and a clear understanding of the build steps are critical to ensuring a cost-effective and functional digester.

Choosing the Right Location

Selecting an ideal site for a biogas digester is crucial. The chosen location should:

Be easily accessible to facilitate the addition of manure and removal of digestate.

Have a stable ground that can support the weight of the digester and its contents.

Be close to the source of manure to minimize transport distances and associated costs.

Be well-ventilated to ensure safety, as biogas production generates flammable gases.

Step-by-Step Construction Process

A straightforward construction approach for a DIY biogas digester involves the following steps:

Prepare the Foundation:

Excavate a pit for the digester tank, ensuring it complies with the size specifications of your design.

Lay a concrete slab as the base to provide a stable and level surface.

Assemble the Digester:

Use robust and durable materials such as intermediate bulk containers (IBC) or reinforced concrete.

Install inlet and outlet pipes for manure and digestate, ensuring they are sealed to avoid leaks.

Set Up the Gas Collection System:

Attach a dome or flexible membrane on the top of the digester to collect the biogas.

Include a valve to control the flow of biogas and storage options such as gas holders.

Ensure Proper Insulation:

Insulate the digester to maintain the optimal temperature for microbial activity which is usually around 35-40°C (95-104°F).

Test the System:

Check for leaks and ensure all connections are secure.

Introduce a small amount of manure and water to start the digestion process and verify that biogas is being produced effectively.

Building a biogas digester on a homestead can be a significant but manageable project for those looking to produce renewable energy from manure. The process is cost-effective and, with the right DIY skills, can be a rewarding addition to sustainable living practices.

Operating and Maintaining a Biogas Digester

Effectively operating and maintaining a biogas digester is crucial for converting manure into renewable energy. It ensures the anaerobic digester functions efficiently and that the system’s longevity is maintained.

Maintaining Optimal Conditions

To achieve the best performance from a biogas digester, one must maintain the balance of solids and liquids, which affects the loading rate and the health of the microbial community inside the digester. Mixing ratios should be consistent, and the organic loading rate must be carefully managed to prevent overload. The optimal temperature for a mesophilic anaerobic digester typically ranges from 30°C to 38°C, which supports the growth and activity of the microbes responsible for biogas production.

Key maintenance tasks include:

Monitoring: Regularly check the digester’s temperature and pH levels.

Balance: Maintain a solid-liquid ratio that promotes microbial activity but prevents clogging.

Loading Rate: Adjust the amount of feedstock to sustain the digester's biogas output without overloading.

Troubleshooting Common Issues

Common issues in biogas digester operations can often be preempted with vigilant monitoring and maintenance. However, when problems arise, prompt action is necessary.

Here are solutions for typical concerns:

Reduced Biogas Production: This could indicate an imbalance in the digester. Assess the feedstock quality and adjust loading rates.

Scum Formation: Scum layers that form on the surface can inhibit gas release. Mix the digester contents more thoroughly to break up scum.

Odor: Offensive smells may suggest improper digestion or that the system is going septic. Check temperatures, pH, and the loading rate, and adjust as needed.

By adhering to these maintenance and troubleshooting guidelines, operators can ensure their biogas digester consistently converts manure to renewable energy effectively.

End Products and Their Uses

Upon successfully converting manure to biogas through anaerobic digestion, two primary products are obtained: biogas, which can be further processed to generate electricity and heat, and digestate, an excellent fertilizer for agricultural use.

Converting Biogas to Energy and Heat

Biogas predominantly consists of methane (CH4) and carbon dioxide (CO2), with trace amounts of other gases. A generator is typically used to convert this biogas into electricity. The produced electricity can be utilized for various residential purposes, including lighting, powering appliances, and charging. Additionally, the heat generated during electricity production can be harnessed for heating spaces or water, making it a versatile energy source.

Use of Biogas in Energy Production:

Electricity: Through a generator, biogas is converted to electricity.

Heating: Waste heat from electricity production can be used for space and water heating.

Cooking: With proper treatment, biogas can be used for cooking, replacing conventional fuels.

Utilizing Digestate as Fertilizer

After the production of biogas, the remaining material is digestate, which is a nutrient-rich byproduct. This digestate can be applied directly to fields as a liquid fertilizer, providing essential nutrients to the soil. Alternatively, it can be composted to create a more stable soil amendment, rich in organic matter. The use of digestate improves soil structure, enhances microbial activity, and boosts plant growth.

Digestate Applications:

Fertilizer: Rich in nutrients, directly applicable to soil.

Soil Amendment: After composting, it enhances soil quality.

Nutrient Source: Provides nitrogen, phosphorus, and potassium to crops.

Environmental and Economic Impact

Constructing a biogas digester on a homestead to convert manure into renewable energy has notable impacts on both the environment and the economy, with reductions in greenhouse gas emissions and potential financial gains for the homestead owner.

Reducing Emissions and Waste

Biogas digesters on dairy farms play a crucial role in managing waste and reducing emissions. These systems capture methane produced by the decomposition of manure, which is a greenhouse gas more potent than carbon dioxide. By diverting methane from the atmosphere, dairy digesters effectively decrease the ecological footprint of a farm. The use of this alternative fuel also promotes clean energy, contributing to a reduction in the reliance on fossil fuels, subsequently lowering overall carbon dioxide emissions.

Impact on greenhouse gases: Captures methane, reduces carbon footprint

Waste management: Converts manure, reduces environmental contaminants

Financial Considerations for Homesteaders

For homesteaders, investing in a biogas digester comes with substantial financial considerations. Initially, the expense can be significant; however, homesteaders can often leverage grants and subsidies designed to support renewable gas projects. In the long term, dairy farmers can benefit economically from the production of biogas by converting it into electricity or heat for on-site use or for sale to the grid, leading to continual profits. Adoption of biogas technology may also be cost-effective over time due to savings on energy costs and potential community benefits.

Initial investment: Can be high, seek grants

Long-term benefits: Energy production, potential profits, community advantages

Regulations and Guidelines

Building a biogas digester requires compliance with a variety of regulations and guidelines to ensure safety, environmental protection, and eligibility for potential incentives. This ensures that the project adheres to the highest standards and contributes positively to both the homestead and the community.

Adhering to Local and Federal Regulations

In the United States, biogas projects must comply with regulations set forth by entities such as the U.S. Environmental Protection Agency (EPA). This includes obtaining necessary permits for construction and operation. Particularly in states like California, Wisconsin, and Pennsylvania, where agriculture and dairy farming are prevalent, additional state-specific environmental regulations may apply. For instance, in Europe, biogas digesters must meet stringent EU standards for emissions and waste processing. All builders must:

Consult with local authorities to verify zoning and waste management regulations.

Follow federal standards for air quality, effluent discharge, and waste handling.

Incentives and Support Programs

Financial incentives are available to help offset the costs of biogas digester projects. Homestead owners can seek:

Grants and matching funds from federal or state resources, designed to promote renewable energy.

In California, programs such as the California Department of Food and Agriculture's Dairy Digester Research and Development Program offer financial assistance.

In Wisconsin, the Focus on Energy program provides incentives for renewable energy projects.

Community-involved programs may also offer support, recognizing the dual environmental and economic benefits of biogas systems.

Future of Biogas Technology

Biogas technology is poised for significant growth, integrating innovations that enhance efficiency and sustainability into the global energy mix.

Advancements and Innovations

Researchers and developers are working on high-performance anaerobic digesters that can operate with greater efficiency and at lower costs. Key improvements include optimizing microbial consortia for faster breakdown of waste and enhanced gas purification systems to increase the quality of biogas. Technological strides such as membrane technology are making biogas production cleaner, with a reduction in contaminants. These innovative steps are crucial for homesteads aiming to utilize renewable energy resources effectively.

The Role of Biogas in Global Energy Transition

Biogas stands at the forefront of the renewable energy sector, offering a sustainable alternative to fossil fuels and playing a vital role in the transition towards a cleaner energy future. As energy needs escalate, biogas presents a dual solution by managing waste and producing energy. It supports the U.N. Sustainable Development Goals and aligns with the targets set by the Paris climate agreement. The expansion of biogas facilities can also help in rural development, improving energy access and reducing health impacts associated with traditional energy use.