The Ultimate Guide to Using an In-Vessel Composter

Efficient Strategies for Rapid Organic Waste Composting

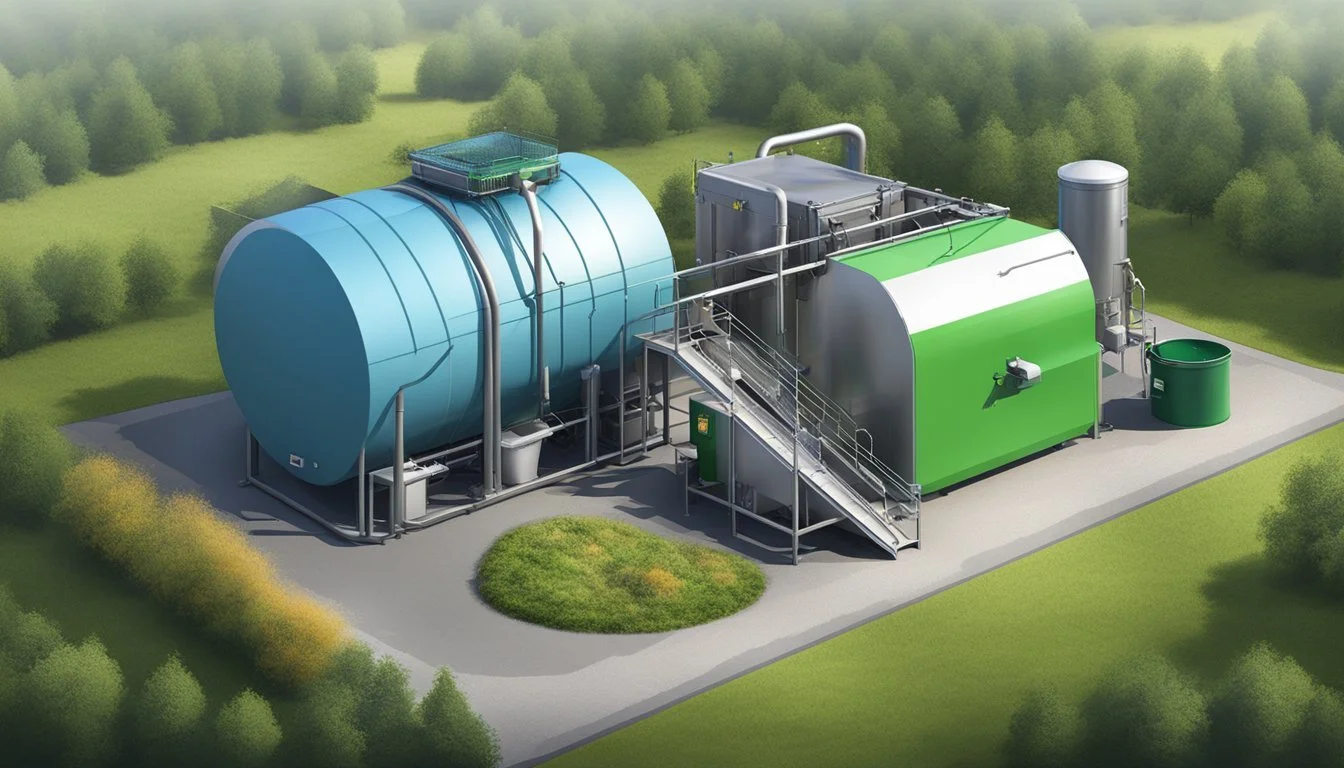

In-vessel composting is an innovative and efficient method for transforming organic waste into valuable compost. This process is conducted within a contained environment, which allows for rapid decomposition of organic materials such as kitchen scraps, yard waste, and even certain types of animal manure. By creating optimal conditions for the composting process, such as ideal temperatures, moisture levels, and aeration, in-vessel systems can significantly reduce the time it takes to produce compost compared to traditional methods.

The closed system not only expedites the composting process but also offers enhanced control over various environmental factors that can affect the quality and safety of the compost. This includes mitigating unpleasant odors, leachate management, and the potential spread of pathogens. In terms of sustainability, in-vessel composting presents a scalable solution for managing organic waste, reducing landfill usage, and contributing to the creation of a circular economy where waste is recast as a resource for enriching soil.

Adopting in-vessel composting supports waste reduction goals and fosters sustainable practices. It can be applicable in a variety of settings, from individual households to large-scale agricultural operations. By leveraging this composting technology, users can turn their organic waste into a nutrient-rich amendment for soils, promoting healthier plant growth and contributing positively to the environment.

Understanding In-Vessel Composting

In-vessel composting is a contained, highly controllable composting method for rapid conversion of organic waste into usable compost. This section will unveil the fundamental principles, advantages, and comparative analysis of composting methods within the context of in-vessel systems.

Principles of In-Vessel Composting

In-vessel composting utilizes enclosed structures like drums, silos, or concrete-lined trenches. These vessels provide an environment where temperature, moisture, and aeration can be closely regulated to accelerate the composting process. The materials decompose through microbial activity in a more predictable manner than uncontained methods. Regular turning or agitation is often part of the protocol to ensure even composting and oxygen distribution.

Key steps in in-vessel composting include:

Selection of an appropriate container: Depending on the scale and type of organic waste, a suitable in-vessel system is chosen.

Waste preparation: Organic materials are collected and, if necessary, shredded to improve the surface area for microbes.

Balancing inputs: A proper mix of carbon-rich and nitrogen-rich materials fosters the right environment for composting.

Monitoring and control: The system allows for regular monitoring of conditions to optimize the process.

Benefits of In-Vessel Systems

In-vessel composting offers numerous benefits:

Control: These systems afford operators precise control over environmental conditions, leading to faster decomposition.

Versatility: A broad array of organic materials, including fruit and vegetable scraps, yard waste, and coffee grounds, can be composted.

Reduced Nuisance: They mitigate common composting nuisances such as odors and pests.

Year-Round Operation: Being contained, in-vessel composting is not affected by external weather conditions.

Constraints, however, include avoiding materials like meats, dairy, and oily waste which could disrupt the composting balance.

Comparing Composting Methods

In-vessel composting is one method among various composting techniques, each with its distinct operational frameworks:

Windrows: This method involves piling organic material into long rows. It is less contained and relies on regular turning of the piles.

Static Piles: Here, piles are not turned; instead, they are aerated through embedded pipes.

Aerated (static or turned) composting allows for air to be introduced into the material to speed up the process.

Vermicomposting: This utilizes worms to digest organic waste, resulting in vermicompost.

Anaerobic Digestion: This method breaks down the material in the absence of oxygen, producing biogas as well as compost.

In-vessel systems often provide more rapid results and require less space compared to methods like windrows or static piles, which can require large areas and more extensive management of environmental factors.

Organic Waste and Its Impact

The proper management of organic waste plays a crucial role in environmental conservation and sustainability efforts. This section examines the varying types of organic waste and their implications for the environment.

Types of Organic Waste

Organic waste is a significant component of municipal solid waste and includes a variety of biodegradable materials. The major types include:

Food Scraps: Remnants of fruits, vegetables, dairy, and meat that are discarded from households and commercial establishments.

Yard Trimmings and Green Waste: Leaves, grass clippings, and branches generated from landscaping activities.

Agricultural Waste: By-products from farming operations, including manure and crop residues.

Solid Waste: Organic fraction of solid waste, which also encompasses biodegradable products such as paper and cardboard.

Sewage Sludge: The organic byproduct of the wastewater treatment process.

Environmental Considerations

When organic waste decomposes in landfills, it releases methane, a potent greenhouse gas with a significant impact on climate change. Consider the following environmental factors:

Greenhouse Gas Emissions: Diverting organic waste from landfills to composting facilities can mitigate methane emissions and reduce the overall carbon footprint.

Soil Health: Composting organic waste produces nutrient-rich soil amendments, crucial for soil fertility and reducing the need for chemical fertilizers.

Resource Efficiency: By composting organic waste such as food scraps and yard trimmings, communities can recycle valuable nutrients and organic matter, leading to sustainable waste management practices.

Key Factors in Composting

To ensure efficient in-vessel composting, one must carefully balance carbon and nitrogen contents, maintain moisture levels, provide sufficient aeration, and regulate temperature.

Balancing Carbon and Nitrogen

The carbon-to-nitrogen (C) ratio is crucial for microbial activity. A balanced C ratio of 25-30:1 is ideal. Materials high in carbon include leaves and wood chips, while those rich in nitrogen are food scraps and green plant matter.

Maintaining Adequate Moisture

Composting organisms require water to survive, but excess moisture can lead to anaerobic conditions. The optimal moisture content for composting is generally between 40-60%, which feels like a wrung-out sponge.

Ensuring Proper Aeration

Oxygen flow is vital for aerobic composting processes. In-vessel systems should be designed to introduce air into the material either passively or with mechanical systems to maintain an oxygen-rich environment.

Temperature Control

Temperature is an indicator of microbial activity. Compost should maintain temperatures between 131-150°F (55-65°C) for pathogen and weed seed destruction while avoiding overheating, which can kill beneficial microbes.

Composting Process and Stages

The in-vessel composting method accelerates the transformation of organic waste into valuable compost through controlled, rapid, and efficient processes.

Decomposition and Microorganisms

Decomposition is the initial stage where microorganisms such as bacteria and fungi play a crucial role. They break down the organic material, effectively converting biomass into simpler substances. The enclosed environment of an in-vessel composter optimizes conditions for these microorganisms to thrive, ensuring a faster decomposition than traditional methods.

Bacteria: Key decomposers that initiate breakdown

Fungi: Continue decomposition of tougher materials

Humification Process

In the subsequent stage, humification occurs, where the by-products of decomposition are further degraded, leading to the formation of humus — a dark, rich, and stable form of organic matter. This process is essential for binding nutrients in forms readily accessible to plants and improving soil structure.

Mineralization: Conversion of organic matter into minerals

Stabilization: Formation of mature compost

Pathogen Reduction

An important benefit of in-vessel composting is the efficient reduction of pathogens and weed seeds. Regulated conditions within the vessel elevate temperatures to between 60-70ºC, a range that is lethal to most pathogens and satisfies EPA regulations. The result is a sanitized product safe for use in various agricultural and horticultural applications.

Temperature Control: Essential for pathogen eradication

Regulatory Compliance: Meets safety standards for compost quality

Designing an In-Vessel Composting System

Designing an efficient in-vessel composting system involves careful consideration of the type of vessel and its compatibility with various waste streams. These systems are engineered to optimize the decomposition of organic matter in a controlled, accelerated environment.

Choosing the Right Vessel

The selection of an appropriate vessel is crucial for the success of in-vessel composting. The two common types of vessels are drums and silos. Each has its own set of advantages:

Drums: Suitable for smaller-scale or decentralized composting operations. They are often cylindrical and can be rotated to mix the composting material effectively.

Pros: Easy to rotate

Cons: Limited size

Pros: Good aeration

Cons:

Pros: Lower cost

Cons:

Silos: Ideal for larger-scale operations. These vertical structures have an advantage in terms of footprint and can be equipped with automated mixing systems.

Pros: High capacity

Cons: Higher cost

Pros: Small footprint

Cons: Requires more planning

When choosing the vessel for in-vessel composting, it is vital to assess the volume of feedstock anticipated and whether the system needs to accommodate scaling up in the future.

Optimizing for Different Waste Streams

An effective in-vessel composting system must be optimized for various types of waste streams, such as kitchen waste, garden waste, or paper. Each type of feedstock requires specific conditions for optimal decomposition:

Kitchen Waste: High moisture content needs a system that can drain excess liquid and regulate humidity.

Garden Waste: Often bulkier and requires more space to break down.

Paper: High carbon material that should be balanced with nitrogen-rich waste for efficient composting.

In-vessel composting reactors must be designed to provide:

Consistent temperature regulation, which is essential for speeding up the composting process and ensuring pathogen kill-off.

Adequate aeration to maintain aerobic conditions, supplying oxygen to microbes responsible for breaking down organic material.

Moisture control to prevent a too wet or too dry environment, which can inhibit microbial activity.

A well-designed in-vessel system is a key component in a more sustainable approach to waste management, creating valuable compost while reducing the environmental impact of organic waste.

Operating an In-Vessel Composter

Efficient operation of an in-vessel composter hinges on strict adherence to feeding protocols, continuous monitoring, and effective troubleshooting. Mastery of these aspects ensures rapid decomposition while maintaining compost quality.

Loading and Feeding Protocols

The success of in-vessel composting largely depends on the initial loading and consistent feeding of organic waste. Operators should follow these steps:

Selecting the waste: Only compatible organic waste materials should be loaded into the composter.

Balancing the feedstock: A balanced ratio of carbon-rich to nitrogen-rich materials optimizes the process.

Scheduling inputs: Regular feeding schedules prevent overloading the system.

Operational guidelines involve ensuring that the volume and composition of waste added aligns with the composter's capacity. Avoiding the introduction of materials that can attract pests or cause odors is crucial.

Monitoring Parameters

Continuous monitoring of in-vessel composters is essential for maintaining an optimal composting environment:

Temperature: The system should maintain a range typically between 55°C to 65°C to effectively manage pathogens.

Moisture Content: Ideally kept at 40-60%, ensuring proper aeration and avoiding excessive wetness that can lead to odors.

Aeration: Oxygen levels must be monitored to prevent anaerobic conditions.

Data Collection: Regular data collection on these parameters is vital for assessing performance and making adjustments.

Maintenance checks should include inspection of mechanical parts and verification that the aeration system functions correctly. Operators must ensure all sensors and gauges are accurately recording crucial compost quality metrics.

Troubleshooting Common Issues

Even with meticulous management, issues can arise during the composting process:

Odors: Addressing unpleasant smells may require adjusting moisture or aeration levels.

Temperature Fluctuations: If the temperature deviates from the optimal range, feedstock ratios and aeration rates may need recalibration.

Pest Infestations: Proper sealing of the system and vigilant operational practices can mitigate unwanted guests.

Routine maintenance and timely intervention when problems are detected are paramount in preventing these issues from disrupting the composting process.

End Products and Their Uses

The end products of in-vessel composting are vital for sustainable practices in agriculture and gardening. They primarily consist of high-quality compost, which serves as a nutrient-rich soil amendment, providing numerous benefits for soil and plants.

Compost Quality and Applications

High-quality compost produced through in-vessel composting is characterized by its rich humus content, which is critical for soil health. The compost has a variety of uses:

Landscaping: It enhances the aesthetic value by improving soil quality.

Agriculture: Compost provides essential nutrients for crop growth.

Gardening: It is used for conditioning garden beds and potting mixes.

The application is often tailored to the specific needs of the plants and the existing soil conditions.

Soil Amendment Benefits

Soil Structure Improvement: Compost adds humus to the soil, which increases soil stability and prevents erosion.

Water Retention: Composted soil retains moisture more effectively, reducing the need for frequent watering.

Microbial Activity Enhancement: The addition of compost supports the proliferation of beneficial soil microbes.

Using compost from in-vessel composters is thus a form of resource recovery, transforming organic waste into a valuable product.

Addressing Specific Plant Needs

Compost use should be based on plant-specific requirements:

Plant Type: Nitrogen-loving

Benefit from Compost: Provides slow-release nitrogen for growth.

Plant Type: Acidic soil preferer

Benefit from Compost: Tailored compost can lower soil pH to match plant preferences.

Plant Type: Heavy feeders

Benefit from Compost: Nutrient-rich compost meets the high nutritional demands.

Determining the right type and amount of compost helps ensure plants receive the appropriate care for optimal growth.

Sustainability and Environmental Impact

In-vessel composting is instrumental in transforming organic waste into valuable compost while reducing the environmental footprint. This method supports a sustainable waste management system and mitigates negative ecological impacts.

Reducing Waste and Landfill Use

Landfills are a significant source of methane, a potent greenhouse gas. By diverting organic waste from landfills, in-vessel composting systems substantially reduce the volume of waste. They accelerate the composting process, converting organic materials like food scraps and yard waste into compost. This curtails the reliance on landfills, thus minimizing landfill expansion and the associated ecological disturbances.

Mitigating Greenhouse Gas Emissions

In-vessel composting controls the decomposition of organic waste, which reduces emissions of methane, carbon dioxide, and other greenhouse gases. A controlled environment within the composting vessel ensures complete decomposition, transforming waste into stable compost with minimal greenhouse gas emissions. This practice contributes to the reduction of the organic waste's carbon footprint.

Promoting Circular Economy

The end product of in-vessel composting -- nutrient-rich compost -- can be returned to the soil, promoting a circular economy. This practice encourages the reuse of organic resources, closing the loop from soil to table and back to soil. It supports sustainable resource management by enhancing soil health, thereby reducing the dependency on chemical fertilizers. Compost use leads to environmental benefits such as improved soil structure, moisture retention, and biodiversity.

Advancements in Composting Technology

The composting industry is experiencing a technological renaissance, enhancing the efficiency and scalability of organic waste conversion into valuable compost.

Innovations in In-Vessel Composting

In-vessel composting has seen remarkable innovation, leading to more rapid decomposition and higher quality end-products. Pilot-scale systems, which provide a controlled environment for testing and improvement, have been instrumental in developing industry standards. They utilize a variety of biodegradable materials and can often convert waste into compost on an accelerated timeline compared to traditional methods.

The technology behind in-vessel composters now often includes automated controls for temperature, moisture, and aeration, ensuring ideal conditions for microbial activity and decomposition. This system monitoring is a key factor in achieving faster composting cycles. Additionally, the development of low-cost mediums for microbial formulations has resulted in improved efficiency and reduction in process time.

Research and Development

Current research efforts focus on optimizing waste decomposition at both lab-scale and pilot-scale levels. Industry collaboration with research institutions has resulted in microbial formulations that are more efficient in the decomposition process—specific strains of bacteria and fungi, like Bacillus cereus C1 and Aspergillus niger P-19 are known for their ability to produce enzymes crucial for the breakdown of organic material.

These advancements are not only about creating efficient composting processes but also about contributing to energy recovery systems. Modern in-vessel composters are being integrated into renewable energy sources networks, allowing the heat generated during the composting process to be captured and utilized, adding an additional layer of sustainability to the technology.

The culmination of innovation and research in in-vessel composting technology has significantly progressed the industry and its capacity to contribute to a more sustainable future by effectively managing and valorizing organic waste.

Legal Compliance and Industry Standards

Ensuring legal compliance and adhering to established industry standards is crucial in the operation of an in-vessel composter. Operators must be aware of the regulatory framework set forth by environmental authorities and strive for certification that reaffirms quality assurance.

Regulatory Framework

The Environmental Protection Agency (EPA) outlines specific regulations for the composting industry, including in-vessel composting. Operators must comply with the Clean Air Act, the Clean Water Act, and other pertinent federal regulations designed to protect the environment. EPA 832-F-00-061, for instance, is a guide that covers in-vessel composting of biosolids, providing essential compliance information.

States also have their own set of regulations which must be observed. These may include permits for the operation and specific requirements for process control. The following are key points that operators should ensure compliance with:

Emissions: Control and monitor emissions in alignment with air quality standards.

Leachate management: Prevent any potential contamination of water resources.

Pathogen reduction: Follow EPA guidelines to ensure pathogen levels are reduced to acceptable levels.

Reporting: Maintain accurate records and report as required to relevant authorities.

Certification and Quality Assurance

Certification plays a paramount role in demonstrating commitment to quality assurance. Industry standards, such as those from the US Composting Council (USCC), often set the benchmark for best practices in composting processes. Composters can attain certifications like the Seal of Testing Assurance (STA) to validate that their compost meets recognized quality parameters. Certification processes typically involve:

Regular Testing: Frequent analysis of compost to verify it meets standards for contaminants, stability, and maturity.

Process Control Documentation: Documenting the composting process ensures consistency and helps in identifying areas for improvement.

Training and Auditing: Ensuring staff are fully trained and conducting periodic audits for continued adherence to industry best practices.

Community Engagement and Education

Effective in-vessel composting programs thrive on an engaged community and well-informed participants. Public awareness programs and workshops are essential for fostering a culture of sustainability and ensuring successful composting initiatives.

Public Awareness Programs

Public awareness campaigns are crucial for educating community members about the benefits and practices of in-vessel composting. These programs clearly communicate the importance of diverting organic waste from landfills and the role composting plays in soil health and reducing greenhouse gases. Material such as informative flyers, web pages, or educational videos can be disseminated to increase the visibility and understanding of the program. Local media can also play a role in amplifying the message.

Objectives of Public Awareness Campaigns:

To raise awareness on the environmental impact of organic waste.

To explain the process and benefits of in-vessel composting.

To encourage the community to participate actively in composting efforts.

Training and Workshops

Training sessions and practical workshops are pivotal in equipping residents with the necessary skills to participate effectively in composting programs. These educational events should include detailed instructions on what can and cannot be composted, the mechanics of operating in-vessel composting units, and best practices for contributing to the cycle of composting.

Components of Effective Workshops:

Introduction to in-vessel composting: Highlighting how this method fits within larger waste management strategies.

Operational training: Guidelines for the proper addition of waste, monitoring, and maintenance of the composter.

Hands-on experiences: Sessions where participants can engage with the composting equipment under supervision.

By focusing on community engagement through education and practical experiences, the in-vessel composting programs ensure long-lasting environmental benefits and sustainability.