The Ultimate Guide to Using a Mobile Grain Dryer

Strategies to Combat Grain Spoilage

Grain spoilage is a critical concern for farmers and agricultural professionals worldwide, as it can lead to significant economic losses and food waste. Mobile grain dryers have emerged as a vital tool in combatting this issue, offering a solution that is as practical as it is effective. With the ability to reduce the moisture content in grains to levels that prevent spoilage, these dryers operate above 140°F using various fuel sources like natural gas, propane, or fuel oil.

The process of drying grain is a delicate balance between temperature control and timing. By employing mobile grain dryers, users have the flexibility to adjust this balance, adapting to different grains and environmental conditions. Ensuring the proper use of these dryers is critical, as it can greatly impact the quality and storability of the grain. Regular maintenance and adherence to safety protocols not only prolong the equipment's life but also prevent fires, which are common hazards associated with grain drying operations.

Authors of relevant articles and studies emphasize the importance of following a maintenance checklist, provided in the dryer's operations manual, which outlines procedures for startup, cleaning, and shutdown. These preventative measures are essential for safe operation and avoiding common pitfalls that lead to dryer fires or insufficiently dried grain. By referencing reliable sources and incorporating the latest best practices, this guide aims to equip readers with the knowledge needed to effectively use mobile grain dryers and preserve their valuable grain harvests.

Understanding Grain Drying Basics

Effective grain drying is crucial for maintaining grain quality and preventing spoilage. This section delves into the causes of grain spoilage, drying principles, and the role of mobile grain dryers.

Grain Spoilage and Its Causes

Grain spoilage is a significant issue that can occur at any stage from harvest to storage. Key factors that contribute to spoilage include:

Moisture content: High moisture levels can encourage the growth of mold, mites, and insects.

Temperature: Elevated grain temperatures accelerate biological processes leading to spoilage.

Humidity: High ambient humidity can lead to condensation and further increase the risk of spoilage.

Contamination: The presence of foreign substances can introduce microorganisms that degrade grain quality.

Principles of Grain Drying

To prevent spoilage and preserve quality, controlling the moisture content and temperature of the grain is essential. The main principles of grain drying include:

Airflow: Consistent and adequate airflow removes moisture from the grain bulk and helps in maintaining uniform grain temperatures.

Temperature Control: Proper regulation avoids heat damage that could degrade the grain quality. Temperatures should be carefully monitored and adjusted.

Energy Efficiency: Balancing drying efficiency with energy costs is important, and proper burner air ratios are key.

Moisture Monitoring: Continuous monitoring of moisture content ensures that grain is dried to the ideal level for safe storage.

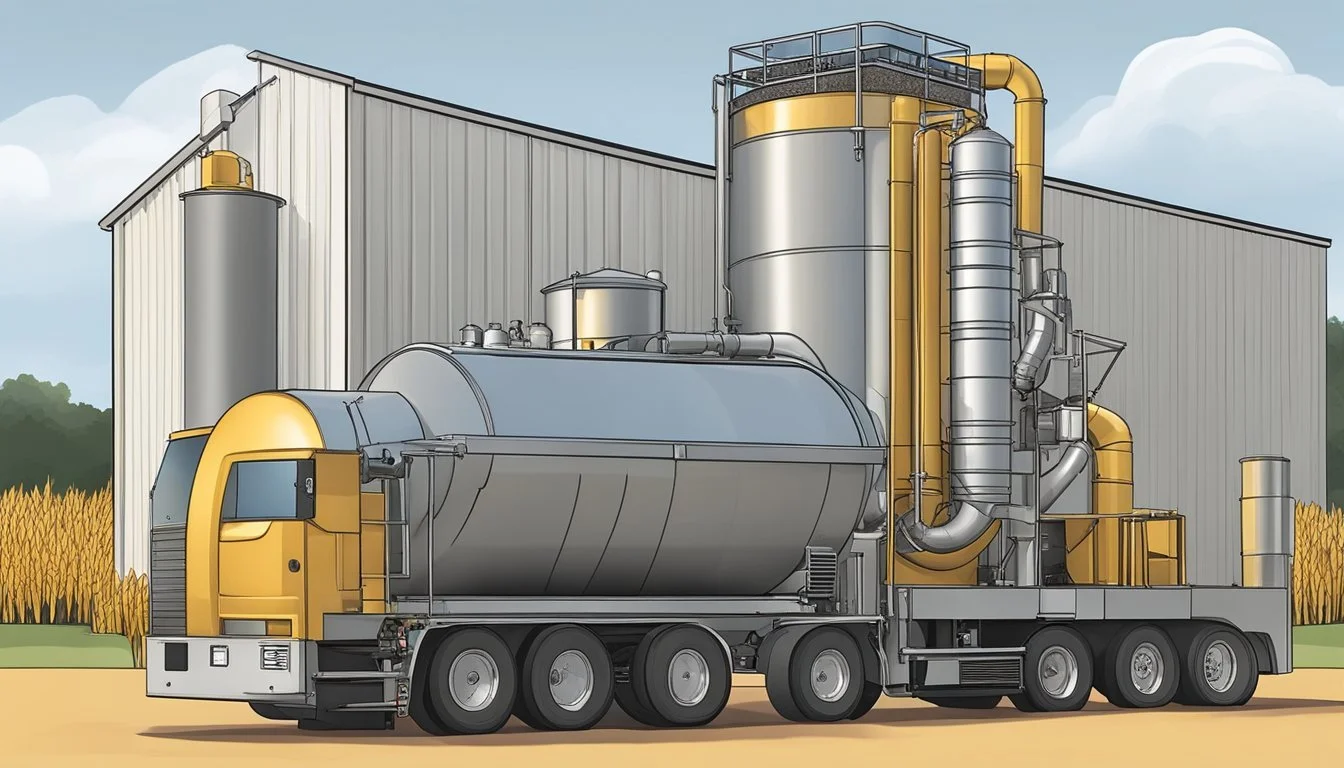

Mobile Grain Dryers: An Overview

Mobile grain dryers offer flexibility and efficiency in managing the drying process. They are deployable on-site and can provide the following advantages:

Portability: Mobile dryers can be easily transported to different storage sites as needed.

Adaptability: These systems can operate under various conditions and generally handle a wide range of grain types.

Cost-Efficiency: Mobile dryers when used properly can optimize energy use, reducing both drying and energy costs.

By understanding these fundamentals, one can effectively utilize mobile grain dryers to safeguard harvests and maintain optimal grain quality during storage.

Operational Guidelines for Mobile Grain Dryers

Mobile grain dryers are pivotal for maintaining grain quality by reducing moisture content to prevent spoilage. Proper operation ensures longevity of equipment, efficiency in drying, and preservation of the grain's integrity.

Pre-Drying Grain Harvest Preparations

Before using a mobile grain dryer, it is critical to assess the moisture content of the grain using a reliable moisture meter or moisture tester. Grains should be harvested at correct moisture levels to reduce dependency on drying which can lead to energy cost savings. Conduct field drying as much as possible, as natural methods are an economical choice before mechanical drying.

Optimizing Temperature and Airflow

The temperature and airflow settings are substantial for ensuring grain quality. Set the grain dryer temperatures based on the specific grain type, considering that high temperatures may hasten drying but risk damaging the grain quality. Use continuous airflow to promote uniform drying. Ambient air temperature also influences drying efficiency; thus, adjust settings to maintain optimal grain temperatures.

Maintaining and Monitoring Grain Dryer Efficiency

Keep your dryer in peak condition by performing regular maintenance checks. Inspect components such as fans and burners to prevent breakdowns that lead to inefficiencies or spoilage. Implement a routine grain monitoring system to check the grain condition throughout the drying process. Efficient dryer operation helps manage energy costs, a substantial part of post-harvest expenses.

Handling and Storing Dried Grain

Once the drying process is complete, handle the grain using procedures that protect its quality. Grains should be cooled to near ambient air temperature before placement in storage bins. Implement an effective grain management strategy to prevent storage problems in stored grain. Properly managing the transition from dryer to bin ensures that the grain remains in optimal condition for long-term grain storage.

Best Practices for Preventing Spoilage

Preventing grain spoilage is crucial for maintaining the quality and financial value of stored grain. Implementing specific strategies for moisture, temperature, and aeration management, producers can preserve grain integrity and minimize losses.

Controlling Moisture to Combat Mold and Insects

One of the primary defense strategies against spoilage is maintaining optimal moisture levels within the grain. Ideally, grain moisture content should not exceed 14%. To achieve this, a mobile grain dryer becomes an invaluable tool, allowing one to strategically lower moisture content in situations where harvest conditions are less than ideal. Reducing moisture content to safe levels is key to preventing mold growth and insect infestations, as both thrive in moist environments.

Temperature and Humidity Management

Temperature is a critical factor influencing stored grain's longevity. Keeping grain temperatures below 60°F (15°C) is advisable to discourage spoilage. Heat can accelerate grain deterioration, leading to potential losses. Consequently, monitoring and controlling the temperatures within grain storage through the careful placement of temperature cables can inform the activation of cooling systems or aeration to maintain suitable conditions. Similarly, humidity must be regulated; high humidity is a precursor to spoilage as it can elevate grain moisture content.

Utilization of Aeration Systems

Aeration plays a pivotal role in preserving stored grain quality. Utilizing aeration fans to move natural air through the grain mass can help balance grain temperature and moisture levels with the ambient air. Aeration systems are effective in maintaining uniformity in the grain's environment, thereby deterring the conditions that favor spoilage. It's crucial that aeration is applied judiciously based on external temperature and humidity readings to avoid unwanted moisture migration within the stored grain.

Cost Management Strategies

Effective cost management strategies are essential for maximizing the profitability of using a mobile grain dryer. Operators must strike a balance between energy consumption and drying efficiency to prevent grain spoilage without incurring excessive costs.

Balancing Energy Use and Drying Efficiency

To achieve the best outcome in terms of drying costs and efficiency, grain dryer operators should employ a multifaceted approach. This involves optimizing the drying process to reduce energy costs while maintaining high efficiency levels.

Energy Efficiency: Upgrading to advanced grain dryers equipped with energy-efficient features can lead to significant savings. Features such as vacuum cooling, heat recovery, and the ability to operate in different modes like All Heat or Dry & Cool contribute to lowering energy consumption.

Drying Efficiency: Operators should calibrate their grain dryers to ensure that they are not over-drying or under-drying the grain. Over-drying can waste energy and cost, whereas under-drying can lead to spoilage, both of which are not optimal for efficient grain dryer operation.

To illustrate the impact of efficiency on drying costs, consider the following example:

Standard Drying

Drying Method: Standard Drying

Energy Source: Propane

Energy Use (per bushel): 0.02 gallons

Cost (per bushel): $0.04

Energy-Efficient Drying

Drying Method: Energy-Efficient Drying

Energy Source: Natural Gas

Energy Use (per bushel): 0.025 therms

Cost (per bushel): $0.02

Note: The above figures are hypothetical and for illustrative purposes only.

Operators must utilize weather data and energy estimators tailored to specific locations within the grain belt to achieve more precise drying schedules and energy use forecasts. By doing so, they can plan the most cost-effective times to dry grains such as corn, wheat, and soybeans.

Continual monitoring and adjustments are necessary, as various factors like humidity, ambient temperature, and grain type affect the drying process. Smart decision-making with the help of accurate weather and energy consumption data leads to improved cost efficiency and the successful prevention of grain spoilage.

Safety Measures and Hazards

Ensuring the safety of grain drying operations necessitates a two-fold focus: adopting preventative measures and understanding the potential hazards associated with grain drying.

Mitigating Fire and Burner Hazards

Fire Prevention: The primary concern in grain dryer operation is the prevention of fires. Operators must empty the dryer completely after use to avoid material residue, which can combust. Regular inspections are crucial to identify and clean any material buildup within the dryer. It is equally important to maintain proper air to fuel ratios, as deviations can lead to overheating or incomplete combustion, both of which are fire risks.

Burner Maintenance: The burner requires particular attention. Safety protocols dictate that an operator should never leave the burner running unattended. Post-operation, a fire watch may be necessary to ensure that any potential after-flame or smoldering grain is addressed. Ensuring the dryer's burner is shielded from water and other contaminants by way of appropriate covering can avert hazards linked to burner malfunction.

Heat Damage Prevention: To protect against heat damage, operators should monitor temperature settings closely and adhere to the manufacturer's recommendations. Excessive heat can degrade grain quality and may contribute to conditions that are conducive to fire hazards. Regularly cleaning and servicing the dryer, including the burner and related components, helps maintain consistent operation and temperature control.

Innovations and Technological Advancements

The agricultural sector has seen substantial progress in grain drying technology aimed at preventing spoilage. With a focus on smart systems, energy efficiency, and sustainability, these innovations are transforming grain management.

Smart Monitoring and Grain Management Technologies

Smart monitoring systems have become integral to grain management, improving the precision and control over the drying process. These technologies use sensors to measure critical parameters such as temperature and humidity, enabling farmers to monitor grain condition in real-time and make data-driven decisions. For example, companies like Pattern Ag have introduced predictive analytics that harness various agronomic metrics to forecast conditions affecting corn and soybeans.

Recent Developments in Grain Dryer Systems

Recent technological developments in grain dryer systems have been focused on increasing efficiency while reducing energy costs. Advances include the implementation of fluidised bed and fixed bed dryers, which have been shown to significantly improve moisture removal rates. They have been enhanced with the integration of desiccants like silica gel and dehumidifiers to boost performance, raising drying efficiency to as high as 59.80% and exergy efficiency to 67.21%.

The Future of Eco-Friendly Grain Drying

The pursuit for eco-friendly grain drying methods is driving innovation toward solutions that reduce the carbon footprint. Heat pump technology, for instance, has been utilized in grain drying with promising results. Studies have demonstrated the efficacy of air source heat pumps with a coefficient of performance (COP) impressive enough to be considered a viable option. Moreover, with research into the use of the cold side of heat exchangers in Europe to cool grain during the final drying stages, the future looks promising for energy-efficient grain drying.

Case Studies and Real-World Applications

In the agriculture industry, the application of mobile grain dryers has concrete impacts on both the preservation of grain quality and cost-efficiency for farmers. Specific examples and comparisons underline their practical value and innovation.

Success Stories from Implementing Mobile Grain Dryers

Case Study 1: A medium-sized farm in the Midwest implemented a mobile grain dryer and reported a substantial decrease in grain spoilage. Prior to using the dryer, they experienced a loss of 10% post-harvest due to improper drying. Post-implementation, losses were reduced to less than 2%.

Impact on Quality: Preserved grain integrity and a significant increase in marketable grain.

Efficiency Gains: Reduced time from harvest to market, with drying times cut by 40%.

Case Study 2: In South America, a large farming cooperative transitioned to mobile grain dryers for their corn harvest. They recorded:

Reduction in Drying Costs: Energy expenses dropped by 30% due to the dryer's efficient design.

Increase in Farmer Revenue: Efficient drying methods led to improved grain quality, fetching higher market prices.

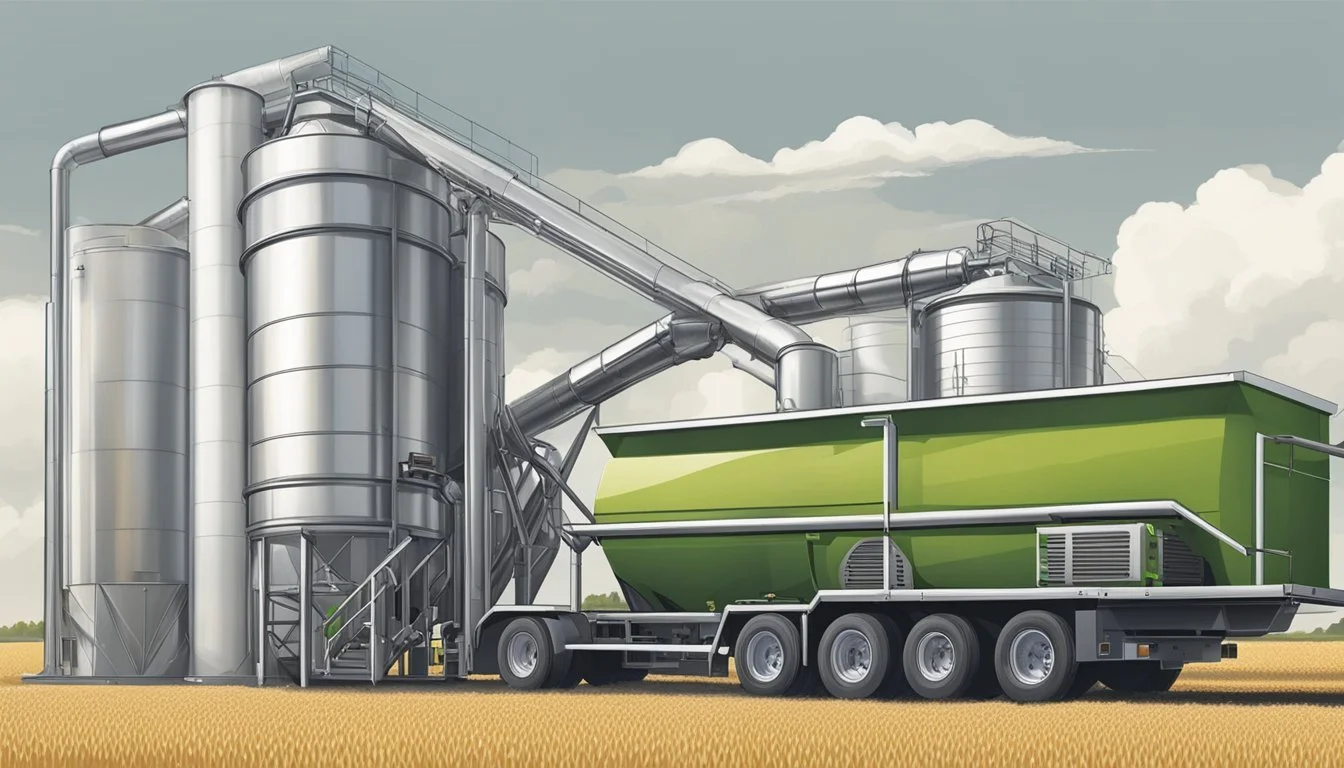

Comparative Analysis of Traditional vs Mobile Dryers

Farmers have often relied on traditional stationary grain drying methods. However, a comparative analysis highlights the benefits of mobility and efficiency in the new generation of grain dryers:

Mobility: Mobile grain dryers provide on-the-spot drying, reducing the need for transportation to stationary facilities.

Energy Costs: The modern mobile dryers are designed to optimize fuel efficiency, which translates to lower energy costs.

Drying Costs: Due to their efficient design, mobile dryers often result in lower overall drying costs when compared with traditional methods.

Farmer Adaptability: Mobile units can be easily adjusted to the scale of the farm operation, making it accessible for small to large-scale farms.

By comparing these two methods, it is clear that mobile grain dryers offer a practical application that leads to higher efficiency and improved grain quality, which are essential factors in the competitiveness of contemporary farming operations.

Conclusion

The proper use of a mobile grain dryer is critical in preventing grain spoilage, ensuring that grain remains at optimal moisture levels for safe storage. Regular maintenance of the dryer is non-negotiable; it is a key factor in avoiding fires and equipment failure.

Before the drying season, maintenance checks should be completed.

During the season, in-season maintenance is crucial to operation.

After drying, a comprehensive shutdown and cleaning help maintain the longevity of the dryer.

Agricultural professionals rely on these dryers to bring moisture content down to specific levels:

Corn: 13-14%

Soybeans: 11-12%

Wheat: 13%

Barley: 12%

Oil Sunflowers: 8%

They must adhere to these moisture content levels meticulously to keep grains from spoiling. For instance, soybeans at 13% moisture have less than 100 days of storage life at 70 degrees Fahrenheit, making careful monitoring essential.

Grain dryers, typically powered by various fuel sources and equipped with electric motors, are designed for automated operation with built-in safety features to shut down in case of overheating.

Energy efficiency is also a consideration, with a broad range of BTU/lb ratings observed across different drying systems. Continuous improvement in efficiency is the result of ongoing research and development in the industry.

In summary, using a mobile grain dryer effectively is fundamental in managing and preserving grain quality. Farmers and grain handlers can remain confident in their products' integrity by observing best practices in dryer maintenance, operation, and energy utilization.